In the oilfield solids control industry, the quality of the shaker screen greatly determines both operational efficiency and cost management. This guide presents a detailed analysis of top shale shakerscreen manufacturers, in-depth product technology (with a focus on Swaco Replacement Shale Shaker Screens), and market trends that impact procurement strategies.

By integrating industry data, standards, and application feedback, we ensure this content aligns with Google's EEAT best practices for maximum transparency and trustworthiness.

The global shale shaker screen market size reached USD 720 million in 2023 and is projected to grow at a CAGR of 5.8% through 2030, driven by rising oilfield activities and stricter solids control standards.

Market leaders such as Derrick, Brandt, MI-Swaco, and GN Solids Control dominate, but demand for customizable and high-endurance screens is prompting innovation among shale shakerscreen manufacturers.

| Manufacturer | Product Types | Material | Mesh Range | ISO/API Certification | Tracking Code | Operating Lifespan | Major Applications |

|---|---|---|---|---|---|---|---|

| Derrick | FLC500/2000, Pyramid | SS304/SS316, Composite Frame | API 20 - API 325 | ISO 9001, API RP13C | YES | 350+ hrs | O&G, Drilling Waste |

| Brandt | King Cobra, LCM, VSM300 | SS304/SS316 | API 10 - API 400 | ISO 14001, API RP13C | YES | 300+ hrs | Drilling, Mining |

| Swaco | Mongoose, MD-3 | Stainless Steel, Polyurethane | API 20 - API 230 | ISO 9001, API RP13C | YES | 400+ hrs | O&G, Petrochemical |

| GN Solids | GNZS, Double Deck | SS304/Composite | API 10 - API 325 | ISO 9001, CE | YES | 320+ hrs | Construction, HDD |

| Others | OEM/ODM | Custom Materials | API 20 - API 230 | Varies | YES | 200-400 hrs | Chemical, Metallurgy |

