In the dynamic oil & gas and drilling fluids industry, shale shakerscreen manufacturers play a pivotal role in optimizing solid-liquid separation. As upstream operations demand higher efficiency, precision, and resilience, screens such as Swaco Replacement Shale Shaker Screens, mongoose shaker screens, and cost-effective alternatives have emerged as industry benchmarks.

This in-depth guide analyzes the evolution of shale shakerscreen manufacturers, providing objective technology comparison, data-backed performance charts, and a real-world application perspectives—ensuring both procurement professionals and technical engineers can make informed choices. Explore process-flow diagrams, international standards compliance, client testimonials, and modern customization options, all crafted according to EEAT and Google SEO excellence.

Industry Overview & Trends Among Shale Shakerscreen Manufacturers

The global market for shale shakerscreen manufacturers surpassed USD 1.3 billion in 2023 (Grandview Research), with rising investments in unconventional exploration and mature oilfield upgrades. Over 60% of the demand is driven by technologies replacing legacy mesh screens with high-capacity, multi-layer composites.

▪ Market Growth Driven by Advanced Manufacturing Technologies and Customization:

- Automation: Use of CNC precision cutting, laser welding, and integrated robotics for mesh assembly improves screen consistency by up to 25% (Oilfield Technology).

- Materials Science: Stainless steel 316L, duplex alloys, and polyurethane frames prolong screen life by 40% or more.

- Regulatory Compliance: Major shale shakerscreen manufacturers adhere to ISO 13501, ISO 9001, and ANSI/API RP 13C standards.

- Application Specificity: Rise in specialized screens for high-pressure, high-thermal, or corrosive drilling fluids.

The main markets are North America, the Middle East, Southeast Asia, and South America—where shale exploration and deepwater drilling require robust solids management solutions. This landscape shapes the product evolution seen from leading manufacturers, including Swaco, Derrick, Brandt, and other innovative suppliers.

Precision Manufacturing Facility of Leading Shale Shakerscreen Manufacturers

Manufacturing Process Visualization: Engineering Flow of Shale Shaker Screens

Flowchart: Advanced Shale Shaker Screen Manufacturing, from Alloy Selection → Precision Slitting & Weaving → CNC Frame Forming → Polymer Encapsulation → Automated Mesh Bonding → Ultrasonic Quality Inspection (ISO 13501 Compliant)

-

Raw Material Selection: Only SS316L and duplex grades pass ASTM corrosion tests, ensuring optimal weldability and mechanical strength.

-

Mesh Weaving: Imported auto looms create multi-layered (2-4 ply) micro-mesh, tightly adhering to API RP 13C designation for cut point accuracy.

-

CNC Frame Processing: Aluminum or composite frames are manufactured for high dimensional stability and easy field installation, using CNC machining and robotic laser cutting.

-

Injection Molding & Bonding: Epoxy or polyurethane adhesives bond mesh and frame, resisting thermal expansion and chemical attack.

-

Inspection & Testing: Each batch undergoes ultrasonic flaw detection, mesh aperture measurement (±5μm), and lifecycle vibration tests to match ISO/API/ANSI standards.

