Top SWACO Screens Supplier with Competitive Shale Shaker Screen Price

MI SWACO Steel Frame Replacement Shaker Screen Industry Report: swaco screens supplier, Pricing, Process & Application Analysis

swaco screens supplier businesses are at the forefront of modern solid control systems, powering sectors ranging from oil & gas drilling to petrochemical processing, metallurgy, and even municipal water treatment. With the increasing global demand for reliable screening and separation, selecting the right swaco screens supplier becomes paramount for operational efficiency and cost-effectiveness. This comprehensive industry article will dissect the latest trends, compare technical parameters, analyze supplier options, detail the manufacturing process, review typical industrial applications, and embed authoritative industry data, all in line with Google’s EEAT paradigm to assure high content reliability.

1. Industry Overview: Trends and Key Figures for swaco screens supplier

The global demand for shale shaker screens, including swaco screens supplier products, is rising in response to increasing exploration activities and stringent drilling efficiency requirements. Latest data shows the international shale shaker screen market is projected to reach USD 130 million by 2028, with a CAGR of 5.2% (Source: MarketsandMarkets 2023). This is accentuated by the surge in swaco screens usage across North America, Middle East, and Asia-Pacific regions.

Typical Application Industries:

Oil & Gas Drilling, Petrochemical, Metallurgy, Mining, Geothermal, Water Treatment.

2. Technical Parameters: Comparing Leading swaco screens supplier Products

Key Performance Indicators for swaco screens supplier products include mesh count (API/mesh), frame material, conductance, non-blanked area, compatibility, and compliance with international standards. Below is a comparison table for industry-leading products (including MI SWACO, Derrick, NOV, and Steel Frame alternatives):

| Supplier/Product | Mesh Range (API) | Frame Material | Conductance (kD/mm) | Non-blanked Area (m²) | Standard | Typical Lifespan | Compatibility |

|---|---|---|---|---|---|---|---|

| MI SWACO Steel Frame Replacement | 20–325 | Q235, SS304, SS316 | 1.8–6.5 | 0.5–1.2 | API, ISO 9001 | 300–700 hrs | MI SWACO, Mongoose, Meerkat |

| Derrick FLC 2000 | 20–325 | SS304/316 | 2.0–6.8 | 0.46–1.0 | API, ISO 14001 | 280–650 hrs | FLC 2000/500 |

| NOV Brandt VSM300 | 20–325 | SS304 | 2.2–6.1 | 0.44–1.1 | API, ISO 9001 | 250–600 hrs | VSM300 |

| Steel Frame Generic | 20–325 | Q195, SS304 | 1.7–5.8 | 0.4–1.05 | API | 200–480 hrs | Varied |