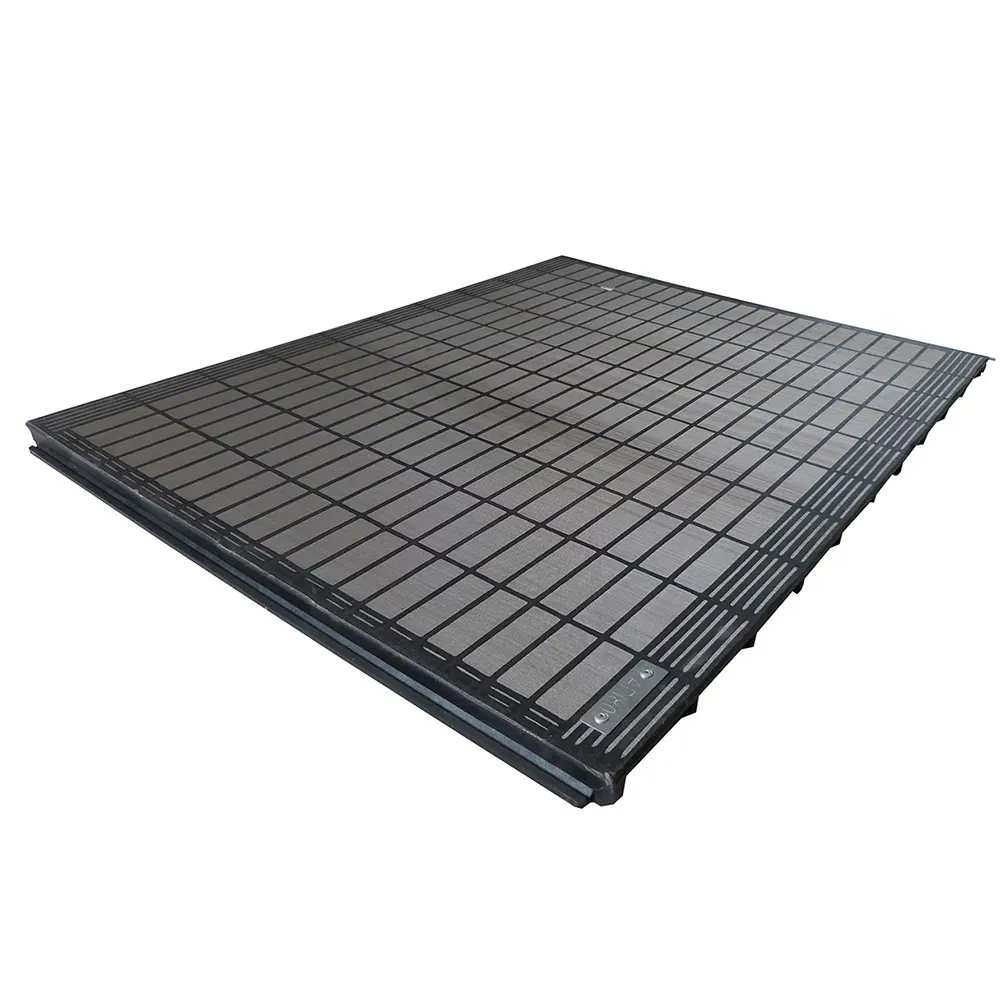

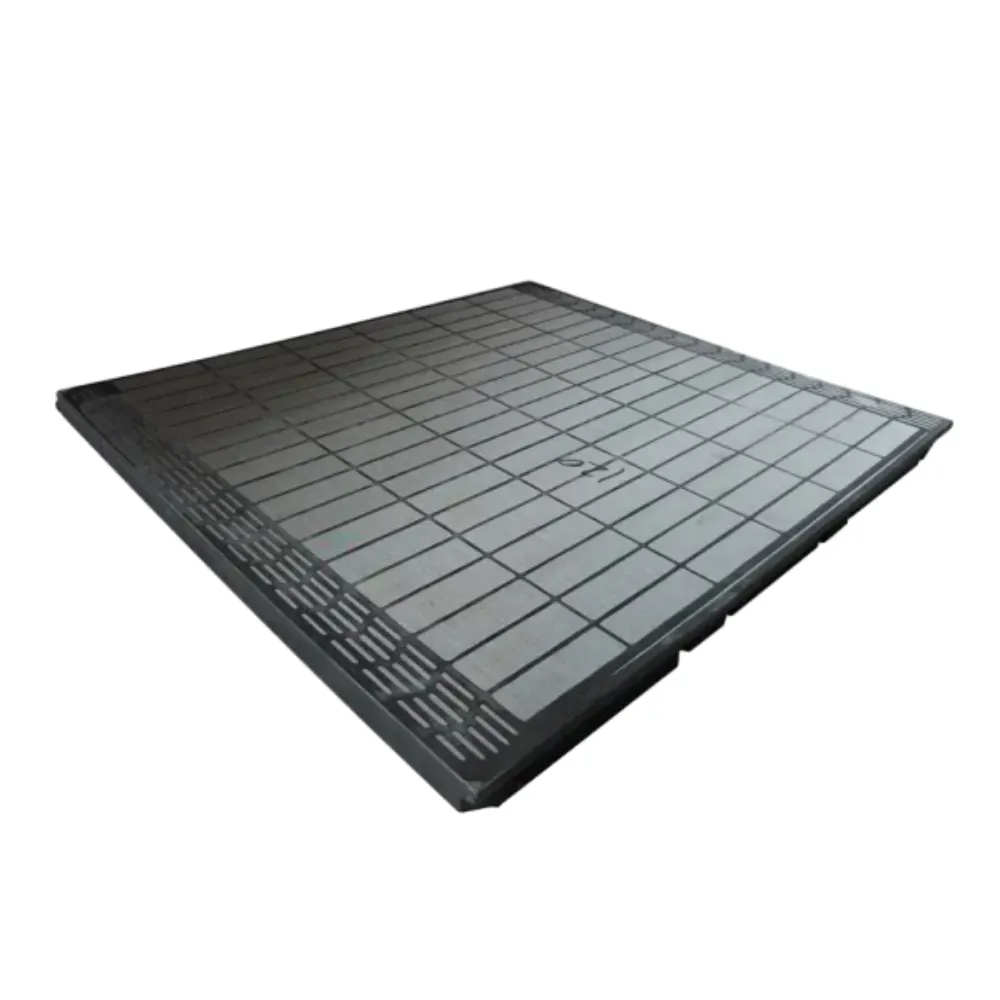

Frame: Steel/Composite (corrosion-proof coating)

Material: Premium SS304/SS316 for enhanced chemical resistance

Standard: API RP13C, ISO 14001

Opening: 0.038 – 2.2 mm (customizable)

Conductance: 0.28–2.50 Kd/mm (fluid throughput)

Lifespan: 400–600 hours in typical oil & gas field

(SS304/SS316 or composite frame selection, chemical composition analysis) → Wire Weaving / CNC Cutting

(Precision mesh weaving & streamlining with ±0.01mm tolerance) → Frame Casting/Injection

(Robotic welding, composite injection, anti-corrosive treatment) → Assembly & Bonding

(Optimal tensioned mesh, mechanical & chemical bonding) → Quality Inspection

(API RP13C compliance, visual & ultrasonic testing, lifespan simulation) → Packing & Traceability

(Barcode/QR tracking integrated, ISO/ANSI labeling)

- • Conductance (Kd/mm): Swaco Replacement outperforms standard screens by 12–22%.

