The Pivotal Role of High-Performance Shaker Screens in Modern Drilling Operations

In the demanding realm of oil and gas exploration, efficient solids control is paramount for optimizing drilling operations, safeguarding equipment longevity, and minimizing environmental impact. Central to this process are shale shakers, and more specifically, their high-performance screens. These screens act as the primary separation stage, removing drilled solids from expensive drilling fluids (muds) to allow for their continuous reuse. The effectiveness of these screens directly influences drilling fluid integrity, penetration rates, and overall operational costs. The industry is currently witnessing a significant trend towards finer separation capabilities, enhanced screen lifespan, and materials that can withstand increasingly aggressive drilling environments, including high-temperature and high-pressure (HTHP) applications and challenging formations. This drive for efficiency and sustainability is pushing the boundaries of screen technology, demanding innovations in mesh design, frame durability, and precise manufacturing tolerances. As a leading swaco screens supplier, we recognize the critical need for solutions that not only meet but exceed these evolving industry demands, ensuring that drilling operators achieve maximum operational efficiency and cost-effectiveness through superior solids control. This includes a strong focus on advanced materials and manufacturing processes that deliver screens with exceptional non-blanked area, improved flow rates, and extended service life, ultimately contributing to a greener and more economical drilling footprint by significantly reducing waste and fluid loss, thereby aligning with global sustainability initiatives and stringent regulatory requirements for environmental protection in drilling activities.

