PRODUCT FEATURES

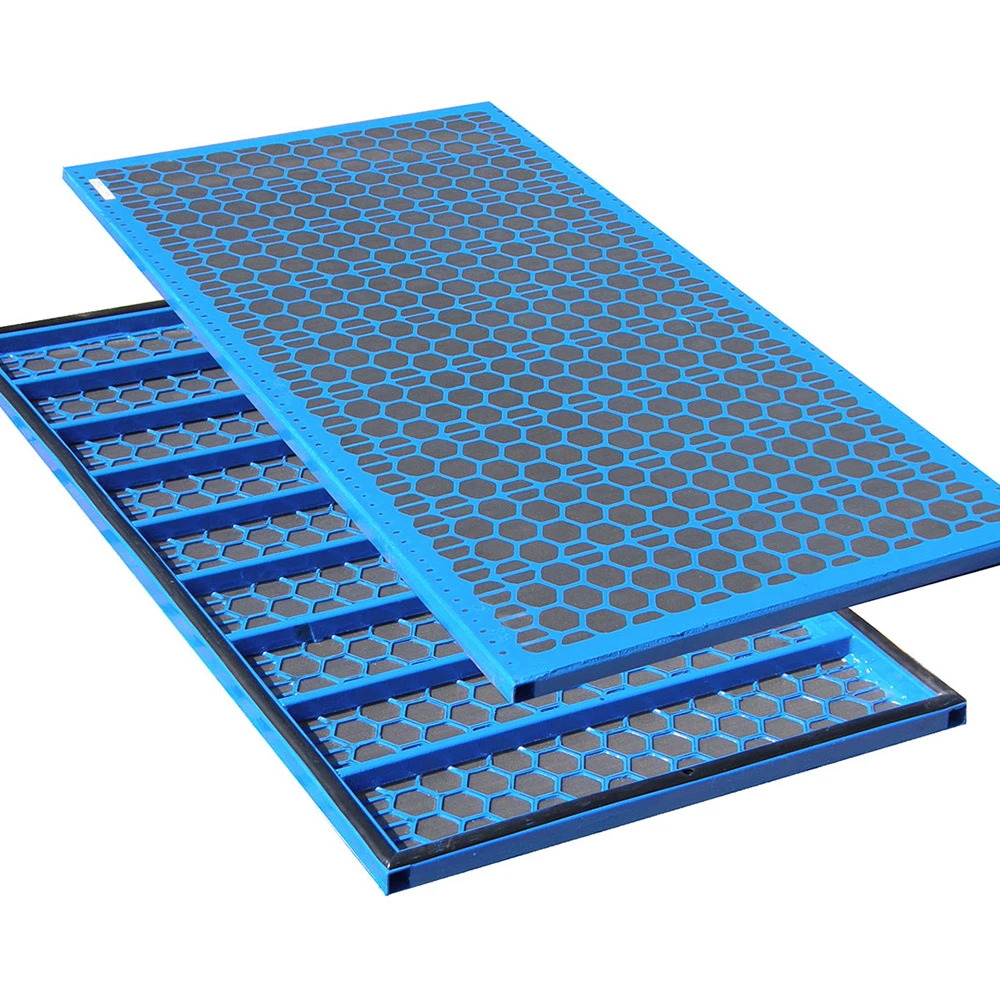

1. Composite Material replacement Shaker Screen is composed of injection molding frame and 2-3 layers of SS304 or SS316 stainless steel mesh directly bonded, no degummed layer, integral molding solid structure.

