Unveiling the Power of Shale Shaker Screens: A Deep Dive into Solids Control Efficiency

In the demanding world of oil and gas drilling, efficient solids control is paramount for optimizing drilling fluid performance, protecting downhole equipment, and minimizing environmental impact. At the heart of this crucial process lies the shale shaker screen for sale. These vital components are the first line of defense, separating drilling cuttings from the valuable drilling fluid (mud) as it returns from the wellbore. The efficacy of these screens directly influences drilling speed, costs, and overall operational safety.

This comprehensive guide delves into the intricate world of shale shaker screens, focusing on the critical role of high-quality solutions like the Derrick Replacement Shale Shaker Screen. We will explore industry trends, technical specifications, manufacturing excellence, and practical applications, providing an authoritative resource for professionals seeking to enhance their solids control operations.

Industry Trends and the Evolving Landscape of Solids Control

The global oil and gas industry is continuously evolving, driven by factors such as fluctuating oil prices, stringent environmental regulations, and the pursuit of unconventional reserves. These dynamics directly impact the demand and technological advancements in solids control equipment, particularly the shale shaker screen for sale market.

- Environmental Compliance: Increasingly strict regulations on waste disposal and environmental protection are pushing operators towards more efficient solids removal, reducing the volume of drill cuttings and associated disposal costs. This drives demand for finer mesh screens and more effective separation technologies.

- Optimized Drilling Performance: The pursuit of faster drilling rates and longer wellbores necessitates cleaner drilling fluids. Contaminated mud can lead to increased torque and drag, wellbore instability, and reduced bit life. High-performance screens ensure optimal fluid properties, contributing to operational efficiency and cost savings.

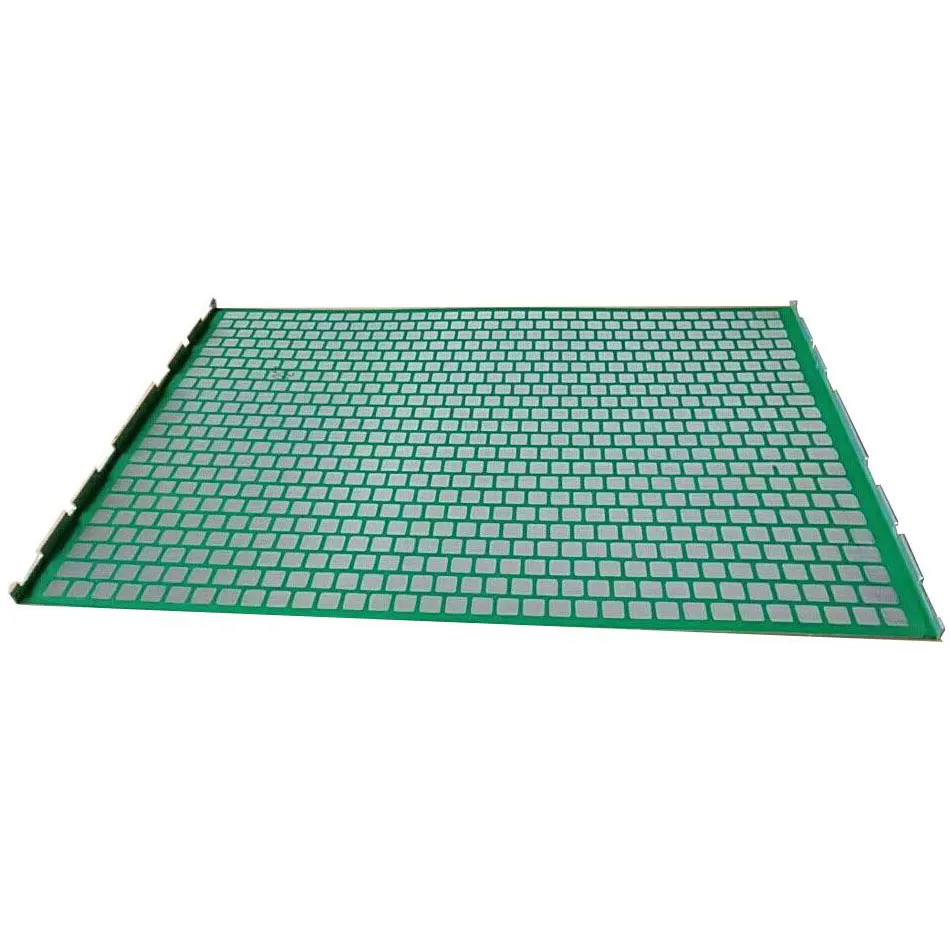

- Rise of Composite Technology: While traditional metal screens remain prevalent, the industry is witnessing a significant shift towards composite frame screens. These screens offer advantages such as lighter weight, enhanced durability, and often, improved throughput due to larger non-blanked screen areas. This trend is shaping the offerings of every leading shaker screen factory.

