All the replacement shaker screens are API RP 13C compliant.

All of our replacement shaker screens are fully compliant with API RP 13C standards. This compliance is a testament to the high - quality manufacturing and performance of our products. API RP 13C sets the industry standard for shale shaker screens, covering aspects such as screen construction, performance, and safety. By choosing our Swaco Replacement Shaker Screens, you are investing in a product that meets the strictest industry requirements.

DESIGNED FOR THE SWACO SHALE SHAKERS

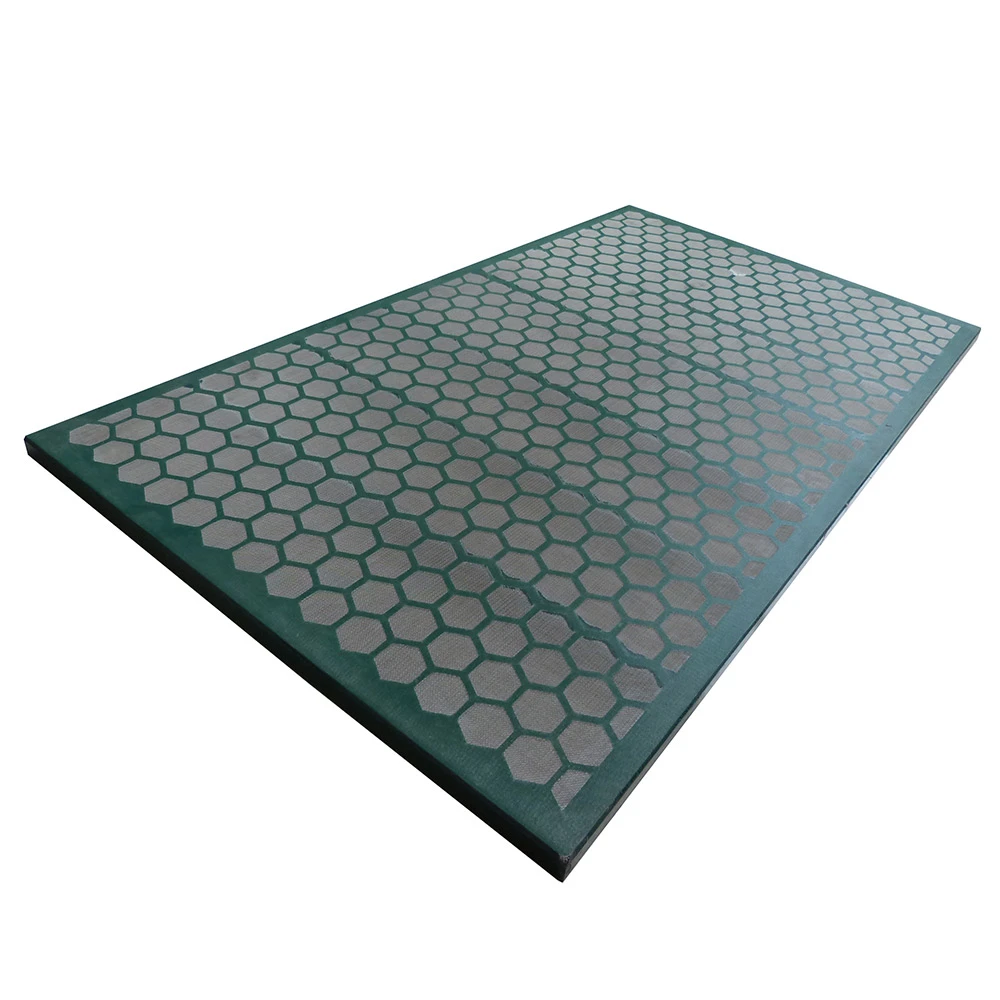

Material : Stainless Steel 304/316/316L

Frame Material : Q235 Steel & Composite

Standard : API RP 13C

API Range : 20-325 Mesh

Mesh Shape : XL;XR;HC;MG Etc.