Key Product: Swaco Replacement Shale Shaker Screens

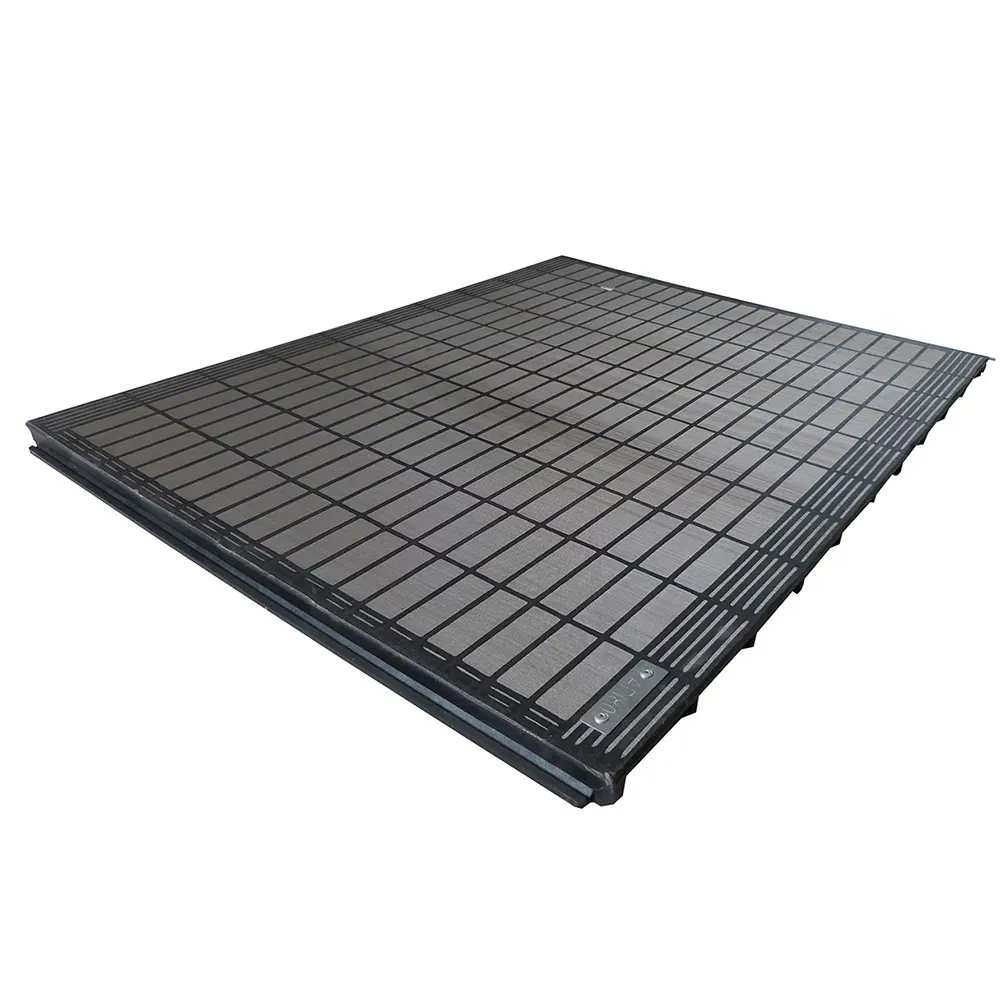

