Brandt Replacement Shaker Screens

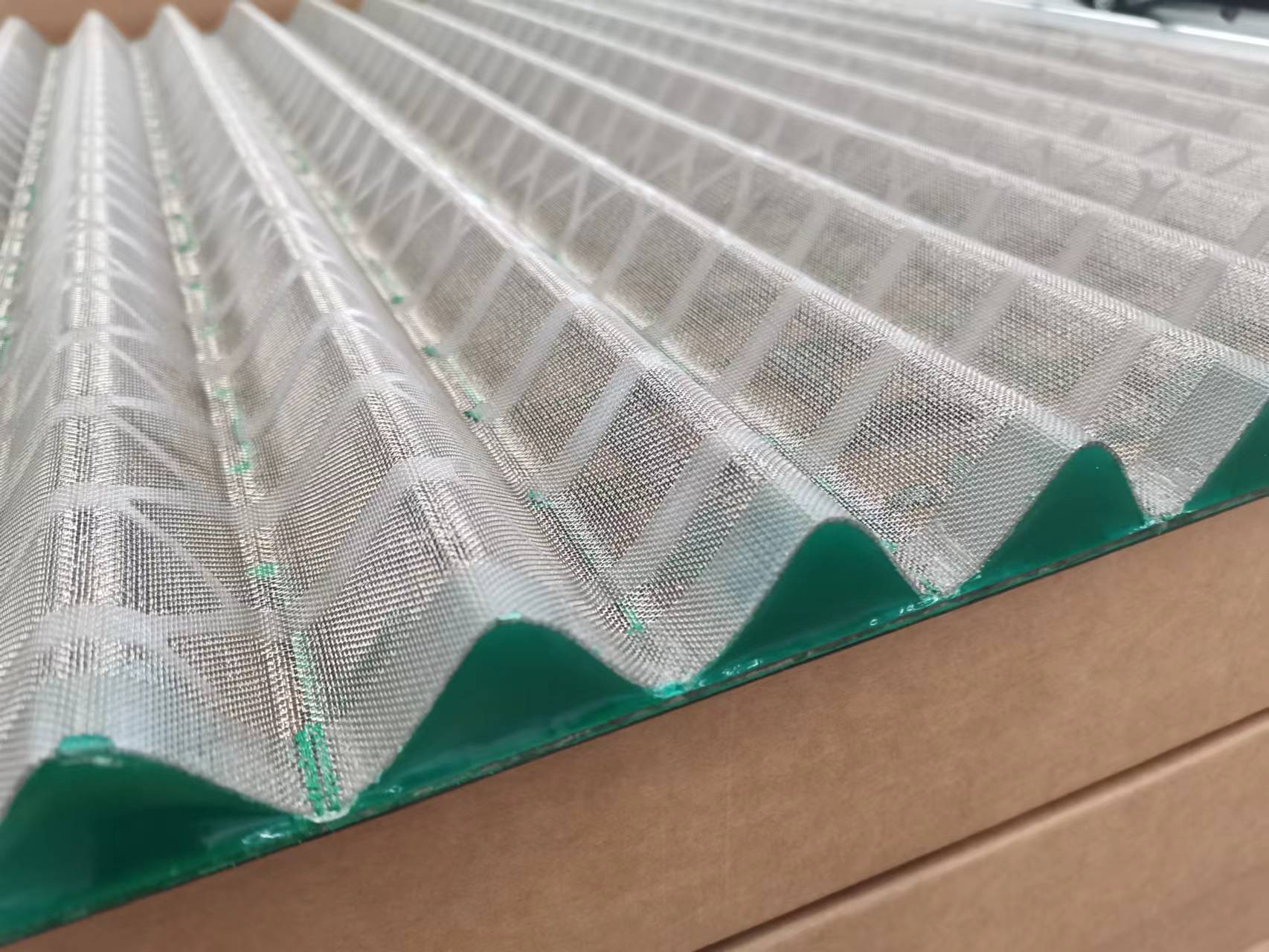

The shale shaker screen is an indispensable component in the solids control system of modern drilling operations, serving as the primary filtration medium that separates drill cuttings from valuable drilling fluid. As the first line of defense in maintaining fluid integrity, these screens play a pivotal role in ensuring operational efficiency, cost control, and environmental compliance across oil and gas, geothermal, and water well drilling applications. Constructed with precision engineering and advanced materials, shale shaker screens must withstand extreme conditions while maintaining consistent performance throughout demanding drilling programs.