|

Replacement Shaker Screens |

For Shale Shaker |

Dimension (MM) |

Weight (KGS) |

|

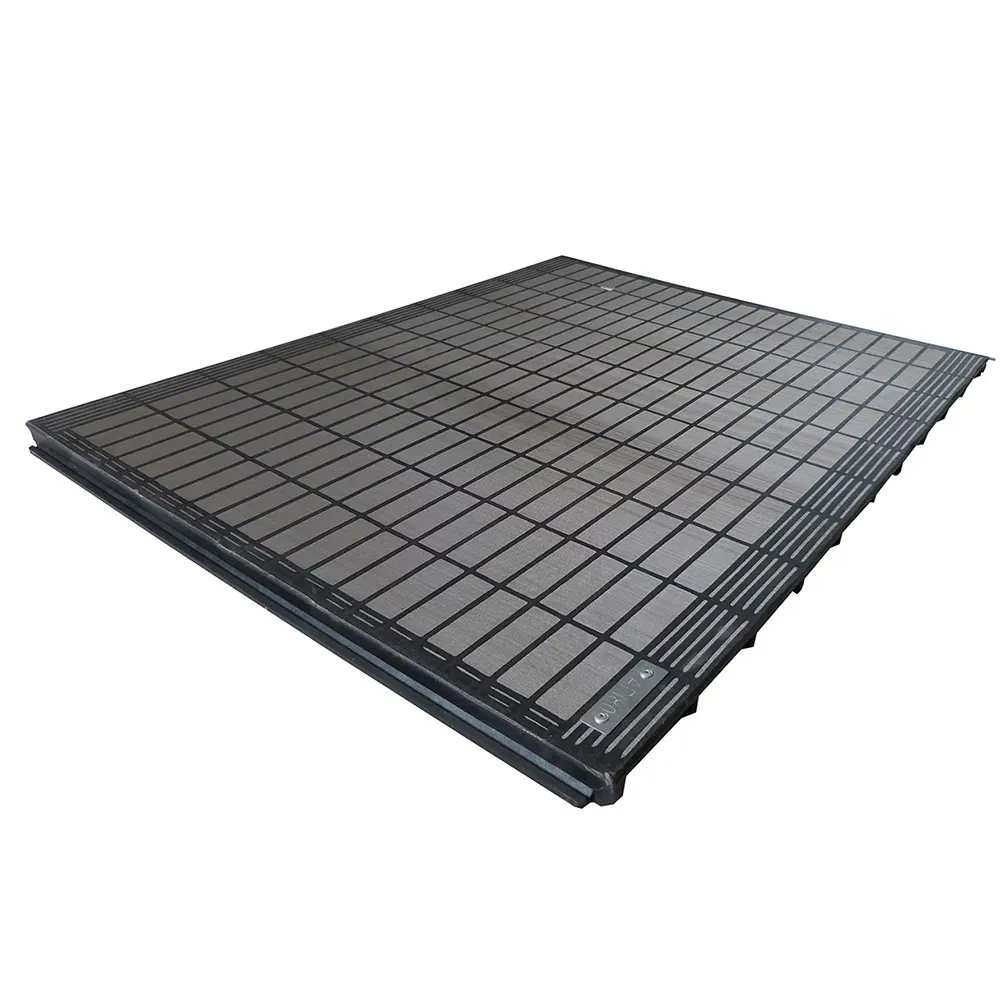

Swaco Mongoose/Meerkat Steel Frame |

r Swaco Mongoose Pro/PT Shale Shaker |

1165mm*585mm |

11 KGS |

|

Swaco Mongoose/Meerkat Composite |

12 KGS |

||

|

Swaco Mongoose/Meerkat Composite PMD |

17 KGS |

||

|

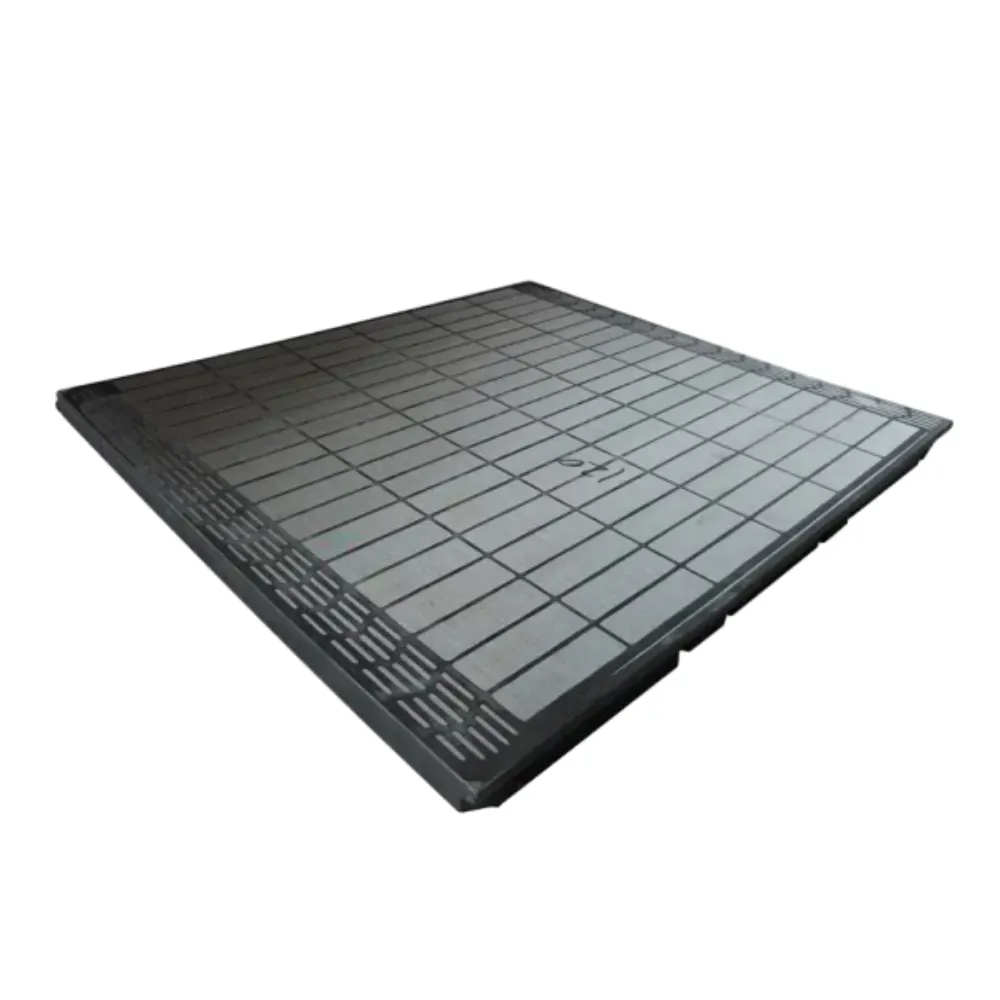

Swaco MD - 2/3 Composite |

Swaco MD - 2/3 Shale Shaker |

610mm*650mm |

6.2 KGS |

|

Swaco D380/D285P Steel Frame |