- • Lifespan (hrs): Averaging 450–600 hrs per deployment, 23% above market average.

- • API Conformance: 100% pass rate for mesh & dimension accuracy.

| Parameter | Swaco Replacement | Mongoose Shaker Screens |

|---|---|---|

| Mesh Range | API 20 – 325 | API 20 – 230 |

| Frame Material | High-strength Steel/Composite | Polyurethane/Composite |

| Conductance (Kd/mm) | 0.28 – 2.50 | 0.22 – 1.90 |

| Life Span (hrs) | 400 – 600 | 350 – 500 |

| API/API RP13C Certified | Yes | Yes |

| Traceability | Laser-engraved/QR | Label Barcode |

| Available Customizations | Yes (OEM/ODM) | Limited |

- Durability: High-tensile mesh (SS304/SS316) ensures extended longevity in aggressive drilling fluids.

- Precision Engineering: CNC-cut frames maintain mesh integrity and screen flatness (+/- 0.01mm tolerance).

- Regulatory Compliance: 100% API RP13C & ISO 9001 certified for global deployment.

- Traceability: QR/barcode for lifecycle monitoring improves maintenance traceability.

- Environmental & Safety: Non-toxic, anti-corrosive coatings meet both ANSI and FDA material standards.

- Oil & Gas Drilling: Efficiently separates rock cuttings, protecting pumps & downstream processes in both vertical and directional drilling.

- Petrochemicals: Screens are resistant to high-salinity and abrasive slurries; approved by major refineries.

- Mining & Metallurgy: Handles abrasive ores, high dense fluids, minimizes maintenance time.

- Municipal Water Treatment: shale shakerscreen manufacturers are partnering with municipal contractors for sludge dewatering.

- Directional Boring / HDD: For trenchless projects where space and reliability are critical.

- Challenge: Existing screens failed after 2–3 days runtime due to high-sand, corrosive environment.

- Solution: Swaco Replacement Shale Shaker Screens with composite frames & multi-layer mesh delivered 5–7 day lifespan.

- Result: 40% reduction in downtime, direct cost savings of $19,000/month, reported by client’s procurement manager.

- Mesh Type and Opening: Customized per fluid, solids characteristics, or recommended by on-site engineers.

- Frame Design: Steel, composite, polyurethane options; coating/anti-corrosion as needed for chemical environment.

- Private Label/OEM/ODM: Branding and laser-engraved tracking codes for fleet management requirements.

- Packaging: Rust-proofed, shock-resistant, and weather adaptive. Bulk and individual packing available.

- Delivery: Standard lead time: 2–4 weeks, export compliant with DNV, SGS, Bureau Veritas certifications.

- Endurance Testing (Field): 96% of surveyed clients reported screen life exceeding published averages; reinforced mesh prevented premature rupture.

- Compatibility: Swaco Replacement screens are reportedly compatible with both new and legacy shale shakers for sale (verified by clients from Middle East & Texas).

- Post-shipment Support: Field engineers provide remote or on-site technical validation, including API RP13C mesh testing kits.

- Warranties: 12-month material and manufacturing warranty; fast replacement assurance within 7–10 days.

- Major Clients: Sinopec, Schlumberger, Baker Hughes, Petrobras.

- Certifications: ISO 9001:2015, API RP13C, ANSI/NSF, FDA Material (upon request).

- Industry Recognition: Cited in Rigzone and JPT Society of Petroleum Engineers Journal.

- Technical Workshop: Quarterly webinars and on-site training for procurement/QA teams.

Selecting high-performance shaker screens impacts not just operational cost but also environmental compliance and wellsite safety. Industry-verified, API RP13C-certified screens deliver measurable advantages in fluid throughput, screen life, and solids rejection.

Whether for shale shakers for sale upgrades, legacy shaker fleets, or new site projects, Swaco Replacement Shale Shaker Screens remain a proven, reliable solution — supported by modern manufacturing and empirical field data.

SPE JPT: "Shaker Screen Selection for Solids Control" (2023)

ISO 9001 Technical Details: ISO Organization

Customer Case Studies: World Oil Magazine