The Strategic Importance of Advanced Shale Shaker Screens in Drilling Operations

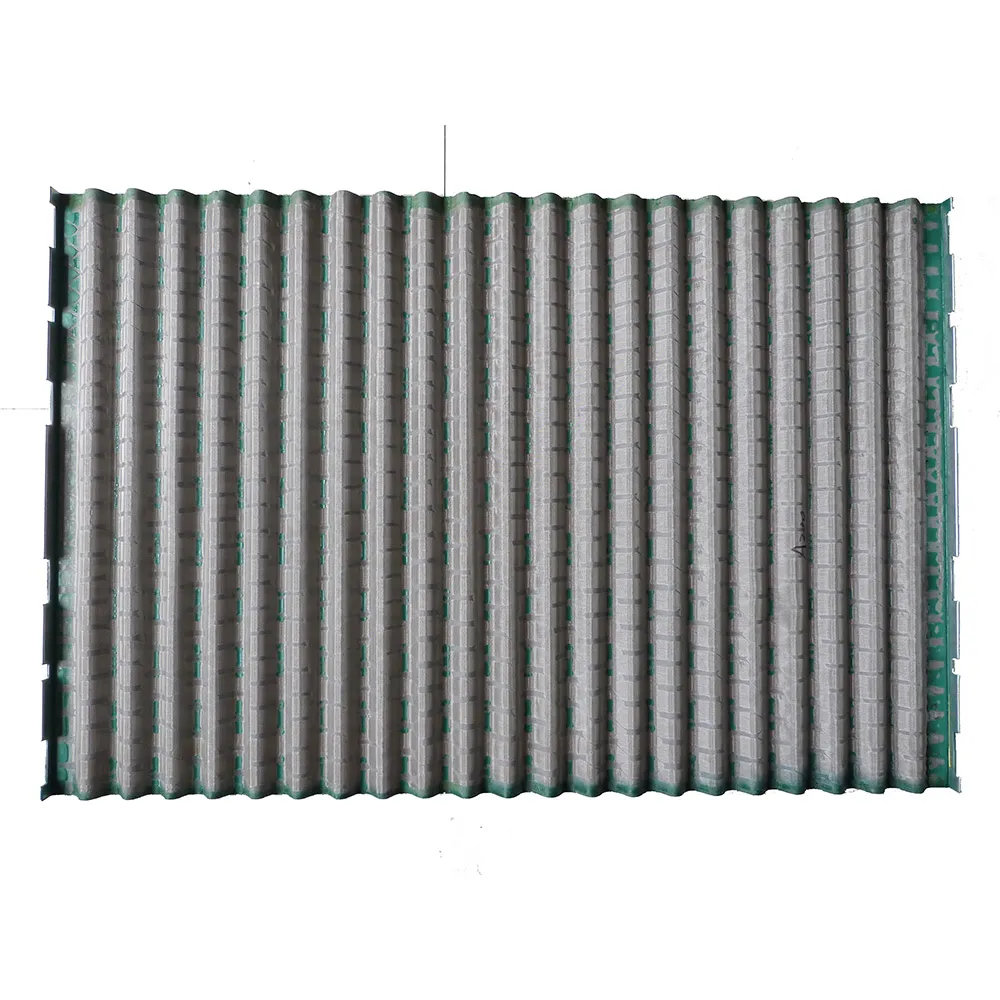

In the intricate world of oil and gas exploration and production, efficient solids control is not merely a technical necessity but a strategic imperative. It directly impacts drilling efficiency, environmental compliance, and operational profitability. For industry leaders and technical professionals tasked with optimizing drilling fluid management, sourcing a high-quality shale shaker screen for sale is a critical decision. These screens, such as the widely recognized Derrick PMD Replacement Shaker Screen, are the frontline defense against undesirable solids in drilling mud, preventing equipment wear, reducing fluid loss, and enhancing overall rig performance.

The market for solids control equipment is evolving rapidly, driven by stricter environmental regulations and the pursuit of greater drilling efficiency. Modern drilling operations demand shaker screens that offer superior separation capabilities, extended lifespan, and resilience against aggressive drilling fluids. As a dedicated swaco screens supplier, we understand these demands and provide solutions engineered to meet the highest industry standards. Our commitment ensures that when you choose to buy shaker screens from us, you are investing in proven technology that delivers tangible operational benefits and aligns with current industry trends towards sustainable and cost-effective drilling.

