PRODUCT FEATURES

1. Corrosion-resisting, heat-resisting, wear-resisting

2. Long working life, higher flow rate.

3. Easy disassembly, rating of temperature,

good performance Conductivity.

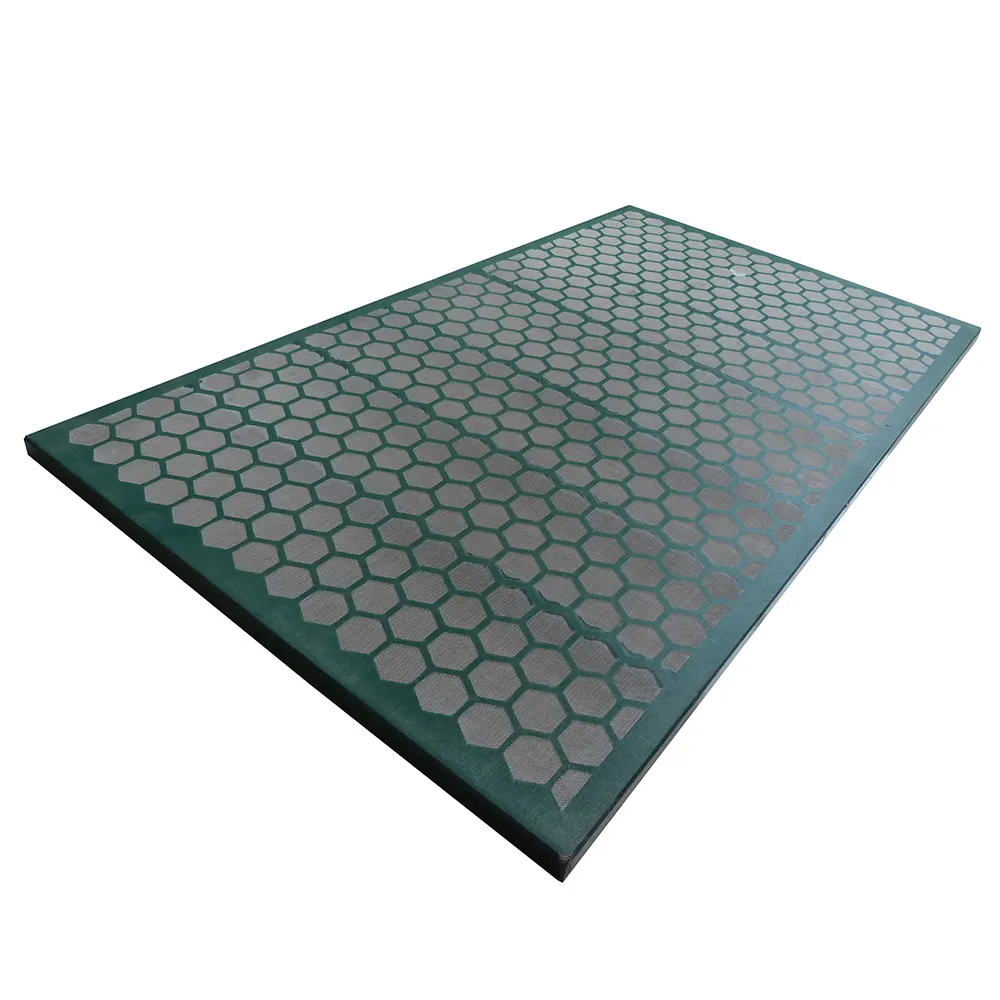

