Navigating the Essential Role of Shale Shaker Screens in Modern Drilling Operations: A Comprehensive B2B Insight

In the highly specialized and demanding world of oil and gas exploration, the efficiency and environmental responsibility of drilling operations are paramount. At the core of managing drilling fluids—often referred to as drilling muds—lies the critical technology of solids control. Effective solids control ensures the integrity of the drilling fluid, protects downhole equipment from abrasive particles, optimizes drilling speed, and minimizes waste volume, thereby reducing operational costs and environmental footprint. Within this intricate system, the shale shaker screen for sale stands out as an indispensable component. These screens are the primary filtration device in the solids control cascade, tasked with separating drilled cuttings from the valuable drilling fluid, allowing the cleaned fluid to be recirculated into the wellbore. The performance of these screens directly impacts the overall drilling efficiency, fluid purity, and the longevity of downstream solids control equipment like desanders and desilters. As an industry, we are constantly striving for higher performance, longer life, and greater cost-effectiveness from these consumable but vital parts. The selection of a high-quality shale shaker screen is not merely a procurement decision but a strategic choice that influences operational uptime, environmental compliance, and ultimately, the profitability of drilling projects. Modern drilling practices, especially those involving horizontal drilling, extended-reach drilling, and operations in challenging geological formations, demand screens capable of handling high fluid volumes, diverse cutting sizes, and varying rheological properties of drilling muds. Furthermore, the global emphasis on sustainability and reduced waste generation means that screens must also contribute to minimizing the volume of drilling waste requiring disposal, which often entails significant costs and logistical challenges. The marketplace for these essential components is dynamic, driven by technological advancements aimed at improving separation efficiency, enhancing durability, and reducing the total cost of ownership. Industry trends point towards the adoption of composite materials, innovative mesh designs, and robust frame constructions to meet the escalating demands of the energy sector. Understanding the nuances of these screens, from their manufacturing process to their application-specific advantages, is crucial for B2B decision-makers seeking to optimize their drilling operations and maintain a competitive edge. This comprehensive analysis aims to shed light on the intricate details of shale shaker screens, empowering stakeholders with the knowledge to make informed decisions for their specific operational needs.

The demand for advanced solids control solutions is experiencing significant growth, driven by several key industry trends and operational imperatives. Firstly, the increasing complexity of drilling operations, including unconventional plays like shale gas and oil sands, necessitates more efficient and robust solids control equipment. These operations often generate fine, abrasive cuttings that demand superior filtration capabilities. Secondly, heightened environmental regulations globally are pushing operators to minimize waste generation and reduce the toxicity of discharged materials, making efficient solids-liquid separation more critical than ever. Thirdly, the ongoing pursuit of operational cost reduction leads operators to seek durable, high-performance components that reduce downtime and maintenance expenses. A recent market analysis projects the global solids control equipment market to grow at a Compound Annual Growth Rate (CAGR) of approximately 4.5% from 2023 to 2030, largely attributed to the robust activity in the oil and gas sector and the continuous drive for operational efficiency. Within this market, replacement components like the shale shaker screen for sale constitute a significant segment, highlighting the ongoing operational demand. The technological evolution in screen design, including advancements in mesh materials, frame designs, and non-blinding technologies, is pivotal in addressing these evolving industry demands. For instance, the transition from traditional steel frames to composite frames offers advantages in terms of reduced weight, enhanced corrosion resistance, and improved service life. Similarly, the development of multi-layered mesh designs and innovative bonding techniques has significantly boosted separation efficiency and screen durability, directly translating into better drilling performance and reduced fluid loss. The competitive landscape for a shaker screen factory is marked by continuous innovation, where manufacturers are striving to differentiate their products through superior performance metrics, reliability, and cost-effectiveness over the entire product lifecycle. This competitive environment benefits end-users by driving down costs and improving product quality, but it also places a premium on detailed technical understanding to discern genuine value. The emphasis on higher conductance and sharper cut points, as defined by API RP 13C, has become a standard benchmark for evaluating screen performance, pushing manufacturers to engineer screens that maximize fluid throughput while maintaining precise particle separation. Moreover, the increasing adoption of digital technologies in drilling operations, such as real-time data analytics for fluid management, further underscores the need for reliable and high-performing shale shaker screens that can consistently deliver the required fluid purity.

