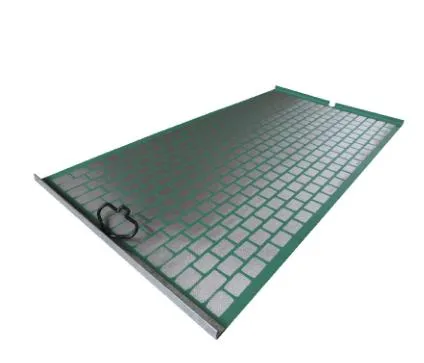

When searching for a shaker screen for sale, it's crucial to understand its vital role in modern solids control systems. As the first step in drilling fluid purification, the shaker screen ensures that large cuttings are efficiently separated from valuable mud, minimizing waste and optimizing fluid reuse. Choosing the right screen enhances not only the efficiency of the drilling operation but also the economics of the entire process.

Among the most sought-after options on the market is the derrick shale shaker, which stands out due to its robust design, performance, and compatibility with advanced screen technologies. Whether you're running a land rig or operating offshore, pairing the derrick shale shaker with high-quality screens can drastically improve mud handling and fluid recovery rates.

Today's energy markets demand more cost-efficient and environmentally conscious drilling. That's why rig operators are constantly on the lookout for a reliable shaker screen for sale that offers extended screen life, maximum fluid throughput, and quick delivery. Suppliers offering screens manufactured in shale shaker screen china facilities have risen to meet this demand, delivering advanced designs at competitive prices.

Derrick Shale Shaker Performance and the Right Screen Selection

The derrick shale shaker is a market leader in solids control, trusted for its high-G force linear motion and expansive screen area. It is engineered for performance, supporting a wide variety of mesh types and configurations that allow operators to customize screen behavior based on formation conditions and drilling fluid characteristics.

One of the key advantages of the derrick shale shaker is its ability to efficiently remove solids while maintaining drilling fluid integrity. The triple-deck configuration seen in some models increases screen surface area, offering more retention time and better separation. To achieve these results, screen selection is vital.

Compatible replacement screens are available from numerous suppliers around the world, including leading manufacturers in shale shaker screen china production hubs. These screens are often made with high-tensile stainless steel mesh, composite frames, and layered configurations that match or even exceed OEM standards.

Whether you are dealing with reactive clays, abrasive sand formations, or high-viscosity fluids, the derrick shale shaker delivers consistent results when paired with the correct screen specifications. Screen efficiency not only reduces mud loss but also extends the shaker’s operational life and minimizes downtime.

Exploring the Manufacturing Advantage of Shale Shaker Screen China Suppliers

Manufacturers based in shale shaker screen china production zones have become global leaders in screen technology and affordability. These suppliers offer a wide range of replacement and OEM-compatible screens that rival those produced in Europe or North America—but often at a much more competitive cost.

Factories in China utilize advanced automation, precision welding, and strict API certification protocols to produce screens tailored for leading shaker brands, including the derrick shale shaker. Their operations typically cover mesh counts from API 20 to API 325 and include features such as composite frames, rubber seals, and corrosion-resistant coatings.

One reason why shale shaker screen china suppliers are increasingly favored is their responsiveness to custom specifications and volume orders. Many can produce thousands of screens per month, allowing for bulk orders and steady inventory for rigs operating globally. They also invest in R&D to continuously improve screen bonding technology and frame durability.

For operators seeking a shaker screen for sale with the best balance between cost and quality, China remains a top sourcing destination. As long as API compliance and mesh quality are verified, these screens perform competitively across various drilling environments—from arctic to desert conditions.

Understanding Shale Shaker Screen Price: What Drives the Cost?

Drilling teams frequently ask what determines shale shaker screen price—and the answer lies in both material and performance. While price variations can be wide, they generally reflect differences in mesh count, frame type, bonding method, and brand compatibility.

