NOV Replacement Shaker Screen

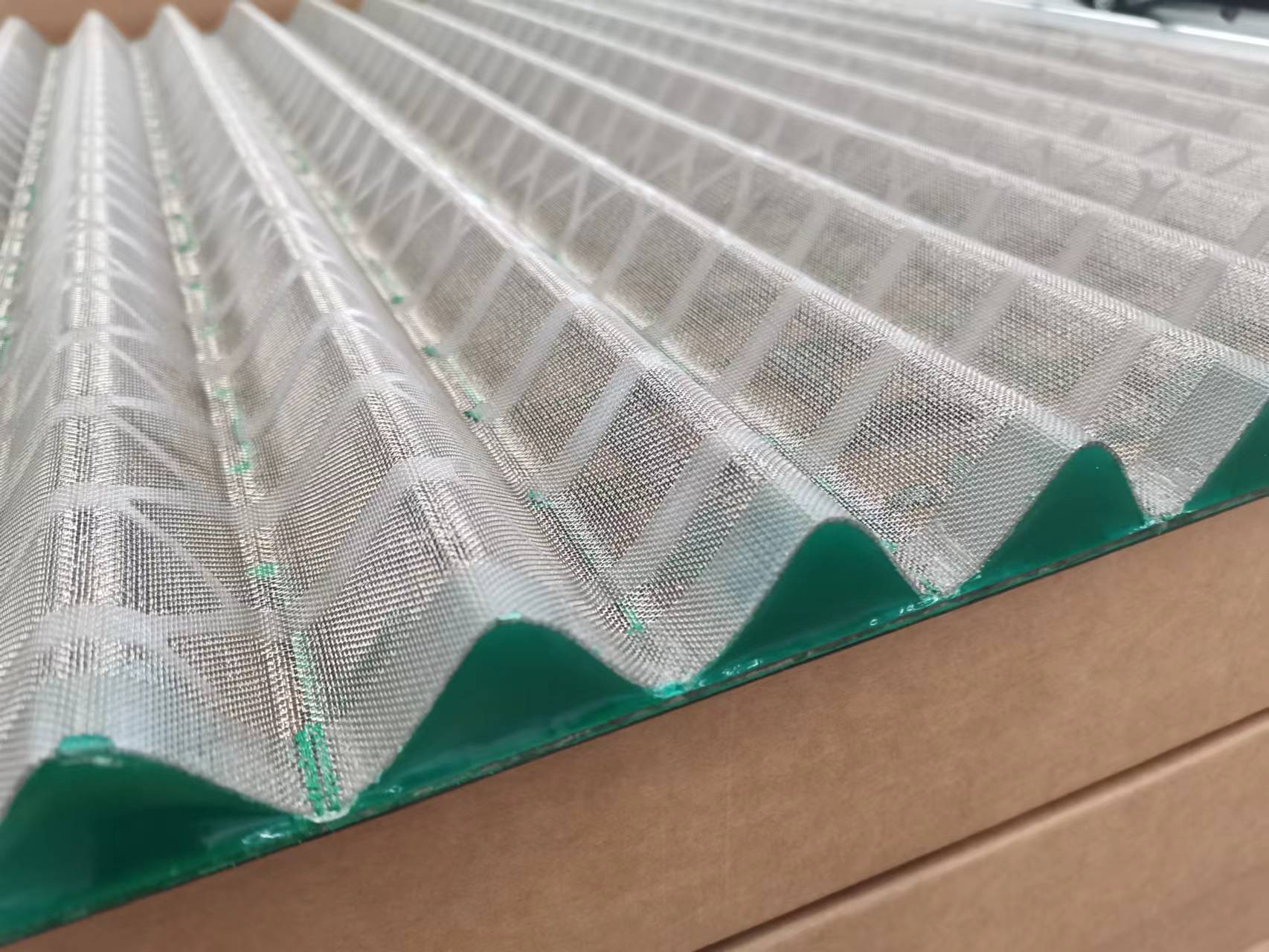

The shale shaker screen industry has undergone significant technological transformation in response to more challenging drilling environments and heightened environmental regulations. Recent developments include three-dimensional screen surfaces that increase effective filtration area, hybrid mesh designs that combine different weave patterns in a single panel, and advanced coating technologies that reduce adhesive wear.

