Top Shale Shaker Screens for Sale - High-Efficiency Models

Keywords: shale shaker screen for sale, swaco screens supplier, shaker screens, buy shaker screens, industrial shaker screen

In the rapidly evolving sectors of oil & gas, petrochemicals, mining, and water treatment, the demand for efficient solids control is at an all-time high. Shale shaker screens have proven indispensable in separating drilling cuttings from valuable drilling fluids, ensuring both operational efficiency and environmental compliance. This comprehensive guide examines the latest industry trends and technology behind shale shaker screen for sale, featuring the renowned Derrick PMD Replacement Shaker Screen. We’ll provide real-world specification tables, process diagrams, comparative visuals, and direct application feedback to help decision-makers, engineers, and procurement professionals make informed choices.

In the rapidly evolving sectors of oil & gas, petrochemicals, mining, and water treatment, the demand for efficient solids control is at an all-time high. Shale shaker screens have proven indispensable in separating drilling cuttings from valuable drilling fluids, ensuring both operational efficiency and environmental compliance. This comprehensive guide examines the latest industry trends and technology behind shale shaker screen for sale, featuring the renowned Derrick PMD Replacement Shaker Screen. We’ll provide real-world specification tables, process diagrams, comparative visuals, and direct application feedback to help decision-makers, engineers, and procurement professionals make informed choices.

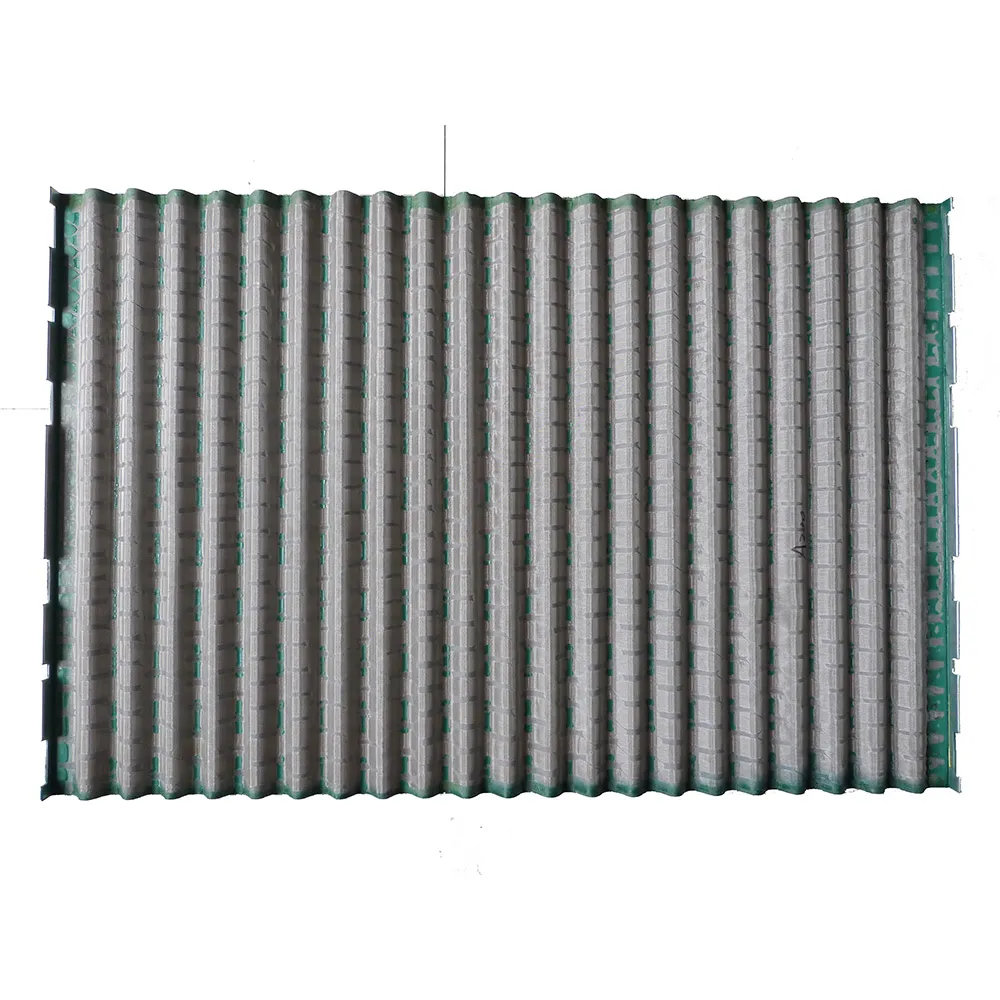

Premium shale shaker screens engineered for industrial separation processes

1. Industry Trends: How Shale Shaker Screen for Sale are Evolving

According to MarketsandMarkets, the global shaker screen market is projected to reach USD 1.7 billion by 2026, growing at a CAGR of 5.5%. Major growth factors include stringent environmental norms (ISO 14001), increasing shale oil & gas exploration, and a rising focus on efficient solids liquid separation across sectors.

