PRODUCT FEATURES

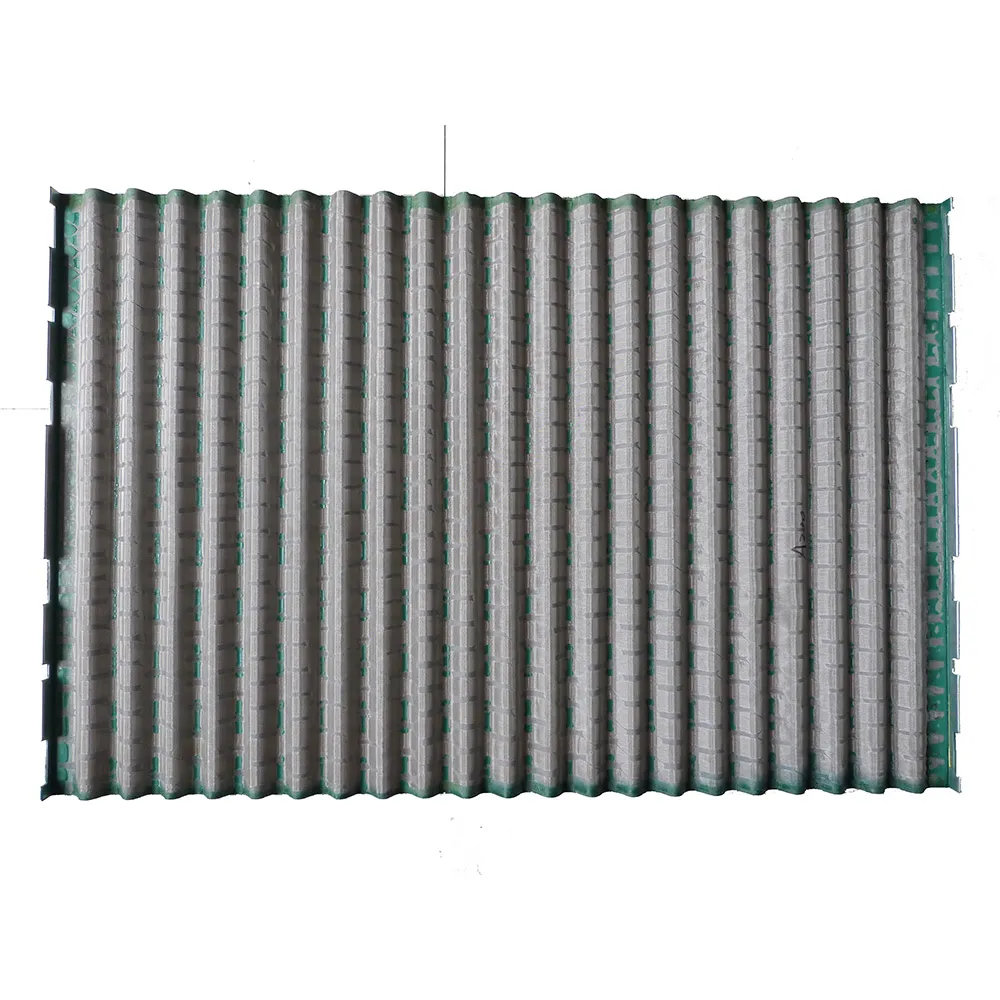

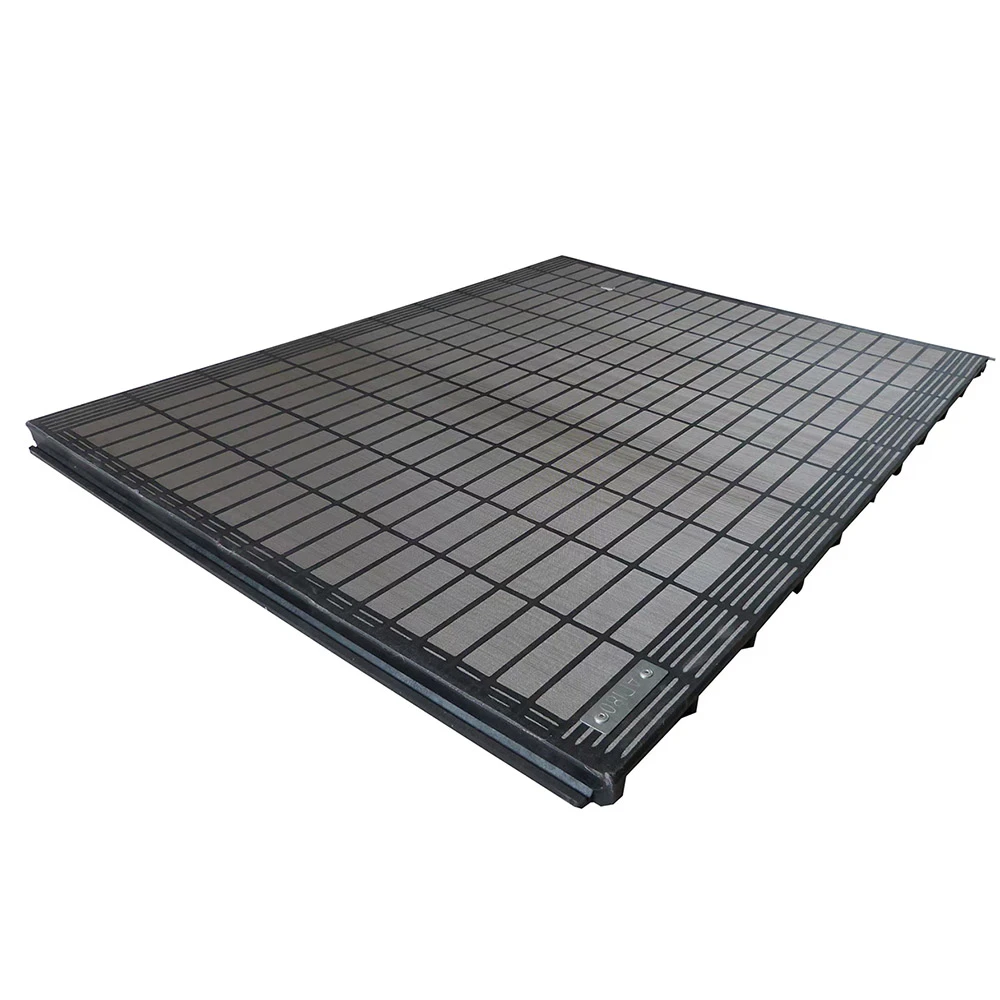

1.Pyramid replacement screens increased shaker capacity compared to the PWP. Fluid-handling capacity is increased up to125%-150%

2.Pyramid replacement screens makes fine separations. Different layers with different density. Arrange these layers reasonably and exactly, the screening effect will become more and better.

3.Pyramid replacement screens maximizes the solids removal efficiency of the shaker.

