All the replacement shaker screens are API RP 13C compliant.

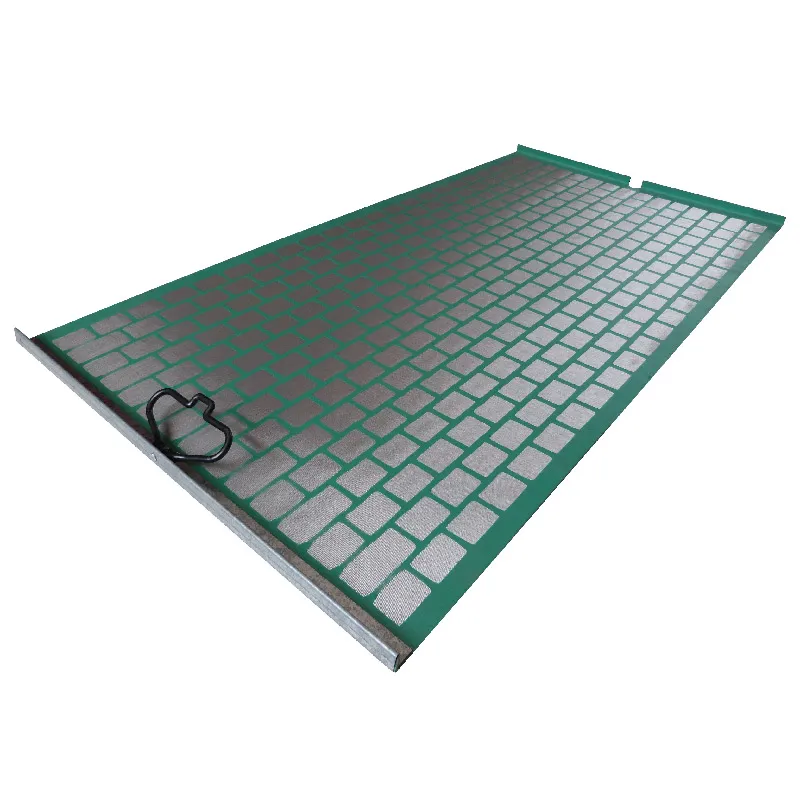

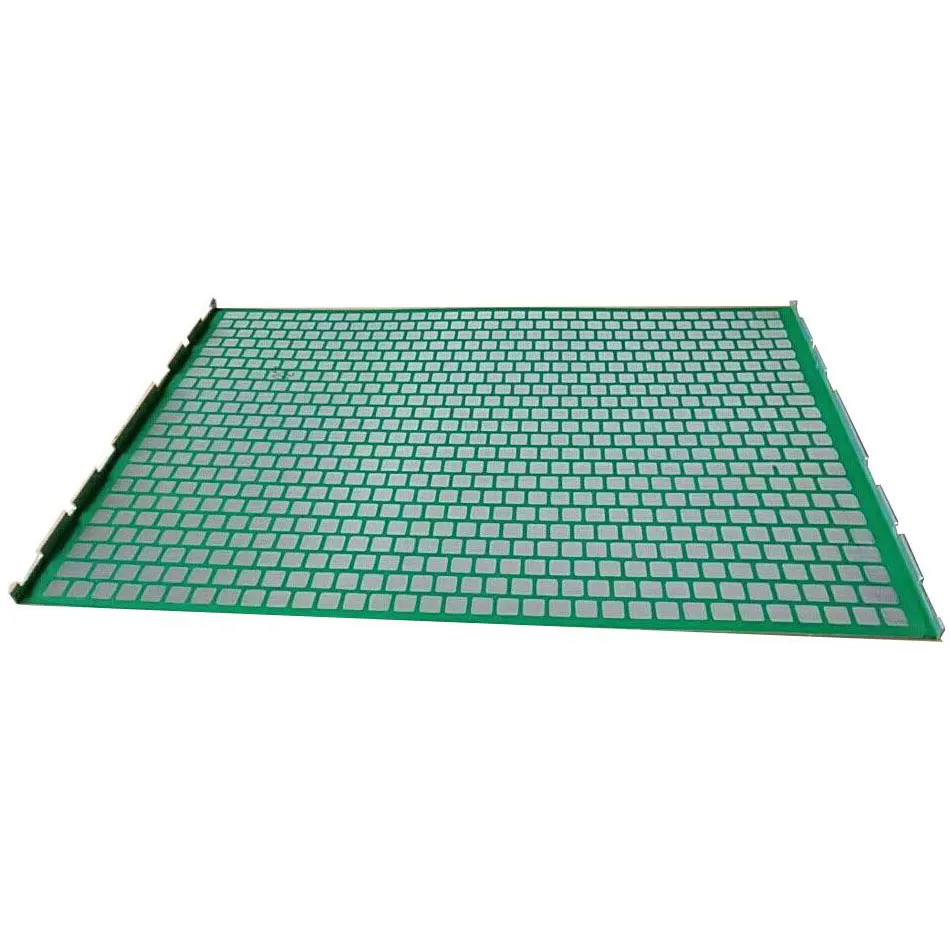

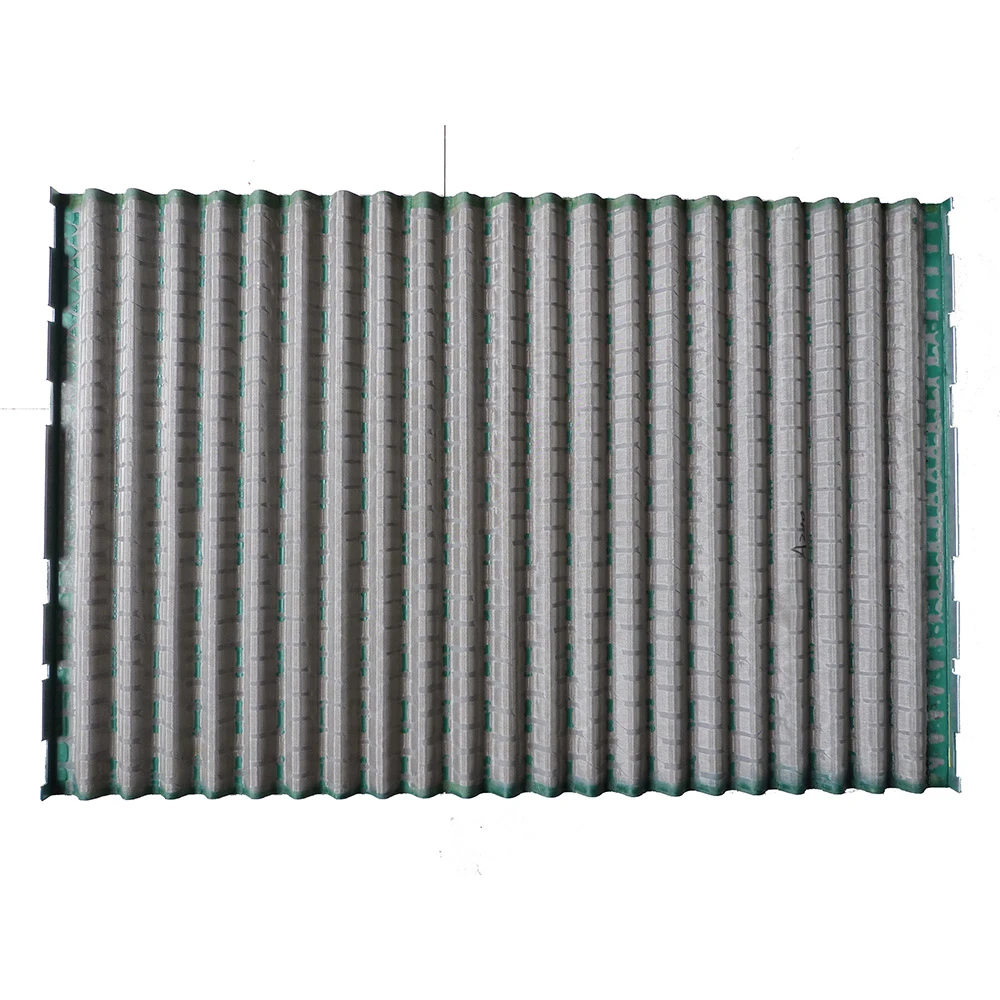

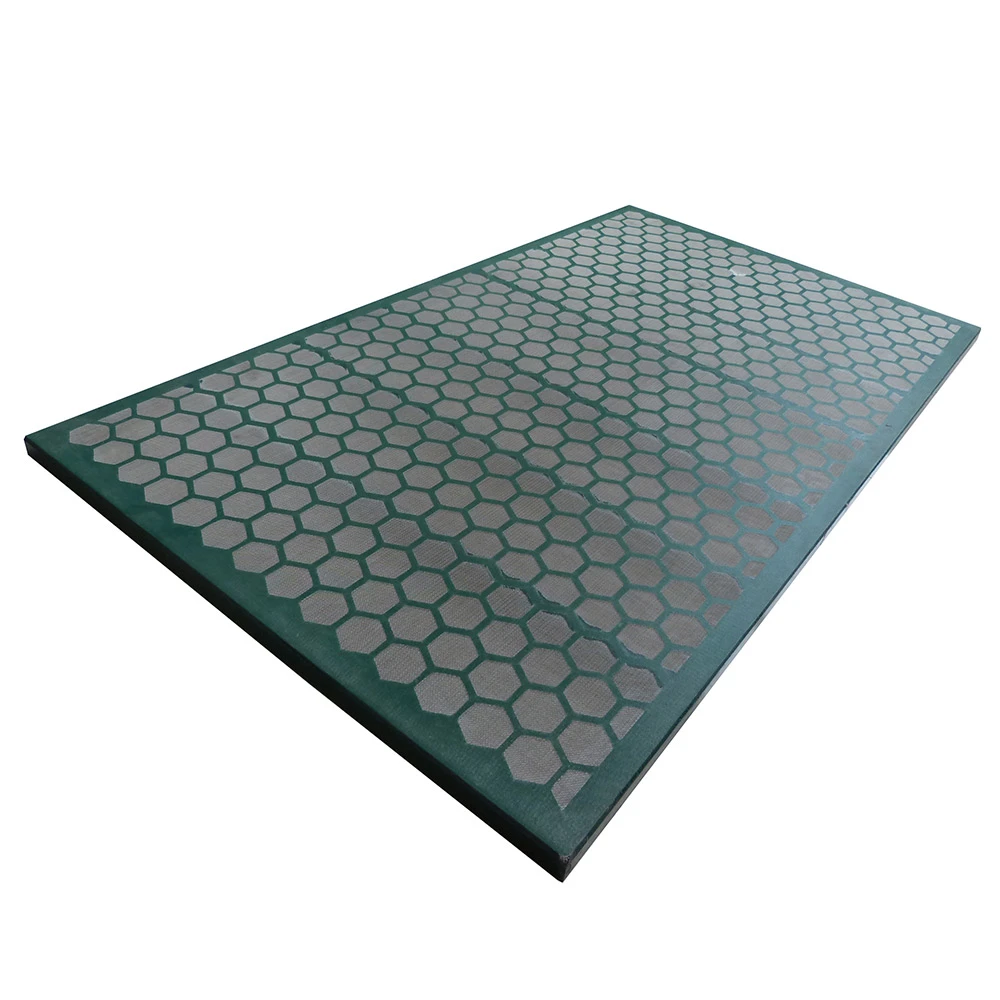

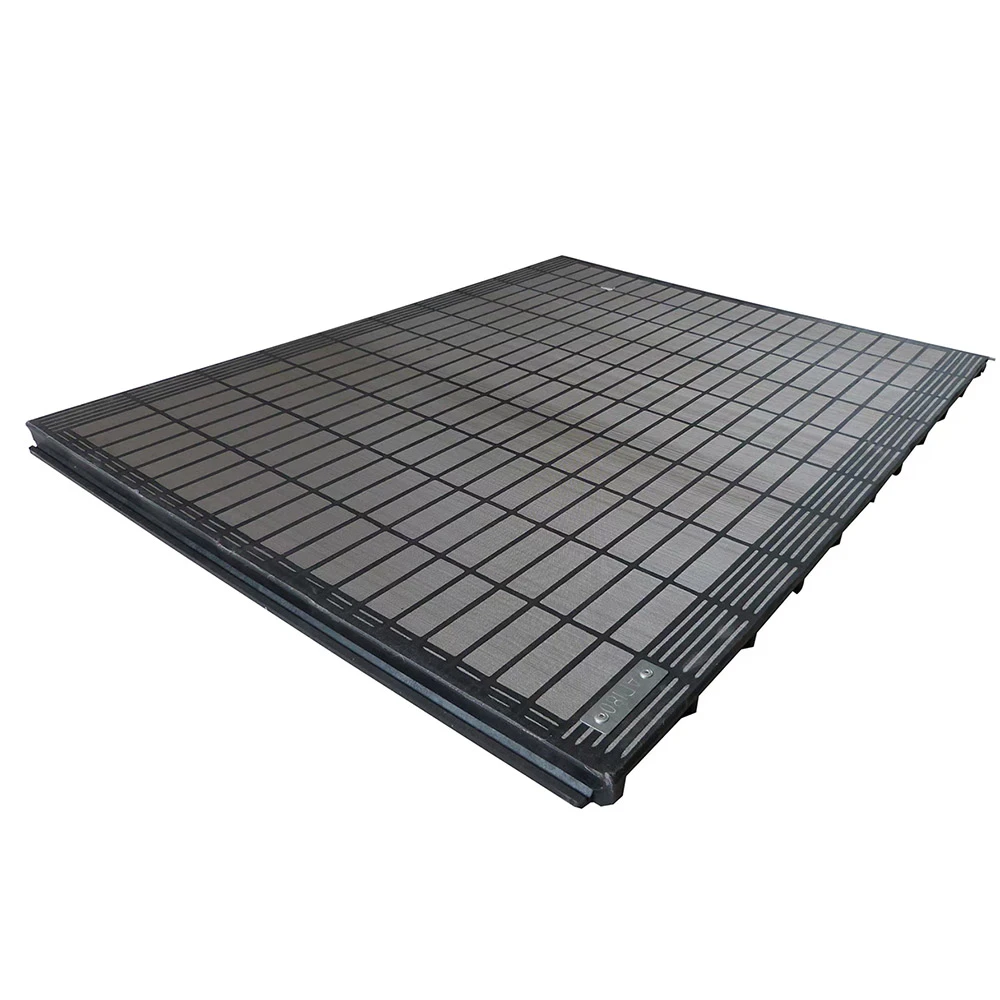

DESIGNED FOR THE DERRICK SHALE SHAKERS

Material: Stainless Steel 304/316/316L

Frame Material: DC03 Steel

Standard: API RP 13C

API Range: 20-325 Mesh

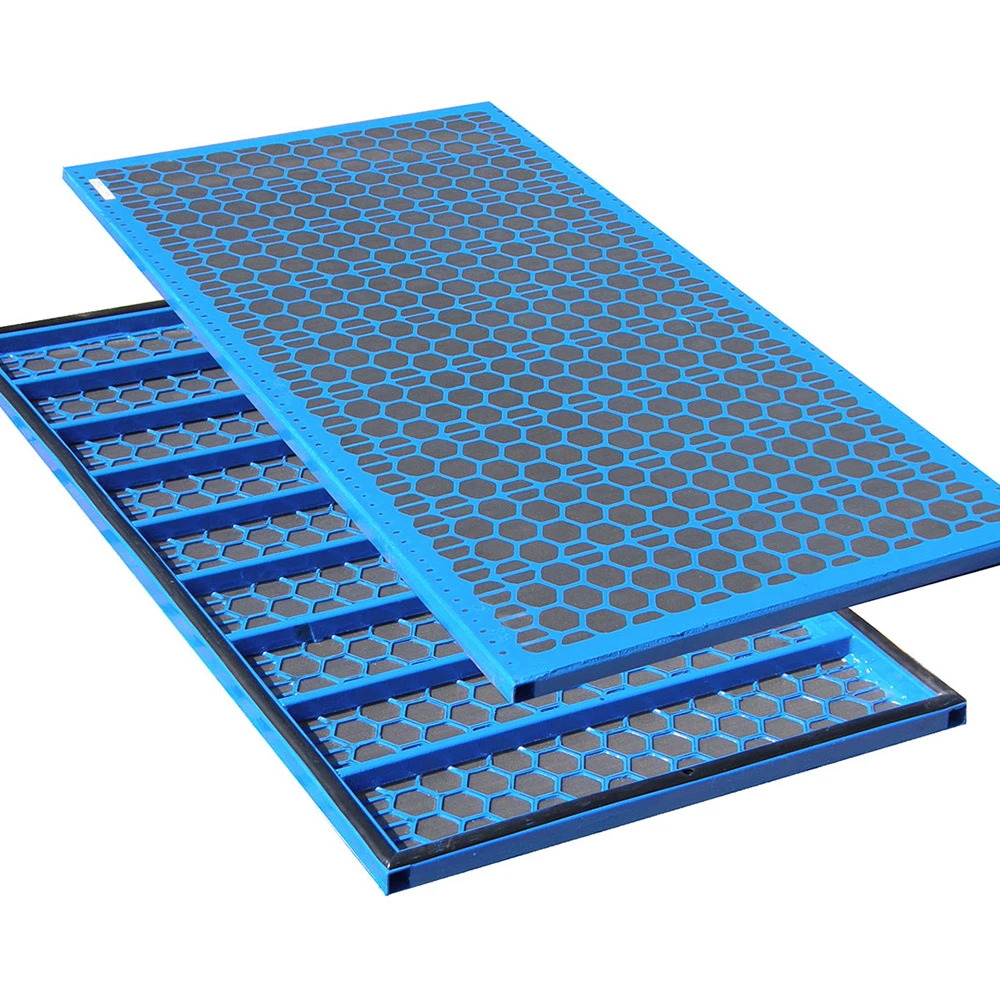

Mesh Shape: HP; DX; DF Etc.

|

Replacement Shaker Screens |

For Shale Shaker |

Dimension (MM) |

Weight (KGS) |

|

Derrick 2000/48-30 PWP |

Derrick FL C 2000 Shaker |

1050mm × 695mm |

5KGS |

|

Derrick 2000/48-30 PMD |

1050mm × 695mm |

6.5KGS |

|

|

Derrick 500 PWP |

Derrick FLC 503/504/513/514 (Drying) Shaker/Vapor Extraction |

1050mm × 695mm |

6.5KGS |

|