Swaco D380/D285P Shale Shaker |

1181mm*712mm |

14 KGS |

|

Swaco D380/D285P Composite |

1181mm*712mm |

15 KGS |

|

|

Swaco Mamut Steel Frame |

Swaco Mamut Shale Shaker |

1155mm*763mm |

15KGS |

|

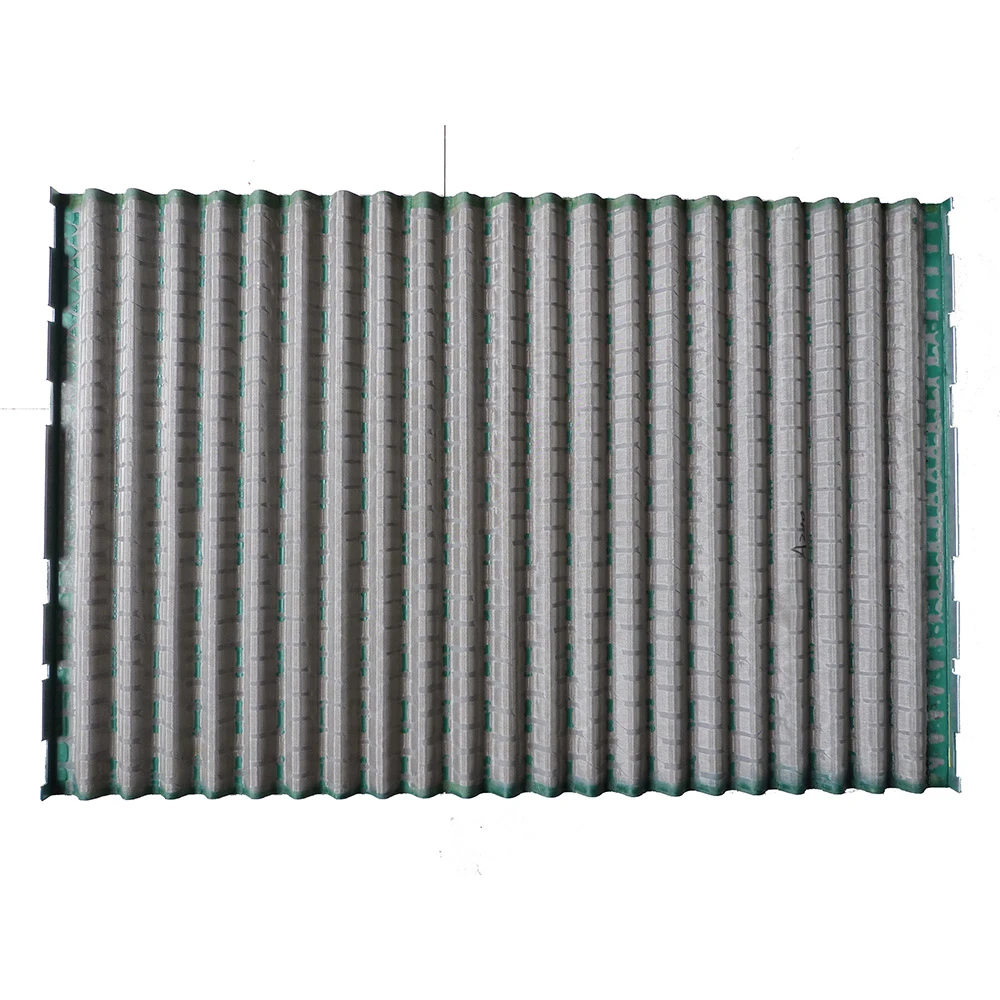

Swaco BEM - 3 Flat Screen |

Swaco Bem - 3 Shale Shaker |

1155mm*903mm |

6 KGS |

|

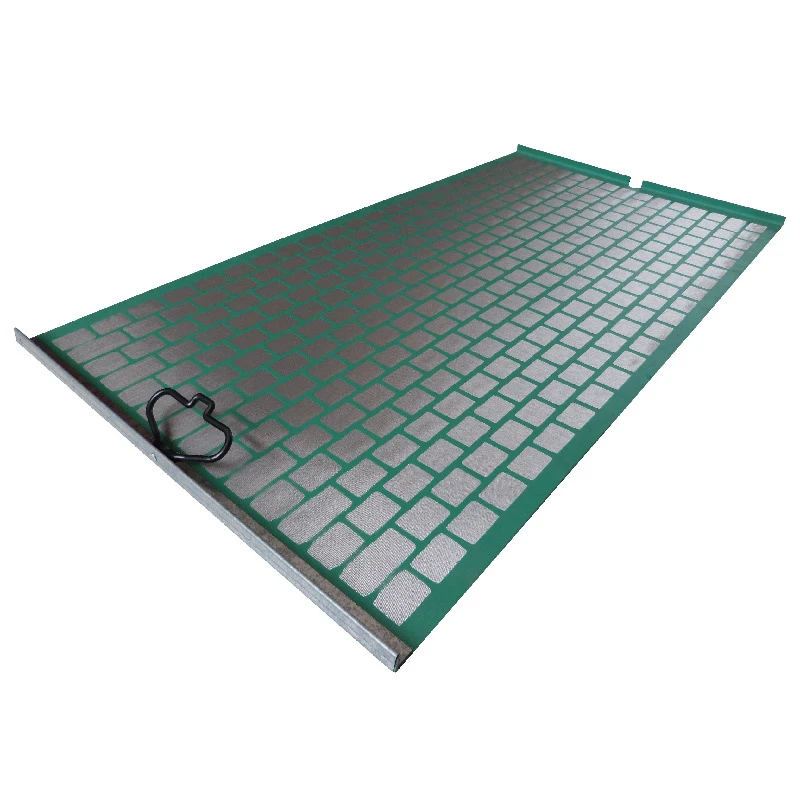

Swaco BEM - 600 Composite |

Bem 600 Shale Shaker |

915mm*700mm |

7 KGS |

|

Swaco ALS - II |

ALS - II Shale Shaker |

1212mm*1141mm |

9 KGS |

High Fluid Capacity and Anti - Blinding Properties

These screens are designed to handle significant fluid volumes, making them ideal for high - intensity drilling operations. Their excellent resistance to blinding, a common issue in shaker screens where solids clog the mesh, ensures that the filtration process remains smooth and efficient. This results in a more continuous and effective separation of solids from the drilling fluids, leading to improved overall drilling productivity.