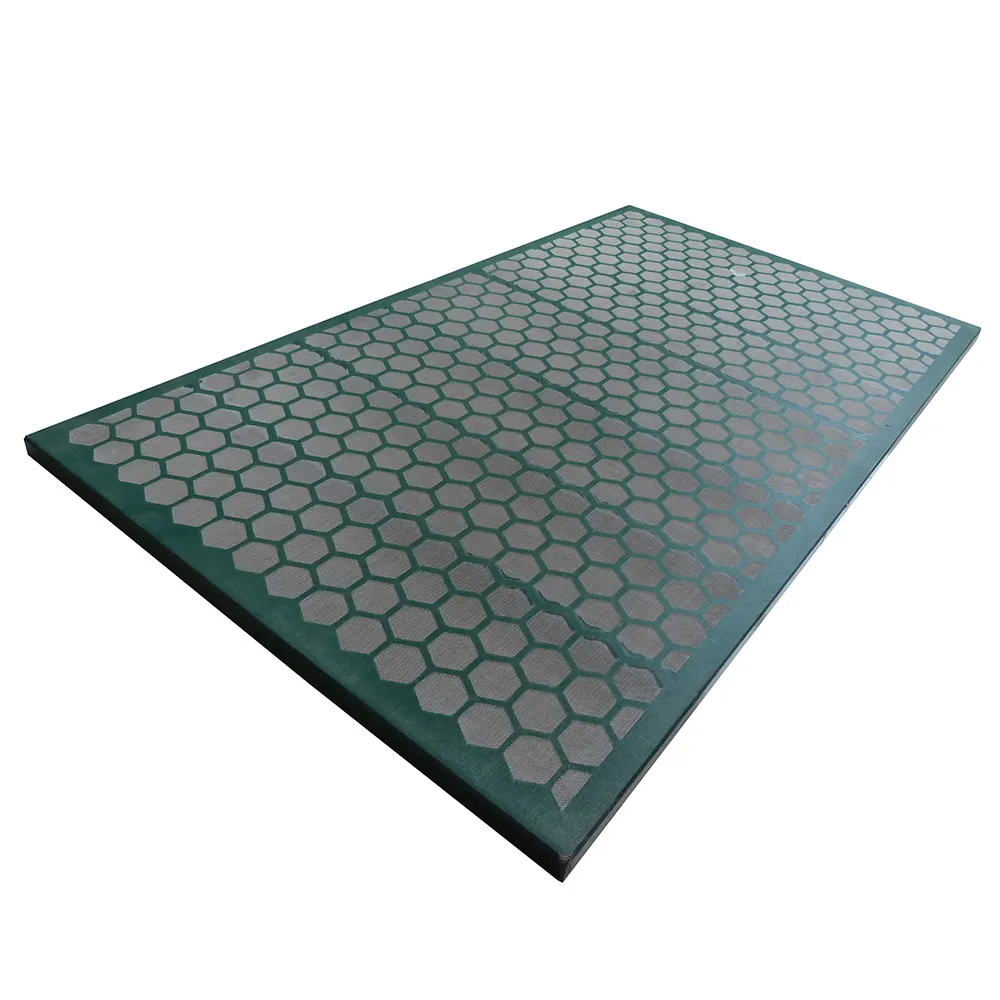

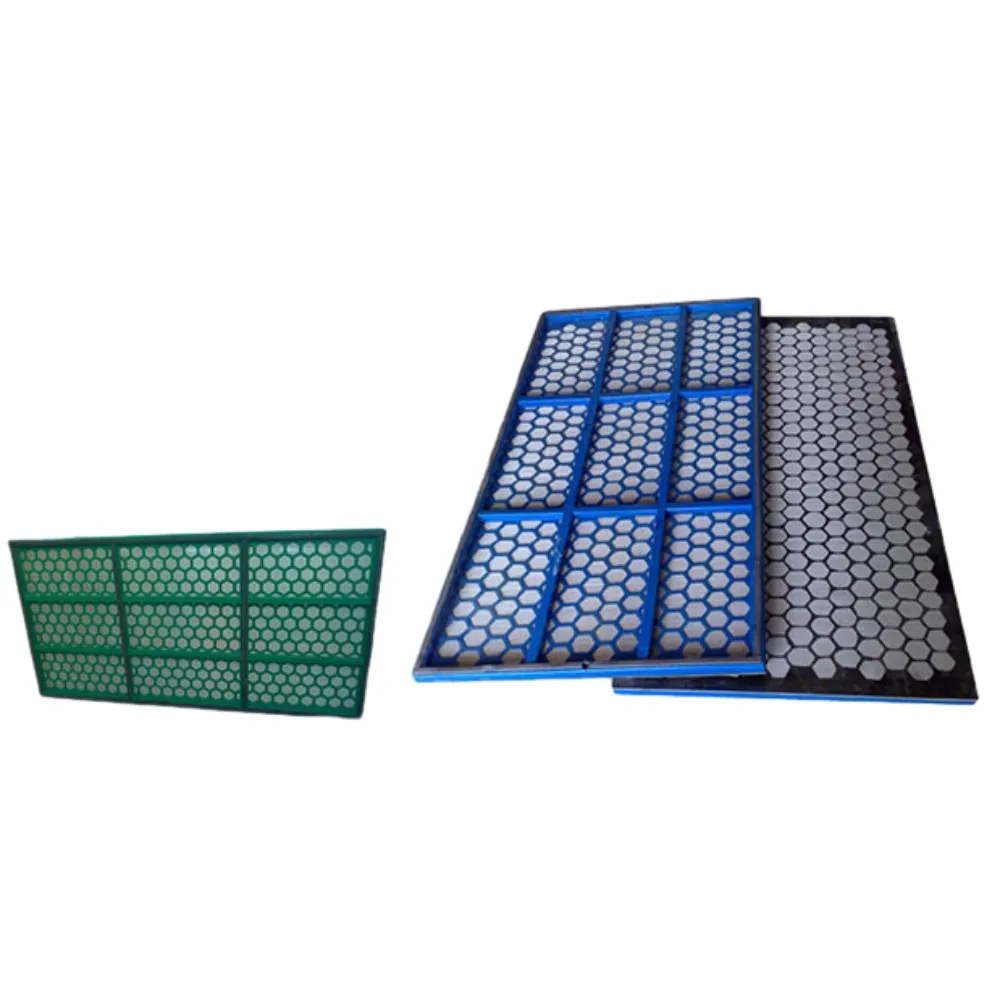

Precision Manufacturing: Crafting Durable MI SWACO Steel Frame Replacement Shaker Screens