2. Good filter fineness.

3. High screening efficiency.

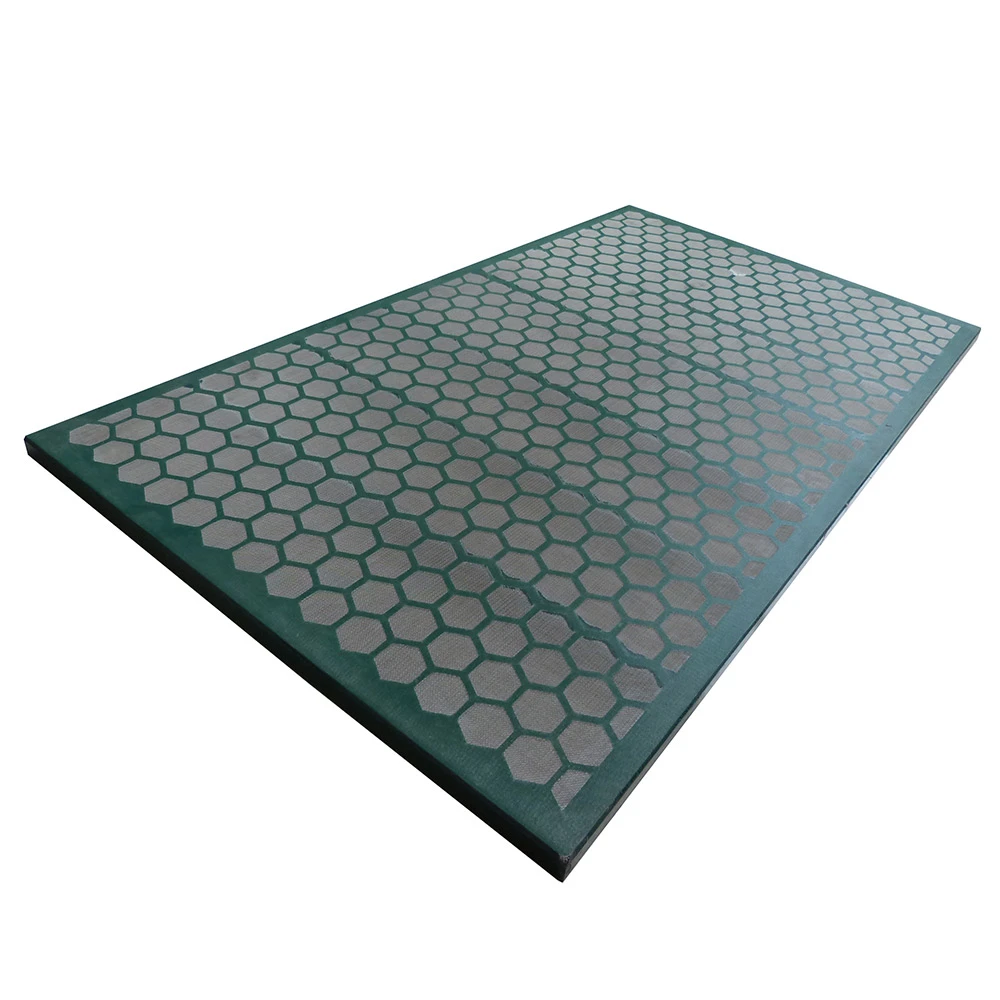