Some manufacturers have introduced intelligent screen systems incorporating sensors to monitor real-time performance metrics such as vibration patterns and loading conditions. The industry continues to explore novel materials including nano-enhanced composites and shape-memory alloys that could revolutionize screen durability and performance. These innovations aim to address persistent challenges such as screen blinding in sticky clay formations and premature failure in high-temperature geothermal applications.

Extend Your Equipment Life with Our Durable Shale Shaker Screens Built for Harsh Drilling Conditions.

Contact Us

Premium Shale Shaker Screens – Unmatched Durability, Customization & Fast Delivery for Optimal Solids Control

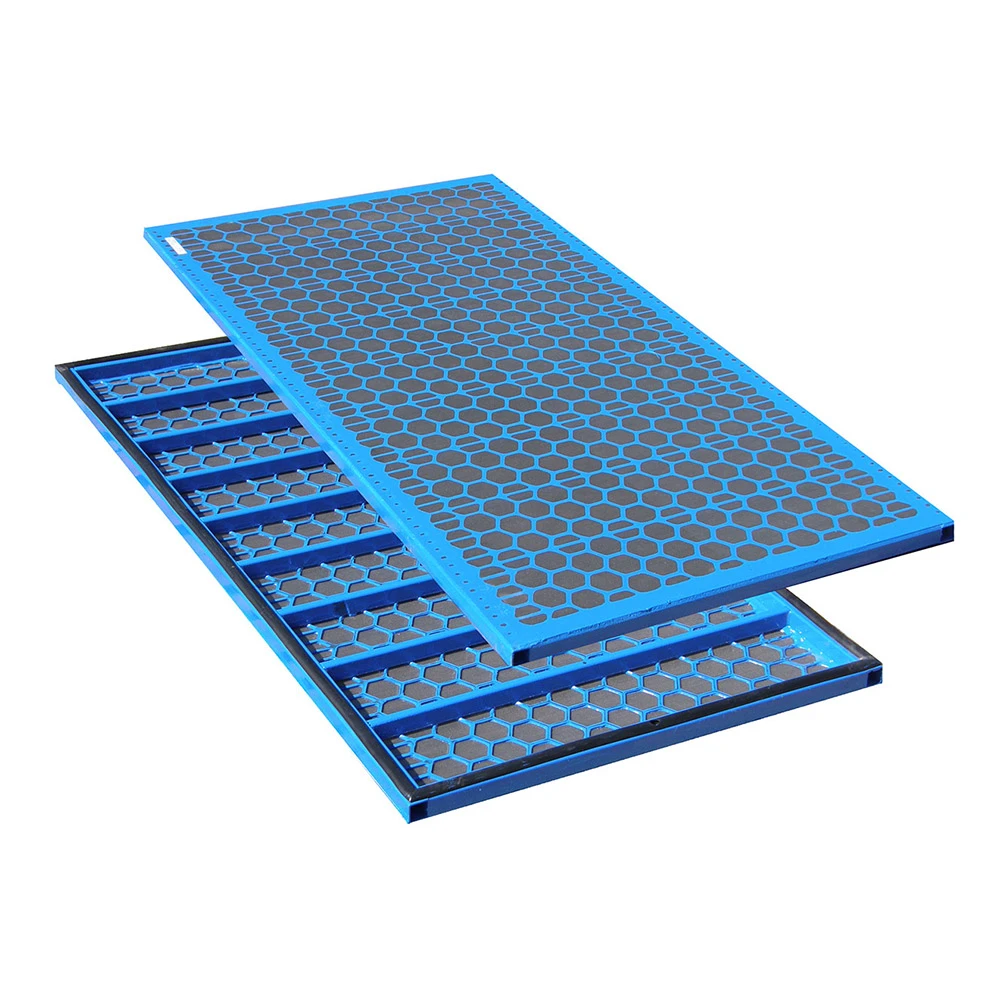

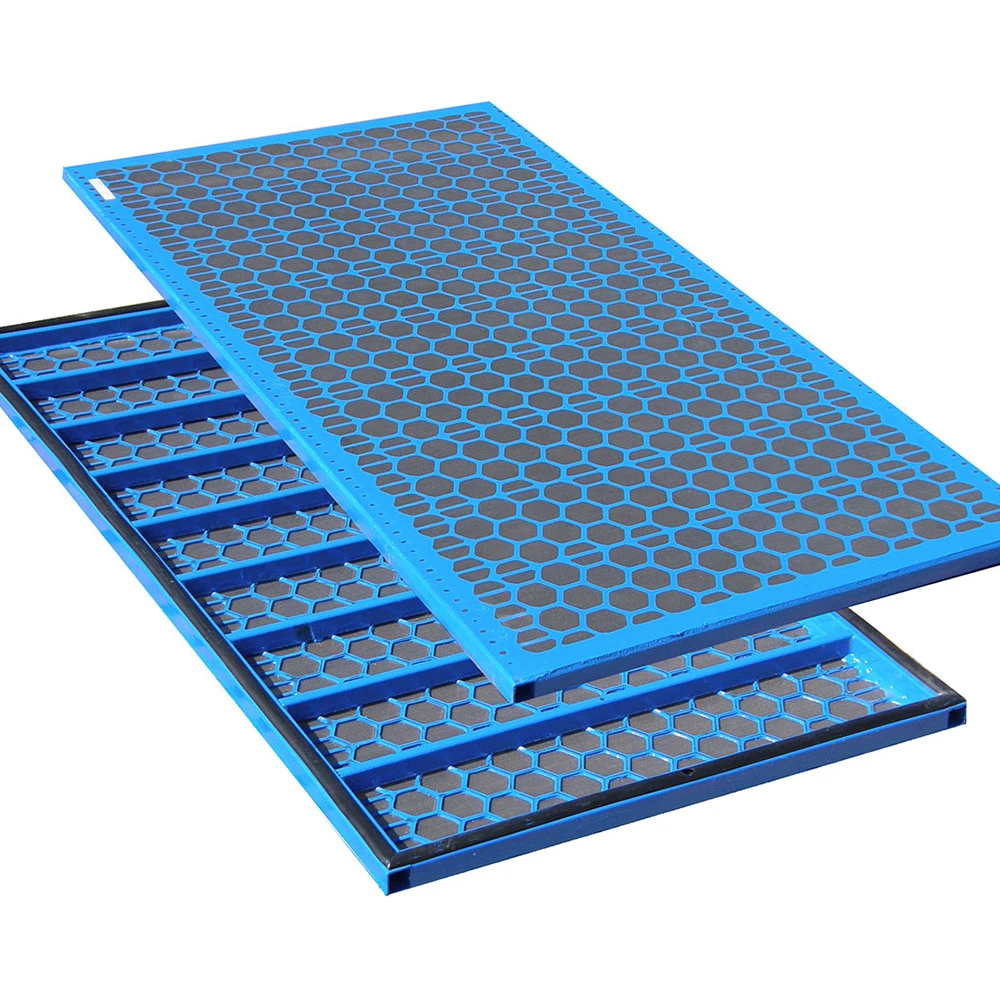

Advanced Composite Frame Design

Features high-strength composite frames that resist corrosion, even in harsh offshore/onshore environments. Eliminates frame warping and extends service life compared to conventional designs