Precision Engineering: The Manufacturing Journey of a Shale Shaker Screen

The creation of a high-performance shale shaker screen for sale is a testament to precision manufacturing and material science. It begins with the careful selection of premium raw materials, typically high-grade stainless steel for the mesh and robust composite or steel alloys for the frame. The manufacturing process for screens like the Derrick PMD Replacement Shaker Screen is meticulously controlled to ensure each unit meets stringent performance criteria.

- Frame Construction: High-strength steel or composite materials are precisely cut, formed, and often welded or molded to create the screen frame. Modern techniques include CNC machining to achieve exact dimensions and tight tolerances, crucial for compatibility with various shaker models and for maintaining structural integrity under continuous vibration.

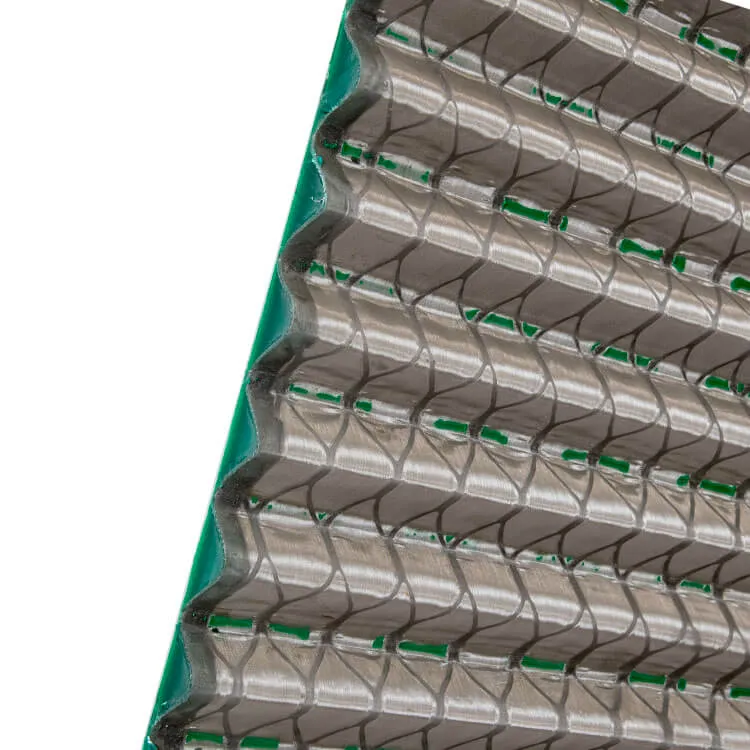

- Mesh Weaving and Layering: Multiple layers of stainless steel wire mesh, adhering to specific API RP 13C designations (e.g., API 100, API 200), are woven with controlled aperture sizes. These layers are then strategically stacked – typically with finer top layers for separation and coarser underlying layers for support and drainage, optimizing the effective screening area, often referred to as Non-Blanked Area (NBA).

- Advanced Bonding Technology: The layered mesh is meticulously bonded to the frame using high-strength polyurethane or epoxy resins. This bonding process is critical; it creates a durable, leak-proof seal, ensures mesh tautness, and prevents "blinding" or "mud bypass," which can severely compromise separation efficiency and screen lifespan.

- Rigorous Quality Assurance: Every industrial shaker screen undergoes comprehensive quality inspections. This includes visual checks, dimensional verification against ANSI standards, mesh integrity tests, and performance validation using advanced laboratory techniques. Adherence to ISO 9001 quality management systems is standard, ensuring consistent product excellence and reliability, contributing to a typical operational lifespan of 400-1000 hours depending on drilling conditions and mud properties.

These meticulously crafted screens are integral in various industries beyond oil & gas, including petrochemicals (refinery wastewater treatment), metallurgy (mineral slurry dewatering), and municipal wastewater treatment (solids separation), showcasing their versatility. Their inherent corrosion resistance, derived from high-grade stainless steel and robust bonding, offers significant advantages in chemically aggressive environments, contributing to energy savings by optimizing fluid flow and reducing pump energy consumption.

