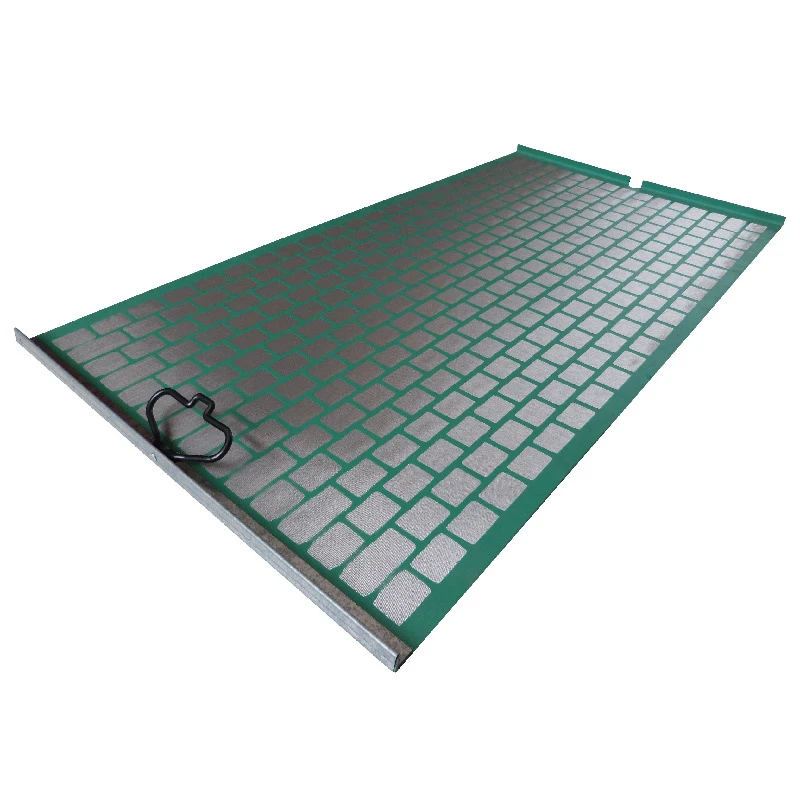

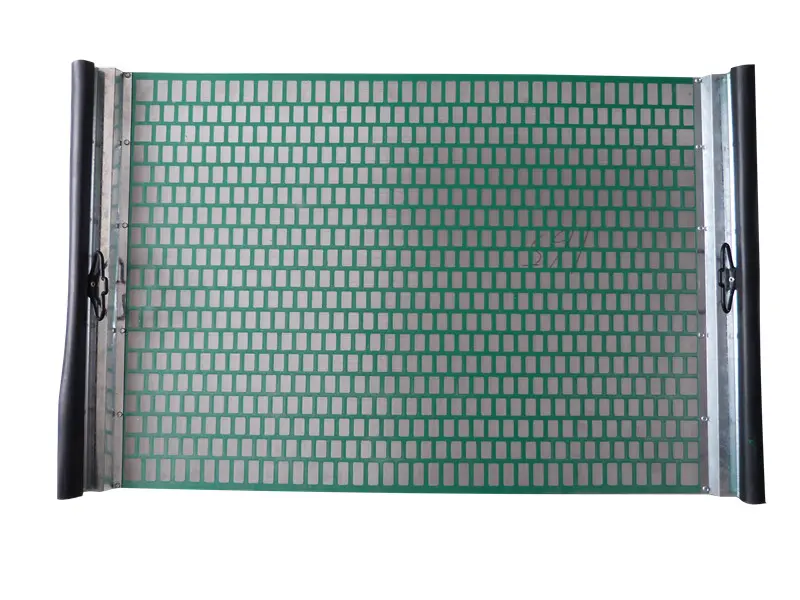

Derrick Replacement Shaker Screen

Functioning as a vibrating filtration device, the shale shaker screen operates on the principle of particle size separation through mechanical vibration and gravity-assisted drainage. When drilling fluid returns to the surface laden with formation cuttings, it cascades onto the inclined screen surface where high-frequency vibrations facilitate the separation process. The screen's precisely calibrated mesh openings allow the liquid phase and fine particles to pass through while retaining larger solids for disposal.

This process is critical for multiple reasons: it preserves the chemical composition and physical properties of the drilling fluid, prevents recirculation of abrasive particles that could damage downstream equipment, and maintains optimal mud weight for wellbore stability. The efficiency of this separation directly impacts operational costs by reducing unnecessary fluid losses and minimizing the need for additional chemical treatments.