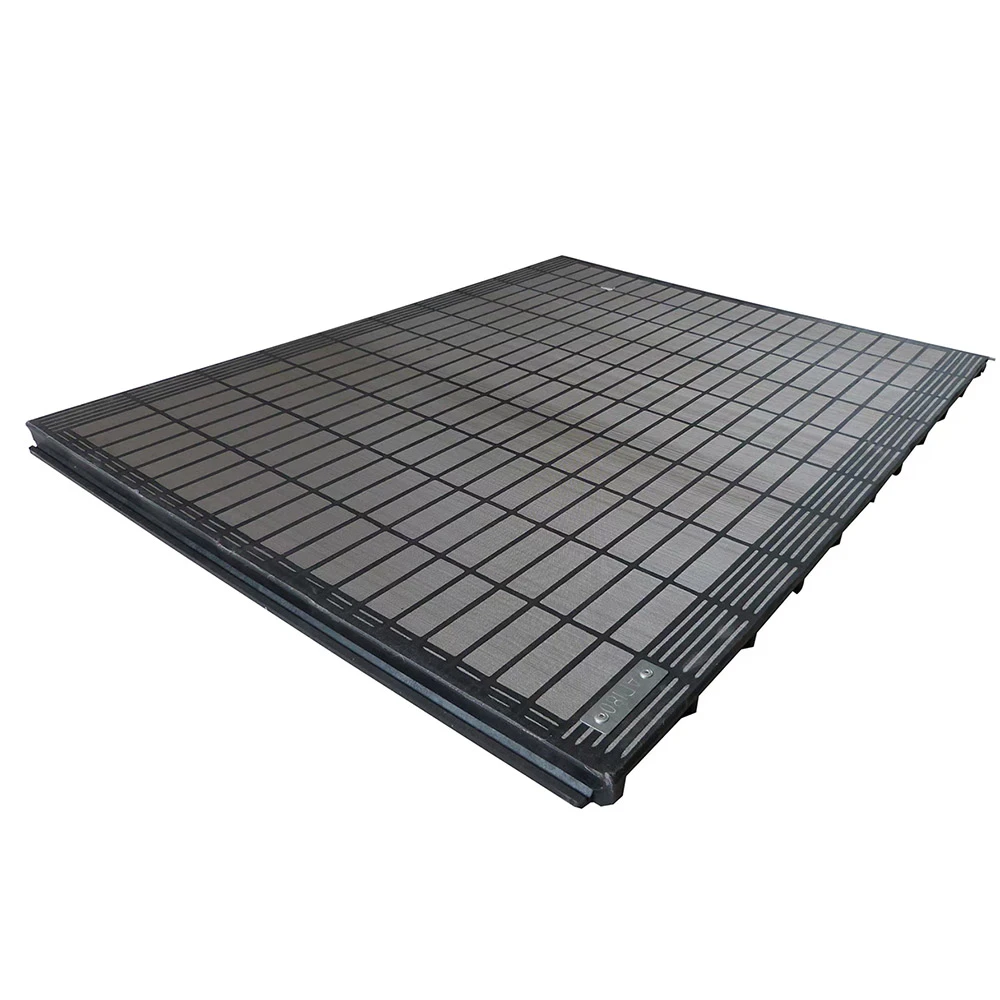

The type of screen

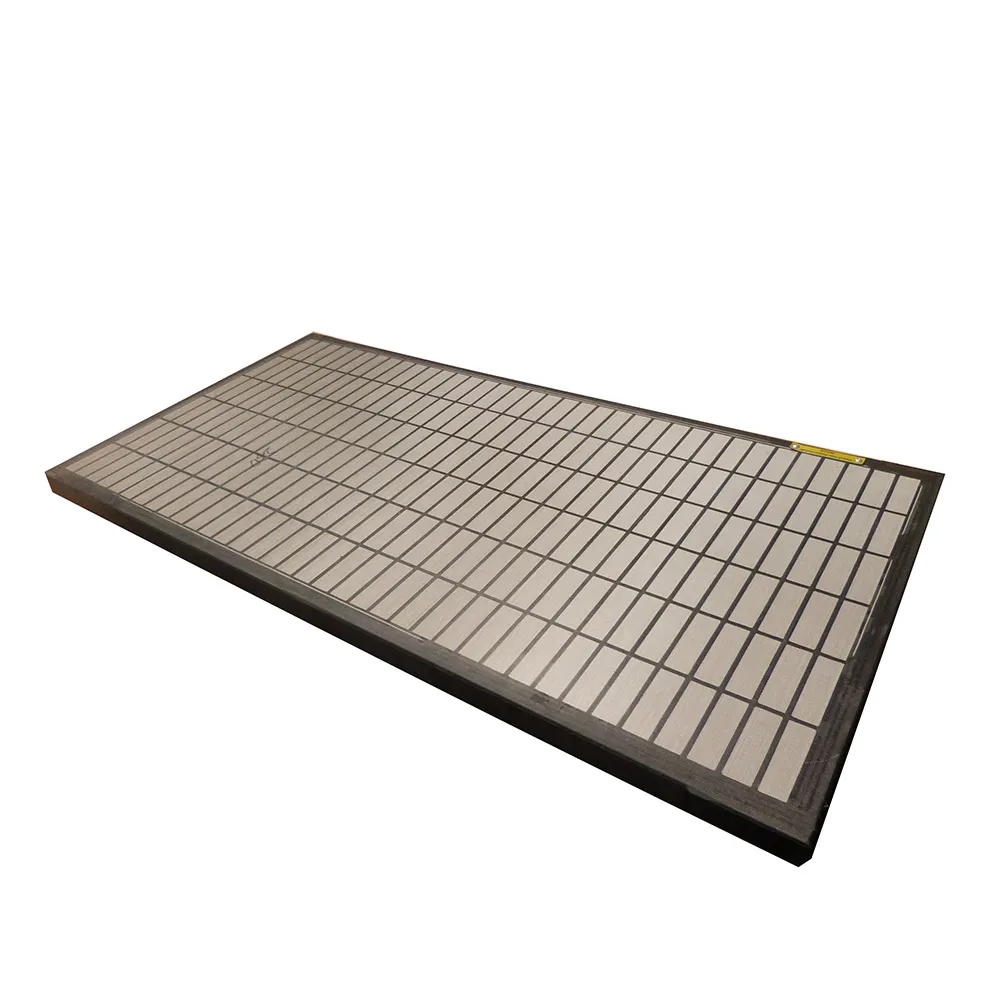

SWACO MONGOOSE COMPOSITE (FRONT)