Lower mesh screens (API 20–60) used for coarse cuttings are usually less expensive due to simpler mesh structures. Higher mesh screens (API 140–325), required for removing fine solids, cost more due to their complexity and shorter working life under high pressure. Screens for the derrick shale shaker, particularly triple-layered pyramid types, also tend to be priced higher due to their engineered design.

Another factor impacting shale shaker screen price is the material. Stainless steel mesh and composite frames add durability and resistance to vibration, temperature, and corrosion. These advanced materials contribute to longer screen life and fewer replacements, justifying a higher upfront cost.

Production location and supplier scale also affect pricing. A shaker screen for sale from a premium brand may cost twice as much as one from shale shaker screen china manufacturers. However, many Chinese suppliers offer API-approved, high-performance screens at 30–50% less, providing cost-effective solutions for budget-conscious operations.

Ultimately, understanding the full lifecycle value of a screen—including replacement frequency, downtime savings, and mud preservation—gives a more accurate picture of the true cost than price alone.

How to Choose the Best Shaker Screen for Sale for Your Derrick Shale Shaker

Finding the most suitable shaker screen for sale requires more than just checking compatibility with your derrick shale shaker. You need to consider drilling fluid properties, formation type, expected solids load, and environmental conditions. A properly chosen screen not only boosts separation efficiency but also reduces maintenance, waste, and chemical usage.

Start by selecting the correct mesh count based on the size of solids you need to remove. For fine solids like silt or clay, go with higher API numbers (e.g., API 170–230). For gravel and coarse debris, lower API mesh screens are ideal. When in doubt, consult the shaker manufacturer or your screen supplier for guidance.

Next, decide between steel and composite frames. Steel-framed screens offer rigidity and strength, ideal for high-impact environments. Composite screens are lighter, corrosion-resistant, and typically last longer—especially useful in offshore or remote drilling.

Don’t forget about supplier credentials. Ensure your screen source—especially if you're buying from shale shaker screen china factories—is API compliant, uses high-grade materials, and provides performance data or samples. A reputable vendor will also offer technical support, warranty coverage, and quick delivery timelines.

Finally, analyze your budget and forecast consumption. The best shale shaker screen price may not be the cheapest—it’s the one that delivers optimal lifespan, efficiency, and reliability under your unique drilling conditions.

shale shaker screen FAQs

What is a shale shaker screen and why is it important?

A shale shaker screen is a mesh panel installed in a shale shaker to separate solid cuttings from drilling fluid. It is the first line of defense in solids control systems and plays a critical role in recovering reusable mud, reducing waste volume, and maintaining wellbore stability. The quality of the screen directly impacts drilling efficiency, fluid costs, and environmental compliance.

How does the Derrick shale shaker improve solids control performance?

The derrick shale shaker enhances performance by using high G-force vibration and an expansive screen deck that accelerates solids separation. Its modular design supports multiple screen types and mesh counts, allowing operators to adapt to different formations and drilling fluids. It is known for reliability, extended uptime, and superior fluid recovery compared to conventional shakers.

What is the average shale shaker screen price?

The shale shaker screen price varies based on mesh count, material, and compatibility. On average, prices range from $25 for standard steel frame screens to $100 or more for advanced composite screens. High-end models used with the derrick shale shaker or triple-layer pyramid screens can exceed $150 each. Bulk orders from shale shaker screen china suppliers may provide additional discounts.

Are screens made in China reliable for oilfield operations?

Yes, screens from top shale shaker screen china manufacturers are highly reliable, provided they meet API RP 13C standards. Many Chinese suppliers use modern manufacturing technologies, high-tensile wire mesh, and automated bonding systems. They offer compatible replacements for the derrick shale shaker and other global brands, often at more economical prices with comparable durability.

How do I choose the right shaker screen for sale for my drilling rig?

Start by identifying the make and model of your shale shaker (e.g., derrick shale shaker) and select screens designed to fit its specifications. Consider the formation type, desired mesh count, and whether you prefer steel or composite frames. Look for API-compliant products, review performance data, and source from trusted suppliers—whether local or from shale shaker screen china factories—for reliable delivery and support.