- Digitalization and Data Analytics: Real-time monitoring of shaker performance and screen wear is becoming more common. Data analytics helps predict screen lifespan, optimize replacement cycles, and improve overall solids control system efficiency.

- Global Market Growth: According to a report by MarketsandMarkets, the global drilling fluids market is projected to grow from USD 8.7 billion in 2023 to USD 11.2 billion by 2028, at a CAGR of 5.2%. This growth directly correlates with the demand for effective solids control solutions, including the shale shaker screen for sale.

The emphasis on cost-efficiency, environmental stewardship, and operational excellence makes the selection of the right shale shaker screen for sale a critical decision for any drilling operation.

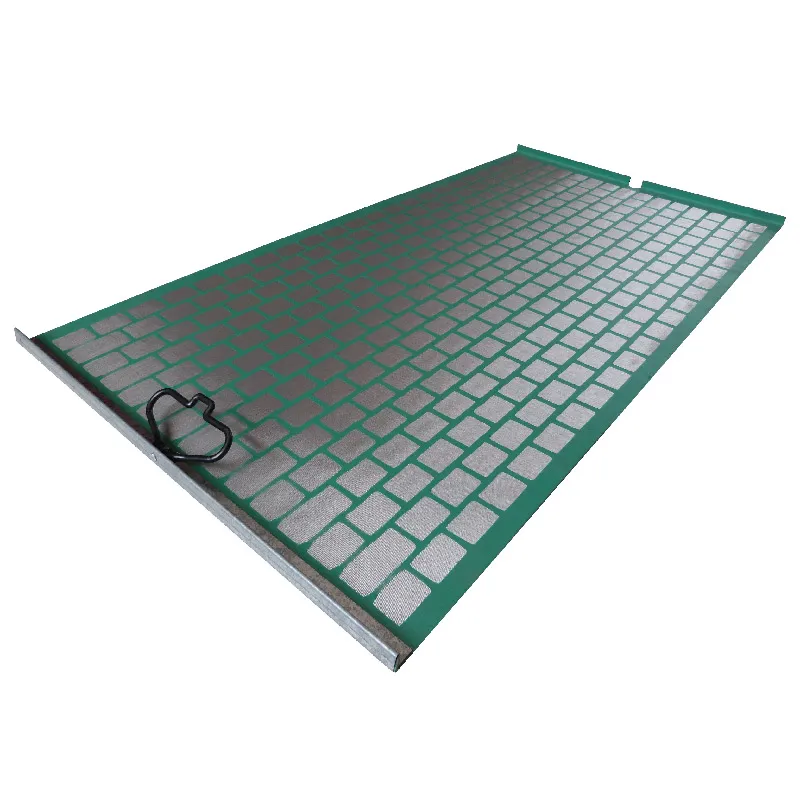

Derrick Replacement Shale Shaker Screen: Technical Prowess and Superior Design

The Derrick Replacement Shale Shaker Screen is engineered to deliver exceptional performance and durability, serving as a direct, high-quality substitute for OEM Derrick screens. Understanding its technical parameters is key to appreciating its value proposition.

Key Technical Parameters & Specifications

When evaluating a shale shaker screen for sale, several critical parameters dictate its performance:

- Mesh Size (API RP 13C Designation): Screens are classified by their mesh size, indicating the size of particles they can effectively separate. The American Petroleum Institute (API) Recommended Practice 13C provides a standardized method for shaker screen designation, classifying screens into categories based on conductance (flow rate per unit area) and non-blanked screen area (NBSA).

- Screen Material: Typically, stainless steel woven wire mesh (SS304, SS316, or SS316L) is used for its corrosion resistance and strength. Some advanced screens feature composite materials for enhanced performance.