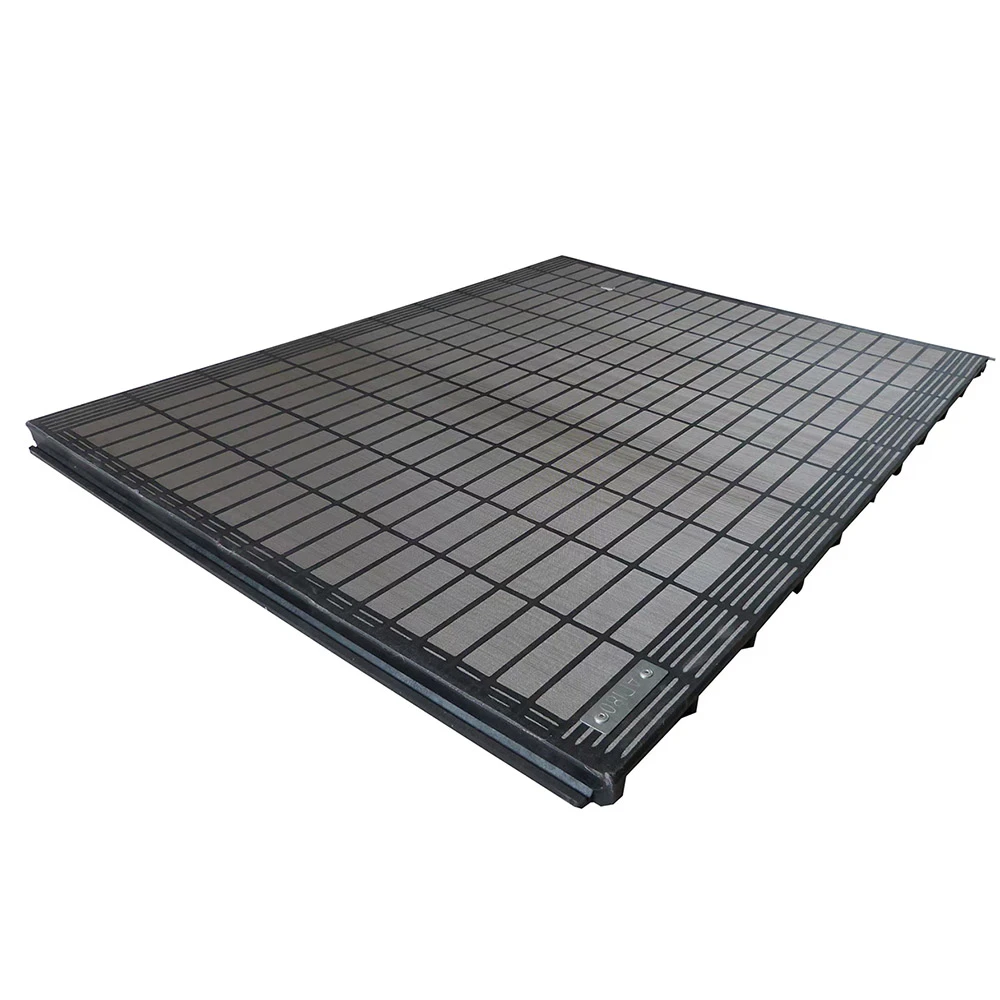

Advantages of Steel frame screen

Robust Steel Frame Construction

Designed with high-tensile steel for enhanced structural integrity, ensuring resistance to impact, deformation, and extreme operational conditions.