Upgrade Your Shaker System Today – Experience Unmatched Durability & Performance!

Precision Engineering & Perfect Fit

Designed to meet or exceed OEM specifications for seamless compatibility.Ensures smooth installation and optimal performance with your existing shaker system.

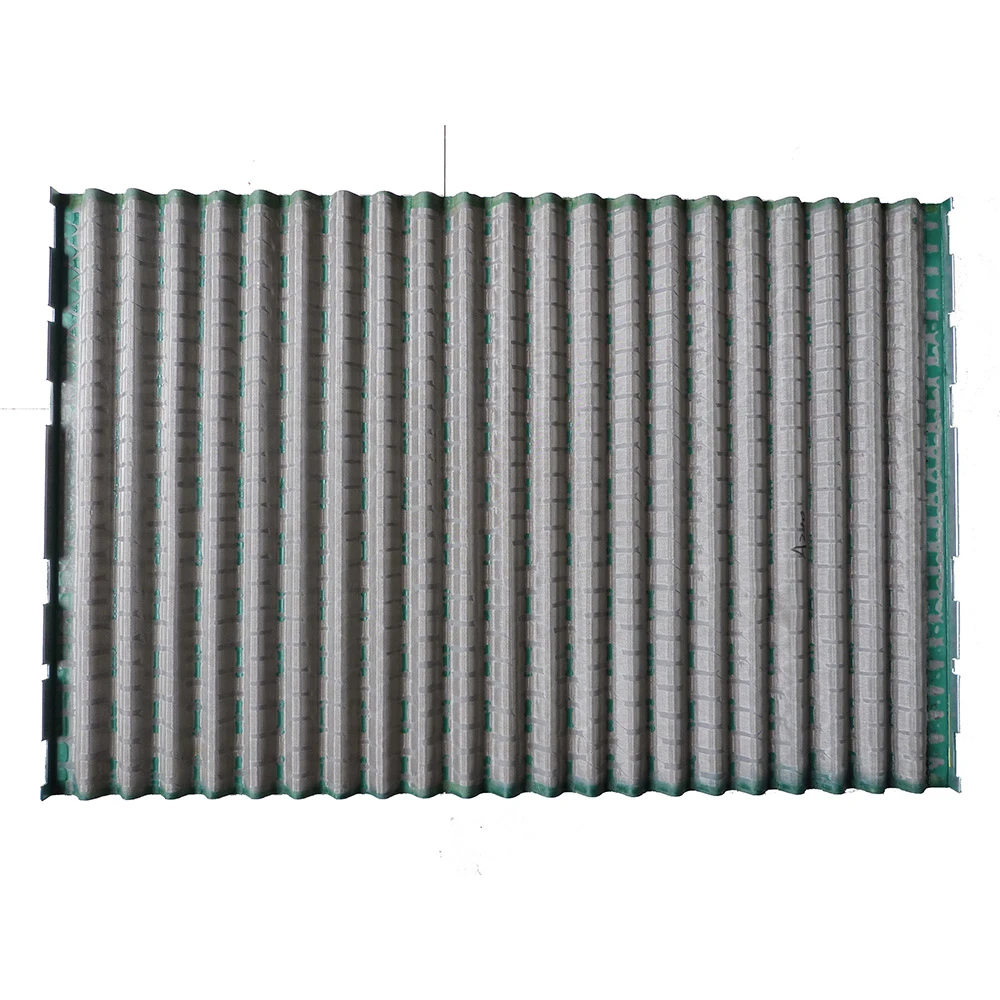

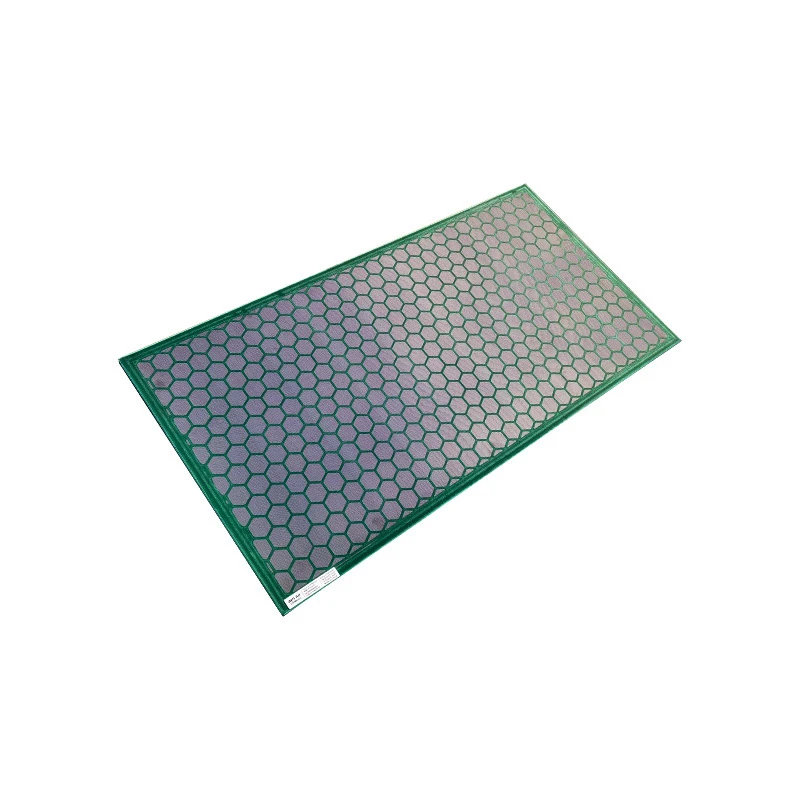

