Understanding the Critical Role of High-Performance Shale Shaker Screens

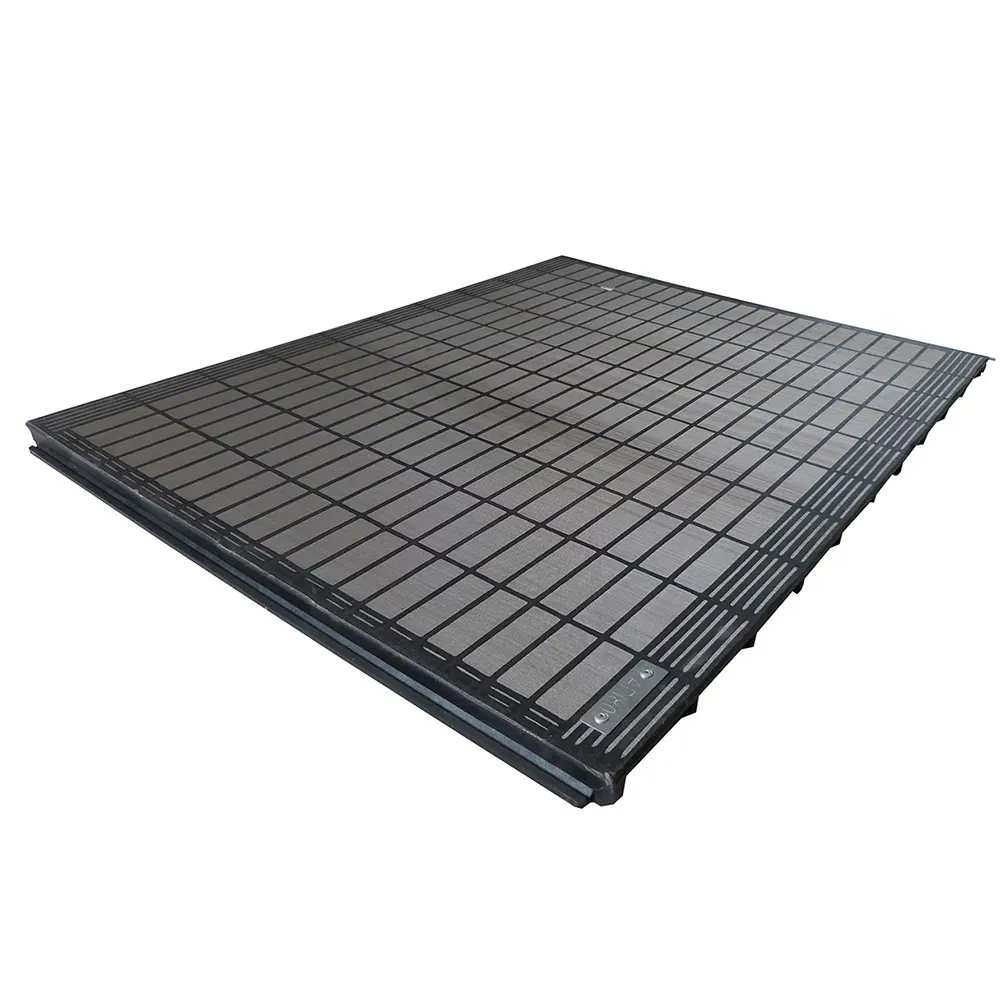

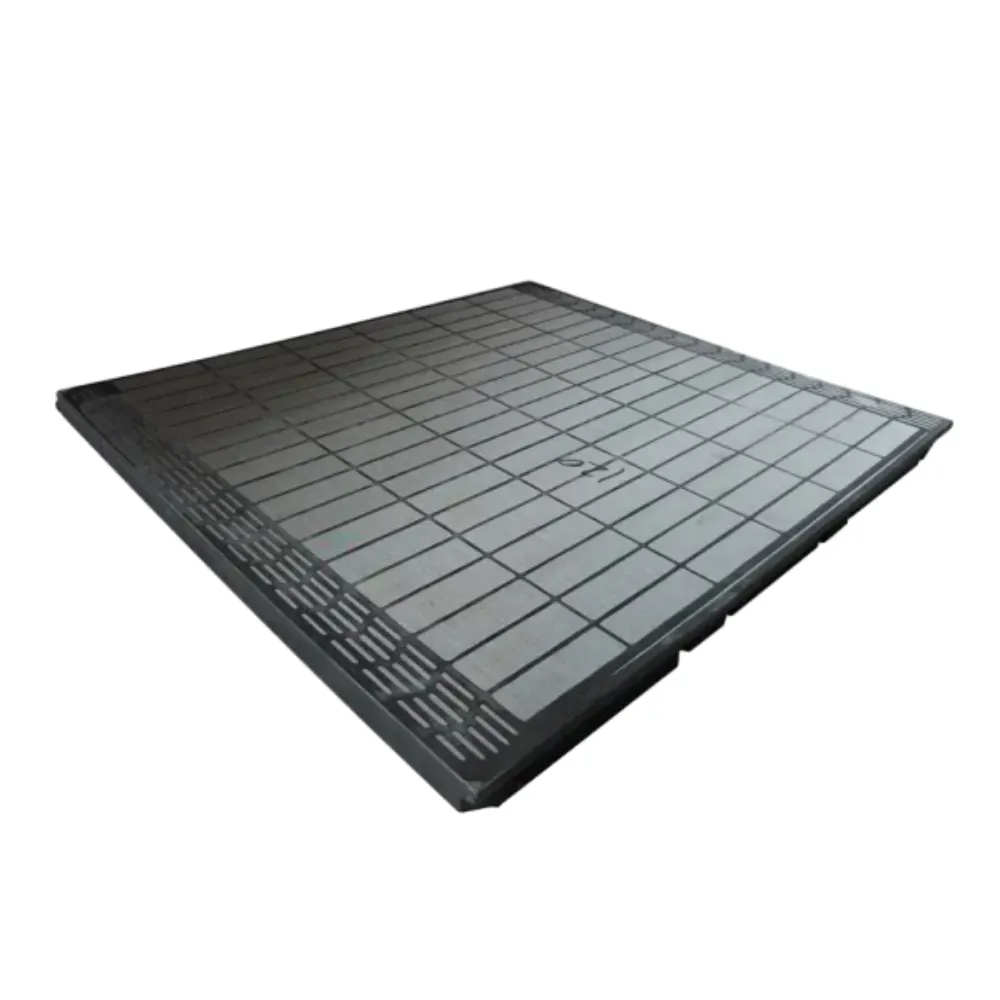

In the intricate world of oil and gas drilling, efficient solids control is paramount for operational success, environmental compliance, and cost-effectiveness. At the heart of this process are shale shaker screens, vital components that separate drilling cuttings from valuable drilling mud. The quality and performance of these screens directly impact drilling efficiency, fluid recovery, and overall project economics. As leading shale shakerscreen manufacturers, our commitment lies in producing advanced screens that meet and exceed the rigorous demands of modern drilling operations. Our product, Swaco Replacement Shale Shaker Screens, exemplifies this dedication, designed for optimal performance and durability.

The industry is continuously evolving, demanding screens with higher conductance, finer cut points, and extended operational lifespans. Trends indicate a significant shift towards more robust designs capable of handling aggressive drilling fluids and high flow rates, while simultaneously minimizing non-productive time (NPT) due to screen blinding or premature wear. This focus on efficiency and sustainability drives innovation among shale shakerscreen manufacturers, pushing for screens that not only perform well but also contribute to a greener footprint by reducing waste volume.

The Advanced Manufacturing Process of Shale Shaker Screens

The production of high-quality shale shakerscreen manufacturers is a meticulously engineered process, ensuring each screen delivers consistent performance in demanding environments. Our manufacturing journey begins with the selection of premium-grade materials, primarily 304 and 316 stainless steel wire mesh, renowned for their exceptional corrosion resistance and mechanical strength. This material choice is critical, especially given the corrosive nature of drilling fluids and the abrasive forces encountered during operation.

The manufacturing sequence involves several precision stages:

- Wire Mesh Preparation: High-tensile stainless steel wire is woven into various mesh configurations, precisely calibrated to API RP 13C standards for optimal conductance and cut point.

- Frame Fabrication: Robust steel or composite frames are engineered for structural integrity, often incorporating techniques like precise CNC machining for exact dimensions and robust welding or casting for durability.

- Mesh Bonding and Tensioning: The wire mesh panels are meticulously bonded to the frame using advanced adhesive technologies and precise tensioning methods. This ensures uniform tension across the screen surface, preventing sagging and maximizing effective screening area.

