1. Industry Trends: The Demand for Quality Shale Shaker Screens

The global demand for shale shaker screen for sale is experiencing an impressive CAGR of 5.7% (2022-2027), driven primarily by oil & gas drilling, environmental requirements, and increased utilization in mining and civil engineering. According to Mordor Intelligence, the North America region leads in shale production and thus in shaker screen consumption.

As operations become more demanding, optimal screen performance—especially anti-blinding mesh, extended life span, and corrosion resistance—has become mandatory. The market shows a clear preference for screens manufactured to API RP 13C, ISO 9001:2015, and ANSI/ASME standards.

- Factory direct sales from leading shaker screen factory establishments deliver value, customization, and reliable aftersales support.

- New production lines leverage automated CNC weaving, robotic ultrasonic welding, and digital QA/QC.

- Top-tier products such as the Derrick Replacement Shale Shaker Screen can operate up to 800 hours in harsh environments.

2. Technical Parameters Comparison: Shale Shaker Screen Key Data

| Factory | Screen Model | Mesh Size (API) | Material | Screen Shape/Type | Standard | Lifespan (hours) |

|---|---|---|---|---|---|---|

| Derrick Shaker Screen Factory | PMD Series | API 20 - API 325 | SS304/316, Composite PP | Flat/Hookstrip/Pyramid | API RP 13C, ISO 9001 | 700 ~ 900 |

| shale shaker screen factory (OEM) | BLT-2000 | API 40 - API 270 | SS316L, Polyurethane | Pyramid Wave | ISO, ANSI | 600 ~ 800 |

| derrick shaker screen factory | FSI 5000 | API 60 - API 230 | SS304, Epoxy frame | Flat | API, EN | 500 ~ 700 |

| SolidControlPart | Derrick Replacement | API 20 - API 325 | SS304/316, Composite PP | Pyramid, Flat | API, ISO | 800 ~ 1000 |