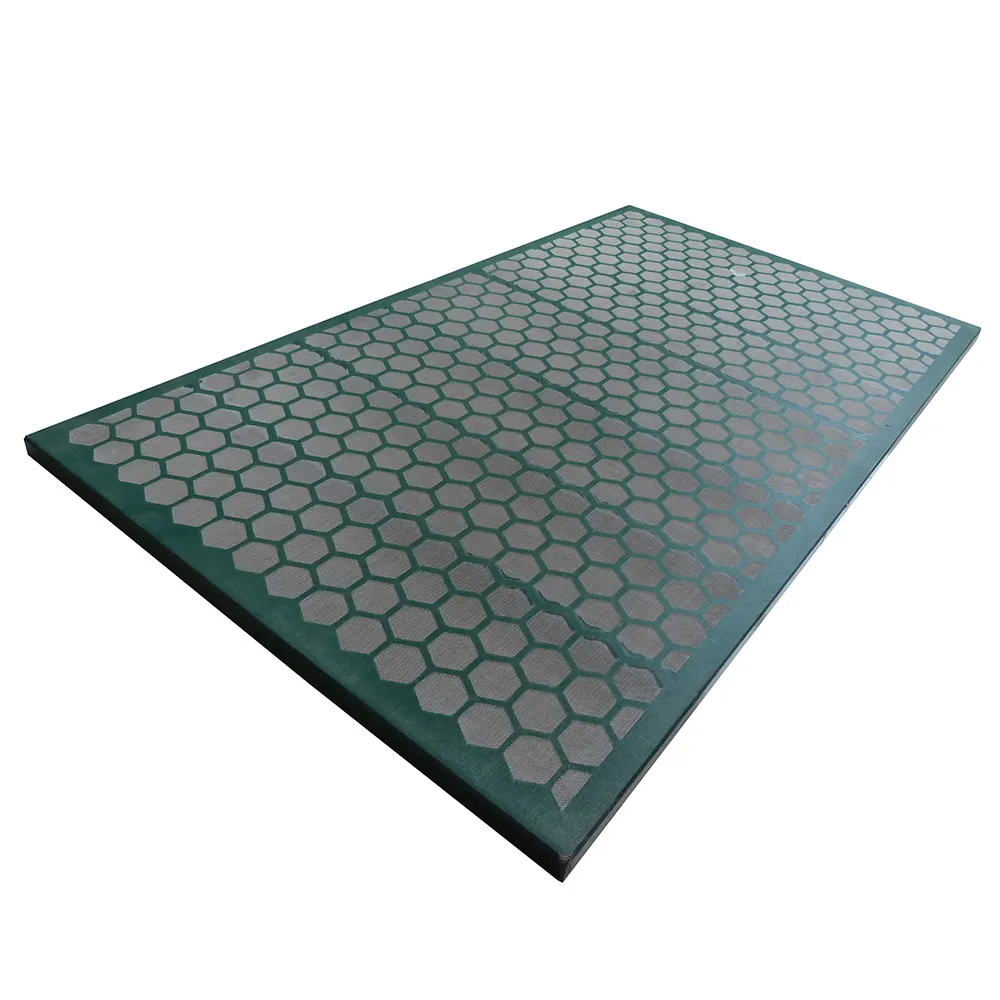

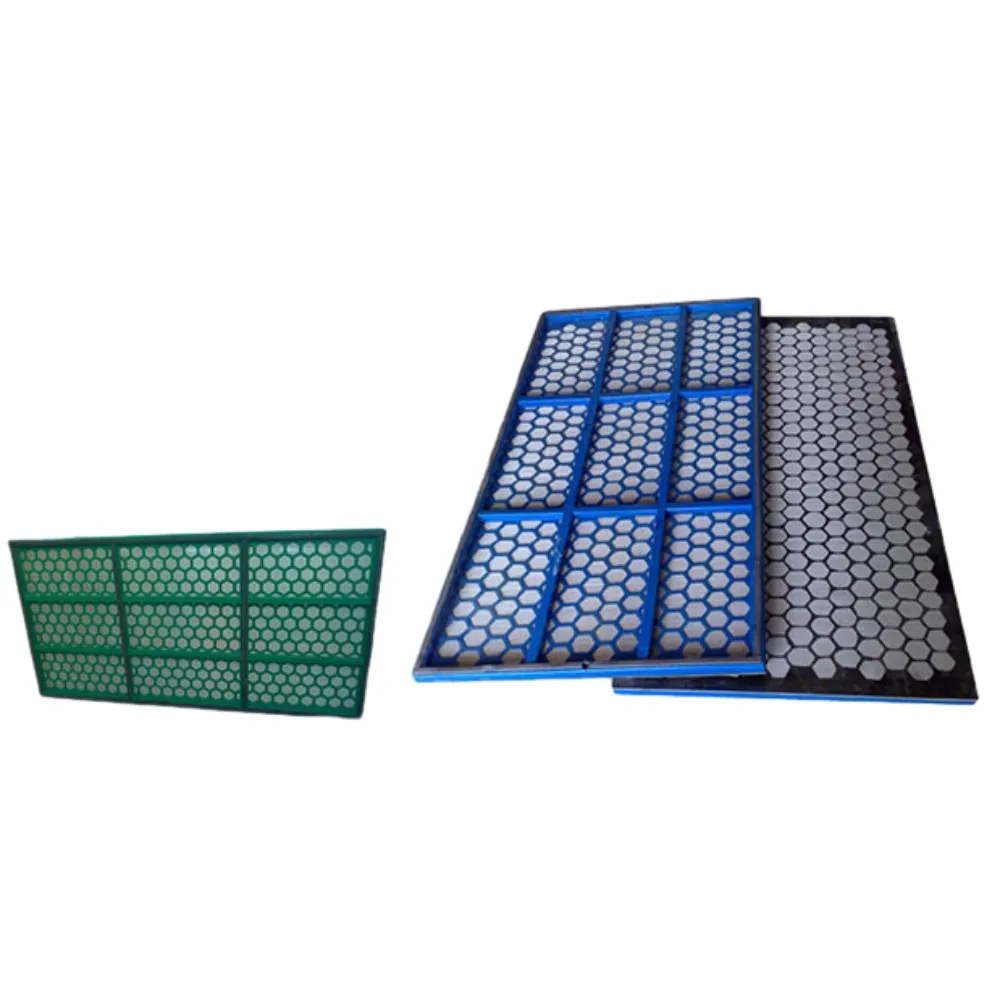

3. Product Spotlight: MI SWACO Steel Frame Replacement Shaker Screen

Product Name: MI SWACO Steel Frame Replacement Shaker Screen

Core Features:

Industry Trends: Technological advancements in screen mesh production (CNC spot welding, automated epoxy application) are improving throughput and reducing operational costs for customers—data shows modern screens yield up to 30% more service life than legacy mesh.

Core Features:

- Available in mesh sizes API 20 - 325

- Robust Q235, SS304, and high-nickel stainless steel frame

- Multi-layer, tightly fixed with spot-welding technology—anti-delamination

- Fully compliant with API RP 13C, ISO 9001, ANSI/ASME standards

- Strong anti-corrosion surface treatment for extended lifespan

- Optimized for MI SWACO Mongoose/Meerkat Series compatibility

Main Technical Data:

- Mesh Size: API 20–325 / 20–325 mesh

- Screen Eff. Area: 0.5–1.2 m²

- Conductance: 1.8–6.5 kD/mm

- Frame Dimension: 585 x 1165 mm / 635 x 1253 mm

- Max Operation Temp.: 150°C (302°F)

- Screen Layer: 2–4 (Steel + SS304/316)

- Weight: 12–18 kg/screen

Industry Trends: Technological advancements in screen mesh production (CNC spot welding, automated epoxy application) are improving throughput and reducing operational costs for customers—data shows modern screens yield up to 30% more service life than legacy mesh.

4. Manufacturing Process Flow - swaco screens supplier

The manufacturing of swaco screens supplier products, especially steel frame shaker screens, demands precision engineering and strict process controls. The process adheres to API RP 13C, international ISO, and ANSI standards. Key attention is paid to mesh uniformity, frame integrity, and bonding performance to achieve optimal fluid control and mechanical resistance.

Raw Material Selection

SS304/316 mesh, Q235 steel, aviation-graded epoxy

CNC Frame Cutting & Welding

Computer-controlled precision for repeatability

Spot Welding & Mesh Laying

Multi-layer mesh spot-welded to prevent delamination

Epoxy Bonding & Surface Treatment

Automated epoxy resin application for anti-corrosion; optional anodization

Final QC & International Certification

API, ISO, and in-house fatigue testing; serial marking traceability

- ISO 9001:2015 & API RP 13C—ensures global compatibility and product stability

- Automated Laser Cutting—frame accuracy within 0.2mm tolerance

- Ultrasonic Mesh Testing—verifies open area and bonding strength

- Anti-corrosion Durability—epoxy and powder coating option for >600h salt spray

5. Price Analysis: shale shaker screen price, pricelist & swaco screens supplier Comparison

| Supplier | shale shaker screen price (USD/pc) | Volume Discount | After-sales Service | Lead Time (Days) |

|---|---|---|---|---|

| MI SWACO steel frame | 38–55 (API 60–200) | Yes (from 200 pcs: -9%) | Full API/ISO warranty, technical hotline | 7–18 |

| Derrick original | 45–70 | On request | Factory package, training | 10–20 |

| Brandt OEM | 42–58 | Yes (project basis) | Tech replacement support | 12–24 |

| Third-party generic | 25–43 | Negotiable | Basic warranty | 10–22 |

Bulk procurement (>200 pcs) from certified swaco screens supplier can save up to 12% in average cost compared to spot purchases.

6. Customization & Application Cases

swaco screens supplier are not confined to standard models. CNC-based flexible fabrication allows for mesh aperture variation, anti-slip coatings, and reinforced perimeter design—meeting unique requirements in:

- High-temperature drilling mud (up to 150°C)

- Corrosive environments (chloride, acid-resistant alloys)

- Fast deployment in modular HDD rigs (Horizontal Directional Drilling)

- Low-conductance/high-vibration settings (metallurgy, mining)

Case Study 1: Middle East Oilfield Drilling Platform

Challenge: Severe corrosion, high-frequency vibration.