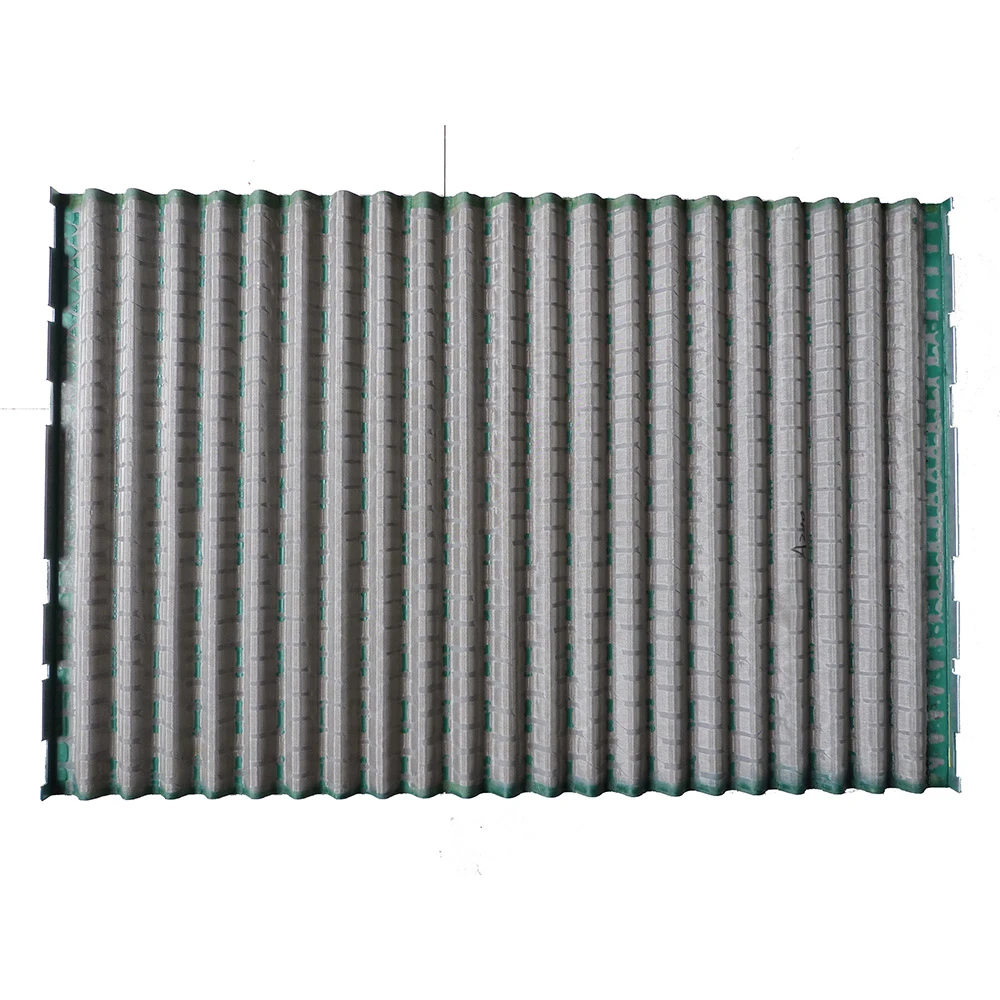

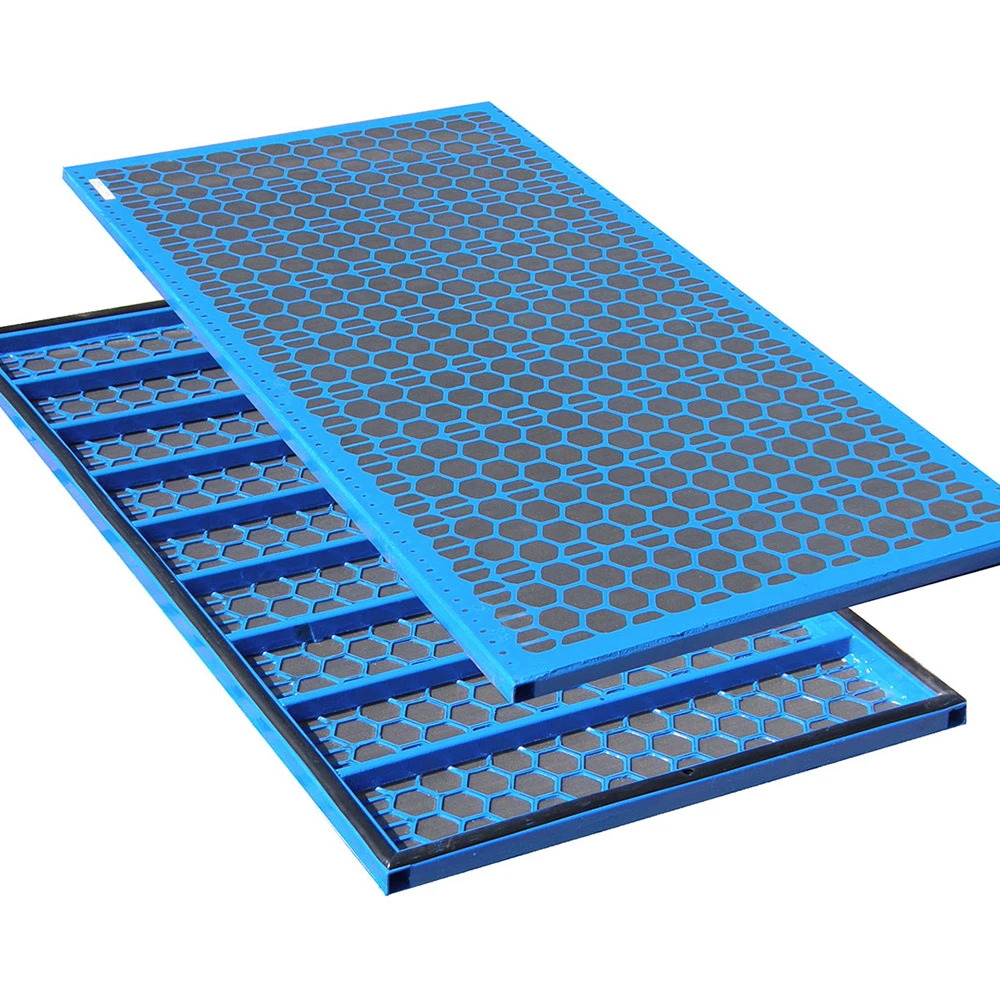

High-Efficiency Mesh Design

Engineered to maximize solid-liquid separation, improving drilling fluid recycling and reducing waste disposal costs.

Extended Service Life