The Precision Behind Performance: Manufacturing Process of Derrick Replacement Shale Shaker Screens

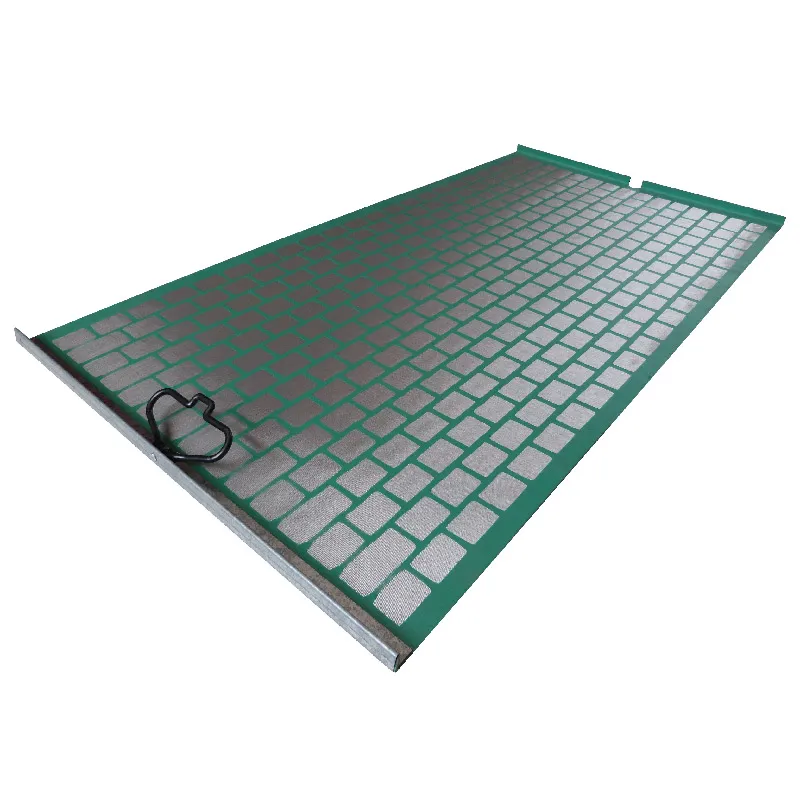

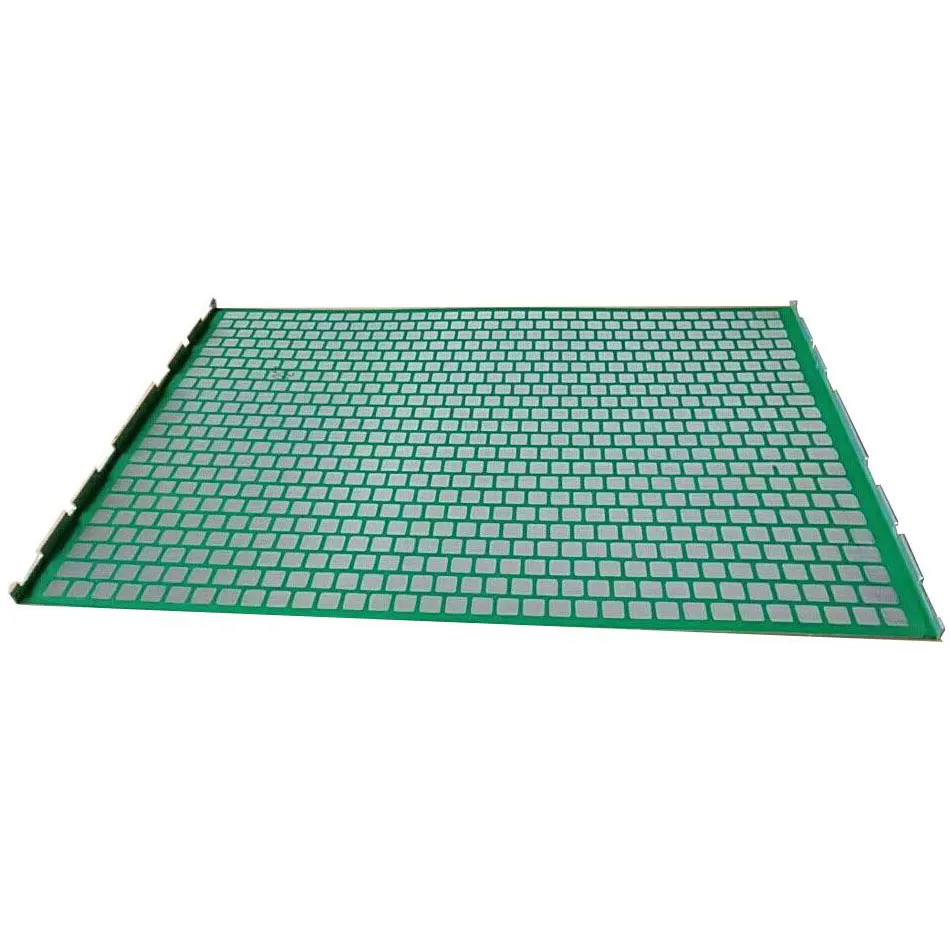

The manufacturing of a high-quality Derrick Replacement Shale Shaker Screen is a complex, multi-stage process that combines precision engineering, advanced material science, and rigorous quality control. It's not merely about weaving a mesh; it's about crafting a durable, high-performance filtration medium that can withstand the harsh realities of drilling operations. The primary product in focus, the Derrick Replacement Shale Shaker Screen, exemplifies this commitment to excellence. The process begins with the careful selection of raw materials, predominantly high-grade stainless steel wire for the mesh and robust steel or composite materials for the screen frame. The choice of stainless steel, typically 304 or 316 grade, is critical due to its superior corrosion resistance and mechanical strength, properties essential for resisting degradation from corrosive drilling fluids and abrasive cuttings. For the frame, a composite material often combines polymers with fiberglass or carbon fiber, offering a significant advantage over traditional steel frames by reducing weight, enhancing durability, and improving resistance to chemical attack and vibration fatigue. Once the materials are procured, the manufacturing sequence for a shale shaker screen factory typically proceeds through several intricate stages. The wire mesh, the heart of the screen, is precision-woven on specialized looms to achieve specific API mesh sizes, ensuring uniform opening sizes and consistent filtration performance. This weaving process is meticulously controlled to prevent any irregularities that could compromise separation efficiency or screen life. Following weaving, multiple layers of mesh (often two, three, or even four, depending on the screen type and desired separation characteristics) are laminated together using proprietary bonding techniques. This multi-layered construction is crucial for progressive filtration, where coarser mesh layers support finer layers, preventing premature blinding and extending screen life. The bonding process is critical; it must create a strong, durable connection between layers that can withstand the forces exerted by drilling fluid flow and vibration without delamination. The edges of the laminated mesh panel are then precisely cut and prepared for attachment to the screen frame.

The fabrication of the screen frame is equally vital. For steel-framed screens, high-strength steel profiles are precisely cut, welded, and then treated for corrosion resistance, often through powder coating or galvanization. For composite frames, the process involves molding high-performance polymer compounds reinforced with fibers, a technique that allows for intricate designs and integrated sealing elements, enhancing the screen's fit and sealing capabilities on the shaker deck. The composite frame technology offers superior vibration dampening and resistance to the harsh chemical environment of drilling fluids. After frame fabrication, the tensioning process begins, where the laminated mesh panels are stretched and securely bonded or vibratory-welded to the frame. Achieving uniform tension across the entire screen surface is paramount. Improper tensioning can lead to premature tearing, reduced efficiency, and uneven wear. This step often employs specialized machinery to ensure precise, consistent tensioning, maximizing the effective screening area and overall lifespan of the shale shaker screen for sale. Integrated