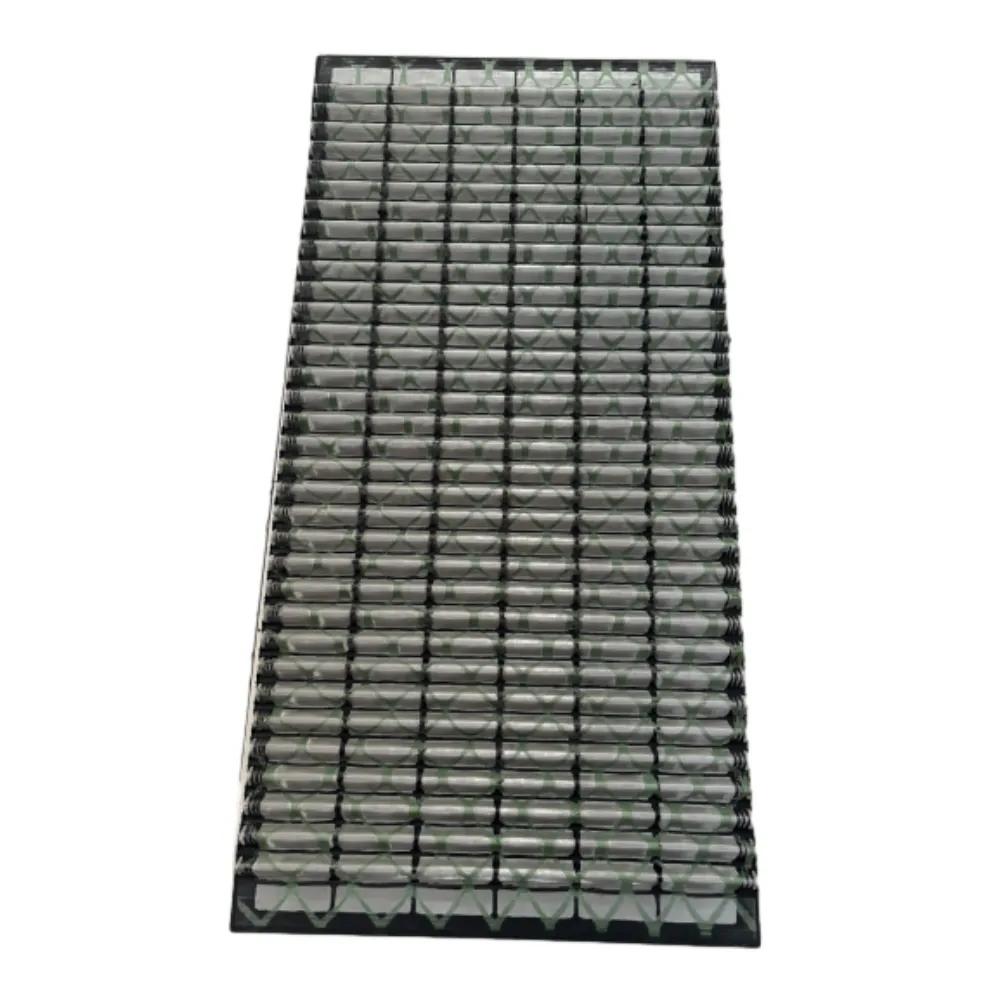

SWACO MONGOOSE COMPOSITE (BACK)