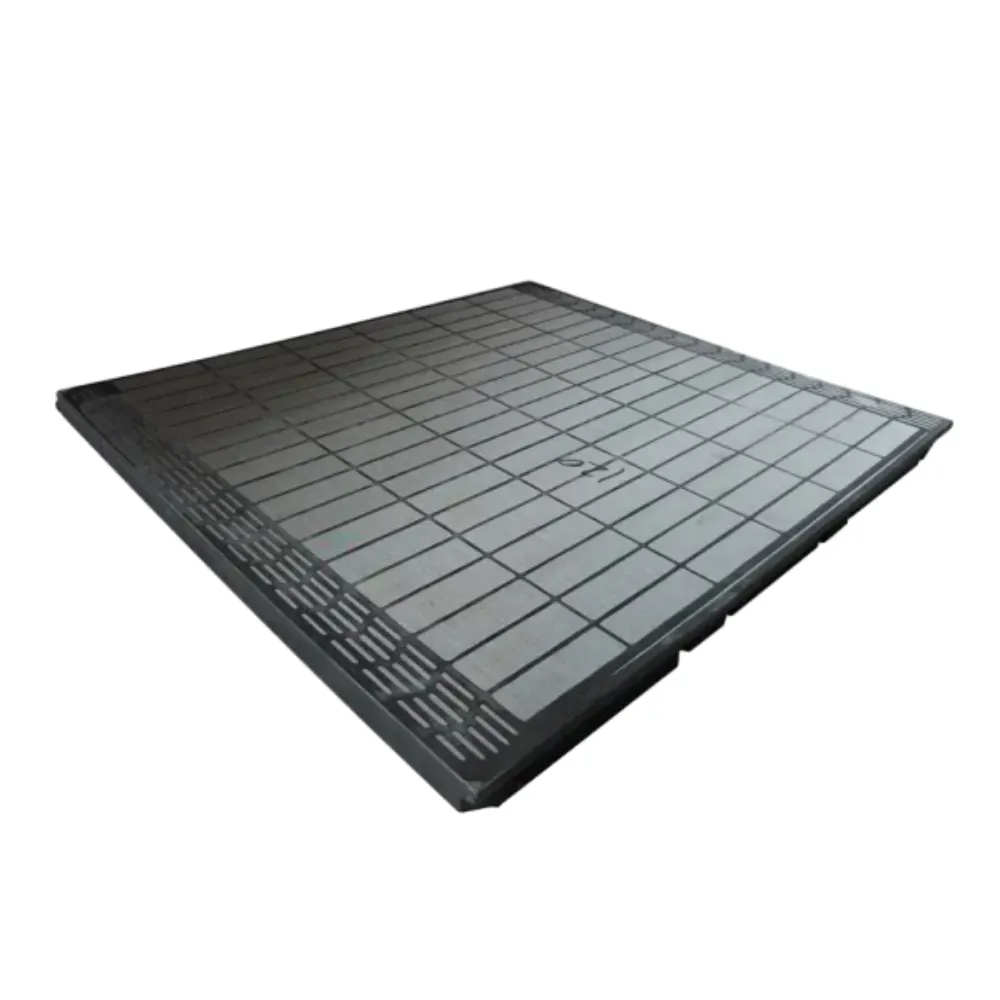

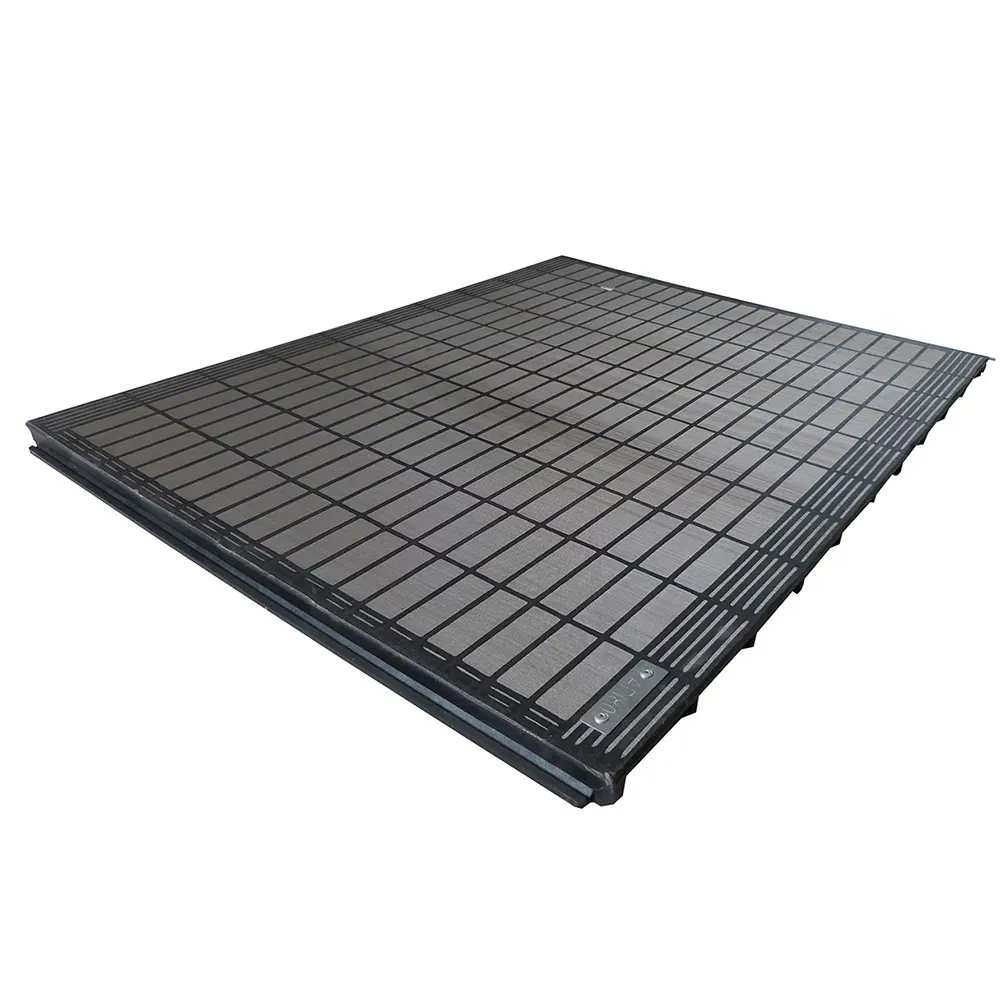

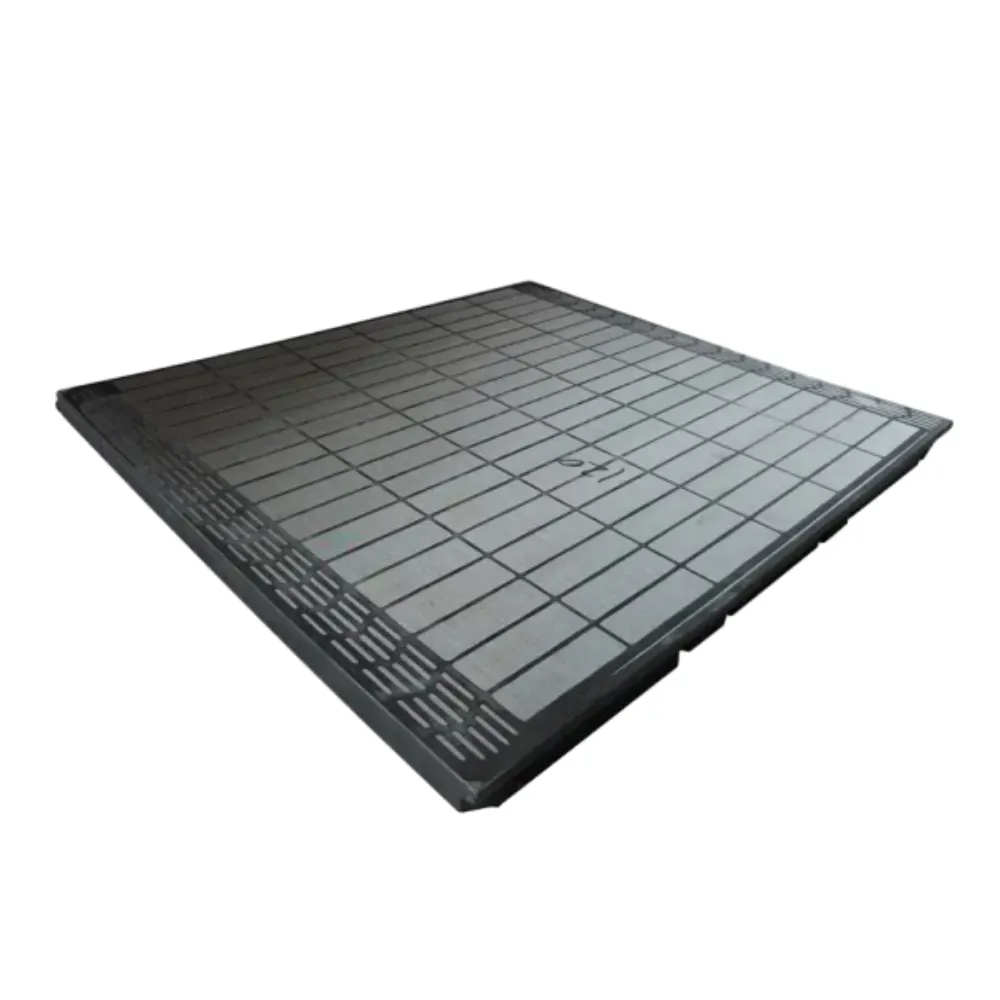

Product: Swaco Replacement Shale Shaker Screens

Suitable for Models: MONGOOSE PT, MEERKAT, MD Series, etc.