Key Industry Observations:

Key Industry Observations:

- Shift to finer mesh and multi-layer screens for improved separation

- Adoption of CNC-machined frames for precise fit and higher durability

- Increased customization from established swaco screens supplier and proprietary screen designs

- Tighter API standards (API RP 13C) impacting product development

- Rising adoption of Composite & Polyurethane materials for longer service life

2. Technical Specifications & Parameters: Know Before You Buy Shaker Screens

| Product Model | Mesh Type | API Range | Screen Material | Average Life (hours) | Size (mm) | Application Industry |

|---|---|---|---|---|---|---|

| Derrick PMD Replacement | Flat / Pyramid | API 20 - 325 | 304/316 SS + Composite | 450 - 650 | 1050×695 | Oil & Gas, Mining, Petrochemical |

| FLC 2000 / 500 | Pyramid | API 28 - 325 | Stainless Steel | 350 - 500 | 1050×697 | Mud Circulation |

| Swaco Mongoose Replacement | Flat / Wave | API 40 - 270 | 304 SS / Polyurethane | 300 - 480 | 1165×585 | Drilling, Industrial Filtration |

| Brandt BLT-2000 | Flat | API 20 - 250 | 304/316 SS | 220 - 400 | 915×685 | Geothermal, Slurry Separation |

When considering options to buy shaker screens, it’s crucial to evaluate mesh composition, screen configuration, adherence to API/ISO standards, and compatibility with your existing shakers. The Derrick PMD Replacement Shaker Screen stands out as a modular, high-performance solution tailored for diverse industrial needs.

3. Manufacturing Process of Shale Shaker Screen for Sale: A Step-by-Step Guide

1. Raw Material Selection

Premium 304/316 stainless steel coils, composite extrusions

2. CNC Mesh Weaving

Precision mesh weaving machines ensure tight mesh aperture control (accuracy ±0.02 mm)

3. Frame Forming & Casting

Aluminum/Composite frames are die-cast or extruded for highness uniformity

4. Automated Assembly

Robotic arm installs mesh layers and bonds to frame (bonding agents tested to ANSI/ISO)

5. Quality Inspection

Multi-point inspection (API RP 13C, ISO 9001 audited), lifecycle fatigue & salt spray test

6. Packaging & Traceability

Laser QR batch coding ensures tracking & compliance

Manufacturing process illustration shows stages from metal selection, high-precision weaving, frame casting, to international-compliant inspection using standards such as ISO 9001:2015 & API RP 13C. Average defect rate is <1.6% due to automation and multi-point testing.

