The Critical Role of shale shaker screen for sale in Modern Drilling Operations

In the demanding world of oil and gas exploration, efficient solids control is paramount to operational success, environmental compliance, and cost-effectiveness. The core of any robust solids control system lies within its shaker screens, specifically high-performance shale shaker screen for sale. These essential components are responsible for separating drilling fluids from drilled cuttings, ensuring the continuous recycling of valuable drilling mud while minimizing waste. The quality and performance of a shaker screen directly impact drilling efficiency, fluid loss, and overall project economics. As operators increasingly focus on optimizing their drilling programs, the demand for superior, reliable, and durable screens, such as the Derrick PMD Replacement Shaker Screen, has surged. Understanding the nuances of these critical filtration tools is key to making informed procurement decisions and achieving peak operational performance in challenging drilling environments globally.

The industry landscape for industrial shaker screen solutions is evolving rapidly, driven by technological advancements and more stringent environmental regulations. Modern drilling techniques, including horizontal drilling and hydraulic fracturing, necessitate screens capable of handling higher flow rates, finer solids separation, and prolonged operational life. Companies looking to buy shaker screens are not just seeking a commodity; they are investing in a critical technology that influences drilling speed, mud integrity, and ultimately, the profitability of their ventures. Whether it's for onshore or offshore applications, selecting the right screen type and ensuring its compatibility with existing shaker models, like Derrick FLC series or M-I SWACO shakers, is a strategic decision that pays dividends in reduced downtime and improved drilling performance. For example, screens compliant with API RP 13C standards offer verified performance metrics, which is crucial for maximizing the efficiency of your solids control equipment and minimizing operational expenditures.

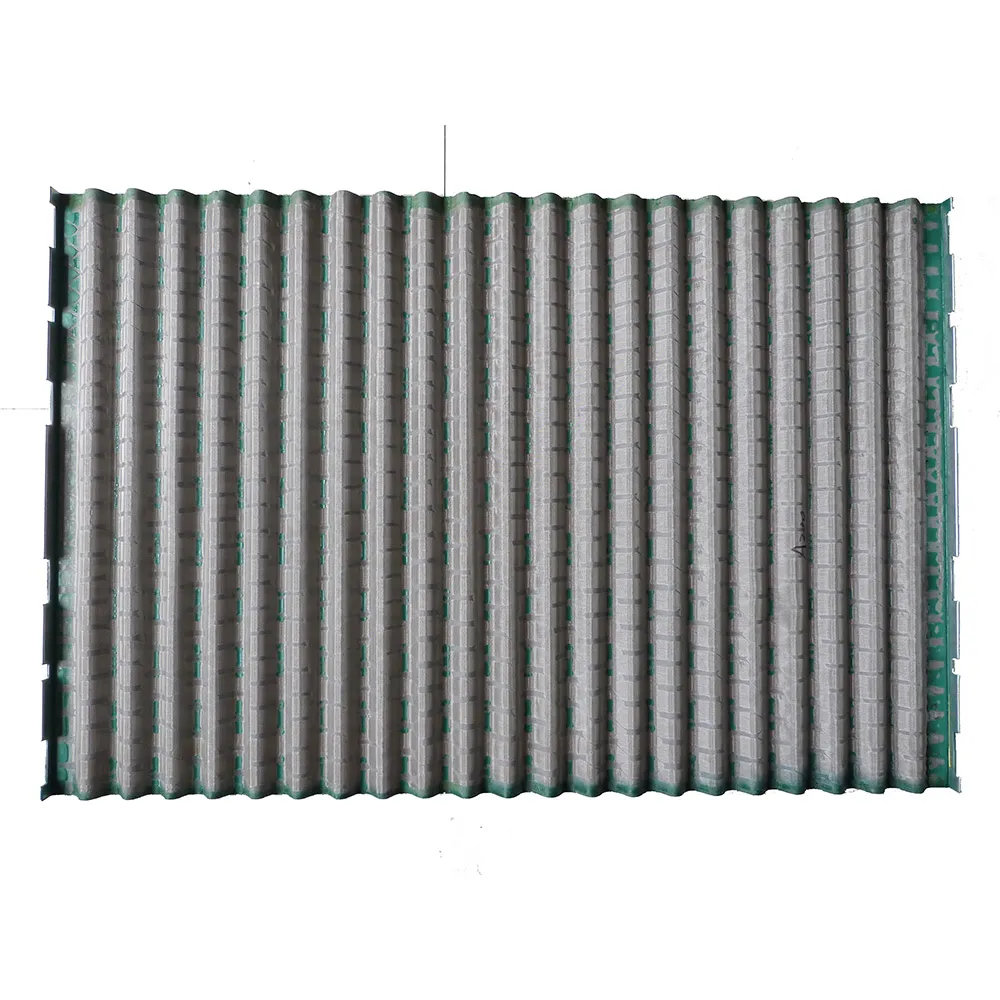

Craftsmanship Explained: The Manufacturing Journey of a Premium Shale Shaker Screen