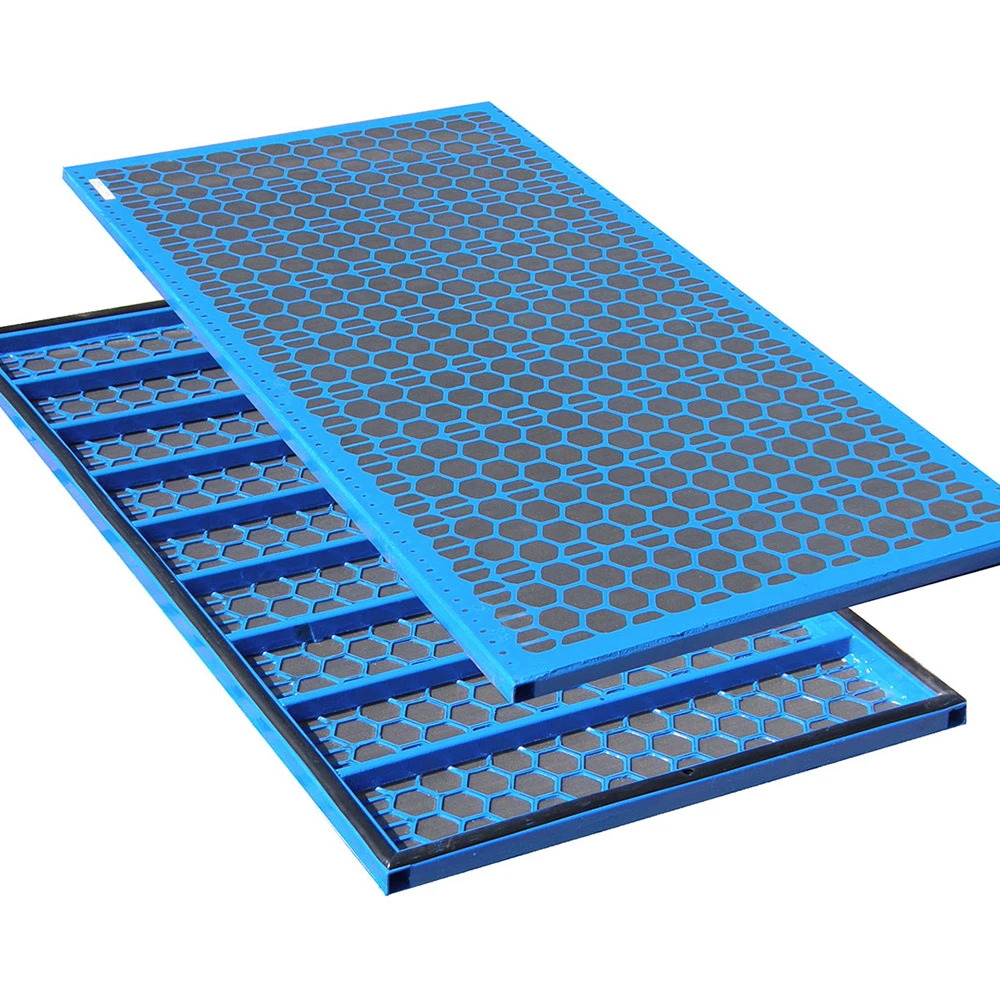

The type of screen:

DERRICK 48-30 PMD、DERRICK 500 PMD、DERRICK 626 PMD、DERRICK HYPERPOOL PMD

Benefits of Derrick PMD Screen

Exceptional Filtration Performance

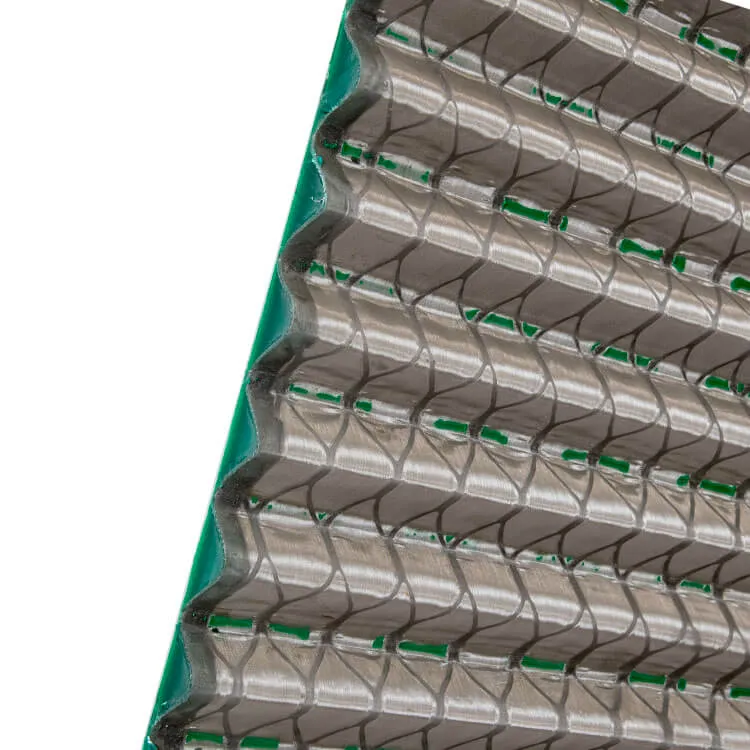

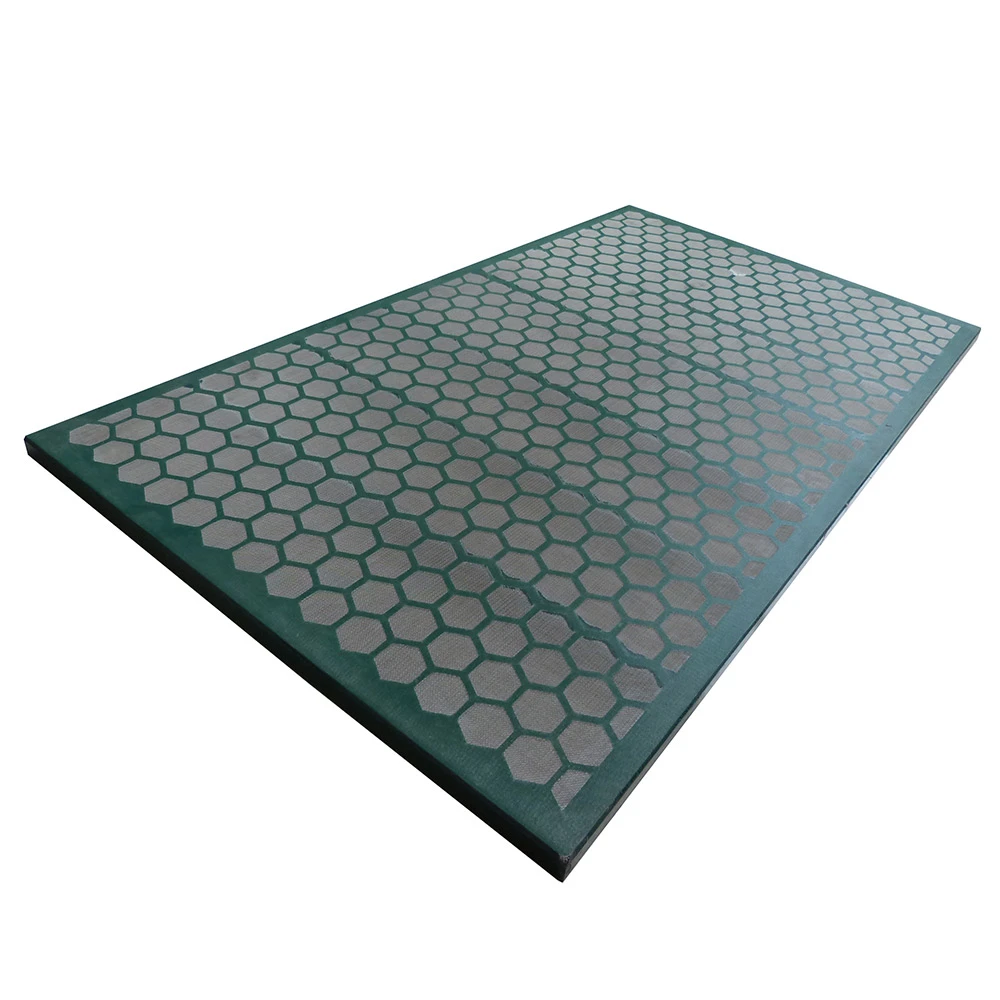

Our Derrick PMD Screens are engineered with a state - of - the - art design to deliver unrivaled filtration performance in drilling operations. The unique mesh pattern is optimized to efficiently separate solids from drilling fluids, ensuring that only clean and high - quality fluids are recirculated. This not only enhances the overall drilling process but also helps in extending the lifespan of downstream equipment. Whether you're engaged in oil and gas exploration, mining, or other industrial drilling applications, our PMD screens will meet and exceed your filtration expectations.