Decoding Performance: Key Technical Parameters of Shale Shaker Screens

For B2B buyers seeking to buy shaker screens, understanding the technical parameters is paramount to selecting the right product for specific operational needs. These parameters, defined by industry standards such as API RP 13C, directly influence a screen's efficiency and longevity. The performance of any given shaker screens depends on a precise balance of these specifications. Below is a detailed breakdown of critical parameters for a high-performance shale shaker screen for sale, exemplified by the capabilities of the Derrick PMD Replacement Shaker Screen.

| Parameter | Explanation and Significance | Typical Specifications (Derrick PMD Equivalent) |

|---|---|---|

| API Mesh Size | Determines the particle size separation capability, defined by the American Petroleum Institute Recommended Practice 13C. Higher numbers indicate finer separation and smaller solids removed. | Ranges from API 40 to API 325. Common choices include API 120 (125 micron) to API 230 (74 micron). |

| Non-Blanked Area (NBA) / Conductance | NBA is the percentage of open screening area. Higher NBA and Conductance (measured in kD/mm) equate to greater fluid processing capacity, reducing the number of screens required and minimizing fluid loss. | Typically 70% - 85% NBA, with Conductance values often exceeding 130 kD/mm. |

| D50 Cut Point | The particle size at which 50% of the solids are retained by the screen. A lower D50 indicates a finer separation capability, essential for maintaining superior drilling mud properties. | Between 65 to 110 microns, depending on the API mesh size. |

| Material Composition | Refers to the grade of stainless steel mesh (e.g., SS304, SS316) and the frame material (e.g., carbon steel, composite). High-grade materials ensure durability and corrosion resistance. | Premium SS304/SS316 woven mesh on reinforced steel composite frames with advanced polyurethane bonding. |

| Dimensions & Compatibility | Physical measurements of the screen (length, width, height) to ensure precise fit with specific shaker models (e.g., Derrick FLC series, M-I SWACO Mongoose). | Designed to be fully interchangeable with OEM Derrick PMD screens (e.g., 1250mm x 635mm, thickness 40mm). |

These technical attributes collectively optimize mud-recovery efficiency, reduce wear on downhole tools, and significantly impact overall drilling costs. Selecting screens with superior conductance and appropriate D50 cut points directly contributes to faster drilling rates and prolonged drilling fluid life, offering a compelling return on investment.

Broadening Horizons: Application Scenarios and Strategic Advantages

The versatility of high-performance shaker screens, including the Derrick PMD Replacement Shaker Screen, extends far beyond conventional drilling. Their ability to efficiently separate solids from liquids makes them indispensable across a variety of demanding industrial sectors.

- Oil & Gas Exploration & Production: The primary application involves processing drilling fluids to remove formation cuttings and recirculate clean mud. This is critical for maintaining mud properties, protecting downhole equipment from abrasive solids, and enhancing drilling penetration rates in diverse environments from onshore shale plays to offshore deepwater projects.

- Environmental Waste Management: These screens play a vital role in dewatering industrial waste slurries, rendering cuttings drier for easier and more economical disposal, and facilitating compliance with strict environmental regulations.

- Mining and Mineral Processing: In mineral beneficiation, industrial shaker screen units are used to classify particle sizes, separate desired minerals from waste materials, and dewater mineral concentrates, optimizing downstream processing.

- Wastewater Treatment: Municipal and industrial wastewater treatment plants utilize these screens for primary solids removal, reducing the load on subsequent treatment stages and improving overall effluent quality.

The strategic advantages derived from deploying superior shaker screens are multifaceted:

- Optimized Drilling Fluid Performance: Effective solids removal maintains the rheological properties of drilling mud, crucial for hole cleaning, wellbore stability, and reducing differential sticking risks.

- Reduced Operational Costs: By minimizing drilling fluid loss and extending the lifespan of costly drilling bits and pumps, these screens directly contribute to significant cost savings.

- Enhanced Environmental Compliance: Drier cuttings mean less hazardous waste volume, simplifying disposal procedures and reducing environmental footprints, aligning with global sustainability initiatives.

- Improved Safety: Fewer mud spills and cleaner work environments contribute to a safer operational setting for rig personnel.

Supplier Comparison and Tailored Solutions ( - Authority)

Navigating the market for a reliable shale shaker screen for sale requires careful consideration of supplier capabilities, not just product specifications. While numerous manufacturers offer shaker screens, their commitment to quality, engineering excellence, and customer-specific solutions can vary significantly. As a recognized swaco screens supplier, we differentiate ourselves through rigorous quality control, deep industry experience, and a flexible approach to client needs. Below is a comparison table highlighting key aspects that set leading suppliers apart when you aim to buy shaker screens.