Drier Solids Discharge and Large Usable Screen Area

The Swaco Replacement Shaker Screens are engineered to achieve drier solids discharge. By effectively separating as much fluid as possible from the solids, they reduce the amount of liquid waste and make the disposal or further processing of the solids more manageable. Additionally, the screens boast a large net usable screen area. This expansive surface area allows for greater filtration capacity, enabling more drilling fluid to be processed in a shorter amount of time.

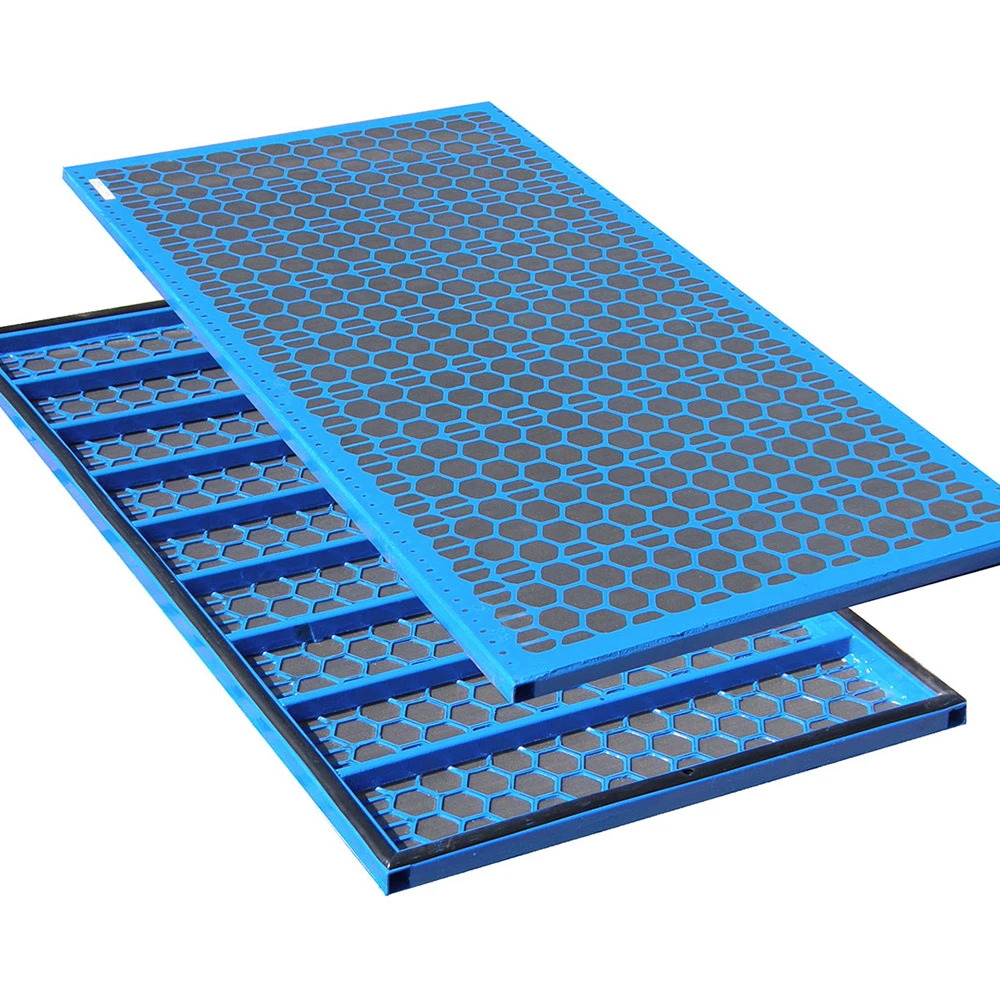

Superior Sealing and Solids Management

The composite construction of our screens creates an ultra - tight seal between the screen and the screen bed. This seal is crucial as it eliminates the problem of solids buildup and costly solids bypass. When solids bypass the screen, it can lead to inefficiencies in the drilling process and potential damage to downstream equipment. With our screens, you can rest assured that the drilling fluids will be properly filtered, and the solids will be effectively managed.

Unique Screen - Locking Mechanism

Our Swaco Replacement Shaker Screens feature a unique screen - locking mechanism. This mechanism wedges the screen firmly in place, ensuring stability during operation. At the same time, it allows for easy removal of the screen when repair or replacement is necessary. This user - friendly design makes maintenance and upkeep of the screens a breeze, minimizing downtime and maximizing the productivity of your drilling operations.

Provide High-quality Solutions for Your Enterprise