The production of top-tier swaco screens involves a multi-stage, meticulously controlled manufacturing process, beginning with the selection of premium materials designed for extreme operational conditions. For our MI SWACO Steel Frame Replacement Shaker Screens, we utilize high-strength, corrosion-resistant steel alloys for the frame, ensuring structural integrity and longevity even in corrosive drilling fluid environments. The mesh panels, the core of the screen's filtration capability, are crafted from high-quality stainless steel wire, specifically chosen for its durability, abrasion resistance, and consistent aperture size. The manufacturing journey commences with precision frame fabrication, often involving automated welding or advanced casting techniques to create a robust and dimensionally accurate framework. Following this, the multi-layered mesh panels are carefully bonded to the steel frame using specialized adhesive technologies and mechanical fastening methods, ensuring an incredibly strong and uniform seal that prevents fluid bypass and extends screen life. Our advanced processes include CNC machining for frame components to achieve unparalleled precision, followed by rigorous quality assurance checks at every stage. Key inspection standards such as ISO 9001:2015 for quality management and adherence to API RP 13C (Recommended Practice for Shaker Screen Area and Designations) are fundamental to our production. These standards dictate mesh cut point (D100 separation), non-blanked screen area, and overall screen performance, guaranteeing that each screen consistently performs to specifications under various drilling conditions. The result is a screen designed for superior longevity, effective solids removal, and significant advantages such as reduced drilling fluid consumption, minimal waste generation, and enhanced equipment protection, contributing to considerable energy savings by optimizing pump performance and extending the life of drilling components susceptible to abrasion. The corrosion-resistant properties of our materials also significantly contribute to the screen's operational lifespan in challenging environments found in petrochemical and metallurgy sectors, extending their applicability beyond traditional oil and gas to industries like mining and industrial wastewater treatment, where precise separation and durability are equally critical for efficient operations.

Technical Specifications & Unrivaled Performance of MI SWACO Replacement Screens

The technical prowess of our MI SWACO Steel Frame Replacement Shaker Screens is evident in their meticulously engineered parameters, designed to deliver exceptional performance across diverse drilling operations. These screens feature a multi-layered mesh design, typically comprising two to three layers of high-quality stainless steel wire cloth, which are precisely bonded to a robust steel frame. This composite structure enhances screen life while maintaining optimal separation efficiency. Key specifications include a wide range of API RP 13C mesh sizes, from coarse screens for high-volume scalping to ultra-fine screens for critical fluid cleaning, ensuring adaptability to various drilling fluid types and solids sizes. Our screens are characterized by a high non-blanked screen area, often exceeding 80%, which translates directly to higher fluid processing capacity and reduced drilling fluid retention, thereby minimizing mud losses. The frame's robust construction ensures a secure fit on compatible MI SWACO shale shakers, eliminating bypass and ensuring all fluid passes through the intended filtration media. The consistent quality across our range of mi swaco shaker screens ensures that operators can rely on predictable performance, crucial for maintaining drilling efficiency and reducing non-productive time (NPT). Our screens are rigorously tested for vibration resistance, tensile strength, and impact durability, far exceeding typical operational stresses. This commitment to engineering excellence directly results in superior filtration capabilities, significantly extending the lifespan of drilling fluid and reducing the volume of waste requiring disposal. The enhanced solids control efficiency not only lowers operational costs by minimizing fluid loss but also improves drilling penetration rates by reducing the recirculating solids load on drill bits and downhole tools, directly contributing to a more efficient and profitable drilling program while mitigating equipment wear and tear.