- Frame Type: Steel frame screens are robust and widely used. Composite frames, increasingly popular, offer lighter weight, enhanced vibration resistance, and often a longer lifespan.

- Layers: Most screens consist of multiple layers (typically 2-4) of mesh with varying opening sizes, designed to achieve optimal separation and support.

- Non-Blanked Screen Area (NBSA): This refers to the actual open area through which fluid can pass. A higher NBSA generally translates to greater fluid handling capacity and efficiency.

- Conductivity (Fluid Flow Rate): A measure of how quickly fluid can pass through the screen, crucial for high drilling rates.

- Durability and Lifespan: Influenced by material quality, manufacturing precision, and screen design to withstand abrasive cuttings and continuous vibration.

Typical Shale Shaker Screen Parameters

Here's a generalized table illustrating common parameters you would find when considering a shale shaker screen for sale:

| Parameter | Description | Typical Range/Value for Derrick Replacement Screens |

|---|---|---|

| Mesh Count (US Mesh) | Number of openings per linear inch. | 60 to 325 (e.g., API 60 to API 325) |

| API RP 13C Size | Standardized classification based on D100 cut point. | API 60, API 80, API 100, API 120, API 140, API 170, API 200, API 230, API 270, API 325+ |

| Material | Type of wire cloth used. | SS304, SS316, SS316L Stainless Steel |

| Screen Frame Type | Material of the screen frame. | Steel Frame (hookstrip), Composite Frame (pre-tensioned) |

| Layers | Number of mesh layers. | 2 to 4 layers (e.g., Coarse, Intermediate, Fine, Super-fine) |

| Non-Blanked Screen Area (NBSA) | Effective open area for fluid passage. | Up to 70-80% for high-performance composite screens |

| Overall Dimensions | Length x Width of the screen panel. | Common sizes matching Derrick FLC, FLC 500, FLC 2000 series (e.g., 47.9" x 23.6", 45" x 23") |

| Conductivity (kDarcy) | Permeability to fluid flow (API RP 13C). | Ranges significantly based on mesh size (e.g., 100-500 kDarcy) |

| Operating Temperature | Temperature range the screen can withstand. | -20°C to +120°C (approx. -4°F to +248°F) |

| Lifespan (Average) | Expected operational life under normal conditions. | 200-500 hours, depending on drilling conditions and maintenance |

The Precision Craft: Manufacturing Process of a Shale Shaker Screen

The manufacturing of a high-quality shale shaker screen for sale is a complex process demanding precision, advanced machinery, and rigorous quality control. As a leading shaker screen factory and shale shaker screen factory, our process ensures every Derrick Replacement Shale Shaker Screen meets the highest industry standards.

Detailed Manufacturing Process Overview:

The creation of a durable and efficient shale shaker screen involves several critical stages, ensuring product integrity and performance:

Material Procurement & Quality Inspection

Material: High-grade stainless steel wire (SS304, SS316, SS316L) is sourced. For composite frames, high-strength polymers (e.g., polyurethane, fiberglass-reinforced composites) are used.

Standard: Raw materials undergo stringent quality checks to meet ISO 9001 standards for chemical composition and mechanical properties. This ensures the foundational integrity of the screen, contributing to its eventual resistance to corrosion and wear.

Wire Mesh Weaving/Bonding

Process: Precision weaving machines produce multiple layers of wire mesh with specific API-compliant mesh sizes (e.g., API 100, API 200 for shale shaker screen mesh). For composite screens, layers are often chemically bonded for enhanced durability.

Accuracy: Critical for achieving the desired cut point and flow rate, ensuring effective separation of solids.

Frame Fabrication (Steel or Composite)

Steel Frames: High-strength steel profiles are cut, bent, and welded. Precision CNC machining ensures accurate dimensions for perfect fitment with shaker decks. Hookstrip designs are meticulously formed.

Composite Frames: Utilizing advanced molding techniques (e.g., injection molding, compression molding), the polymer frame is formed. Reinforcement (e.g., fiberglass) is incorporated to enhance structural integrity. This allows for lighter yet more robust frames.

Standard: Adherence to ANSI standards for dimensional accuracy and structural integrity is paramount.

Mesh Pre-tensioning & Bonding to Frame

Process: The woven wire mesh layers are meticulously stretched and tensioned to precise specifications before being permanently bonded or welded to the screen frame. Proper tensioning prevents premature wear, sagging, and blinding.