sealing gaskets, typically made of high-quality rubber or polyurethane, are then molded onto or securely attached to the screen frame. These gaskets are essential for creating a tight seal between the screen and the shaker deck, preventing fluid bypass and ensuring all drilling fluid passes through the mesh. The quality of these gaskets directly impacts fluid integrity and prevents leakage. Throughout the entire manufacturing process, stringent quality control measures are implemented. This includes raw material inspection, in-process checks at each stage (e.g., mesh opening size verification, weld integrity checks, bonding strength tests), and final product inspection. Manufacturers adhere to international standards such as ISO 9001 for quality management systems and API RP 13C (Recommended Practice for Drilling Fluid Processing Systems Evaluation) for performance testing. API RP 13C specifies methods for determining critical performance parameters like D100 separation point and non-blinding screening area, ensuring that each screen meets defined performance criteria.

The final stages of manufacturing for a derrick shaker screen factory involve comprehensive performance testing and packaging. Each finished screen undergoes visual inspection to check for defects, proper bonding, and frame integrity. Critical performance parameters, such as mesh size, API conformance, and overall dimensions, are often verified against design specifications. Some manufacturers also conduct simulated vibration tests or flow tests to ensure the screen will perform reliably under operational conditions. Furthermore, screens are typically subjected to burst strength tests to ensure the mesh can withstand differential pressures without rupture, confirming its structural integrity and reliability in high-flow scenarios. The service life of a shale shaker screen mesh is a crucial economic factor, and it is intrinsically linked to the quality of materials and manufacturing processes. High-quality screens, through their robust construction and superior materials, offer extended operational lifespans, reducing the frequency of screen changes and associated downtime, which directly translates to significant cost savings for drilling operators. Applicable industries for these screens primarily include the oil and gas sector (onshore and offshore drilling, unconventional gas extraction), but the underlying technology of solids separation is also relevant in mining, wastewater treatment, and other industrial fluid processing applications where solid-liquid separation is critical. The advantages of using a well-engineered shale shaker screen for sale in typical application scenarios are manifold: they contribute to energy efficiency by reducing the workload on downstream solids control equipment, minimize corrosion through effective removal of abrasive solids that can damage pumps and other components, and enhance overall fluid quality, leading to improved drilling performance and reduced non-productive time. For example, in a deep well drilling scenario, maintaining the rheological properties of the drilling fluid is paramount. A high-efficiency screen ensures that fine solids, which can significantly alter mud viscosity and density, are effectively removed, thereby preventing costly mud conditioning treatments and maintaining borehole stability. The consistent performance and durability derived from meticulous manufacturing processes directly translate into tangible benefits on the drill site, making the initial investment in quality screens a highly strategic decision for long-term operational success.