Typical MI SWACO Steel Frame Replacement Shaker Screen Specifications

| Parameter | Description / Value Range |

|---|---|

| Product Name | MI SWACO Steel Frame Replacement Shaker Screen |

| Frame Material | High-Strength Steel Alloy |

| Mesh Material | High-Quality 304/316 Stainless Steel Wire Cloth |

| Mesh Layers | 2 to 3 Layers (depending on API size) |

| API RP 13C Sizes | API 20 to API 400 (Custom available) |

| Non-Blanked Area | Typically > 80% |

| Overall Dimensions | Standard MI SWACO dimensions (e.g., 48" x 30" or specific models) |

| Operating Temperature | Up to 120°C (248°F) |

| Expected Lifespan | Varies with usage, but optimized for extended service (e.g., 300-500 drilling hours under normal conditions) |

Understanding the factors that influence shale shaker screen price and shale shaker screen pricelist is crucial for procurement. Our pricing reflects the superior materials, advanced manufacturing processes, and stringent quality control that contribute to the screen's extended lifespan and high performance. While initial costs might be a factor, the long-term savings from reduced fluid loss, fewer screen replacements, and improved drilling efficiency invariably make our screens a more cost-effective solution over the entire drilling program. We are committed to transparency in our pricing and provide detailed quotes based on specific requirements, ensuring that clients receive maximum value for their investment in premium solids control technology.

Versatile Applications and Documented Impact in Drilling Operations

Our MI SWACO Steel Frame Replacement Shaker Screens are engineered for universal compatibility with a wide array of MI SWACO shale shakers, making them an ideal choice across diverse drilling applications, from conventional vertical wells to complex directional and horizontal drilling projects, both onshore and offshore. They are indispensable in managing various types of drilling fluids, including water-based muds (WBM), oil-based muds (OBM), and synthetic-based muds (SBM), effectively separating drilled cuttings while preserving the integrity and properties of the valuable drilling fluid. In practical terms, these screens deliver tangible benefits. For instance, in a recent deep-well drilling project, the adoption of our high-performance mi swaco shaker screens resulted in a 15% reduction in drilling fluid consumption over a three-month period, translating into substantial cost savings and a significant decrease in environmental footprint. This was achieved through superior cut point efficiency and minimized blinding, ensuring less good mud was discarded with cuttings. Furthermore, feedback from rig operators consistently highlights the screens' extended operational life, often exceeding conventional screens by 20-30%, which directly reduces the frequency of screen changes, thereby minimizing NPT and improving overall drilling uptime. Our technical team provides expert consultation to help clients select the optimal screen configuration for their specific geological formations, drilling fluid rheology, and shaker setup, ensuring peak performance and maximum return on investment. This tailored approach, combined with our robust product design, addresses the unique challenges of each drilling environment, from abrasive sands to sticky clays, and from high-viscosity muds to highly reactive formations, showcasing our commitment to providing comprehensive solutions.

Beyond direct cost savings, the enhanced solids control facilitated by our screens contributes significantly to downhole equipment longevity. By effectively removing abrasive solids, they reduce wear and tear on pumps, motors, and drill bits, leading to lower maintenance costs and extended operational life for these critical components. This synergistic effect underscores the holistic value proposition of investing in high-quality swaco screens supplier products. Our commitment extends to providing comprehensive support throughout the product lifecycle, including pre-sales consultation, technical assistance during deployment, and post-sales support for performance optimization. We stand as a reliable partner in driving drilling efficiency and sustainability.

Navigating the Competitive Landscape and Custom Solutions

In a competitive market for solids control equipment, distinguishing factors for a preferred swaco screens supplier extend beyond mere product availability to encompass quality, consistency, and unparalleled technical support. While numerous manufacturers offer replacement screens, the superior engineering and adherence to strict API RP 13C standards set our MI SWACO Steel Frame Replacement Shaker Screens apart. Our products consistently demonstrate a more uniform cut point, higher flow rates, and significantly greater resistance to blinding compared to generic alternatives, leading to enhanced drilling efficiency and reduced operational costs over the long term. This quality assurance minimizes the unpredictability often associated with lower-cost options that might promise an attractive shale shaker screen price but fail to deliver consistent performance or durability in the field. Furthermore, we understand that "one size fits all" is rarely true in complex drilling scenarios. Therefore, we offer bespoke screen solutions tailored to specific project requirements. This includes custom mesh configurations for unusual formations, specialized frame coatings for highly corrosive environments, or unique panel designs to optimize performance on modified shaker systems. Our engineering team collaborates closely with clients to analyze their drilling parameters, fluid properties, and desired solids separation goals, providing expert recommendations and designing screens that precisely meet their operational needs. This commitment to customized excellence ensures that every screen delivered is optimized for peak performance in its intended application, solidifying our reputation as a trusted partner in advanced solids control technology.