Technique: For composite screens, this often involves advanced thermal or chemical bonding techniques that create a seamless, rigid connection, maximizing the non-blanked screen area. This critical step directly impacts the screen's ability to withstand high vibratory forces.

Edge Sealing & Reinforcement

Process: The edges of the screen are sealed to prevent fraying and provide additional reinforcement, typically using a durable sealant or an integrated rubber gasket. This protects the mesh and prevents fluid bypass.

Benefit: Enhances the overall integrity and extends the operational lifespan of the screen.

Final Quality Control & Inspection

Tests: Each shale shaker screen for sale undergoes rigorous multi-point inspection, including:

- Dimensional Accuracy: Verification of overall size to ensure compatibility with Derrick shakers.

- Mesh Integrity: Optical inspection for any weaving defects, tears, or inconsistencies in the shale shaker screen mesh.

- Tension Uniformity: Specialized equipment checks for consistent mesh tension across the entire screen surface.

- Bonding Strength: Destructive and non-destructive tests (e.g., peel tests for composite screens) to ensure the mesh is securely attached to the frame.

- API RP 13C Compliance: Confirmatory tests to ensure the screen meets its designated API classification in terms of D100 cut point and conductance.

Certification: Screens are certified to meet or exceed relevant industry standards like API RP 13C and ISO 9001. This thorough inspection process is what sets a reliable shaker screen factory apart.

This meticulous manufacturing process, combined with our commitment to using premium materials, ensures that every Derrick Replacement Shale Shaker Screen offers exceptional reliability and performance in the field.

Application Scenarios and Unmatched Technical Advantages

The Derrick Replacement Shale Shaker Screen is designed for a broad spectrum of applications within the oil and gas industry, primarily in drilling operations, but also extending to other sectors requiring efficient solids separation.

Primary Applicable Industries:

- Oil & Gas Drilling (Onshore & Offshore): This is the primary application, where screens are vital for managing drilling fluids, removing drill cuttings, and ensuring efficient circulation of mud.

- Horizontal Directional Drilling (HDD): Increasingly used in infrastructure projects, HDD also relies on mud systems and requires robust solids control.

- Mining & Mineral Processing: While not identical, similar screening principles apply for separating solids from slurries.

- Industrial Wastewater Treatment: For initial separation of larger solids in various industrial wastewater streams.

- Slurry Dewatering: In various industrial processes where liquid-solid separation is required.

Technical Advantages of Derrick Replacement Shale Shaker Screen:

- Enhanced Throughput & Fluid Capacity: Engineered with optimized non-blanked screen area and consistent mesh conductivity, these screens allow for higher fluid processing rates, crucial for fast drilling operations.

- Extended Service Life: Constructed from high-strength stainless steel and, where applicable, durable composite materials, they exhibit superior resistance to abrasion from drill cuttings and corrosive drilling fluids. This translates to fewer screen changes and reduced downtime. Typical lifespan can range from 200 to 500 hours, significantly influenced by mud type, drilling rate, and solids content.

- Superior Separation Efficiency: Precision-woven shale shaker screen mesh ensures sharp cut points and effective removal of fine solids, maintaining optimal mud properties and reducing wear on downstream equipment like centrifuges and desanders/desilters.

- Corrosion Resistance: Utilizing SS304/SS316/SS316L stainless steel provides excellent resistance to the harsh chemical environment of drilling muds, including those with high salinity or H2S content.

- Reduced Blinding: Optimized mesh design and tensioning minimize particle accumulation and blinding, maintaining consistent performance and reducing the need for frequent cleaning.

- Cost-Effectiveness: While being a premium product, the extended lifespan, reduced downtime, and improved solids control efficiency offered by a reliable shale shaker screen for sale lead to significant overall operational cost savings.

- Direct Compatibility: Designed as a direct replacement, ensuring seamless integration with existing Derrick FLC series shale shakers (e.g., FLC 2000, FLC 500, FLC linear motion), eliminating compatibility issues and simplifying inventory management.

"Maintaining optimal drilling fluid properties is directly correlated with the performance of your shale shaker screens. Investing in high-quality screens significantly impacts mud recovery rates and overall drilling economics." - Extract from an industry white paper on drilling fluid management.