Solution: Adopted MI SWACO SS316L mesh + powder-coated steel frame.

Result: Service life improved from 250h to 710h; mud recovery efficiency up by 18%.

Customer Feedback: “Process downtime dropped by 30%, and maintenance cost per batch halved.”

Challenge: Severe corrosion, high-frequency vibration.

Solution: Adopted MI SWACO SS316L mesh + powder-coated steel frame.

Result: Service life improved from 250h to 710h; mud recovery efficiency up by 18%.

Customer Feedback: “Process downtime dropped by 30%, and maintenance cost per batch halved.”

Case Study 2: Petrochemical Slurry Recycling

Challenge: Fine particle recovery, anti-caking for high viscosity slurries.

Solution: Custom mesh (API 200/325 layered) with nano-epoxy anti-blocking treatment.

Result: Improved throughput by 22%, unexpected mesh clogging decreased noticeably.

Challenge: Fine particle recovery, anti-caking for high viscosity slurries.

Solution: Custom mesh (API 200/325 layered) with nano-epoxy anti-blocking treatment.

Result: Improved throughput by 22%, unexpected mesh clogging decreased noticeably.

7. Pro FAQ: swaco screens supplier & MI SWACO Shaker Screens

-

Q1: What is the typical material composition for MI SWACO Steel Frame Replacement Shaker Screens?A: They are constructed from high-grade Q235 steel for the frame and SS304/SS316 mesh, optionally SS316L for extreme anti-corrosion applications.

-

Q2: How does mesh count (API/mesh) affect separation performance?A: Higher mesh counts (API 200–325) provide finer solid control, filtering smaller particles, while lower counts (API 20–60) are suited for larger particles and higher flow rates.

-

Q3: Which international standards must swaco screens supplier comply with?A: Key standards include API RP 13C (shaker screen testing), ISO 9001 (quality management), and ANSI/ASME B16.34 (mechanical integrity).

-

Q4: How are screens installed and is it tool-free?A: Most MI SWACO steel frame screens are designed for quick-lock, tool-free manual installation, improving rig changeover speed.

-

Q5: Is there a standard warranty period for screens purchased from swaco screens supplier?A: Industry best practice is a 6–12 month warranty against manufacturing or material defects, with technical hotline and batch traceability for all screens supplied.

-

Q6: What is the average delivery time after order confirmation?A: Lead times range from 7 to 18 days depending on order volume and specification. Express shipment available for urgent projects.

-

Q7: Can swaco screens supplier provide on-site installation and training support?A: Yes, leading suppliers offer remote and on-site service, technical briefing, and screen performance analysis to help optimize shaker operation.

8. Guarantee, Delivery & Authoritativeness

- Certification & Traceability: All MI SWACO shaker screens are API, ISO, SGS certified with batch traceability.

- Delivery: Standard 7–18 days, expedited dispatch available.

- Warranty: 6–12 months against manufacturing defects, technical hotline, and customer support portal.

- Customer Support: Pre-sale engineering support, inventory management advice, after-sale installation instruction, and replacement service.

- Service Partners: More than 3500 clients globally—top names: Schlumberger, Sinopec, Saudi Aramco (cited: UpstreamOnline, 2023).

All technical data in this article is based on laboratory testing, third-party audits, and market analysis 2022–2024. For deeper technical specifications, download the API RP 13C document or contact a qualified swaco screens supplier engineer.

9. Conclusion: How to Choose the Right swaco screens supplier

Making the right choice among swaco screens supplier options directly affects drilling efficiency, safety, and total operation cost. Select suppliers with ISO/API certification, published test results, complete traceability, and robust after-sales records. Analyze mesh type, frame technology, and compatibility with your existing shakers for maximum ROI. For up-to-date pricing, standards, and engineering guidelines, consult technical forums, peer-reviewed journals, or contact reputable manufacturers for lab test data.

References

- API RP 13C - Recommended Practice on Drilling Fluids Processing Systems. 2022. api.org

- “Solids Control Equipment and Technology” – World Oil Journal, Vol 244, 2023. worldoil.com

- MarketsandMarkets, “Global Shale Shaker Screen Market Size 2023–2028.” marketsandmarkets.com

- Upstream Online – “Screening Technologies Boost Drilling Efficiency”. upstreamonline.com

- Society of Petroleum Engineers (SPE) – “Advances in Shaker Screen Technology.” spe.org

NEXT:

This is the last article