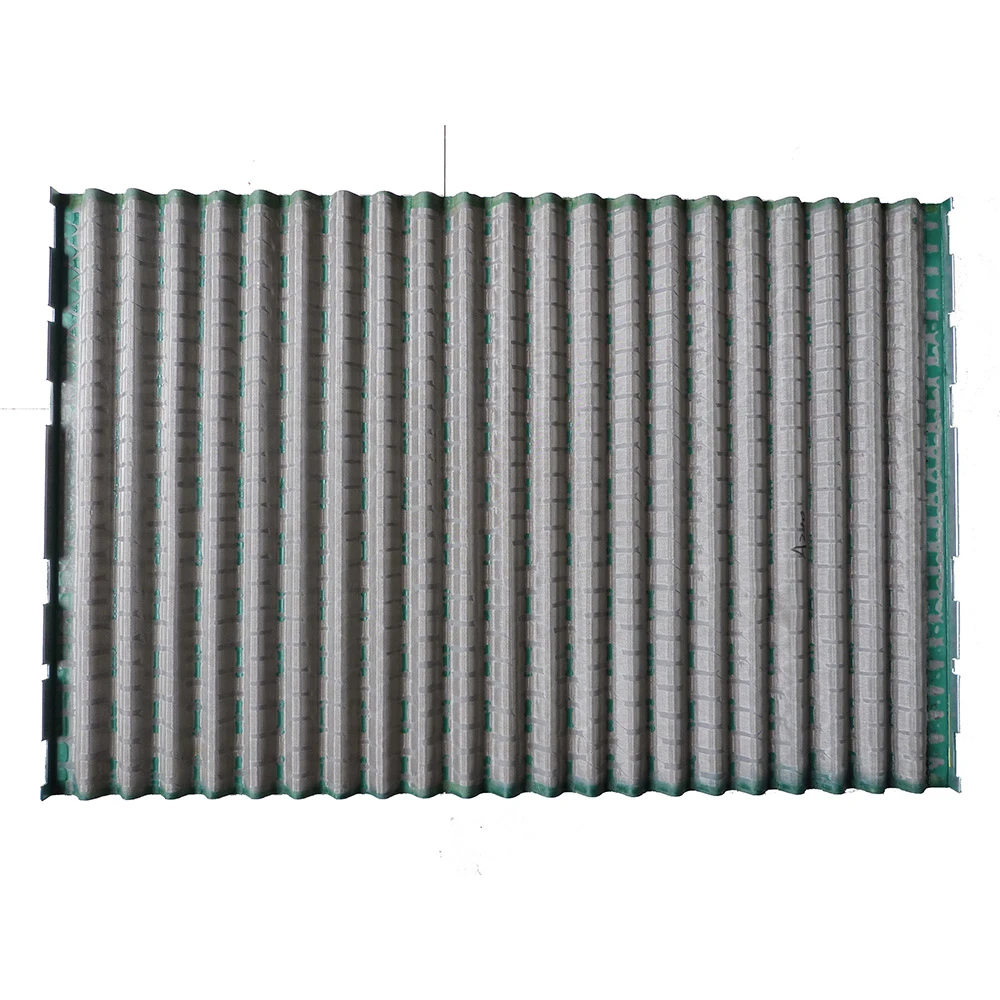

SWACO MD-3 COMPOSITE

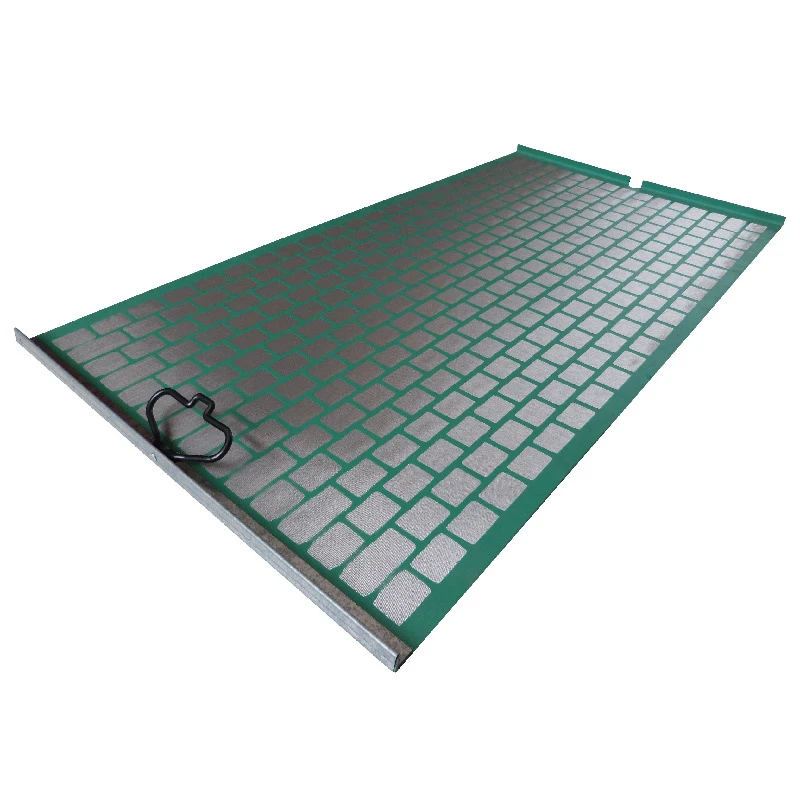

SWACO D380 COMPOSITE

Advantages of Mi SWACO composite screen

High-Strength Composite Frame: Made from reinforced composite materials, ensuring excellent corrosion resistance, reduced deformation, and extended service life.

Lightweight and Easy Installation: The composite frame structure is significantly lighter than traditional metal screens, reducing labor intensity and simplifying installation and replacement.

Superior Screening Efficiency: The advanced mesh design enhances the separation of solid particles, ensuring efficient drilling fluid processing and improving drilling operations.

Extended Service Life: The fatigue resistance of composite materials enables stable performance in high-amplitude, high-frequency working environments, reducing screen replacement frequency and lowering operational costs.

Wide Compatibility: Compatible with various shaker models such as Mongoose, MD-3, Meerkat, and more, enhancing screen versatility and reducing inventory pressure.

Why Choose Mi SWACO Composite Screen?

More Durable: High-performance composite materials ensure long-lasting operation.

More Efficient: Optimized screen structure enhances drilling fluid processing efficiency.

More Cost-Effective: Extended screen lifespan reduces replacement frequency and lowers operational expenses.

More Compatible: Suitable for a variety of mainstream shaker models.

Provide High-quality Solutions for Your Enterprise