| Feature/Metric | Typical Market Offering | Our Derrick PMD Replacement Screen Offer (Example) |

|---|---|---|

| Manufacturing Standards | Basic QC, variable adherence to API. | ISO 9001 certified processes, strict API RP 13C compliance with verifiable test reports. |

| Mesh Life & Durability | Standard lifespan, prone to premature tearing or blinding. | Enhanced bonding (e.g., polyurethane) and reinforced mesh design for extended service life, reducing replacement frequency by up to 25%. |

| Flow Performance | Moderate conductance, some mud bypass issues. | Optimized Non-Blanked Area (NBA) and flow conductance, minimizing mud loss and maximizing solids capture. |

| Customization & R&D | Limited or no custom options, standard products only. | Ability to engineer custom mesh sizes, frame configurations, and material compositions for specific drilling challenges. Active R&D into next-gen industrial shaker screen technologies. |

| Technical Support | Basic pre-sales support, limited post-sales. | Dedicated team of engineers and field experts providing comprehensive pre-sales consultation and robust post-sales technical assistance. |

Our company prides itself on decades of specialized experience in solids control, having served a global clientele with solutions that consistently deliver on performance and reliability. We not only provide a superior shale shaker screen for sale but also offer comprehensive custom solutions. This includes developing specialized mesh patterns for unique drilling fluid properties or designing custom frames for non-standard shaker models. Our engineering capabilities ensure that every client can procure shaker screens that precisely fit their operational parameters, guaranteeing optimal performance and maximum cost-efficiency.

Real-World Impact and Commitment to Excellence ( - Experience & Trustworthiness)

The true measure of a product's value is its performance in real-world scenarios and the trust it inspires. Our Derrick PMD Replacement Shaker Screens have been instrumental in numerous successful drilling projects globally. For instance, a notable client in the North Sea reported a substantial 20% reduction in screen consumption over a six-month period when using our screens compared to previous suppliers. This was directly attributable to the enhanced durability and superior mesh bonding of our shaker screens, translating into significant savings in replacement costs and operational downtime. Another client highlighted a tangible improvement in mud system cleanliness, leading to reduced chemical additive consumption and extended life for expensive drilling bits.

Our reputation as a reliable swaco screens supplier and provider of top-tier industrial shaker screen solutions is built on a foundation of transparent practices and unwavering quality. We rigorously adhere to international standards, including full compliance with API RP 13C and ISO 9001 certifications, ensuring every shale shaker screen for sale meets the highest benchmarks for performance and safety. Our commitment extends to providing verifiable test data, transparent product specifications, and unparalleled customer service, solidifying our role as a trusted partner in solids control technology. We empower our clients to make informed decisions and achieve optimal drilling efficiency with confidence.

Frequently Asked Questions (FAQ) - Building Trust

- Q: What is the typical delivery schedule for bulk orders of shale shaker screen for sale?

- A: For large volume orders of our Derrick PMD Replacement Shaker Screens, we typically maintain a lead time of 7-10 business days, depending on inventory levels and order size. Expedited manufacturing and shipping options are available upon request to meet urgent project timelines. We prioritize efficient logistics to minimize your downtime.

- Q: Do your shaker screens have specific storage requirements before use?

- A: To ensure optimal performance and longevity, we recommend storing shaker screens in a dry, temperate environment, away from direct sunlight and extreme temperatures. They should be stored flat, ideally in their original packaging, to prevent any deformation or damage to the mesh. Proper storage is key to preserving the integrity of the industrial shaker screen until deployment.

- Q: What is your warranty policy when I buy shaker screens from your company?

- A: We stand by the quality of our shaker screens with a robust 12-month limited warranty against manufacturing defects from the date of purchase. This warranty covers material and workmanship issues under normal operating conditions. Our goal is to ensure complete satisfaction and provide peace of mind for your investment.

- Q: How does your company provide technical support for screen selection and troubleshooting?

- A: Our dedicated technical support team, composed of experienced engineers, is available to provide expert guidance on screen selection, installation best practices, and troubleshooting any operational issues. We offer telephone support, email consultations, and can provide detailed technical documentation to ensure you maximize the performance of your shaker screens.

References

- American Petroleum Institute. (2010). API Recommended Practice 13C: Recommended Practice for Drilling Fluid Processing Systems Evaluation. 6th Edition. Washington D.C.: API Publishing Services.

- Bourgoyne, A. T., Millheim, K. K., Chenevert, M. E., & Young, F. S. (1991). Applied Drilling Engineering (SPE Textbook Series). Society of Petroleum Engineers.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements. Geneva, Switzerland: ISO.

- Kjærstad, J., & Dyrøy, F. (2014). Shale Shaker Performance Optimization in Water-Based Mud Systems. Journal of Petroleum Technology, 66(12), 108-115.