The steel frame provides superior wear resistance, reducing screen replacement frequency and lowering maintenance costs.

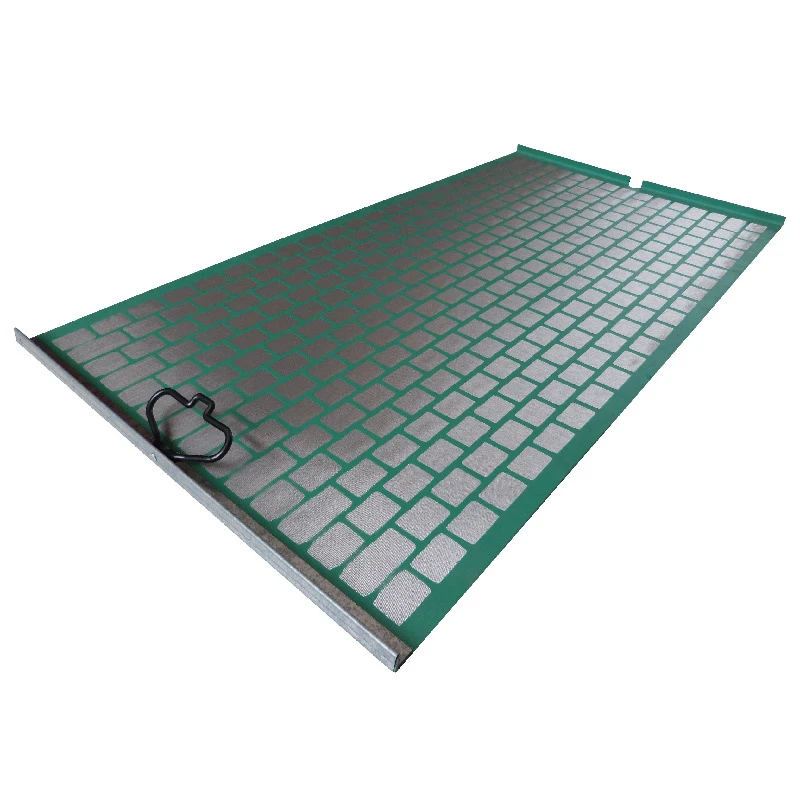

Easy Installation and Replacement

The precise frame structure allows for quick and hassle-free installation, minimizing downtime and improving operational efficiency.