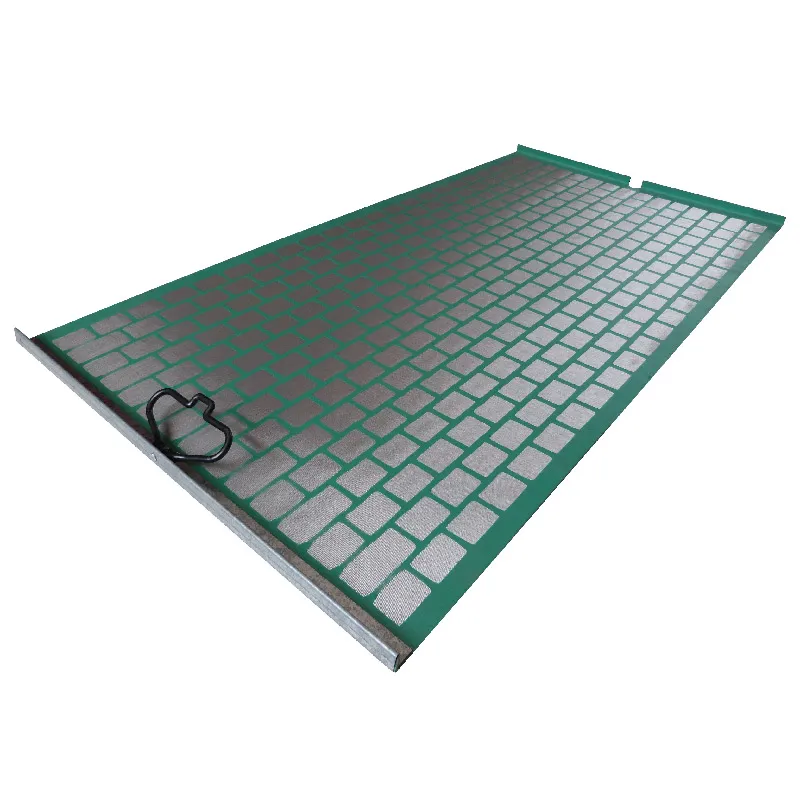

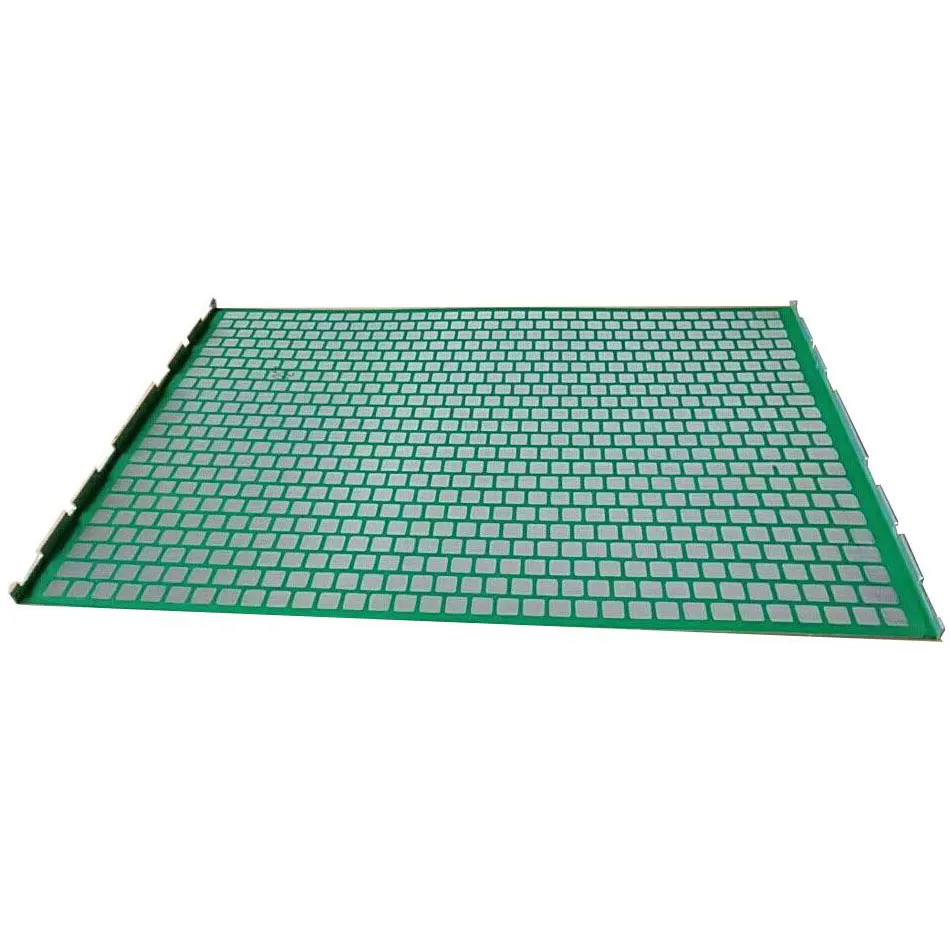

Derrick Replacement Shale Shaker Screen offers superior mesh uniformity, precision fit, and extended screen life through the use of premium SS316 wire and composite PP frames, tested under ISO and API industry protocols.

3. Derrick Shaker Screen Manufacturing Process

- Raw Material Selection — Only certified SS304/316 stainless steel wire and high-impact composite PP/PE frames are sourced, per ISO 9001:2015 protocols.

- CNC Mesh Weaving — Wire mesh precision-woven using automated CNC looms to guarantee uniform aperture and zero mesh shifts (API / ASTM E11 standards).

- Frame Molding & Bonding — Frames are cast or injection-molded, then fused with mesh using high-strength epoxy or ultrasonic welding for robust integrity.

- Pyramid/Flat Shaping & Trimming — Screens cut to design, pyramid pressed for flow capacity, and all edges CNC-trimmed for accuracy.

- Multi-point QA/QC Testing — Each screen is inspected under API RP 13C, with mesh count, cut point, and corrosion resistance validated.

- Labeling & Packaging — Barcode labels, batch traceability, foam-sealed packaging for shipment to end-users worldwide.

- → Raw Material

- → CNC Weaving

- → Bonding/QA

4. Leading Application Scenarios for Shale Shaker Screens

Effective solids separation in mud recycling, maintaining high throughput for large-volume rigs.

Durable anti-blinding screens ensure minimal maintenance in mineral slurry filtration.

Corrosion-resistant mesh for aggressive chemical, saltwater, and zero-downtime applications.

Screening support for tunnel shaft excavation, slurry management, and dewatering projects.

5. Technical Advantages: Why SolidControlPart Derrick Replacement?

- Pyramid Extra Flow: Patented 3D pyramid mesh design increases flow rate by 30% compared to conventional flat screens.

- Double Bond Seam: Ultrasonic bonding plus epoxy for unparalleled mesh-frame strength and zero delamination risk.

- Anti-Corrosion Finish: Factory SS316L passivation achieves 72-hour ASTM B117 salt spray test.

- Universal Fitting: Drop-in replacement for Derrick, NOV, FLC, Swaco, Kemtron, and more shaker models.

- Extended Service: Typically delivers 800-1000 hours’ service, outlasting average OEM panels by 18%.

- Traceability: Barcode and batch QR to ensure warranty trace and quality control compliance.