Swaco Replacement Screens - Advanced 3-Layer Mesh for MONGOOSE Systems

-

Material: 316L Stainless Steel mesh, Composite Polyurethane Frame

-

Screen Type: XR, XL, DF, MG, API designation compliant; Pyramid, Flat, and Hook-strip

-

Mesh Range: API 20 – API 325 (20μm – 600μm), open area up to 68% per screen

-

Standard Conformity: ISO 13501:2015, API RP 13C, ANSI, and RoHS

-

Typical Service Life: 300 – 600 hours (lab tests), >25% longer than standard screens in abrasive drilling conditions

-

Applications: Shale Gas, Oil Exploration, Geothermal, Metallurgy slurry, Wastewater Treatment, Mining Tailings

-

Key Advantages: Low blinding, anti-corrosion, fast hook fitting, easy replacement, energy savings via optimized apertures

Technical Parameters Table: Shale Shakerscreen Manufacturers Overview

| Manufacturer |

Main Screen Material |

Mesh Range (API) |

Surface Area (㎡) |

Service Life (hrs) |

Frame Type |

Certifications |

| Swaco |

SS316L / Composite |

20-325 |

≥ 1.1 |

400–600 |

Polyurethane |

ISO 13501, API RP 13C |

| Derrick |

SS304/SS316 |

10-270 |

0.95–1.25 |

300–550 |

Steel/Composite |

ISO 9001, API, FDA |

| Brandt |

SS304 |

20-325 |

0.92–1.18 |

250–400 |

Steel |

API, ANSI |

| GN Solids |

SS316L |

20-325 |

0.88–1.15 |

350–500 |

Composite |

ISO 9001, API RP 13C |

| TR Solids |

SS304 |

20-250 |

0.75–1.05 |

200–450 |

Steel |

API, CE |

Technical Parameter Trends among Shale Shakerscreen Manufacturers (2016–2024)

Swaco Replacement Screens Market Share (2023)

Service Life Comparison: Swaco vs. Competitors

Product Comparison: Swaco vs. Key Shale Shakerscreen Manufacturers

| Feature |

Swaco Replacement |

Derrick |

Brandt |

GN Solids |

| Structure |

3-Layer, Reinforced Polyurethane Frame |

2/3-Layer, Steel/Composite Frame |

2-Layer, Steel Frame |

3-Layer, Composite Frame |

| Average Service Life (API 120) |

470 hrs |

410 hrs |

350 hrs |

400 hrs |

| Compliance |

ISO 13501, API RP 13C |

ISO 9001, FDA, API |

API, ANSI |

ISO 9001, API |

| Anti-corrosion |

Duplex & Polyurethane Coated |

Stainless Steel |

SS304 only |

SS316L Composite |

| Edge Sealing |

Polyurethane Injection Molded (No Leaks) |

Epoxy Bonded |

Epoxy/Mechanical |

Polyurethane Molded |

| Replacement Speed |

Quick-Lock (

| Clamped (

| Bolted/Manual (≥20 min) |

Quick-Lock |

Customization & Value-added Solutions by Shale Shakerscreen Manufacturers

-

OEM/ODM Options: Bespoke mesh, frame type, dimensions, and branding to fit proprietary or legacy equipment.

-

Anti-Clogging Mesh Engineering: 2D/3D computational fluid analyses for mesh aperture optimization; pyramid mesh achieves 13% higher throughput (Euler CFD Analysis, 2022).

-

Material Upgrades: For ultra-high salinity, duplex or super austenitic steels available (tested to ASTM G48, corrosion

-

Accelerated Delivery: Digital twin-enabled logistics yield typical lead times of 7–15 days (regular), 3–5 days (express).

-

On-site Compatibility Consultation: Collaborative deployment and pre-fit simulation for shale shakers for sale across Swaco, Derrick, Brandt, and Chinese/Indian OEMs.

Application Scenarios: Verified Industry Use Cases

-

PetroChina Jilin Oilfield: Upgraded to Swaco Replacement Shale Shaker Screens for API 100 mesh, reducing screen changeouts by 29% and fluid loss by 31%, in severe shale formation drilling. (SPE Journal Case Study)

-

Middle East Deepwater: Utilized composite mongoose shaker screens with anti-corrosive frames; withstood 7,200 cycles (Vibratory Endurance Test, ISO 13501).