Trust and Support: Your Partner in Solids Control Excellence

Building and maintaining trust with our clients is at the core of our operations as a leading swaco screens supplier. We achieve this through transparent processes, robust quality control, and comprehensive customer support that extends far beyond the point of sale. Our commitment to client satisfaction is underpinned by a clear understanding of the challenges faced in drilling operations, which drives our proactive approach to providing reliable solutions and assistance.

Frequently Asked Questions (FAQ)

-

Q1: How do I choose the correct mesh size for my drilling operation?

A1: The optimal mesh size depends on several factors, including the type of drilling fluid (WBM, OBM, SBM), the desired cut point for solids removal, the drilling rate, and the geological formation. Our technical experts can provide a detailed consultation based on your specific operational parameters and target shale shaker screen price to recommend the most effective screen configuration from our comprehensive shale shaker screen pricelist. -

Q2: What is the expected lifespan of your MI SWACO Steel Frame Replacement Shaker Screens?

A2: While lifespan varies depending on drilling conditions, fluid abrasiveness, and operational practices, our screens are engineered for extended durability. Under typical conditions, our screens often outlast competitors by 20-30%, contributing to fewer change-outs and reduced NPT. Regular maintenance and proper handling further extend their service life, ensuring consistent performance over longer periods. -

Q3: Do you offer customization for specific shaker models or unique drilling challenges?

A3: Yes, absolutely. We specialize in providing custom-engineered swaco screens solutions. Our team works closely with clients to develop screens with specialized mesh configurations, frame designs, or material treatments to meet the precise demands of unique drilling projects, ensuring optimal performance even in the most challenging environments.

Delivery & Quality Assurance

We maintain robust inventory levels and efficient logistics channels to ensure timely delivery of our MI SWACO Steel Frame Replacement Shaker Screens to drilling sites globally. Our standard delivery cycle typically ranges from 5-10 business days for stock items, with expedited shipping options available for urgent requirements. For custom orders, lead times are communicated clearly during the quoting process, ensuring transparency and reliability. Each screen undergoes stringent quality checks, including API RP 13C compliance verification, before dispatch. We stand behind the quality of our products with a comprehensive warranty against manufacturing defects, guaranteeing peace of mind and demonstrating our unwavering commitment to providing dependable, high-performance solids control solutions that minimize operational risks and maximize efficiency. Our dedicated customer support team is available 24/7 to address any technical queries, provide operational guidance, or assist with order fulfillment, ensuring uninterrupted service and optimal performance of your solids control system.

Conclusion: Partnering for Advanced Solids Control and Drilling Excellence

In the dynamic landscape of oil and gas drilling, the efficacy of solids control directly impacts operational efficiency, environmental compliance, and profitability. As a dedicated swaco screens supplier, we are committed to providing superior MI SWACO Steel Frame Replacement Shaker Screens that are not merely components but strategic assets designed to optimize your drilling fluid management. Our commitment to advanced manufacturing processes, adherence to international quality standards, and continuous innovation ensures that our screens deliver unparalleled performance, longevity, and cost-effectiveness. By investing in our high-quality mi swaco shaker screens, operators can achieve significantly improved solids separation, reduced drilling fluid consumption, extended equipment lifespan, and ultimately, a more sustainable and economically viable drilling operation. We invite you to partner with us to enhance your solids control capabilities and achieve new benchmarks in drilling excellence, supported by our technical expertise and comprehensive customer service.

Authoritative References

- American Petroleum Institute. (2013). API Recommended Practice 13C: Drilling Fluids Processing Equipment Evaluation.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems.

- SPE Journal of Drilling and Completion. (Various issues). Research on drilling fluid solids control and screen efficiency.

- Journal of Petroleum Technology. (Various issues). Articles on advances in solids control technology.

- Elsevier - Journal of Cleaner Production. (Various issues). Studies on environmental impact of drilling waste and fluid recycling.