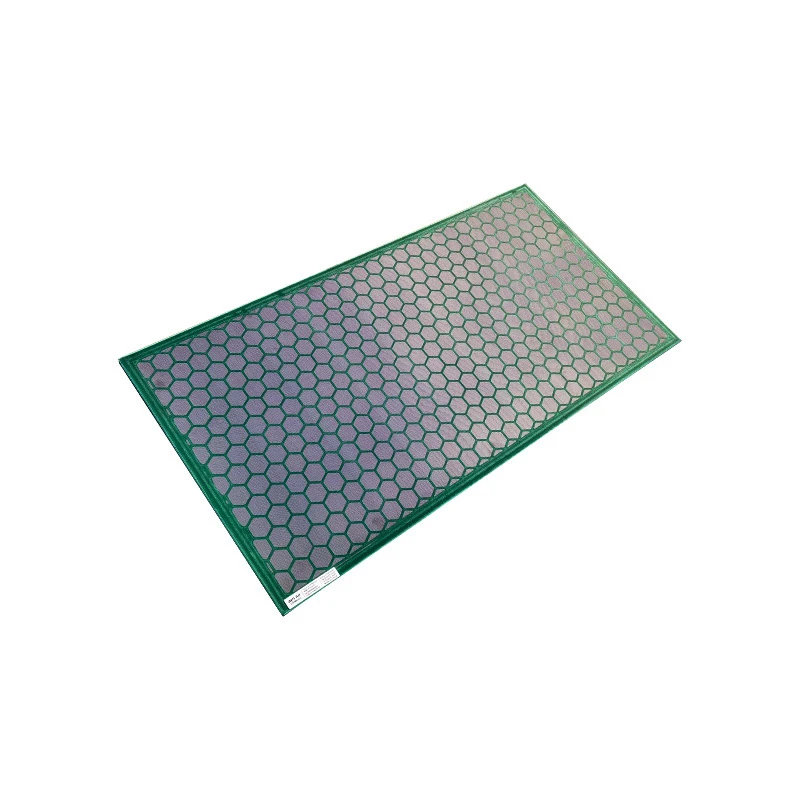

Premium Stainless Steel Wire Mesh

Constructed with top-grade 304/316 stainless steel for exceptional wear and tear resistance. Maintains precise filtration performance throughout extended operation periods

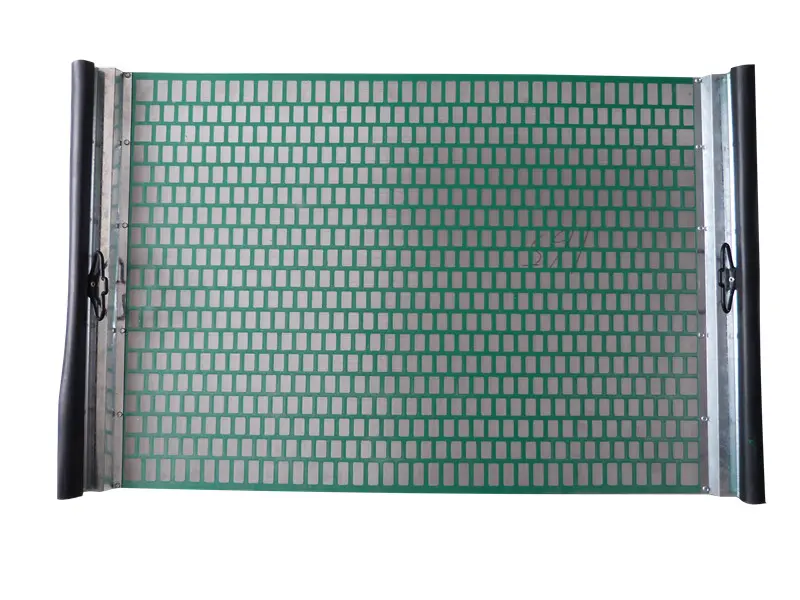

Flexible Framework Options

Customers can choose between durable steel framework or lightweight composite materials. Customizable to match specific operational requirements and equipment specifications

Optimized Cost Control

Scientific production management system ensures competitive pricing without quality compromise. Streamlined supply chain reduces unnecessary costs, passing savings to customers