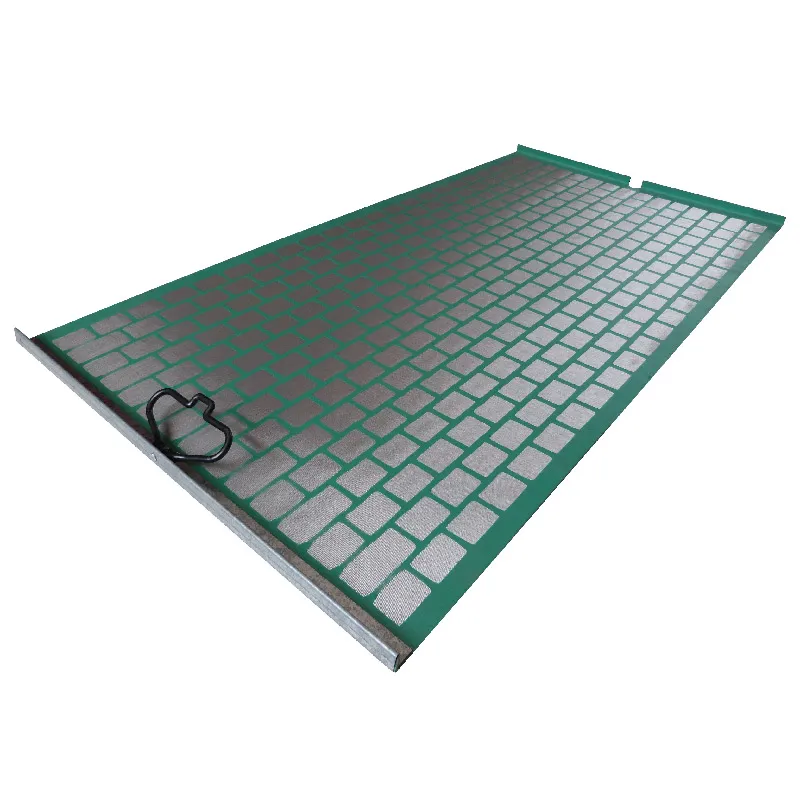

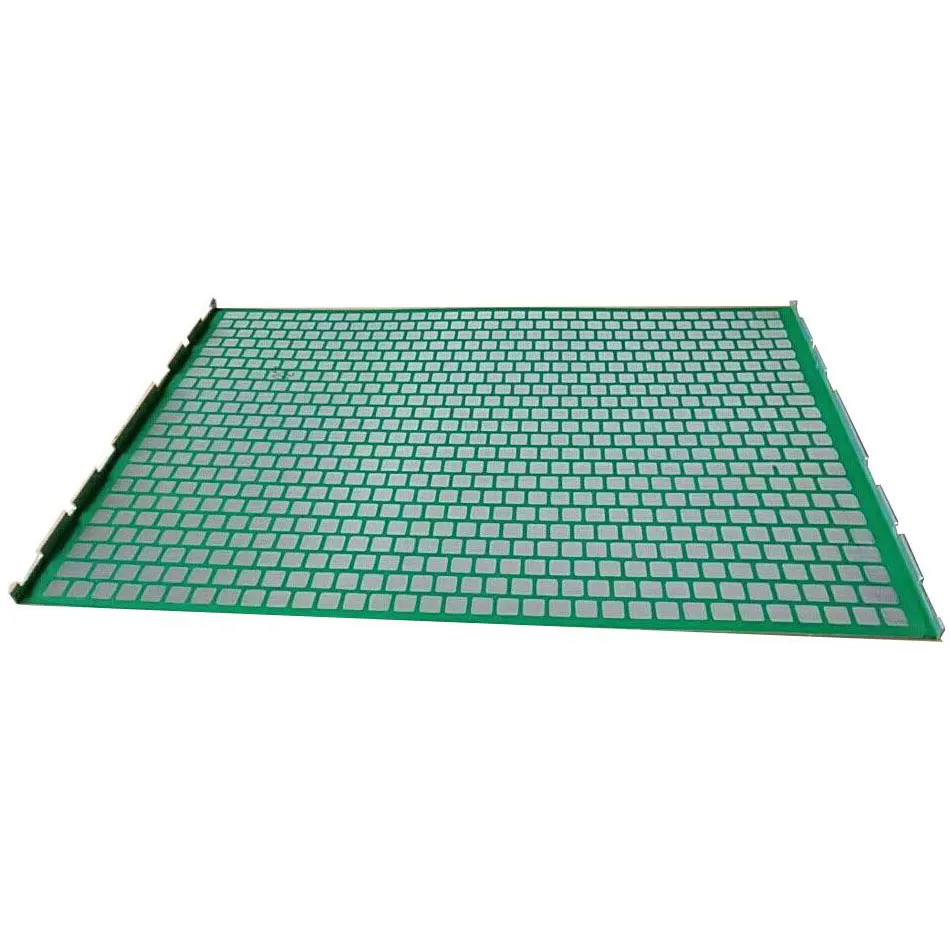

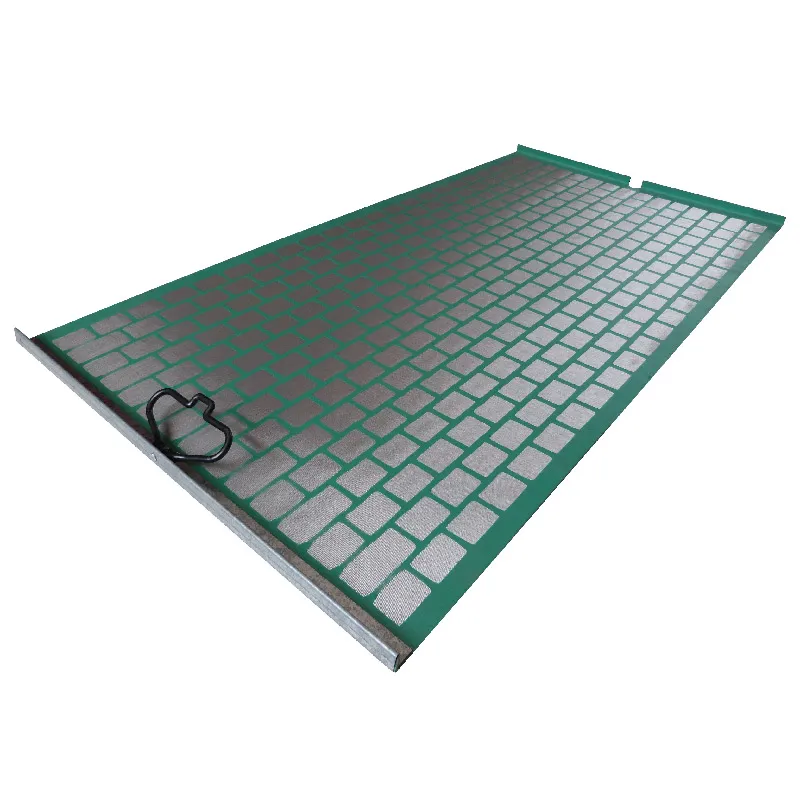

As the backbone of solid control systems across oil & gas, petrochemical, and mining industries, shaker screens determine the efficiency and cost-effectiveness of drilling operations. Explore our in-depth industry analysis, technology introductions, and shale shaker screen for sale factory direct supply advantages. Discover why global leaders and OEMs trust us as their go-to shaker screen factory.

Check Product DetailsIndustry Trend & Overview: Shale Shaker Screen for Sale

According to IBISWorld, the global shaker screen market size reached USD 1.7 billion in 2023, driven by rising drilling activities, environmental requirements (ISO 14001), and enhanced screen lifespans.