Trusted Replacement Shaker Screens for Industries

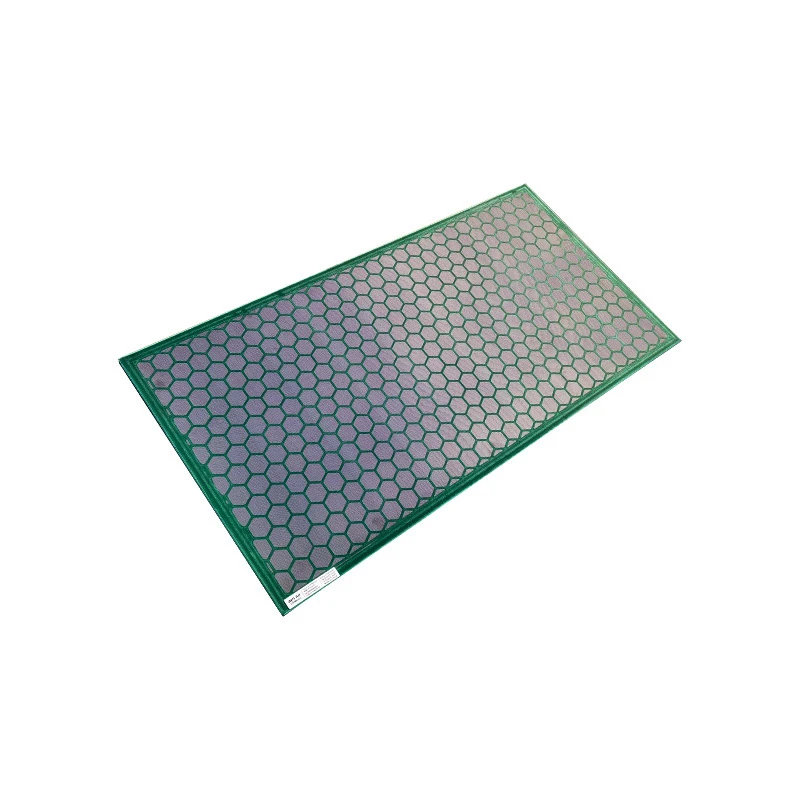

Oil & Gas Drilling

Engineered to withstand extreme conditions on both land-based and offshore rigs, our screens provide consistent, reliable solids control for conventional and shale gas exploration, ensuring optimal drilling fluid recovery.

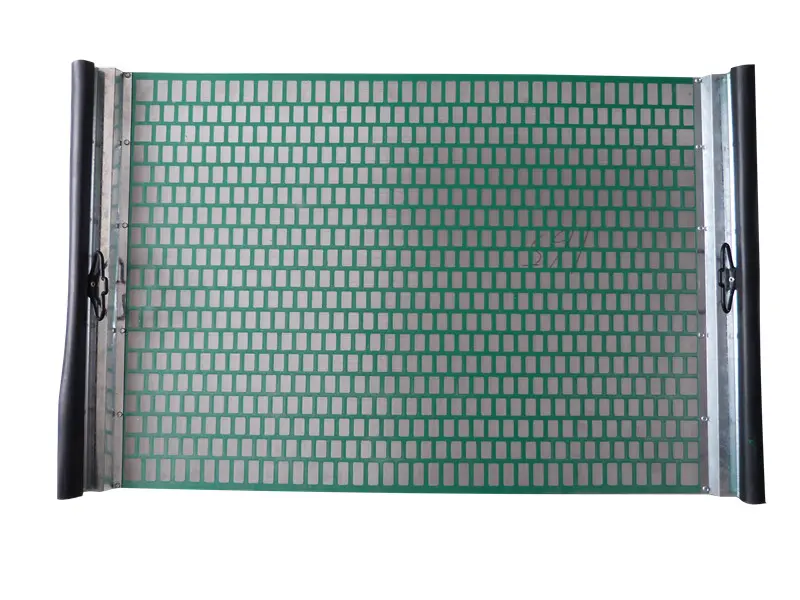

Mining & Mineral Processing

Designed for heavy-duty slurry separation, our durable screens effectively manage high-volume mineral processing and tailings operations, reducing wear and maintenance costs in abrasive environments.