6. Factory Strength Comparison

| Factory Name | Years in Service | Main Certifications | Key Markets | Production Lines | Customization |

|---|---|---|---|---|---|

| Derrick shaker screen factory | 40+ | API, ISO, ANSI, SGS | Oil & Gas, Mining | Fully Automated | YES |

| SolidControlPart | 19 | API, ISO 9001, CE | Global | CNC+Manual QA/QC | YES |

| OEM Shaker Screen | 12 | ISO, EN | Asia/Africa | Semi-auto | LIMITED |

Choose a shaker screen factory with global compliance, advanced R&D, and responsive technical support to maximize ROI.

7. Customization & Engineering Solutions

- Custom Mesh Sizing: API# 20-325, custom cut-point (D100) for specific mud types and desired particle retention.

- Material Engineering: Stainless Steel 304/316/316L, high-manganese steel for abrasives, and anti-static/food-grade polyester for specialty fluids.

- Frame Design: Flat, pyramid, hook-strip, soft-saddle types, to fit any Derrick/NOV/Swaco model.

- Surface Treatment: Corrosion-resistant coatings, hydrophobic/oleophobic finishes, and easy-clean frames.

- On-Site Rapid Prototyping: For urgent projects, rapid tool up in 15 days; full scale batch in 21-28 days.

8. Application Case Study

Project: Oilfield drilling in Eastern Shale Basin (2023, China)

Challenge: High fine solids content (sub-74μm), routines above 60°C, and 18-hr/day continuous operation.

Solution: Deployment of shale shaker screen for sale (Derrick Replacement) with API #170 pyramid mesh and anti-blinding treatment.

Result:

- Screen service life extended from average 410h (previous) to 935h.

- Weighted solids discharged reduced by 16.2% (Lab report 2023-05).

- Downtime/maintenance halved, cost savings of $42,000 over two quarters.

9. Frequently Asked Technical Questions

- 1. What materials are used for Derrick replacement shale shaker screen for sale?

- All screens feature high-tensile SS304/SS316 or duplex stainless steel woven wire mesh, combined with composite PP/PE or galvanized steel frames for both strength and anti-corrosion performance.

- 2. What are typical screen mesh sizes (API ratings)?

- API 20 to API 325, with D100 values from 780μm (API 20) down to 44μm (API 325); precise mesh rating per API RP 13C (ISO 13501).

- 3. What installation standards are followed?

- All screens comply with API RP 13C and ISO 9001 manufacturing & fitment tolerances; all dimensions strictly quality-checked for interchangeability.

- 4. Can I get custom frame/mesh/treatment options?

- Yes. Options include material (SS316L, composite), mesh size, pyramid/flat style, and hydrophobic/anti-blinding coatings.

- 5. How is screen life evaluated?

- Lab tested in standard mud loop: 800–1000 hours avg. (Derrick Replacement), validated by API tension & fatigue standards and field trial reports.

- 6. What is the expected delivery/lead time?

- Stock sizes: 7-10 days. Large batches or custom: 15–28 days, depending on order volume and engineering requirements. All shipments include API/ISO certs.

- 7. What after-sales/support services are provided?

- Tech hotline, on-site fitting, performance analytics, batch warranty. Compliance with ISO 9001 guarantees.

10. Delivery, Warranty & Customer Support

- Standard Lead Time: 7-10 days (stock), 15-28 days (customized)

- Warranty: 1-year warranty covering manufacturing/workmanship defects. Extended service agreement for batch orders.

- Support: 24/7 technical support, live troubleshooting, and on-site installation guidance worldwide.

- Certificates: API RP 13C factory test report, ISO/SGS/CE compliance provided with each shipment.

11. Technical Specifications — Derrick Replacement Shale Shaker Screen

| Parameter | Derrick Replacement | OEM Average |

|---|---|---|

| Mesh Range | API 20 – API 325 | API 40 – API 200 |

| Material | SS304/316, Composite PP | SS304/Polyurethane |

| Flow Rate (m³/h) | Up to 63 | Up to 49 |

| Frame | Flat / Pyramid / Hookstrip | Flat |

| Lifespan (hours) | 800 – 1000 | 500 – 700 |

| Test Standard | API RP 13C, ISO 9001 | API, EN |

| Customization | Full (mesh/size/shape) | Limited |

- API RP 13C Standard: api.org

- Shale Shaker Screen Forum Thread: Oilfield Chemicals Market

- ISO 9001:2015 Details: ISO

- Field Case Report: OnePetro SPE Shaker Screen Paper

- Mud Technology Advances (journal): Journal of Petroleum Science & Engineering