Technical Parameters & Performance Metrics: Decoding the Efficacy of Shale Shaker Screens

Understanding the technical parameters of a shale shaker screen for sale is essential for B2B procurement specialists and drilling engineers to make informed decisions that align with specific operational demands and performance expectations. These parameters, often standardized by bodies like the American Petroleum Institute (API), provide a quantifiable basis for comparing different screens and predicting their performance in the field. The API Recommended Practice 13C (API RP 13C), specifically, is the industry benchmark for evaluating shaker screen performance. It defines critical metrics such as API RP 13C Designation (or API Number), Conductance (C), and D100 Separation Point. The API Number relates to the median particle size that can pass through the screen. Conductance (C) is a measure of the screen's ability to allow fluid to pass through, expressed in kD/mm (kilodarcy/millimeter). A higher conductance value indicates better fluid throughput and reduced fluid loss, which is crucial for maintaining mud volume and composition. The D100 separation point, also known as the cut point, represents the particle size at which 100% of the particles larger than this size are retained by the screen. A sharper cut point indicates more precise separation, leading to cleaner drilling fluid and more efficient removal of fine solids. Other critical parameters include the Non-Blinding Screening Area, which accounts for the actual usable area of the screen without obstructions from the frame or support structure, maximizing the filtration capacity. Mesh material, typically high-grade stainless steel (e.g., SS304, SS316), and frame material (steel or composite) also significantly influence screen durability, corrosion resistance, and overall service life. The composite frames, often made from advanced polymers reinforced with fiberglass or carbon fiber, offer superior resistance to corrosion and vibration, extending screen life and reducing operational weight. Dimensions (length, width, thickness) are crucial for ensuring compatibility with specific shale shaker models, such as those manufactured by Derrick, which require precise fitment for optimal sealing and performance. The number of mesh layers (e.g., single, dual, triple, or quad layers) is also a key design feature, influencing both separation efficiency and screen robustness; multi-layered screens are designed for progressive filtration, offering enhanced solids removal and extended screen life compared to single-layer designs.

| Parameter | Description/Significance | Typical Range / Example Values for Derrick Replacement Screens |

|---|---|---|

| API RP 13C Designation (API No.) | Standardized grading of screens based on the D100 separation point. Essential for consistent screen selection. | API 60 (250 µm) to API 325 (45 µm), up to API 400+ |

| Conductance (C) | Measure of fluid flow capacity through the screen. Higher values mean faster processing and less fluid loss. | Typically ranges from 5 to 30 kD/mm, depending on mesh size |

| D100 Separation Point (Microns, µm) | Particle size at which 100% of larger particles are retained. Indicates fineness of separation. | Ranges from ~40 µm (fine) to ~250 µm (coarse) |

| Non-Blinding Screening Area (ft²) | Effective filtration area. Larger area allows for higher processing rates and reduces screen changes. | Varies by screen size, typically 8-15 ft² for standard panels |

| Mesh Material | Material used for the wire mesh. Affects corrosion resistance and durability. | SS304, SS316 (Stainless Steel) for superior corrosion resistance |

| Frame Material | Material of the screen frame. Influences strength, weight, and chemical resistance. | Steel or advanced composite (e.g., fiberglass reinforced polymer) |

| Number of Mesh Layers | Affects filtration precision, capacity, and robustness. Multi-layered designs are common. | Typically 2-4 layers (e.g., Dual, Triple, Quad) |

| Dimensions (L x W x T) | Physical size for compatibility with shaker models. | Specific to Derrick shaker models (e.g., FLC 503, FLC 504, etc.) |

The performance of a derrick shaker screen factory's product is not merely theoretical; it directly translates into tangible operational benefits. High conductance screens allow for faster drilling rates by effectively processing large volumes of drilling mud, reducing the risk of mud overflow and spillage. A precise D100 separation point ensures optimal removal of fine solids, which are detrimental to drilling fluid properties. These fine solids can increase mud viscosity, leading to higher pump pressures, reduced penetration rates, and increased wear on pumps and drill bits. By effectively removing these particles, the screen helps maintain the desired rheological properties of the drilling fluid, leading to improved borehole stability and reduced risk of differential sticking. The non-blinding design of a shale shaker screen mesh, often achieved through innovative mesh patterns and support structures that minimize solid accumulation, ensures that the effective screening area remains consistent over prolonged periods. This feature is particularly important in challenging drilling environments where high viscosity muds or sticky cuttings are encountered, preventing premature screen blinding and the need for frequent cleaning or replacement. Furthermore, the selection of appropriate API mesh sizes is crucial for balancing fluid recovery with solids removal. For instance, in top-hole sections, coarser screens (lower API numbers) are used to handle large volumes of cuttings, while finer screens (higher API numbers) are employed in deeper sections to remove finer particles and maintain fluid integrity. The ability to precisely select screens based on these parameters allows drilling operators to optimize their solids control system for various drilling phases, fluid types (e.g., water-based, oil-based, synthetic-based muds), and geological formations. Investing in screens that meet or exceed API RP 13C standards is a strategic decision that guarantees consistent performance, enhances drilling efficiency, and significantly contributes to reducing operational expenditures associated with drilling fluid management and waste disposal.