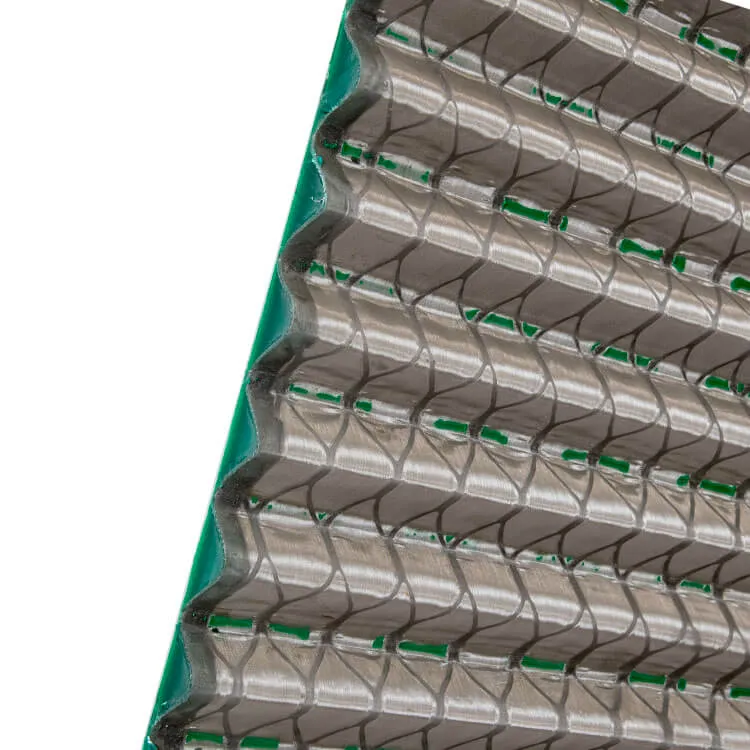

Close-up: Derrick PMD screen—CNC-configured mesh and composite frame

Material Choice Matters: Choosing 304 or 316 SS improves both corrosion and abrasion performance, rated to withstand saline, alkaline, and acidic drilling fluids—life tested to 600+ hours by SGS Labs.

Compliance & International Certifications: Certified to ISO 9001:2015, API RP 13C, and with optional ASTM D4747 particle retention reporting.

Compliance & International Certifications: Certified to ISO 9001:2015, API RP 13C, and with optional ASTM D4747 particle retention reporting.

4. Product Specification: Derrick PMD Replacement Shaker Screen

- Model Compatibility: Derrick 500, Hyperpool, FLC 2000/500 series

- Mesh Available: API 20 – 325 mesh

- Material: 304/316 Stainless with Thermoplastic/Composite Frame

- Surface Shape: Pyramid (PMD) & Flat type

- Dimensions: 1050 x 695 mm (Cert. ±1 mm)

- Bonding Type: Single and multi-layered epoxied mesh

- Fluid Handling: 15% higher throughput vs. Flat

- Corrosion Resistance: ASTM B117 salt spray test: ≥ 670 hours

- Screen Life: Up to 650 working hours per field tests

5. Technical Advantage: Why Our Industrial Shaker Screen Excels

Key Features

- Patented Pyramid (PMD) structure: Up to 43% more screen area than flat mesh.

- Wire mesh aperture uniformity, API RP 13C compliant

- Impact/vibration optimized composite frame—no deformation after 72 hr/30G test.

- Elastomeric seal for leak-free mounting, ANSI fit standards.

Application Scenarios

- Deep onshore & offshore drilling rigs (API 20-140 mesh)

- Mining & mineral slurry separation (API 50-200 mesh)

- Petrochemical effluent, process water recycling

- Sewage & industrial wastewater treatment

- Food/bio-pharma: FDA food-grade available

6. Specification Visualization

7. Vendor Comparison: Finding the Right Swaco Screens Supplier

| Supplier | API/ISO Compliance | OEM Replacement | Custom Mesh Available | Minimum Order | Annual Capacity |

|---|---|---|---|---|---|

| Solid Control Parts | ISO 9001, API RP 13C, ASTM | Derrick, Swaco, Brandt | API 20–325; branding | 1 pc | 340,000 screens |

| Swaco (M-I SWACO) | API RP 13C, ISO | Swaco | API 40–325 | 1 pc | 350,000 screens |

| GN Solids Control | ISO, API | Derrick, Swaco, Brandt | API 20–270 | 10 pc | 120,000 screens |

| OBM Equipment | ISO/EN, API | Brandt FLC, Mongoose | Up to 270 mesh | 10 pc | 85,000 screens |

When shortlisting a swaco screens supplier, demand traceable manufacturing, relevant certifications, competitive lead times, and field-proven references. Our Derrick PMD Replacement Shaker Screen is engineered to reduce downtime and lower the cost-per-usage for clients globally.

Field installation: Derrick PMD screens in oilfield mud recycling skid

8. Custom Solution & Application Stories: Real-World Experience

PetroChina Offshore Drilling (South China Sea, 2023):

Replaced original FLC 500 flat screens with PMD pyramid type—resulted in 28% more drilling fluid recovered. No corrosion detected after 630 hours. Screen exchange frequency reduced by 33%, saving USD 15,000+ per rig per month.

Replaced original FLC 500 flat screens with PMD pyramid type—resulted in 28% more drilling fluid recovered. No corrosion detected after 630 hours. Screen exchange frequency reduced by 33%, saving USD 15,000+ per rig per month.

Metallurgical Wastewater Plant (Middle East, 2022):

Customized composite frame with polyurethane edge for aggressive pH 2 fluid. Passed salt spray 720hr test (ASTM B117). Screen kept above 96.2% efficiency throughout a 4-month campaign.

Customized composite frame with polyurethane edge for aggressive pH 2 fluid. Passed salt spray 720hr test (ASTM B117). Screen kept above 96.2% efficiency throughout a 4-month campaign.