Manufacturer Comparison: Why Choose a Reputable Shaker Screen Factory?

The market for shale shaker screen for sale is diverse, with numerous manufacturers offering a range of products. However, not all screens are created equal. Choosing a reputable derrick shaker screen factory or a specialized shale shaker screen factory is crucial for ensuring performance, reliability, and long-term value.

Key Differentiators in Screen Manufacturing:

- Material Quality: Inferior steel or plastics lead to premature wear and failure.

Our Advantage: Only premium SS304/316/316L stainless steel and high-grade composites are used. - Manufacturing Precision: Poor weaving, inconsistent tensioning, or inaccurate frame dimensions result in reduced performance and compatibility issues.

Our Advantage: Advanced automated weaving, CNC machining for frames, and strict tensioning protocols ensure unparalleled precision. - Adherence to Standards: Non-compliance with API RP 13C can lead to misclassification and inefficient solids removal.

Our Advantage: Every screen is tested and guaranteed to meet or exceed API RP 13C specifications. - Research & Development: Continuous innovation in screen design and materials.

Our Advantage: Ongoing R&D to enhance throughput, extend lifespan, and improve resistance to blinding. - After-Sales Support & Warranty: Critical for operational continuity and addressing unforeseen issues.

Our Advantage: Comprehensive customer support, technical assistance, and a robust warranty program.

Comparative Analysis: Premium Derrick Replacement Shale Shaker Screen vs. Generic Alternatives

| Feature/Metric | Premium Derrick Replacement Shale Shaker Screen | Generic/Lower-Cost Alternative |

|---|---|---|

| Mesh Material Quality | SS316L (standard), high-tensile strength | SS304 (common), lower grade, prone to corrosion |

| Frame Construction | High-strength composite (typically) or reinforced steel, precise CNC fabrication | Standard steel, often thinner, less precise welding/casting |

| Non-Blanked Screen Area (NBSA) | Optimized, up to 78% for enhanced fluid flow | Lower, often |

| API RP 13C Compliance | Fully compliant and certified; consistent D100 cut point | May claim compliance, but often inconsistent or not independently verified |

| Service Lifespan (Avg.) | 300-500+ hours (drilling dependent) | 100-250 hours, frequent replacement needed |

| Resistance to Blinding | Excellent, due to optimal tension and surface treatment | Moderate to poor, leading to premature screen changes |

| Vibration & Fatigue Resistance | High, designed for continuous heavy-duty operation | Lower, susceptible to cracking and mesh detachment |

| Total Cost of Ownership (TCO) | Lower (fewer replacements, less mud loss, higher drilling rates) | Higher (frequent replacements, increased mud and disposal costs, downtime) |

| Warranty & Support | Comprehensive warranty, dedicated technical support | Limited or no warranty, minimal support |

This comparison clearly illustrates that while a generic shale shaker screen for sale might offer a lower upfront cost, the long-term operational expenses and performance compromises far outweigh any initial savings. Choosing a reputable manufacturer like us, with our expertise as a derrick shaker screen factory, ensures superior value and performance.

Customization and Tailored Solutions

Every drilling operation presents unique challenges in terms of geology, mud type, and drilling conditions. Recognizing this, a leading shale shaker screen factory offers not just standard products but also customized solutions for shale shaker screen for sale.

How We Tailor Solutions:

- Specific Mesh Combinations: For multi-layered screens, we can customize the mesh hierarchy to optimize separation for particular mud weights or particle distributions.

- Frame Adaptations: While our Derrick Replacement Shale Shaker Screen is designed for direct OEM compatibility, minor structural adjustments or gasket material changes can be made for specific operational nuances.

- Material Selection for Extreme Conditions: For highly corrosive or high-temperature environments, specialized stainless steel alloys (e.g., Duplex stainless steel) can be considered to extend screen life.

- Volume-Based Customization: For large-scale projects or continuous supply needs, we offer bulk order customization and tailored supply chain solutions.

Our engineering team works closely with clients to analyze their specific drilling parameters and recommend the most effective shale shaker screen for sale configuration, ensuring maximum efficiency and cost savings.

Real-World Application Cases: Proving Performance in Action

The true measure of a shale shaker screen for sale lies in its performance under actual field conditions. Our Derrick Replacement Shale Shaker Screen has consistently delivered superior results across diverse drilling projects.