Derrick 500 PMD |

1050mm × 695mm |

7.5KGS |

|

|

Derrick 500 Composite |

1050mm*695mm |

10KGS |

|

|

Derrick 600 PMD |

Derrick DP 626 |

710mm × 626mm |

5KGS |

|

Derrick Hyperpool PMD |

Derrick Hyperpool Shaker |

1070mm*570mm |

7.7KGS |

Derrick Replacement Shale Shaker Screen - High-Quality Solution for Your Drilling Needs

Superior Performance and Durability

Our Derrick Replacement Shale Shaker Screens are engineered to deliver exceptional performance in even the most demanding drilling environments. Designed to fit Derrick shale shakers perfectly, these screens offer efficient separation of solids from drilling fluids, ensuring smooth operations and enhanced productivity.

Constructed with high-quality materials, our screens are built to last. The robust mesh construction resists wear and tear, providing long service life and reducing the need for frequent replacements. This not only saves you time and money but also minimizes downtime, keeping your drilling operations running smoothly.

Precise Filtration for Optimal Results

With a focus on precision filtration, our shale shaker screens are designed to remove fine solids effectively. The advanced screen technology allows for a high degree of separation, ensuring that only clean drilling fluids are recirculated, which is crucial for maintaining the integrity of your drilling operations. Whether you're working on oil and gas wells, mining projects, or other industrial applications, our screens will help you achieve optimal results.

Easy Installation and Maintenance

We understand the importance of ease of use in the field. Our Derrick Replacement Shale Shaker Screens are designed for quick and hassle-free