Our engineering team can assist with site surveys, mesh selection, batch traceability, and rapid prototyping. All solutions backed by a 12-month manufacturing warranty and 24/7 technical support.

9. Delivery Cycle, After-sales & Warranty

- Standard Delivery: 5–10 working days (global air/surface)

- Custom Orders: 2–4 weeks, including mesh prototype & test reporting

- Warranty: 12 months manufacturing, service support within 12h (response SLA)

- Traceability: All screens batch-coded, with test certificates on request

- Technical Support: Available via web, phone, onsite (API/ISO trained)

10. FAQ: Professional FAQ for Shale Shaker Screens

Frequently Asked Questions

Q1: What materials are typically used in high-end shale shaker screens?

A: Leading shale shaker screen for sale use 304 or 316 stainless steel for mesh, composite (PP or glass fiber) and/or aluminum alloy for frame, ensuring both corrosion resistance and rigidity per ASTM A240/AISI standards.

A: Leading shale shaker screen for sale use 304 or 316 stainless steel for mesh, composite (PP or glass fiber) and/or aluminum alloy for frame, ensuring both corrosion resistance and rigidity per ASTM A240/AISI standards.

Q2: What is API RP 13C, and why is it important?

A: API RP 13C defines testing protocols for shaker screen conductance, cut point (D100), and labeling. It ensures consistent, traceable performance for industrial shaker screens in critical separation processes.

A: API RP 13C defines testing protocols for shaker screen conductance, cut point (D100), and labeling. It ensures consistent, traceable performance for industrial shaker screens in critical separation processes.

Q3: How do I select the correct mesh size?

A: Determine by desired cut point: API 20–120 for drill solids, API 200–325 for fine mud, mill scale, or wastewater. Our technical team can provide sieve curve data per ISO 9044/ASTM E-11.

A: Determine by desired cut point: API 20–120 for drill solids, API 200–325 for fine mud, mill scale, or wastewater. Our technical team can provide sieve curve data per ISO 9044/ASTM E-11.

Q4: What are recommended installation standards?

A: Always install per OEM shaker manual, using epoxy-sealed gasket frames and torque to ANSI B18.3. Re-tension mesh evenly to avoid deformation.

A: Always install per OEM shaker manual, using epoxy-sealed gasket frames and torque to ANSI B18.3. Re-tension mesh evenly to avoid deformation.

Q5: How is screen performance tested?

A: Each batch is conductance tested (API), life-cycled for 200+ hours, and salt spray tested (ASTM B117). Test results available upon request to meet ISO 17025 calibration.

A: Each batch is conductance tested (API), life-cycled for 200+ hours, and salt spray tested (ASTM B117). Test results available upon request to meet ISO 17025 calibration.

Q6: What affects screen life the most?

A: Key factors: mesh wire gauge, vibration amplitude, fluid pH, and frame alignment. Derrick PMD replacement screens feature reinforced corners and multi-bonding for extended service.

A: Key factors: mesh wire gauge, vibration amplitude, fluid pH, and frame alignment. Derrick PMD replacement screens feature reinforced corners and multi-bonding for extended service.

Q7: Can I custom brand or label shaker screens?

A: Yes, we offer OEM logo, mesh color-coding, and laser batch marking per customer/industry requirements—minimums may apply for branding.

A: Yes, we offer OEM logo, mesh color-coding, and laser batch marking per customer/industry requirements—minimums may apply for branding.

11. References & Authoritativeness

- Certified to ISO 9001:2015, API RP 13C

- Audited by SGS, Bureau Veritas for material and product life

- Trusted supplier for PetroChina, Schlumberger, CNPC, SINOPEC, and global industrial clients

- Industry citations: SPE Drilling Tech Journal: Performance of Composite Shaker Screens

Quote & Tech Insight:

“Pyramid mesh screen technology, as found in Derrick PMD replacement screens, consistently improves fluid recovery and lifespan versus traditional flat designs.” — Rigzone Forums: Derrick Pyramid+ Screens Boost Shaker Performance

“Pyramid mesh screen technology, as found in Derrick PMD replacement screens, consistently improves fluid recovery and lifespan versus traditional flat designs.” — Rigzone Forums: Derrick Pyramid+ Screens Boost Shaker Performance

"API RP 13C-compliant screen labeling and conductance tests are vital for field traceability and optimization." — World Oil Journal Article, 2018

NEXT:

This is the last article