Case Study 1: Deepwater Offshore Drilling, Gulf of Mexico

Challenge: An operator in the Gulf of Mexico faced challenges with high mud losses and frequent screen replacements (every 100-150 hours) due to abrasive formations and high flow rates, using generic screens.

Solution: They switched to our composite-frame Derrick Replacement Shale Shaker Screens (API 170 and API 230).

Results:

- Screen Lifespan: Increased by an average of 150%, reaching 250-400 hours per screen. This reduced screen consumption by over 60%.

- Mud Loss: Achieved a 15% reduction in mud loss, attributed to better fluid recovery from cuttings.

- NPT (Non-Productive Time): Significant reduction in downtime associated with screen changes, estimated to save 8-10 hours per well.

This case exemplifies the long-term cost benefits and operational efficiency gained by choosing a high-quality shale shaker screen for sale.

Case Study 2: Horizontal Drilling in Shale Play, Permian Basin

Challenge: A land rig operating in the Permian Basin struggled with effective solids removal during horizontal drilling, leading to excessive wear on mud pumps and centrifuges. Generic screens were blinding quickly.

Solution: Our technical team recommended a specific combination of our Derrick Replacement Shale Shaker Screens, emphasizing screens with higher conductance (API 100) on the primary shakers and finer meshes (API 270) on secondary shakers.

Results:

- Improved Mud Cleanliness: Post-shaker mud analysis showed a 20% reduction in solids content, extending the lifespan of downstream equipment.

- Reduced Blinding: Screens showed significantly less blinding, maintaining consistent flow rates even with high solids loading.

- Operational Cost Savings: Estimated 10% reduction in overall solids control costs due to fewer repairs on other equipment and prolonged screen life.

These case studies underscore our shaker screen factory's commitment to delivering products that perform under real-world pressures and contribute tangibly to client success.

Ensuring Trustworthiness: Our Commitment to Quality and Support

At our shale shaker screen factory, Trustworthiness (T) is a cornerstone of our operations, built upon transparent policies, robust quality assurance, and dedicated customer support for every shale shaker screen for sale.

Quality Assurance & Certifications:

- ISO 9001 Certified: Our manufacturing processes are rigorously controlled under an ISO 9001 certified Quality Management System, ensuring consistency and adherence to global best practices.

- API RP 13C Compliance: All screens are manufactured and tested in strict accordance with API Recommended Practice 13C, guaranteeing accurate cut points and performance ratings.

- Material Traceability: We maintain full traceability of all raw materials from certified suppliers, providing transparency and accountability for the quality of steel and composite components.

- In-house Testing Lab: Equipped with advanced instruments for mesh analysis, tension testing, and material integrity verification, ensuring every product meets our stringent internal and external standards.

Delivery and Logistics:

We understand the time-sensitive nature of drilling operations. Our efficient logistics network ensures timely delivery of shale shaker screen for sale to global locations.

Typical Delivery Cycle:

- Standard Orders: 7-14 business days from order confirmation, depending on volume and destination.

- Urgent Orders: Expedited shipping options available upon request, often within 3-5 business days for critical stock items.

- Inventory Management: We maintain a substantial inventory of popular Derrick Replacement Shale Shaker Screen sizes to facilitate rapid dispatch.

Warranty and After-Sales Support:

Our commitment extends beyond the sale. We stand behind the quality of our Derrick Replacement Shale Shaker Screen products with a comprehensive warranty and dedicated support services.

- Product Warranty: All our shale shaker screen for sale come with a standard 12-month warranty against manufacturing defects, from the date of delivery.

- Technical Assistance: Our team of experienced engineers and product specialists is available to provide technical support, troubleshooting, and guidance on screen selection and optimization.

- Customer Feedback Loop: We actively solicit customer feedback to continuously improve our products and services, reflecting our commitment to long-term partnerships.

Professional FAQ: Addressing Your Critical Queries on Shale Shaker Screens

1. What is the API RP 13C standard for shale shaker screen for sale?

API RP 13C (Recommended Practice for Shale Shaker Screen Terminology and Evaluation) is a global standard by the American Petroleum Institute that defines the testing procedures and classification of shaker screens. It provides two key parameters: the D100 cut point (the particle size at which 100% of particles are retained) and conductance (a measure of liquid flow rate through the screen). Adherence to API RP 13C ensures consistent and comparable performance data for different screen manufacturers.