Diverse Applications & Strategic Advantages: Where Shale Shaker Screens Excel

The application scenarios for a high-quality shale shaker screen for sale are as diverse as the global oil and gas industry itself, spanning conventional and unconventional drilling operations, onshore and offshore environments, and various types of drilling fluids. In conventional vertical drilling, screens are fundamental for initial solids separation, ensuring the drilling mud circulated back into the wellbore is free of larger cuttings that could abrade downhole tools or destabilize the wellbore. The efficiency of the primary shale shakers, equipped with optimal screens, directly impacts the load on subsequent solids control equipment such as desanders and desilters, thereby extending their service life and reducing power consumption across the entire solids control system. For horizontal and extended-reach drilling (ERD), where hole cleaning is particularly challenging due to long lateral sections and the tendency for cuttings to settle, highly efficient screens are even more critical. They help maintain lower mud weights and consistent rheological properties, which are essential for effective cuttings transport and preventing differential sticking in these complex wellbores. In offshore drilling, where space is limited and environmental regulations are stringent, the compact footprint and high efficiency of advanced Derrick replacement screens contribute significantly to reducing the volume of waste requiring disposal or treatment, aligning with stricter environmental compliance requirements. The ability to process large volumes of mud efficiently minimizes the need for costly and space-consuming dewatering units.

Furthermore, the type of drilling fluid heavily influences screen selection. For water-based muds (WBM), which are less tolerant of fine solids, screens with sharper cut points and higher API numbers are often employed to maintain fluid purity. In contrast, oil-based muds (OBM) and synthetic-based muds (SBM), while more expensive, are often used in challenging formations due to their superior lubricity and shale inhibition properties. For these fluids, screens must be compatible with the chemical composition of the mud to prevent degradation of the screen material, while still providing excellent separation. A robust shale shaker screen factory ensures its products are designed to perform optimally across all mud types, maintaining their structural integrity and filtration performance. Beyond oil and gas, the underlying principles of solid-liquid separation make these high-performance screens applicable in various industrial sectors. For instance, in trenchless technology (e.g., Horizontal Directional Drilling - HDD), the efficient removal of excavated solids from Bentonite slurry is crucial for recycling the drilling fluid and managing spoils. Similarly, in mining operations, especially those involving slurry transport and dewatering, specialized screens can be adapted for separating valuable minerals from waste streams. The specific technical advantages offered by superior shale shaker screen mesh designs are numerous and directly contribute to improved drilling economics and environmental performance. Firstly, enhanced solids removal efficiency leads to cleaner drilling fluid, which in turn reduces wear and tear on pumps, bits, and other downhole tools. This translates into extended equipment life, reduced maintenance costs, and fewer non-productive time (NPT) events associated with equipment failure. Secondly, superior fluid recovery significantly minimizes fluid loss. Drilling fluids are costly, and minimizing their loss through inefficient solids removal directly impacts operational expenditure. Screens with high conductance ensure maximum fluid throughput while retaining solids, allowing for more effective mud recycling and reduced volumes of new mud required. Thirdly, improved separation leads to reduced waste volume. By concentrating the solids in a drier state, the overall volume of drilling waste requiring disposal is minimized, resulting in substantial savings in transportation and disposal costs, which can be a major component of drilling expenses, especially in remote or environmentally sensitive areas. This contributes significantly to environmental compliance and sustainability goals.

Fourthly, consistency in performance across the screen's lifespan is a critical advantage. High-quality screens are designed to maintain their separation efficiency and throughput even under prolonged vibratory stress and exposure to abrasive solids. This consistency ensures predictable operations and reduces the need for frequent screen changes, thereby maximizing operational uptime. Downtime associated with screen replacement, even for a few minutes per shift, accumulates rapidly and can significantly impact drilling progress. By extending screen life, a high-quality shale shaker screen for sale directly contributes to maximizing drilling days and minimizing operational delays. Lastly, the ability to select specific API sizes allows for optimized solids control across different geological formations and drilling phases. For instance, when drilling through unconsolidated formations with large, abrasive cuttings, a coarser screen might be initially used. As the well deepens and formations become tighter, requiring finer particle removal, screens with higher API numbers (finer mesh) can be rapidly interchanged to maintain optimal fluid properties. This adaptability is key to maintaining peak drilling performance and minimizing drilling complications. For example, a major offshore drilling contractor reported a 15% reduction in mud disposal costs and a 5% improvement in drilling fluid quality after switching to a new generation of composite-framed Derrick replacement screens across their fleet, highlighting the tangible economic and operational benefits of investing in advanced screen technology. This case underscores that the strategic advantage of superior shale shaker screens is not just about filtration; it's about holistic improvement in drilling efficiency, cost management, and environmental stewardship, making them a cornerstone of modern, responsible drilling practices.

