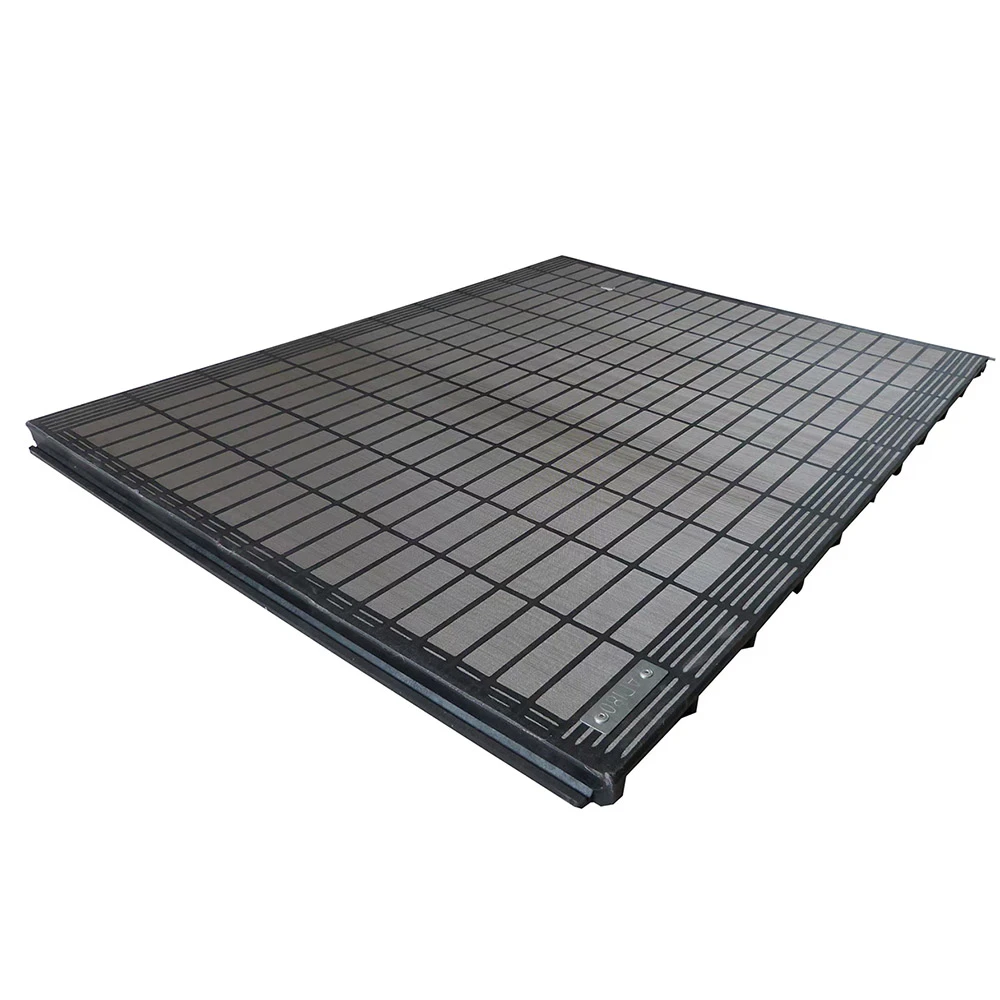

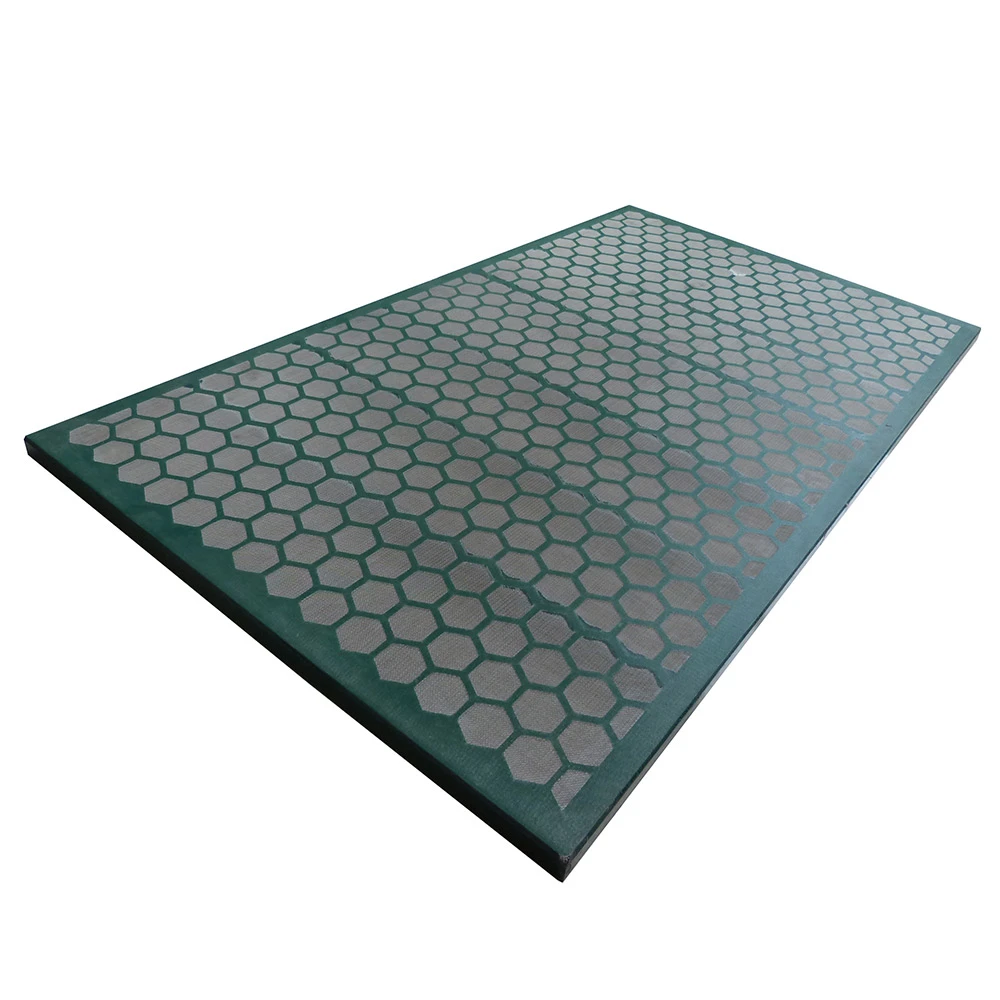

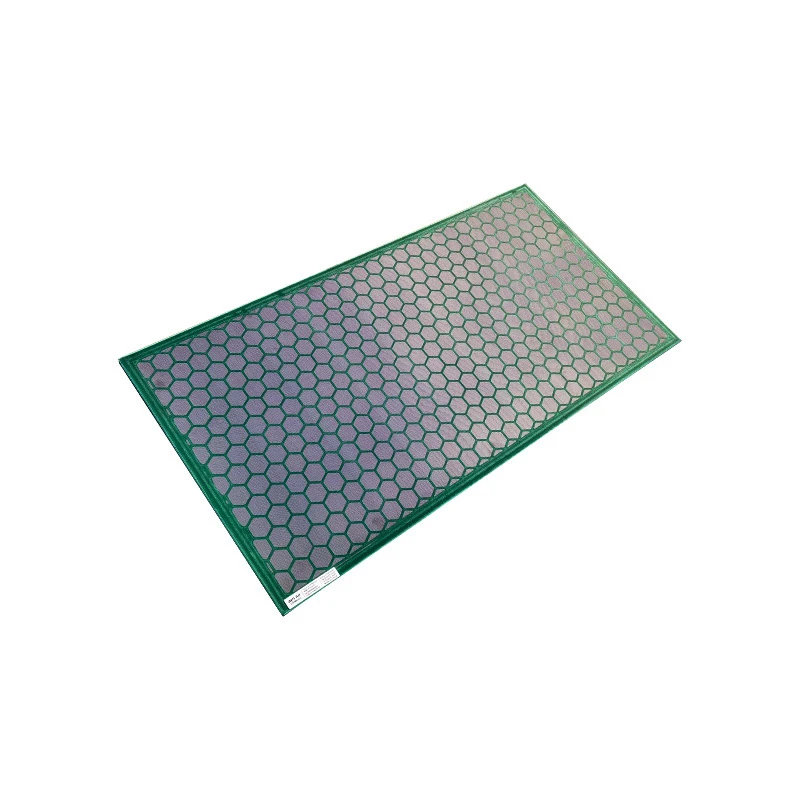

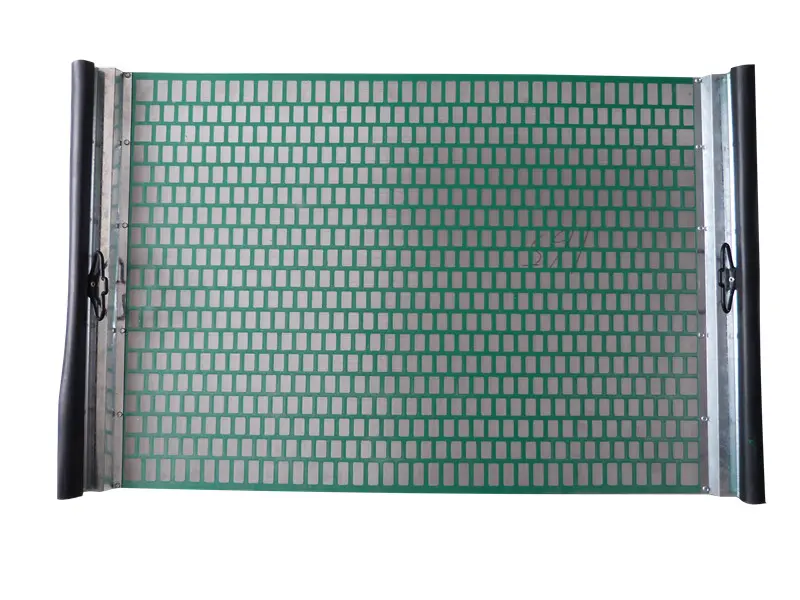

SWACO Replacement Shaker Screen

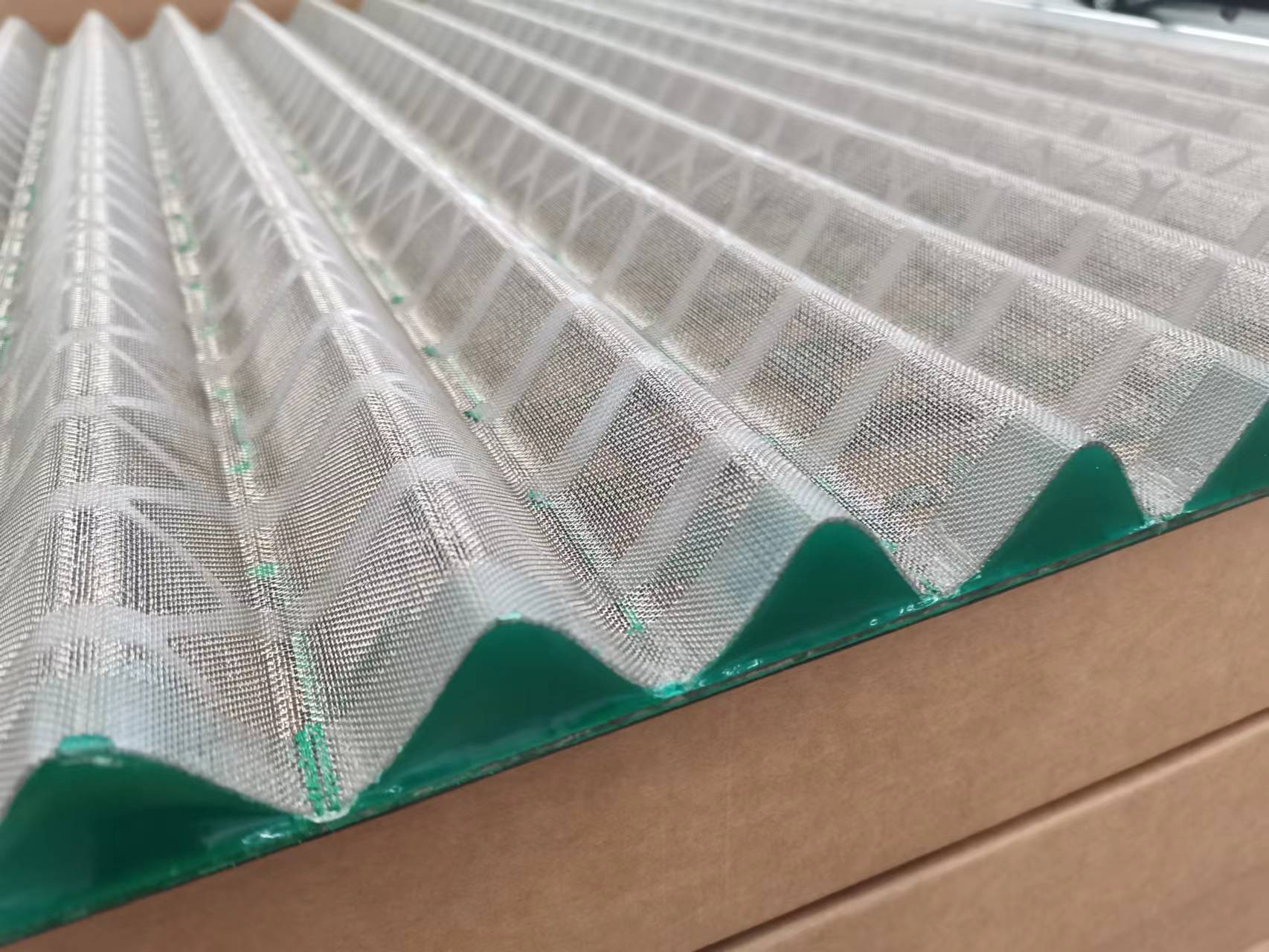

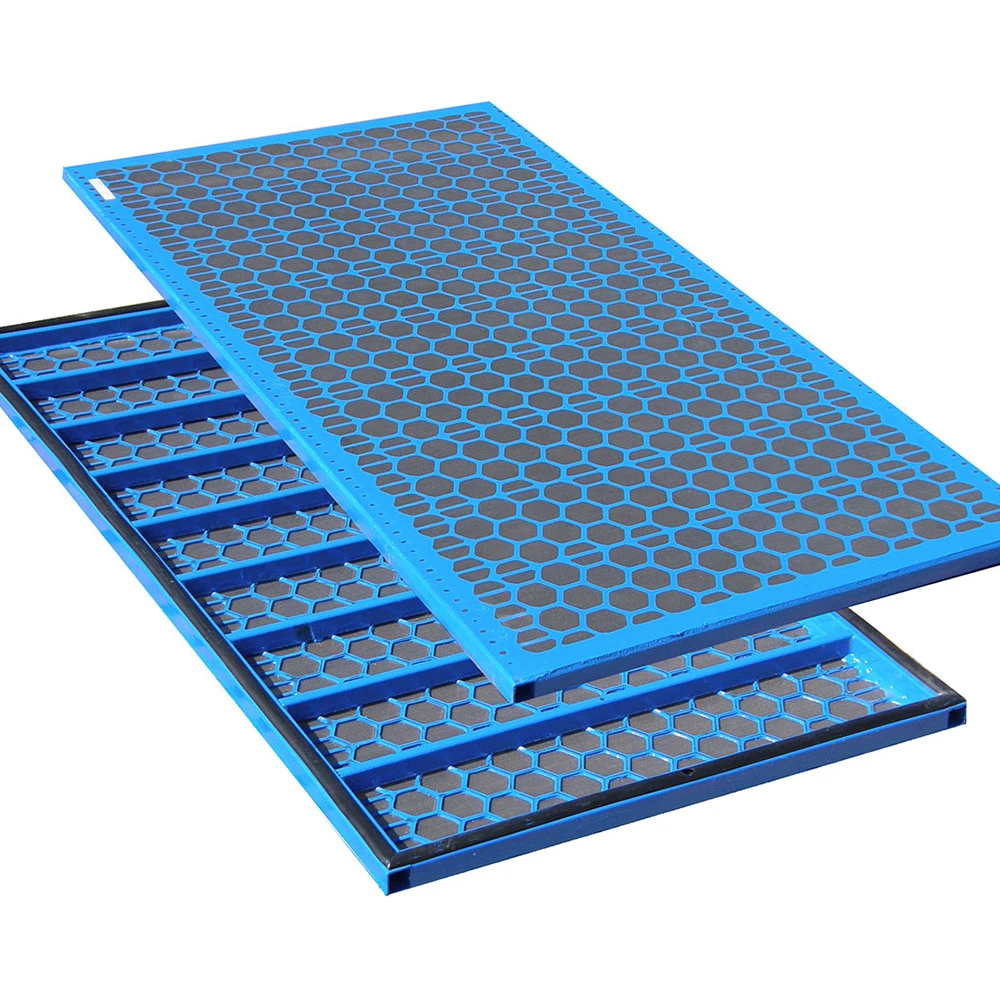

Modern shale shaker screens represent a significant advancement from their wire mesh predecessors, incorporating layered composite structures that optimize both durability and filtration performance. The typical screen assembly consists of multiple components working in concert: a fine mesh filtration layer supported by coarser backing screens, all bonded to a rigid frame under precise tension.

High-performance screens utilize corrosion-resistant materials such as stainless steel alloys for the mesh and polyurethane or epoxy compounds for structural bonding. Some advanced designs incorporate synthetic polymers with engineered surface properties that resist blinding (pore clogging) while maintaining particle rejection efficiency. The tensioning system, whether employing glue-down, hook-strip, or modular designs, must maintain consistent screen flatness under variable loads and vibrational stresses to prevent premature failure or compromised filtration performance.

A reliable shale shaker screen is critical for effective solids removal, cost savings, and uninterrupted drilling operations.

First Line of Defense

Shaker screens remove large drill cuttings and solids, protecting downstream equipment from damage and clogging.

Efficient Fluid Recovery

Proper screening ensures maximum drilling fluid reuse, reducing waste and operational costs.

Optimized Performance

High-quality screens enhance separation efficiency, improving overall solids control and drilling efficiency.

Reduced Downtime & Costs

Durable screens minimize replacements and maintenance, keeping operations running smoothly.