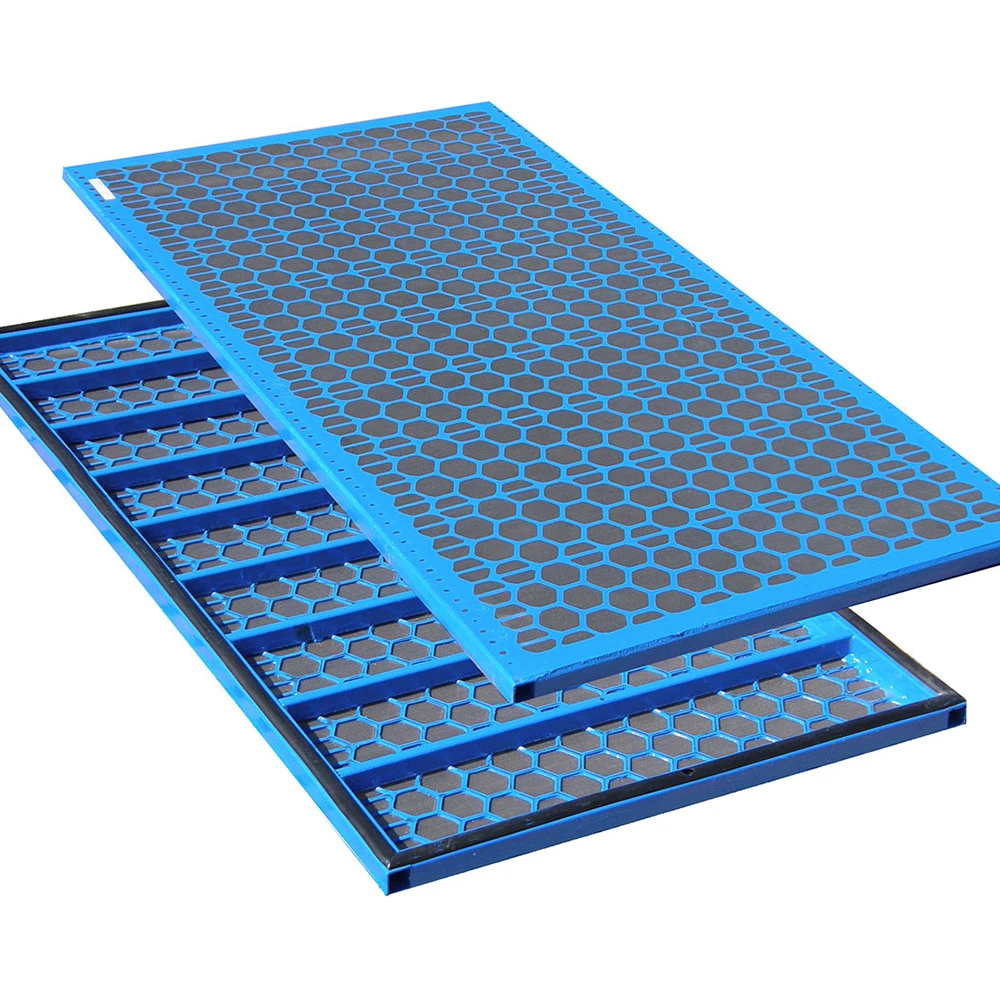

Geothermal & Water Well Drilling

Featuring precision mesh configurations, our screens offer exceptional particle removal in environmentally sensitive applications while maintaining maximum fluid flow rates for efficient operations.

Environmental Remediation

Our contamination-resistant screens provide superior filtration for soil and water treatment projects, meeting strict environmental standards with reliable performance in remediation applications.