Achieving Unparalleled Performance: The Edge of a Leading Derrick Shaker Screen Factory

When sourcing a shale shaker screen for sale, understanding the critical factors that differentiate a leading manufacturer from others is paramount for B2B decision-makers. It goes beyond mere price comparison; it involves a holistic evaluation of a manufacturer's commitment to quality, technological innovation, adherence to standards, and comprehensive customer support. A distinguished derrick shaker screen factory distinguishes itself by a steadfast dedication to research and development. This commitment translates into continuous innovation in mesh design, frame materials, and bonding technologies. For instance, advancements in multi-layered screen technology, such as the patented pyramid technology or flat panel designs that increase non-blinding screening area, are direct results of significant R&D investment. These innovations lead to screens with higher conductance, sharper cut points, and extended service life, ultimately enhancing drilling efficiency. Quality assurance is another cornerstone. A reputable factory implements rigorous quality control processes at every stage of manufacturing, from raw material inspection to final product testing. This typically includes adherence to ISO 9001 quality management systems, which ensures consistency and traceability in production. Furthermore, screens should be rigorously tested to meet or exceed API RP 13C standards for performance metrics like D100 separation and conductance. This adherence to industry-specific standards provides an objective benchmark for performance and reliability, ensuring that the screens will perform as expected in demanding field conditions. Without this stringent testing, the claimed performance metrics may not hold up under operational stress, leading to costly downtime and fluid quality issues.

The materials used by a leading shale shaker screen factory are of the highest quality. This includes premium-grade stainless steel wire (e.g., SS304L, SS316L) for corrosion resistance and strength, and advanced composite materials (e.g., reinforced polypropylene or polyurethane) for the screen frames. Composite frames offer distinct advantages over traditional steel, including lighter weight, superior corrosion and abrasion resistance, enhanced vibration dampening, and improved sealing capabilities due to integrated gaskets. These material choices directly impact the screen's durability and overall service life, which translates into significant cost savings for operators by reducing replacement frequency. Expertise in manufacturing techniques, such as precise wire weaving, multi-layer bonding, and tensioning, is also crucial. Advanced bonding methods, like vacuum hot pressing or high-frequency welding, ensure that the multi-layered mesh panels are securely fused, preventing delamination and extending the screen's operational life even under intense vibratory forces. The ability to achieve uniform tension across the entire screen surface is vital, as inconsistent tension can lead to premature tearing and reduced efficiency. A prime example of a manufacturer excelling in these areas would be one that consistently supplies high-performance Derrick Replacement Shale Shaker Screens. Their reputation would be built on delivering screens that not only meet but often exceed the performance of OEM parts, providing an economical yet high-quality alternative. This level of quality ensures that their shale shaker screen for sale products contribute to maximized drilling fluid recovery, optimized solids removal, and extended operational uptime for drilling contractors globally.

Furthermore, a top-tier shaker screen factory offers robust customization capabilities. Recognizing that drilling conditions vary significantly, they should be able to provide tailored screen solutions, whether it’s specific mesh combinations, frame designs for unique shaker models, or specialized materials for corrosive environments. This customization ensures that clients receive screens perfectly suited to their operational needs, maximizing efficiency and performance. A prime example might be offering screens with enhanced non-blinding properties for sticky, high-viscosity muds, or screens designed for ultra-fine particle separation in specific drilling phases. Beyond the product itself, comprehensive technical support and after-sales service are hallmarks of a superior manufacturer. This includes expert advice on screen selection, troubleshooting assistance, and efficient logistics for timely delivery to drilling sites worldwide. The ability to provide quick turnaround times for orders and resolve technical issues swiftly can significantly reduce drilling downtime, making it an invaluable aspect of the B2B relationship. Trustworthiness is built on transparency, reliability, and a strong track record. A manufacturer that openly provides performance data, holds relevant certifications (e.g., ISO, API), and boasts a long history of successful client partnerships instills confidence. They should be able to provide case studies or testimonials demonstrating how their screens have solved complex solids control challenges, saved costs, or improved operational efficiency for clients. In essence, selecting a partner for your shale shaker screen for sale needs involves looking for a manufacturer who acts as a true collaborator, committed to long-term performance and shared success through continuous innovation, unwavering quality, and dedicated support. This strategic partnership approach ensures that the screens procured are not just commodities, but critical assets that enhance overall drilling project profitability and sustainability.