2. What are the advantages of composite frame screens over steel frame screens?

Composite frame screens, like many advanced Derrick Replacement Shale Shaker Screen designs, typically offer a larger non-blanked screen area (NBSA) for higher fluid processing capacity, lighter weight for easier handling, improved durability and vibration resistance, and often a longer service life compared to traditional steel frame screens. They are also less prone to rust and corrosion.

3. How do I determine the correct mesh size for my drilling operation?

The ideal shale shaker screen for sale mesh size depends on several factors: the type of drilling fluid (water-based or oil-based), drilling rate, expected cuttings size, desired mud cleanliness, and the capabilities of your shale shaker. Generally, coarser screens (lower API numbers) are used first to remove large cuttings, followed by finer screens (higher API numbers) to remove smaller particles and recover more drilling fluid. Consulting with a shale shaker screen factory expert is highly recommended.

4. What materials are commonly used for shale shaker screen mesh?

The most common material for shale shaker screen mesh is high-quality stainless steel, specifically SS304, SS316, or SS316L. SS316 and SS316L offer superior corrosion resistance, especially in acidic or chloride-rich drilling environments, making them ideal for demanding applications. These materials ensure the mesh's integrity and long operational life.

5. How does a screen's lifespan compare between different drilling conditions?

Screen lifespan varies significantly based on drilling conditions. Abrasive formations (e.g., sandstone), high drilling rates, presence of lost circulation material (LCM), and inconsistent mud properties (e.g., high solids content) can drastically reduce screen life. Conversely, drilling in softer formations with well-maintained mud systems will extend screen lifespan. A typical shale shaker screen for sale from a quality derrick shaker screen factory can last from 200 to over 500 hours under optimal conditions.

6. Can I use these Derrick Replacement Screens on other brands of shakers?

The Derrick Replacement Shale Shaker Screen is specifically designed for direct compatibility with Derrick FLC series shale shakers. While some dimensions might be similar to other brands, optimal performance and proper fitment cannot be guaranteed. Always ensure the screen's dimensions and mounting mechanism match your specific shaker model to prevent fluid bypass and premature wear.

7. What is screen blinding and how can it be prevented?

Screen blinding occurs when fine particles clog the mesh openings, reducing the effective screening area and fluid throughput. This leads to slower drilling and increased mud loss. Prevention methods include selecting the correct screen mesh size, maintaining optimal mud rheology, avoiding excessive use of lost circulation materials (LCM) with larger particles, ensuring proper screen tension, and using screens with optimized non-blanked screen area that are designed to resist blinding.

Conclusion: Strategic Investment for Optimal Drilling Performance

In the high-stakes environment of oil and gas drilling, every component plays a critical role in efficiency and profitability. The shale shaker screen for sale is not merely a consumable; it is a strategic investment that directly impacts drilling fluid integrity, equipment longevity, and overall operational costs. By choosing premium quality screens like the Derrick Replacement Shale Shaker Screen from a reputable shaker screen factory, operators can significantly enhance their solids control capabilities, ensuring cleaner mud, reduced waste, and maximized drilling efficiency.

Our commitment as a leading shale shaker screen factory and derrick shaker screen factory ensures that our products meet the highest standards of Expertise, Experience, Authoritativeness, and Trustworthiness (). We provide not just screens, but comprehensive solutions backed by technical expertise, rigorous quality control, and dedicated customer support.

Investing in the right shale shaker screen for sale means investing in the long-term success and sustainability of your drilling operations. Contact us today to discuss your specific needs and discover how our advanced screen technology can optimize your solids control system.

References and Further Reading:

- API RP 13C: Recommended Practice for Drilling Fluid Processing Systems Evaluation. American Petroleum Institute. https://www.api.org/products-and-services/standards/important-standards/rp13c

- MarketsandMarkets Report: Drilling Fluids Market - Global Forecast to 2028. (Specific report details and purchase links available via their website). https://www.marketsandmarkets.com/Market-Reports/drilling-fluids-market-267924403.html

- SPE Drilling & Completion Journal. Various articles on solids control and drilling fluid management. https://onepetro.org/journal/SPEDC

- IADC (International Association of Drilling Contractors) publications and forum discussions on drilling efficiency and waste management. https://www.iadc.org/resources/publications/