Superior Filtration Performance

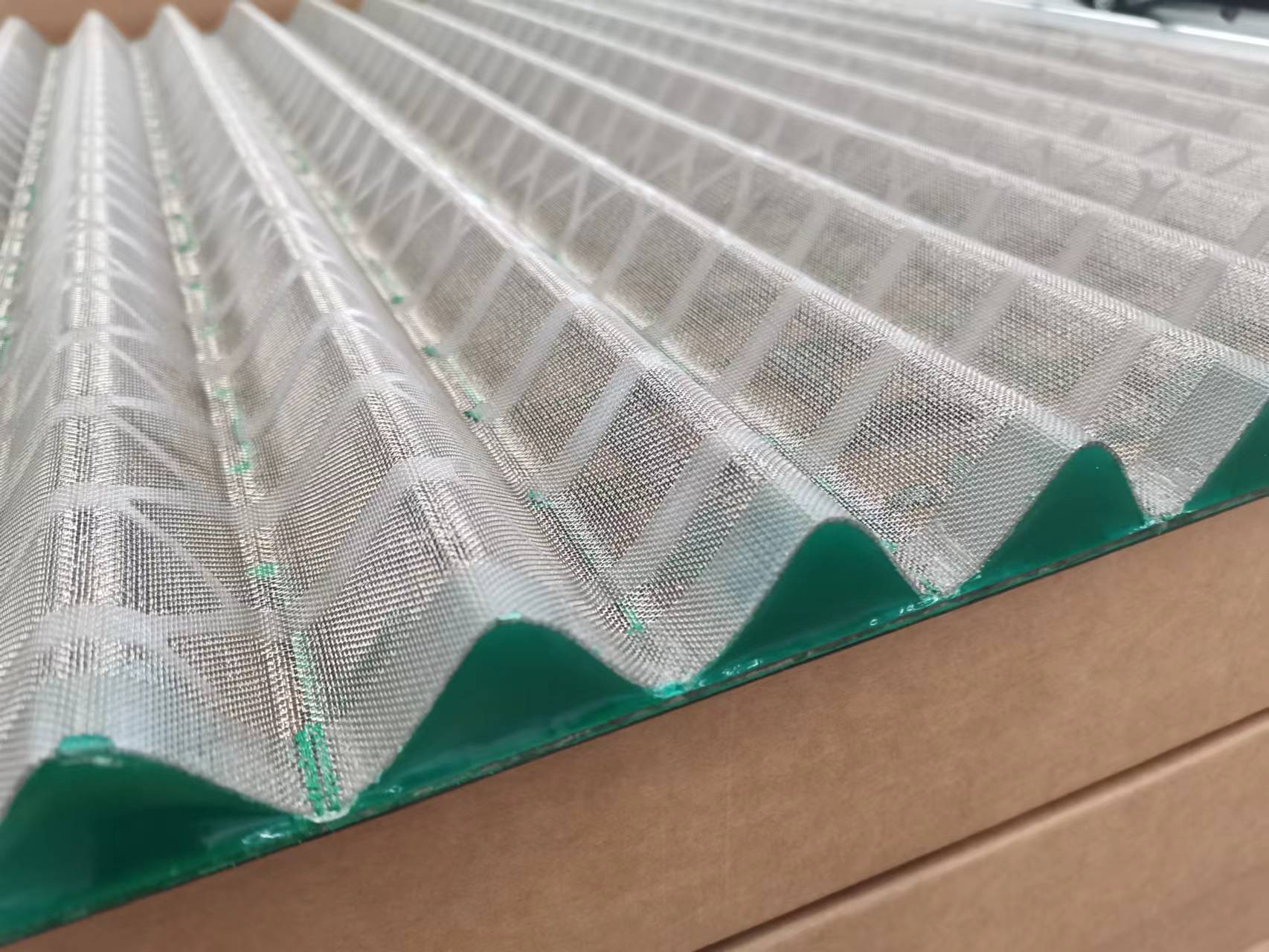

Precise mesh sizes for accurate particle separation (coarse to fine filtration).Optimized screen design enhances fluid recovery and solids control.Reduces blinding and clogging for consistent flow rates.

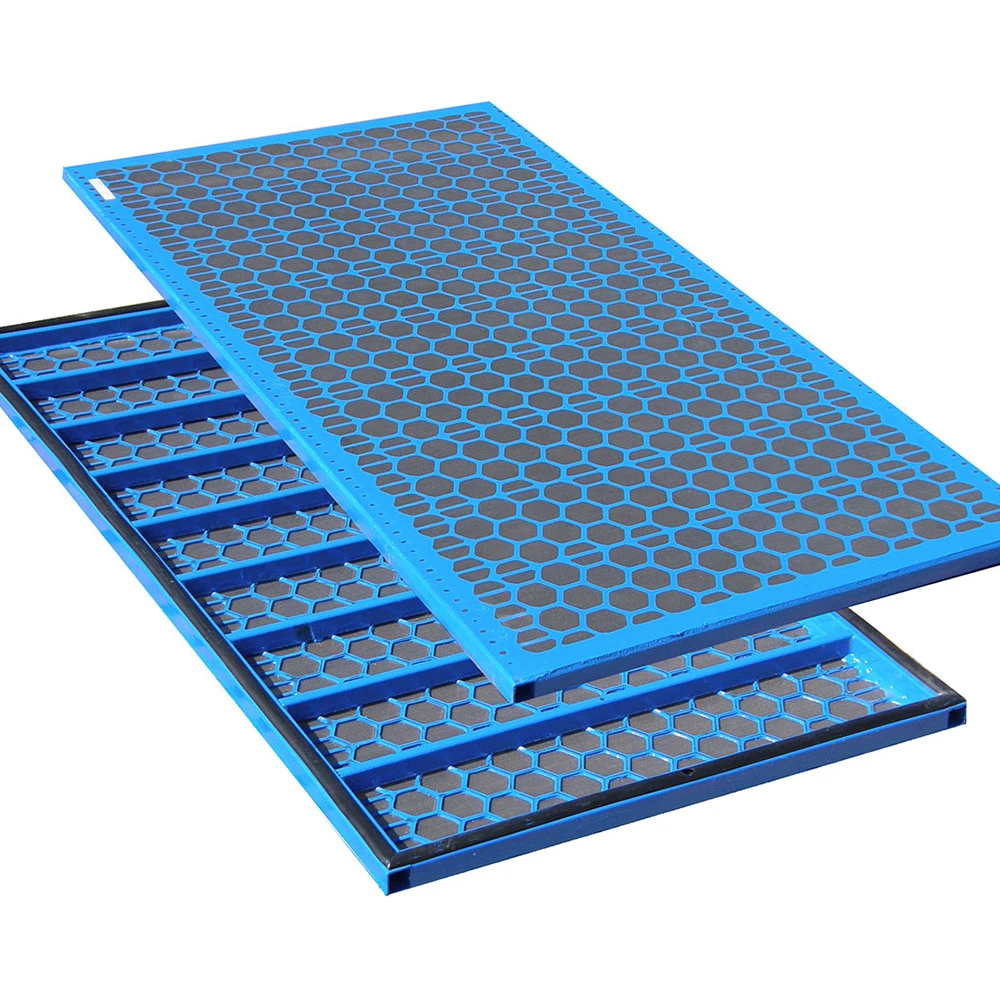

Enhanced Durability for Demanding Environments

Withstands harsh conditions in oil & gas drilling, mining, and industrial applications.Resistant to chemicals, high temperatures, and mechanical stress.

Versatile Applications

Ideal for oilfield drilling rigs, mining operations, wastewater treatment, and industrial separation processes.Available in various sizes and configurations to match different shaker models.