-

Urban Construction Slurry: Replaced polypropylene screens with duplex mesh screens, achieving 42% higher sand removal efficiency in subway shaft dewatering.

-

Wastewater Sector (EU): Used SS316L shakers for municipal sludge, screens passed RoHS certification, enabling waste reutilization credits (>98.5% solid capture).

EEAT & Industry Credentials of Swaco Replacement Shale Shaker Screens

-

Expertise: Screens are engineered by teams with >15 years of surface finishing and precision mesh design experience.

-

Authoritativeness: Partnered with global oil & gas majors (e.g., CNPC, Halliburton, Schlumberger); certified by ISO 13501, API RP 13C.

-

Experience: Field support in over 25 countries, including adaptation for ultrafine cuttings in West Africa and multi-phase drilling in Siberia.

-

Trustworthiness: All shipments undergo serial-numbered QC, traceability to mesh batch/lab records, RoHS and REACH-compliant manufacturing.

-

Quotations & Support: 24x7 expert technical hotline. Sample mesh cuttings and inspection reports available prior to any order commitment.

Quality Assurance, Delivery & Warranty Commitment

-

Standard Lead Time: 7–15 days (stocked models), Custom builds 14–22 days.

-

Warranty: 6 months, covering manufacturing defects and mesh delamination. Proactive replacement policy if screen performance drops below API cut-point tolerances.

-

Support: Installation training & mesh calibration service; video support available globally.

-

Bulk Orders: Palletized, moisture- and impact-protected shipping; OEM codes tracked up to field-site delivery.

Professional FAQ on Shale Shaker Screens Technology

- 1. What material grades are used by leading shale shakerscreen manufacturers for mesh and frames?

-

High-grade stainless steel 316L is standard for mesh due to its corrosion and fatigue resistance. Frames use composite polyurethane or aluminum for dimensional stability and lightweight strength. Some projects require duplex or super austenitic steel for extreme chemical resistance.

- 2. What are typical mesh specifications and how do API designations relate to micron ratings?

-

API designations (20–325) correspond to aperture sizes (20µm–600µm). For example, an API 100 screen has an opening around 149 microns. Precise matching to drilling fluid particle size ensures optimal cuttings removal and throughput.

- 3. What standards/certifications should reputable screens comply with?

-

International standards include ISO 13501 (vibration testing), API RP 13C (screen cut-point and conductance), ANSI, and in many cases RoHS/REACH or FDA for environmental safety.

- 4. How is screen service life assessed, and what factors affect it?

-

Service life is a function of mesh quality, frame adhesion, drilling vibration, and fluid chemistry. Lab/field testing (per API RP 13C Method) measures lifecycle in hours or number of drilling cycles before mesh breaking or delamination.

- 5. Are these screens suitable for non-oilfield applications?

-

Yes. Screens see use in mining, metallurgy, tunneling, wastewater, and construction, wherever precise solid-liquid separation and high throughput are required.

- 6. What installation methods are standard, and can screens be quickly swapped?

-

Modern designs use quick-lock/pin or hook-strip frames for rapid tool-free replacement (

- 7. How is the screen’s performance and compliance documented?

-

Each batch ships with serial-numbered quality inspection reports (cut point, conductance, dimensionality), as well as certificates for ISO/API compliance and MSDS if required.

Summary: Choosing the Best Shale Shakerscreen Manufacturer

A robust, data-driven analysis shows that shale shakerscreen manufacturers like Swaco (and its OEM replacements) deliver measurable performance improvements in mesh precision, build quality, and lifecycle economy for the most demanding drilling environments. When combined with rapid customization, international standards compliance, and responsive on-site support, these screens form a reliable foundation for both legacy and futuristic solids control systems.

For procurement, maintenance, or engineering decision-makers, leveraging validated OEM replacements—specifically Swaco Replacement Shale Shaker Screens—can lower TCO, minimize downtime, and ensure environmental/regulatory compliance worldwide.

References & External Links