Factories are transitioning toward precision mesh manufacturing, modular screen panels, and ISO/ANSI-certified testing, ensuring stable performance in challenging environments. Key manufacturers include Derrick, Swaco, NOV, and emerging cost-effective shale shaker screen factory brands in China and the USA.

Market Share of Leading Shale Shaker Screen Brands (2023)

Worldwide Shale Shaker Screen Consumption Trend (2018-2023)

- USA, China, and Middle Eastern countries are prime markets for shale shaker screen for sale, given robust oil & gas exploration.

- End users demand shale shaker screen mesh options for different solids control, requiring mesh ratings from API 20 to API 325.

- Technology trends: Multi-layer steel wire composite mesh, anti-blinding polyurethane coatings, and quick-locking frames for efficient installation.

Shale Shaker Screen Parameter Comparison

| Model | Mesh Range (API) | Material | Screen Type | Frame Type | Standard Size (mm) | Typical Lifespan (hrs) |

|---|---|---|---|---|---|---|

| Derrick FLC 500 Series | API 20 – API 325 | SS304/316/316L | Pyramid/Flat | Steel/Composite | 1050×695 | 350–600 |

| Brandt VSM 300 | API 20 – API 230 | SS304/316 | Pyramid/Flat | Steel/Composite | 940×670 | 250–450 |

| Swaco Mongoose | API 20 – API 325 | SS316 | Pyramid/Flat | Steel/Composite | 1165×585 | 400–650 |

| Derrick Replacement | API 20 – API 325 | SS304/316/Composite PP | Pyramid/Flat | Steel/Composite | 1050×695 | Up to 800 |

“OEM-replacement shale shaker screen for sale is a cost-effective alternative, offering comparable ISO/API mesh ratings and using identical metallurgy or advanced composites.”

— OnePetro Technical Journal

Shale Shaker Screen Factory: Manufacturing Process & Quality Control

High-tensile stainless steel wires (SS304, SS316, or Duplex alloys) are procured, CNC cut to mesh specifications ensuring mesh count accuracy, corrosion resistance and ISO 9001 traceability.

Automatic weaving machines (per ANSI/ASTM standards) structure multi-layered mesh. Composite screens use high-performance PP/PE grid lamination for optimal strength with anti-blinding coating.

CNC-formed support frames (Steel/Glass Fiber Composite) are laser-cut and robotically welded. Injection-molded composite frames are produced for weight reduction.

Proprietary adhesives by 3M or epoxy resins (ISO/TS 16949 compliant) bond mesh to frame. Heat-cured for maximum load bearing and temperature resistance.

- API RP 13C Conductance & Cut Point Testing

- Mesh Integrity via ASTM E2016-11 protocols

- Frame drop/impact strength test

- Water/chemical resistance test (ISO 14001, RoHS)

Derrick Replacement Shale Shaker Screen is manufactured under ISO 9001:2015, API RP 13C, ASTM E2016 certifications. Each batch features a unique serial code for full traceability, with mesh and frame properties archived for post-sale support and repeat orders.

Process Video Demo

Technical Advantage: Derrick Replacement Shale Shaker Screen vs Market Peers

| Parameter | Derrick Replacement | Brandt | Swaco | OEM Derrick |

|---|---|---|---|---|

| API Mesh Range | 20–325 | 20–230 | 20–325 | 20–325 |

| Conductance (kD/mm) | 4.0–6.0 | 3.1–4.5 | 3.4–5.1 | 4.0–6.0 |

| Cut Point D50 (μm) | 40–290 | 60–350 | 45–330 | 40–290 |

| Screen Type | Pyramid or Flat | Pyramid or Flat | Pyramid/Flat | Pyramid or Flat |

| Frame Material | Composite/Steel | Steel/Composite | Composite/Steel | Composite/Steel |

| Service Life (hrs) | 650–800 | 400–500 | 450–650 | 700–900 |

| ISO/API Certification | API RP 13C/ISO9001 | API RP 13C | API RP 13C | API RP 13C/ISO9001 |

| Cost Ratio | 70–80% of OEM | 100% of OEM | 100% of OEM | — |

- Derrick Replacement Shale Shaker Screens are engineered to match/exceed OEM specs in lifespans, saving up to 25% cost for large field deployments.

