When it comes to effective solids control in drilling operations, shale shakers for sale represent the front line of defense. These machines are crucial in separating large solids from drilling fluid to ensure a clean, reusable mud system that keeps the entire drilling process efficient and cost-effective. Whether for land-based rigs or offshore platforms, the availability of high-performance shale shakers for sale has revolutionized drilling operations across the globe.

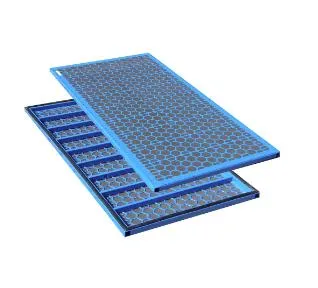

Modern shale shakers for sale come with advanced features including adjustable deck angles, multiple screen panels, and high G-force vibration motors, all engineered to enhance solids removal and minimize fluid loss. Investing in premium shale shakers for sale is more than an equipment upgrade—it’s a long-term savings plan through improved drilling fluid quality, extended bit life, and reduced waste disposal costs.

Operators seeking reliable shale shakers for sale can choose from linear motion, balanced elliptical, or circular motion designs depending on their wellbore conditions. With a focus on durability and performance, many shale shakers for sale are now built with composite screens and modular parts, making maintenance easier and less frequent. Selecting the right shaker is the first step toward a clean, high-performing mud system.

Understanding Shale Shaker Screen Sizes for Optimized Separation

Selecting the correct shale shaker screen sizes is a crucial part of solids control. Screen size determines the mesh's ability to filter particles and, therefore, impacts both drilling fluid recovery and cuttings disposal. With so many models of shale shakers for sale on the market, understanding screen size compatibility is vital.

Shale shaker screen sizes are typically measured in mesh count (the number of openings per inch) and conform to API RP 13C standards, which standardize screen designation to help users evaluate separation performance. Screens with lower mesh counts (e.g., 20-40 mesh) are ideal for coarse solids, while higher mesh screens (e.g., 200-325 mesh) handle finer solids, especially in deeper wells with expensive fluid systems.

The physical dimensions of shale shaker screen sizes—length, width, and frame type—must also align with the shaker deck. Oversized or ill-fitting screens can result in bypass, screen movement, or vibration inefficiency. Matching mesh count with the right shale shaker screen sizes ensures that operators achieve optimal throughput and separation efficiency without overloading downstream equipment like desanders and centrifuges.

Using the Shale Shaker Screen Mesh Sizes Table to Choose the Right Mesh

The shale shaker screen mesh sizes table is an indispensable tool for drilling engineers. It provides standardized comparisons between mesh count, micron retention size, and API designation, making it easier to select the proper screen for any drilling condition. By referencing a shale shaker screen mesh sizes table, users can make data-driven decisions instead of relying on trial and error.

For example, a mesh count of 100 typically corresponds to an API 100 screen, with a D100 cut point of around 137.5 microns. This information allows operators to predict fluid loss, cuttings retention, and separation capacity before running the shaker. A comprehensive shale shaker screen mesh sizes table will also include screen conductance values, which measure the fluid permeability of the mesh—a key indicator for maximizing throughput.

Operators can also use the shale shaker screen mesh sizes table to adjust their screen selection based on formation type. Sticky, clay-rich formations might require lower mesh counts to prevent blinding, while hard rock formations with fine cuttings benefit from higher mesh API ratings. With this data, screen selection becomes strategic, optimizing performance and extending the life of the screen and shaker unit.

Top Shale Shaker Screen Manufacturers in the Global Market

The quality of your shaker system often comes down to the expertise of shale shaker screen manufacturers. A reputable manufacturer ensures that screens are produced with strict quality control, API RP 13C certification, and compatible design features to match a variety of shaker models. The global market includes both OEMs (Original Equipment Manufacturers) and aftermarket shale shaker screen manufacturers who deliver custom-fit solutions for specific drilling applications.