installation, allowing your crew to get back to work in no time. Additionally, maintenance is a breeze, with simple cleaning procedures that can be carried out on-site. This reduces the complexity and cost associated with maintaining your shale shaker equipment.

Derrick Replacement Shale Shaker Screen FAQ

Q: How do I choose the right screen size for my Derrick shale shaker?

A: We offer a wide range of screen sizes to fit different Derrick shale shaker models. Please provide us with the model number of your shaker, and our experienced team will assist you in selecting the most suitable screen size.

Q: What is the lifespan of your shale shaker screens?

A: The lifespan of our screens depends on various factors such as the operating conditions and the type of drilling fluids used. However, our high-quality construction ensures a significantly longer lifespan compared to many other products on the market. In general, with proper use and maintenance, our screens can last for several months to years.

Q: Do you offer custom screen designs?

A: Yes, we understand that some drilling operations may have unique requirements. We can provide custom screen designs to meet your specific needs. Please contact us with your details, and our engineering team will work with you to develop a tailored solution.

Q: How soon can I receive my order?

A: Our lead times vary depending on the order quantity and the current production schedule. Once you place an order, our sales team will provide you with an estimated delivery time. We strive to process and ship orders as quickly as possible to minimize any delays in your operations.

Provide High-quality Solutions for Your Enterprise