Beyond the Standard: Customization, Case Studies, and Client Trust

In the dynamic landscape of oil and gas drilling, a one-size-fits-all approach to solids control is rarely optimal. This is where the ability to offer tailored customization solutions for a shale shaker screen for sale becomes a significant competitive advantage. Leading manufacturers understand that specific drilling conditions—ranging from geological formations, drilling fluid types (WBM, OBM, SBM), well depths, and drilling speeds—necessitate screens with unique performance characteristics. Customization can involve modifying mesh combinations to achieve specific D100 separation points or conductance values not typically found in standard offerings. For instance, in drilling through highly reactive shale formations, a specific mud system might require ultra-fine mesh combinations to prevent clay hydration and mud solids build-up, demanding a bespoke screen design. Custom frame designs are also possible to ensure perfect fitment with older or specialized shaker models that might not conform to current industry standards, ensuring seamless integration without requiring expensive equipment upgrades. Material selection for both mesh and frame can also be customized. For operations in extremely corrosive environments, such as those encountering high levels of hydrogen sulfide (H2S), specialized alloys of stainless steel or advanced composite formulations with enhanced chemical resistance can be employed to extend screen life and reduce replacement frequency. The sealing mechanism, whether integrated into the composite frame or as separate gaskets, can also be optimized for specific shaker types or extreme temperature conditions, ensuring a perfect seal and preventing fluid bypass. The essence of customization lies in collaborating closely with the client, understanding their specific operational challenges, and leveraging deep technical expertise to engineer a solution that maximizes performance and cost-efficiency. This bespoke approach ensures that the client's investment in a shale shaker screen mesh yields optimal results for their unique drilling parameters, going beyond what off-the-shelf products can offer.

Illustrative application cases further demonstrate the tangible benefits derived from high-quality derrick shaker screen factory products. Consider an operator drilling an unconventional gas well in a challenging basin known for sticky, clay-rich formations. Traditional screens were constantly blinding, leading to excessive mud loss, frequent screen changes (every 4-6 hours), and significant downtime. After consulting with a specialized shaker screen factory, a customized composite-framed screen with an optimized multi-layer mesh featuring enhanced non-blinding properties was recommended. This new screen design, specifically engineered for high-viscosity mud and problematic cuttings, extended screen life to over 24 hours, drastically reducing screen consumption by 75% and minimizing associated labor costs. Furthermore, mud loss was reduced by 10%, leading to substantial savings in fluid costs over the project duration. Another example could be an offshore deepwater drilling project where space and waste disposal are premium concerns. By implementing advanced, high-conductance Derrick replacement screens, the operator was able to process drilling fluid at a higher rate with superior solids removal efficiency. This not only improved fluid quality, enhancing drilling performance, but also significantly reduced the volume of waste generated by producing drier cuttings. The total volume of drilling waste requiring offsite disposal was reduced by 20%, translating into millions of dollars in savings for waste management and transportation over the course of the drilling campaign. These real-world scenarios underscore how strategic investment in superior screen technology, coupled with expert consultation, directly impacts the bottom line and operational efficiency.

Building trustworthiness with B2B clients extends beyond product performance to encompass comprehensive service and support. A transparent and reliable provider of shale shaker screen for sale solutions will offer a dedicated FAQ module addressing common inquiries regarding product selection, installation, maintenance, and troubleshooting. This empowers clients with immediate access to information, reducing reliance on direct support for routine issues. For example, an FAQ might cover topics like "How to select the correct API mesh size for your drilling phase?", "What are the signs of screen blinding?", or "Best practices for screen storage to extend shelf life." Clear communication regarding delivery cycles is also paramount. Given the time-sensitive nature of drilling operations, understanding the typical lead times, expedited shipping options, and inventory management support is crucial. A reliable supplier will maintain sufficient stock of popular Derrick replacement screens and have robust logistics in place to ensure timely delivery to remote drilling sites globally. Furthermore, a firm quality assurance commitment and warranty are non-negotiable. A reputable manufacturer will stand behind its products with a comprehensive warranty against manufacturing defects, providing peace of mind to clients. This commitment signals confidence in their product's durability and performance, fostering long-term trust. Excellent customer support, available through multiple channels (phone, email, dedicated online portal), ensures that clients can quickly receive assistance for technical queries, order tracking, or any operational challenges related to the screens. This holistic approach, combining product excellence with transparent, responsive support, solidifies a manufacturer's reputation as a trusted partner in the demanding world of oil and gas drilling, ensuring that every shale shaker screen for sale delivered contributes to the client's success.

Frequently Asked Questions (FAQ) about Shale Shaker Screens

-

Q1: What is the primary function of a shale shaker screen for sale in drilling operations?

The primary function of a shale shaker screen is to act as the first line of defense in the solids control system during drilling operations. It is responsible for separating drilled cuttings and larger solid particles from the valuable drilling fluid (mud) that is returned from the wellbore. By effectively removing these solids, the screen helps to maintain the desired rheological properties of the drilling fluid, prevents excessive wear on downhole equipment (such as mud pumps and drill bits), optimizes drilling rates, and reduces the overall volume of drilling waste requiring disposal. High-efficiency screens ensure that the cleaned drilling fluid can be recirculated back into the well, minimizing fluid loss and reducing operational costs. This process is crucial for maintaining borehole stability, preventing differential sticking, and ensuring the overall efficiency and safety of the drilling process.