Leading shale shaker screen manufacturers like Derrick, M-I SWACO, NOV Brandt, and Kemtron invest heavily in R&D to develop screens with high conductance, long service life, and resistance to corrosion and wear. Their products often feature composite frame designs, precision bonding techniques, and advanced multi-layer mesh structures to handle even the harshest drilling conditions.

Besides the big players, there are several emerging shale shaker screen manufacturers in China and Southeast Asia who provide cost-effective alternatives without compromising quality. Some of these companies specialize in producing replacement screens for major shaker brands at competitive prices. Working with a trusted shale shaker screen manufacturer ensures consistent screen availability, technical support, and compatibility with the newest shaker technologies.

How Shale Shakers for Sale and Screen Compatibility Shape Drilling Success

Ultimately, success in solids control comes down to the synergy between shale shakers for sale and the screens chosen for them. The right combination of shaker model and screen mesh guarantees reduced mud loss, lower disposal costs, and improved fluid properties throughout the drilling process.

Many drilling companies now operate multiple rigs with varying shale shaker screen sizes, making it critical to keep an updated inventory of compatible screens from reliable shale shaker screen manufacturers. As screen wear and tear are inevitable during high-volume operations, choosing high-quality screens ensures fewer changeouts, less non-productive time (NPT), and consistent mud quality.

Modern shale shakers for sale now come equipped with automation-ready interfaces, screen clamping systems, and self-cleaning functions. When paired with the correct screens as determined by a shale shaker screen mesh sizes table, these machines can adapt fluidly to changing drilling conditions, optimizing cuttings removal and reducing the environmental footprint of drilling waste.

Whether you're drilling vertical wells in Texas or horizontal shale plays in the Middle East, the key to a successful operation is the integration of top-tier shale shakers for sale, precision shale shaker screen sizes, informed mesh selection from a shale shaker screen mesh sizes table, and a reliable partnership with experienced shale shaker screen manufacturers.

shale shaker screen FAQs

What are shale shakers used for in drilling operations?

Shale shakers are used to remove large solid particles (cuttings) from drilling fluid, also known as drilling mud. As the mud returns to the surface from the wellbore, it passes over vibrating screens on the shaker, which separate the solids from the liquid. Clean mud is then recycled back into the drilling process, which reduces waste and lowers fluid costs.

How do I choose the right shale shaker screen sizes for my rig?

Choosing the right shale shaker screen sizes involves evaluating your drilling conditions, cuttings size, and the type of drilling fluid being used. Lower mesh counts (20–80) are suitable for coarse cuttings, while higher mesh counts (100–325) are better for fine solids. It’s important to ensure the physical screen dimensions match your shaker model. Referencing a shale shaker screen mesh sizes table can help you make the best choice.

What does a shale shaker screen mesh sizes table tell me?

A shale shaker screen mesh sizes table provides standardized information on mesh count, API designation, and the cut point (measured in microns) for various screens. It allows you to compare different screen types and choose one that offers the right balance between fluid throughput and solids separation. It also helps ensure compliance with API RP 13C standards for solids control equipment.

Who are the leading shale shaker screen manufacturers?

Some of the most recognized shale shaker screen manufacturers include Derrick Equipment Company, M-I SWACO (a Schlumberger company), NOV Brandt, and Kemtron. These companies produce screens that are API certified and compatible with a wide range of shaker models. Additionally, there are reputable manufacturers in China and Asia offering reliable replacement screens at competitive prices.

Where can I find shale shakers for sale and ensure screen compatibility?

You can find shale shakers for sale through oilfield equipment dealers, OEM manufacturers, or online platforms that specialize in drilling products. It's crucial to ensure the shaker you purchase is compatible with readily available screen sizes from trusted shale shaker screen manufacturers. Some suppliers offer bundled packages that include screens, shaker spare parts, and technical support to help with integration.