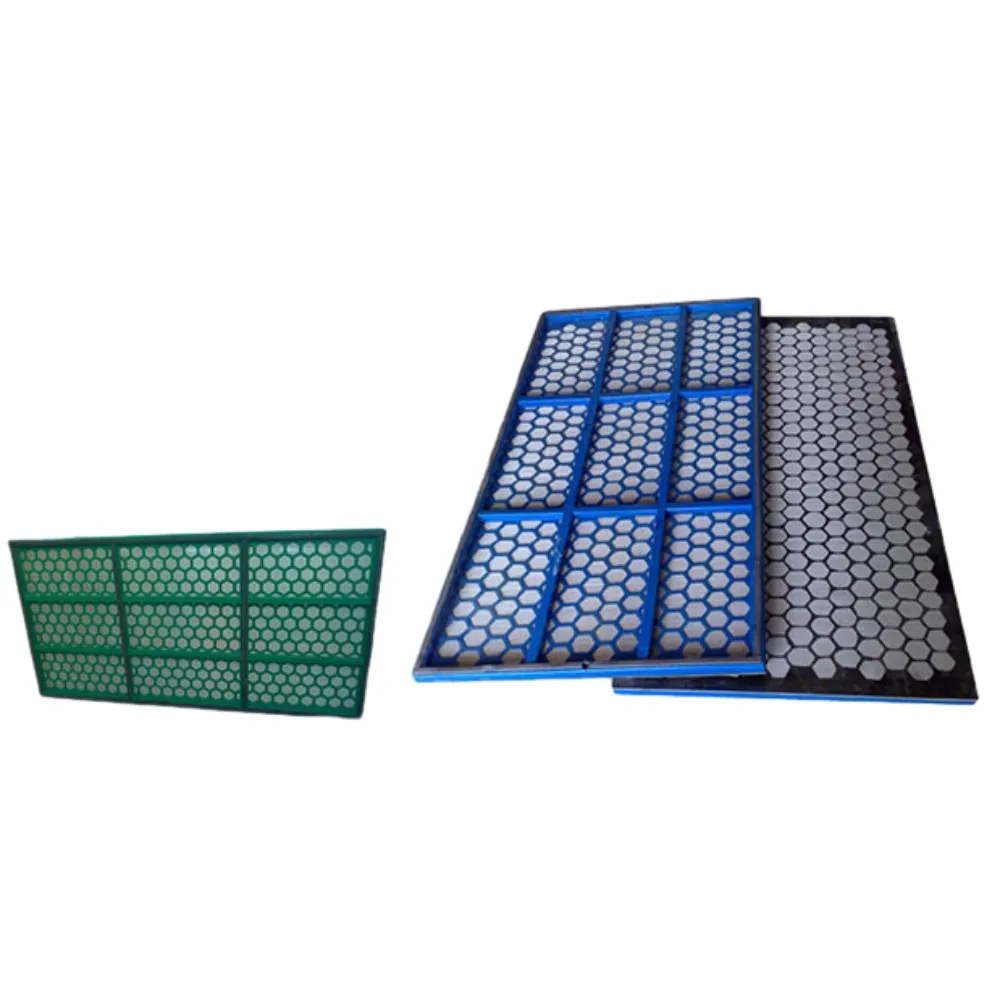

Wide Compatibility

Compatible with major shaker models such as Mongoose, MD-3, Meerkat, and more, ensuring seamless integration with existing equipment.

Applications of Steel frame screen

Oil and gas drilling: Enhances drilling fluid management by efficiently separating solids, improving drilling efficiency and reducing fluid loss.

Solids control equipment: Works as a key component in solids control systems, ensuring effective removal of cuttings and debris.

Mud recovery systems: Helps optimize mud recovery by filtering unwanted particles, extending the life of drilling fluids.

Mining and mineral processing: Plays a crucial role in separating valuable minerals from unwanted materials, improving processing efficiency.

Environmental waste management: Supports sustainable operations by aiding in wastewater treatment and solid waste separation.

Steel Frame Screen FAQs:

Q: Are your Steel Frame Screens compatible with all shale shakers?

A: Our screens are designed to be compatible with most standard shale shakers. However, we recommend contacting our sales team to confirm compatibility with your specific shaker model.

Q: What is the expected lifespan of your Steel Frame Screens?

A: The lifespan of our screens depends on various factors, including drilling conditions, fluid properties, and maintenance practices. However, our screens are engineered to provide exceptional durability and longer service life compared to standard screens.

Q: Do you offer custom sizes and specifications?

A: Yes, we can customize screens to meet your specific needs. Please contact our sales team to discuss your requirements.

Q: What is your lead time for orders?

A: Our standard lead time is X weeks. However, we can expedite orders upon request. Please contact us for more information.

Q: Do you provide international shipping?

A: Yes, we offer reliable and cost-effective international shipping to most countries.

Provide High-quality Solutions for Your Enterprise