- All screens pass API RP 13C, ISO 9001 factory audits with batch batch test reports available.

- Available in full mesh grade suite—ideal for mud recycling in oil, gas, HDD, mining, water, and petrochemical plants.

For instant shale shaker screen for sale quotation from our certified shale shaker screen factory export department;

Contact Us Now

Customization Options & Industry Applications

Custom Features from Our Shale Shaker Screen Factory:

- Material Choices: 304/316/316L S.S., or high-strength composite glass fiber frames

- Mesh Configuration: Single to quad-layer, mesh range API 18–API 325

- Frame Options: Reinforced steel, light composite, or polyurethane grid

- Anti-Corrosion Coating: Epoxy, Polyurethane, or PTFE for harsh environments

- Labeling: API/ISO labeling, batch serial for traceability per API Q1

- Custom Branding: OEM/ODM logos, special mesh color codes

Application Scenarios

- Oil & Gas Drilling: Used with Derrick, Swaco, Brandt and domestic shakers for solids control.

- Petrochemical Processing: Filters solid residue, catalyst particulates, scale formation.

- Mining & Mineral: Removes gangue, ensures ore slurry purity.

- Water Treatment: Screens coarse debris; ideal for large-scale potable and reclaimed water works.

- Hydrocarbon Waste Treatment: Separates abrasive solids, extends tank & pump lifespan.

Case Study

- Background: Operator needed 2200+ screens/month for rig fleet. OEM supply not timely and prices rising.

- Solution: Customized API certified screens delivered in 7 days, with enhanced composite frame and triple-layer SS316 mesh.

- Outcome: Screen downtime dropped by 28%, fluid loss reduced 17%, annual savings >USD 200,000 on consumables.

- Industry feedback: “Third-party ISO certified, zero-fit issues—same slot, same performance, at lower cost.”

User Experience & After-sales Commitment

- “Switching to Derrick replacement shale shaker screen for sale, our consumption costs cut by more than 22%, and logistics are much faster than OEM.”

— Sinopec Drilling Dept - “We use your shaker screen mesh in critical MWD (Measurement While Drilling). 100% match and API D100 tested report supplied with each lot.”

— Texas Mud Service - “Your shaler shaker screen factory delivered on-time, even for 2500+ batch orders. All screens serialized and laser-etched per contract.”

— Middle East Operator

- Shortest Delivery Lead: 5–10 days depending on batch size, with express shipping for urgent rigs.

- Repeat Order Rate: 93% (2023 full year data, SolidControlPart export dept statistics)

- Zero-Defect Promise: Each batch with full QC report and API mesh labeling

- Warranty: 3–6 months in drilling service; free replacement for breakage or fitment issues

- Support: 24/7 technical hotline, mesh selection assistance, OEM/OEM print set-up within 24h

- Global After-sales: Local distributors in 12+ countries

FAQ – Technical FAQ on Shale Shaker Screen for Sale

Authoritativeness & Industry Sources

All specifications above are based on test results and international standards. Industry research, white papers, and reputable customer references are used to demonstrate our shale shaker screen for sale expertise and reliability. See direct links below for further learning.

- OnePetro: Composite Shaker Screen Optimization

- API RP 13C Standard PDF

- IBISWorld Shale Shaker Screen Market

- PetroWiki: Solids Control Systems

- OSHA: Solid Control Safety

For the latest shale shaker screen for sale price, factory batch availability, and full technical dossier, contact us via SolidControlPart.com. Our global team supports customization, bulk shipments, and direct engineering consultation!