-

Q2: How does API RP 13C relate to the performance of a shale shaker screen mesh?

API Recommended Practice 13C (API RP 13C) is the industry standard for evaluating the performance of drilling fluid processing equipment, including shale shaker screens. It defines standardized testing procedures and metrics to determine a screen's API RP 13C Designation (or API Number), Conductance (C), and D100 Separation Point (cut point). The API Number classifies screens based on their median particle separation capability. Conductance measures the screen's ability to allow fluid to pass through, indicating fluid throughput efficiency. The D100 separation point specifies the particle size at which 100% of larger particles are retained, indicating the fineness of separation. Adherence to API RP 13C ensures that screen performance claims are verifiable and comparable across different manufacturers, providing a reliable benchmark for quality and effectiveness. Screens that conform to API standards typically offer superior and consistent performance, leading to better solids control and fluid management.

-

Q3: What are the benefits of composite frames over traditional steel frames for shale shaker screen for sale products?

Composite frames offer several significant advantages over traditional steel frames for shale shaker screens. Firstly, they are considerably lighter, making screens easier and safer to handle during installation and replacement, which can reduce manual handling risks on the drill floor. Secondly, composite materials typically exhibit superior corrosion resistance to drilling fluids and environmental factors compared to steel, leading to extended screen life, especially in highly corrosive mud systems. Thirdly, composite frames possess better vibration dampening properties, which can contribute to quieter operations and potentially reduce wear on the shaker equipment itself. Fourthly, composite frames often allow for more intricate and integrated sealing gasket designs, leading to a tighter seal with the shaker deck, preventing fluid bypass and enhancing overall solids removal efficiency. Finally, their robust yet flexible nature makes them less prone to deformation or fatigue cracking under continuous vibration, contributing to improved durability and reduced screen consumption over the long term. These benefits collectively enhance operational efficiency and reduce total cost of ownership.

-

Q4: How does a longer service life for a derrick shaker screen factory's product impact drilling costs?

A longer service life for a shale shaker screen significantly impacts drilling costs in multiple ways. Firstly, it directly reduces the frequency of screen replacements, which means lower procurement costs for replacement screens over the duration of a drilling project. Secondly, fewer screen changes translate into reduced labor costs associated with swapping out screens, and critically, less non-productive time (NPT) for the drilling rig. Each minute of downtime can cost thousands of dollars, so minimizing this through durable screens yields substantial savings. Thirdly, screens with extended life are often indicative of superior design and materials, which also means they maintain optimal performance for longer, leading to more efficient solids removal and better drilling fluid quality. This in turn reduces wear and tear on other expensive solids control equipment and downhole tools, decreasing repair and replacement costs for these components. Overall, the extended service life of a high-quality screen contributes to a lower total cost of ownership and improved operational profitability.

-

Q5: What should I consider when selecting a shaker screen factory for my supply needs?

When selecting a shaker screen factory, several key factors should be considered to ensure a reliable and high-quality supply. Firstly, verify their adherence to international quality standards such as ISO 9001 and API RP 13C, which are indicators of consistent product quality and verifiable performance. Secondly, assess their manufacturing capabilities, including the quality of raw materials used (e.g., SS316 for mesh, advanced composites for frames) and the precision of their manufacturing processes (e.g., multi-layer bonding, tensioning). Thirdly, inquire about their R&D efforts and innovative technologies, such as enhanced non-blinding designs or specific mesh patterns that address common drilling challenges. Fourthly, evaluate their customization capabilities to ensure they can provide tailored solutions for your specific drilling conditions or shaker models. Finally, consider their logistical capabilities for timely delivery, their warranty policy, and the quality of their technical support and after-sales service. A reputable factory will offer comprehensive support and stand by their products, building a long-term, trustworthy partnership.

References & Industry Insights

The information presented herein is underpinned by established industry practices, standards, and research in solids control technology. The critical role of shale shaker screens in optimizing drilling efficiency and managing drilling waste is widely acknowledged across the oil and gas sector. For further in-depth understanding, we recommend consulting authoritative industry publications and academic research.

- American Petroleum Institute (API) RP 13C: "Recommended Practice for Drilling Fluid Processing Systems Evaluation." This standard is fundamental for understanding shaker screen performance metrics. (View API Standards)

- SPE (Society of Petroleum Engineers) Papers: Numerous technical papers discuss advancements in solids control, drilling fluid management, and shaker screen technology. Searching the OnePetro database for terms like "shale shaker optimization" or "drilling fluid solids removal" can yield valuable insights. (Access OnePetro)

- World Oil Magazine & Journal of Petroleum Technology: These reputable industry publications frequently feature articles on new technologies, operational case studies, and market trends in the drilling and completion sector, including solids control. (Visit World Oil) / (Visit JPT)

- Industrial Forums & Conferences: Participation in industry forums and conferences, such as the Offshore Technology Conference (OTC) or IADC/SPE Drilling Conference, provides access to the latest innovations and discussions in drilling fluid solids control.