- Multi-Layer Stacking: For composite screens, multiple layers of mesh with varying apertures are strategically stacked to enhance screening efficiency, increase fluid throughput, and extend screen life. This often involves techniques like plasma welding or thermal bonding.

- Quality Assurance & Testing: Every screen undergoes stringent quality control inspections, adhering to international standards such as ISO 9001 for manufacturing quality and API RP 13C for screen performance validation (e.g., D100 separation point, non-blinding area, and conductance). Tests include visual inspection, dimensional checks, and performance tests to ensure compliance with design specifications.

The application of our screens spans across diverse sectors, including petrochemicals, metallurgy, and water treatment, though their primary utility remains in oil and gas drilling. These screens are engineered to deliver significant advantages, such as enhanced energy efficiency through superior fluid recovery, minimizing the need for new fluid production, and exceptional anti-corrosion properties that extend service life even in highly aggressive drilling environments. Our screens typically offer a service life significantly exceeding industry averages, reducing downtime and operational costs for our clients globally.

Key Technical Parameters and Performance Metrics

Understanding the technical specifications of shale shaker screens is crucial for selecting the right product for specific drilling conditions. The performance of shale shakers for sale is quantified by several critical parameters, which are often standardized by API RP 13C (Recommended Practice for Solids Control Equipment and Processing). This standard provides a uniform method for screen evaluation, enabling direct comparison between products from different shale shakerscreen manufacturers.

| Parameter | Description | Typical Range / Value | Impact on Performance |

|---|---|---|---|

| API Mesh Size (D100) | The separation point (d100) where 100% of particles are retained. | API 60 to API 325 | Defines the fineness of separation; higher API numbers mean finer separation. |

| Conductance (kiloDarcy) | A measure of a screen's capacity to pass fluid through. | Typically 100 to 500 kD | Higher conductance means higher fluid throughput and reduced fluid loss. |

| Non-blinding Area (NPSHA) | The percentage of the total screen area available for fluid flow. | 35% - 70% | Maximizes effective screening surface, reduces blinding, extends screen life. |

| Frame Material | Material used for the screen frame. | Steel, Composite (Polyurethane, Polypropylene) | Affects durability, vibration resistance, and chemical compatibility. |

| Layers | Number of wire mesh layers in a screen. | 2-4 layers (e.g., Triple Layer) | Improves separation efficiency and extends wear life. |

Our Swaco Replacement Shale Shaker Screens are engineered to meet or exceed these industry benchmarks, providing operators with a reliable and high-performance solution. For instance, our API 100 mesh screens typically achieve a conductance of 250 kD, ensuring rapid fluid processing, while maintaining a D100 separation point of approximately 150 microns, delivering superior solids removal. These screens are directly compatible with various mongoose shaker screens models, offering a seamless and efficient upgrade path for existing systems.

Application Scenarios and Strategic Advantages

The versatility and robustness of our Swaco Replacement Shale Shaker Screens make them indispensable across a wide range of drilling and solids control applications. These screens are ideally suited for vertical and horizontal drilling, where effective solids removal is critical for maintaining wellbore stability and maximizing penetration rates. They are also highly effective in managed pressure drilling (MPD) operations, where precise control over drilling fluid properties is essential. Our screens help optimize MPD by ensuring efficient separation and minimal fluid loss.

Key technical advantages offered by our screens include:

- Superior Separation Efficiency: Designed with optimized mesh configurations and high non-blinding area, our screens achieve finer cut points, leading to more effective removal of drilled solids and cleaner drilling fluid. This directly translates to reduced wear on downhole tools and improved drilling performance.

- Extended Wear Life: The use of premium stainless steel wire mesh, combined with advanced bonding technologies and robust composite frames, significantly extends the operational life of our screens, reducing the frequency of screen changes and associated downtime.

- Reduced Fluid Loss: High conductance values ensure maximum drilling fluid recovery, minimizing the need for costly new fluid additions and contributing to significant cost savings on drilling fluid management.

- Enhanced Compatibility: Our Swaco Replacement screens are precisely engineered to be fully interchangeable with original Swaco shaker models, as well as compatible with many mongoose shaker screens systems, ensuring seamless integration into existing solids control setups.

Clients consistently report improved drilling economics and environmental performance after implementing our screens. For example, a recent project in the Permian Basin reported a 15% reduction in drilling fluid consumption and a 10% increase in average penetration rate due to the superior performance of our Swaco Replacement Shale Shaker Screens. Such results underscore our expertise and commitment as reliable shale shakerscreen manufacturers.