High - Quality Construction for Durability

Built to withstand the harshest drilling conditions, our Derrick PMD Screens are constructed using top - grade materials. The heavy - duty frame and corrosion - resistant mesh are designed to endure the rigors of continuous use, high - pressure fluid flow, and abrasive solids. This robust construction results in a long - lasting product that reduces the need for frequent screen replacements, saving you both time and money in the long run.

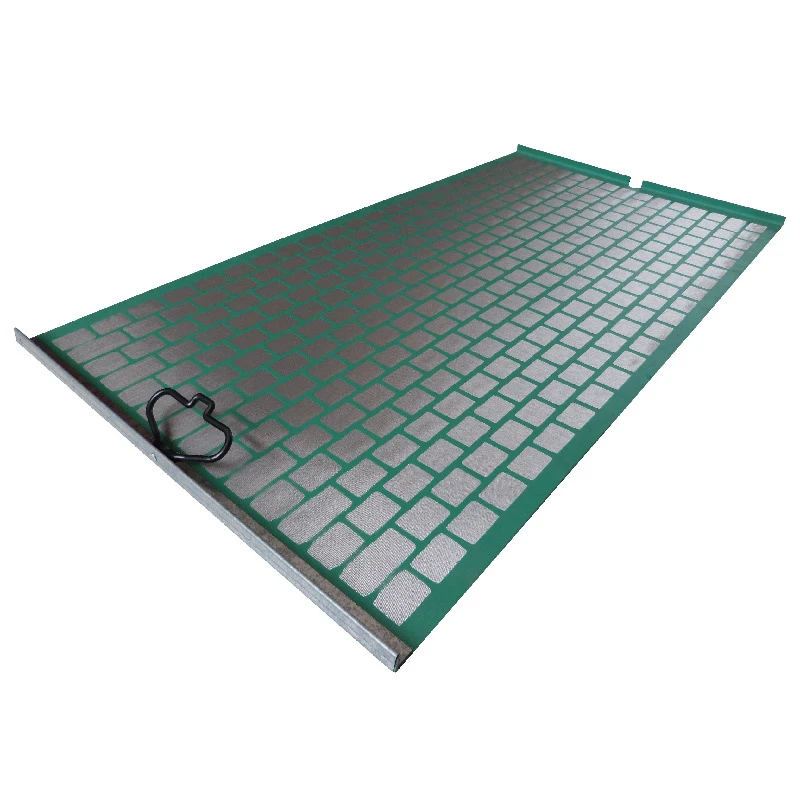

Precise Fit for Derrick Equipment

Designed as a perfect fit for Derrick shale shakers, our PMD screens ensure easy and seamless installation. The exact dimensions and connection points are engineered to match Derrick equipment, allowing for a quick swap - out during maintenance or when upgrading your screening system. This hassle - free installation process minimizes downtime, keeping your drilling operations running smoothly and efficiently.

Diverse Applications Tailored to Perfection

Our Derrick PMD Screen is a top choice for a wide range of applications with distinct needs.

Oil and Gas Drilling

In oil and gas drilling, efficiency and reliability are crucial. Our PMD Screen separates solids from complex drilling fluids, maintaining fluid quality. This protects equipment and boosts productivity, leading to more successful well completions.

Geothermal Drilling

Geothermal drilling has challenges like extreme subsurface temperatures and abrasive fluids. The Derrick PMD Screen can endure thermal stress and harsh chemical conditions, filtering out solids to enable efficient heat transfer.

Horizontal Directional Drilling (HDD)

For HDD, which requires accuracy in tight spaces, the PMD Screen's compact design and great filtration capabilities separate solids from drilling mud. This ensures smooth borehole drilling and minimizes blockages.

Mineral Processing

In mineral processing, separating valuable minerals from waste is essential. Our PMD Screen efficiently sifts through slurry, separating fine minerals from gangue, improving product quality and recovery rates.

Provide High-quality Solutions for Your Enterprise