Manufacturer Comparison and Tailored Solutions

When evaluating shale shakerscreen manufacturers, several factors distinguish leading suppliers. Beyond product specifications, companies should consider a manufacturer's research and development capabilities, their adherence to stringent quality control, their flexibility in providing customized solutions, and the robustness of their after-sales support. Our approach focuses on delivering not just a product, but a complete solution tailored to specific operational needs.

We pride ourselves on our ability to offer customized solutions. While our standard Swaco Replacement Shale Shaker Screens cover a broad range of applications, we understand that unique drilling conditions may require specialized screens. This includes:

- Specific Mesh Sizes: Developing screens with non-standard API mesh sizes for ultra-fine or coarse separation requirements.

- Alternative Frame Designs: Customizing frame materials or dimensions to fit non-standard shaker models or to enhance durability in extreme environments.

- Optimized Layer Configurations: Designing multi-layer screen packages to achieve specific fluid throughput and separation efficiency goals, particularly relevant for specialized drilling fluids.

Our commitment to quality is reinforced by a comprehensive internal testing regimen that complements third-party API RP 13C certifications. We maintain a continuous feedback loop with our clients, utilizing their field experience to refine designs and improve product performance. This collaborative approach solidifies our position as a trusted partner among shale shakerscreen manufacturers, delivering reliable and optimized solutions for the most demanding drilling projects worldwide.

Trust and Support: Your Partner in Solids Control

As a leading provider in the solids control industry, we understand that trust is built through reliable products and comprehensive support. Our commitment to clients extends beyond product delivery, encompassing a full spectrum of services designed to ensure operational continuity and success. This dedication reinforces our standing as a dependable entity among shale shakerscreen manufacturers.

Frequently Asked Questions (FAQ)

A: Yes, our screens are designed for direct interchangeability with most popular Swaco shaker models, including Mongoose PT, Mongoose PRO, and Mongoose MEER. We provide detailed compatibility lists upon request to ensure a perfect fit.

A: For standard orders, our typical delivery cycle ranges from 1-2 weeks depending on quantity and destination. For large-scale projects or custom specifications, we work closely with clients to establish a realistic and efficient production and delivery schedule, often leveraging our extensive inventory and streamlined logistics.

A: We offer a 12-month limited warranty against manufacturing defects from the date of purchase. Our commitment to quality ensures that our screens meet stringent performance criteria and are free from material or workmanship flaws.

A: Absolutely. Our team of experienced technical consultants is available to provide expert guidance on screen selection, optimization strategies, and troubleshooting. We assist clients in analyzing their drilling fluid properties and operational parameters to recommend the most effective screen solutions for maximizing solids control efficiency.

Our dedication to customer satisfaction is evident in every interaction. From initial consultation to post-sale support, we aim to be a long-term partner in optimizing your drilling operations and solids control processes.

Conclusion: Partnering for Peak Performance

Choosing the right shale shakerscreen manufacturers is a strategic decision that profoundly impacts the efficiency, cost-effectiveness, and environmental footprint of drilling operations. Our Swaco Replacement Shale Shaker Screens represent the pinnacle of engineering and material science, designed to deliver unparalleled performance in the most challenging environments. By combining superior manufacturing processes, adherence to international standards like API RP 13C and ISO 9001, and a relentless focus on customer support, we empower drilling companies to achieve optimal solids control and maximize their operational returns.

We invite you to explore how our advanced screen technologies can transform your drilling fluid management. For detailed specifications, custom solutions, or inquiries regarding shale shakers for sale, please visit our product page or contact our technical sales team. Partner with us to experience the difference that true quality and expertise make.

References

- American Petroleum Institute. API Recommended Practice 13C: Recommended Practice for Drilling Fluid Processing Systems Evaluation. 8th ed. Washington, D.C.: API Publishing Services, 2020.

- International Organization for Standardization. ISO 9001: Quality Management Systems – Requirements. Geneva: ISO, 2015.

- Neal, H. "Solids Control Equipment: Selection and Operation for Improved Drilling Efficiency." Journal of Petroleum Technology, Vol. 72, No. 05, May 2020.

- Xu, X., et al. "Advances in Shale Shaker Screen Technology for Enhanced Drilling Waste Management." SPE Drilling & Completion, Vol. 35, No. 03, September 2020.