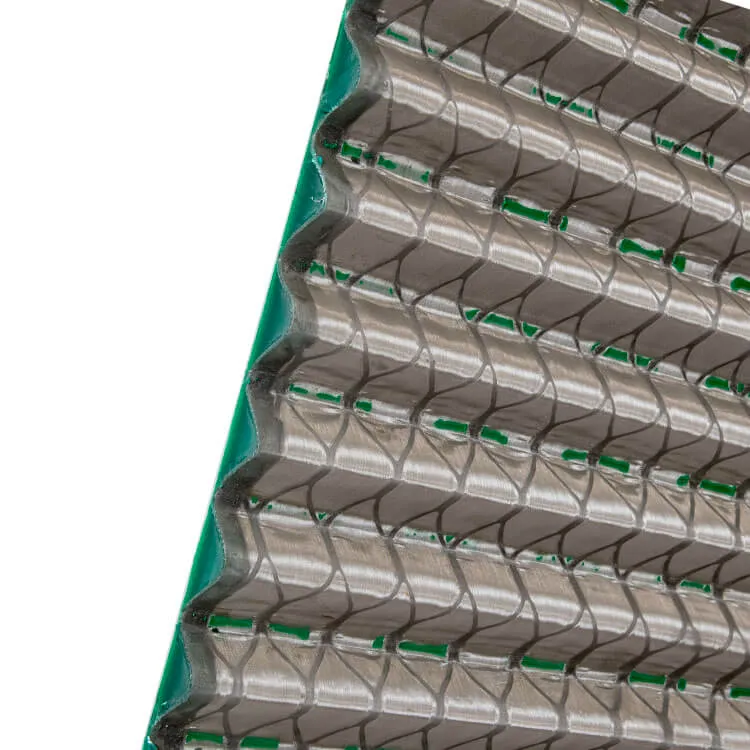

The journey of a high-quality shale shaker screen for sale, such as the Derrick PMD Replacement Shaker Screen, begins with meticulous material selection and culminates in a product engineered for extreme durability and performance. Typically, screens utilize high-grade stainless steel mesh (SS304 or SS316) for its exceptional corrosion resistance and mechanical strength. The manufacturing process often involves a combination of advanced techniques to achieve optimal filtration efficiency and longevity. This includes precision weaving of multi-layered mesh, followed by sophisticated bonding processes that attach the mesh to a robust steel or composite frame. Frame construction often involves technologies like injection molding or advanced welding techniques to ensure structural integrity under the high G-forces experienced during operation. Each step is designed to meet or exceed stringent industry standards, ensuring the final product can withstand the rigors of continuous drilling.

Critical manufacturing processes for a superior industrial shaker screen encompass several stages: first, material preparation, where stainless steel wire is drawn and precision-woven into multiple layers of mesh with specific opening sizes (measured in microns or API mesh numbers). Second, the multi-layer mesh panels are then bonded to a composite or steel frame using proprietary techniques, often involving advanced polyurethane or epoxy resins, ensuring excellent adhesion and resistance to drilling fluids. Finally, the frames themselves are either precision-welded from high-strength steel profiles or molded using advanced composite materials, offering superior vibration dampening and extended service life. The entire process is subject to rigorous quality control checks at every stage, from raw material inspection to final product verification. This includes tensile strength tests, mesh integrity checks, and precise dimensional measurements, ensuring compliance with international standards like ISO 9001 and API RP 13C. These stringent standards guarantee the screen's ability to withstand harsh operating conditions in industries such as petrochemical, mining, wastewater treatment, and especially oil and gas drilling, offering benefits like energy savings due to efficient fluid recovery and superior corrosion resistance due to material selection and advanced coatings.

The expected service life of a high-quality shaker screens can vary significantly based on the abrasive nature of the drilled cuttings, drilling fluid properties, and operational parameters. However, premium screens designed to API RP 13C standards, with their multi-layered design and durable frame construction, are engineered for extended use, often outperforming conventional screens by 20-30%. This longevity directly translates into reduced replacement costs, less downtime for screen changes, and improved operational efficiency, making them a wise investment for any drilling operation. Furthermore, the precise cut-point and high conductance of these screens contribute to reduced mud loss and improved solids removal efficiency, leading to significant economic advantages over the drilling campaign. Optimized designs minimize plugging, ensuring consistent performance over longer periods.

Technical Parameters & Performance Benchmarks for Shale Shaker Screen

Selecting the correct shale shaker screen for sale requires a deep understanding of its technical specifications. Key parameters dictate a screen's performance in terms of solids removal efficiency, fluid throughput, and overall durability. The API RP 13C standard is the globally recognized benchmark for evaluating shaker screen performance, defining mesh designation, non-blanked area, cut point (D100 separation), and conductance. For instance, a screen with a higher API mesh number will typically remove finer solids, while a greater non-blanked area indicates higher fluid handling capacity. These metrics are crucial for optimizing solids control systems for various drilling conditions, ensuring maximum recovery of drilling fluids and efficient disposal of solids.

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Screen Type | Pyramid (PMD) or Flat Screen Design | Pyramid (Increased Surface Area) |

| API RP 13C Designation | Mesh Size based on ISO 14688 standard | API 60 - API 400 (e.g., API 120) |

| D100 Separation Point (Microns) | Micron size where 100% of particles are retained | 125 - 40 microns (e.g., 74 microns for API 200) |

| Conductance (kL/m²/hr/kPa) | Fluid handling capacity per unit area | 15 - 50+ (Higher is better) |

| Non-Blanked Area (%) | Percentage of open area for fluid flow | 35% - 50% (Derrick PMD typically higher) |

| Material | Screen Mesh and Frame Material | SS304/SS316 Mesh, Steel/Composite Frame |

| Dimensions | Length x Width (e.g., for Derrick 500 series) | Approx. 1250mm x 635mm (varies by model) |

The D100 separation point, also known as the "cut point," is a crucial metric indicating the screen's efficiency in removing solids. A lower D100 value signifies finer solids removal, which is beneficial for maintaining drilling mud properties and reducing wear on downstream equipment. Conductance, on the other hand, reflects the screen's ability to process drilling fluid. A higher conductance value means more fluid can pass through the screen, preventing mud overflow and improving drilling rates. Advanced screen designs, like the pyramid (PMD) type common for Derrick shakers, enhance non-blanked area, thus increasing conductance and solids-handling capacity compared to conventional flat screens. This technical superiority is what distinguishes a premium shaker screens provider from competitors, offering a tangible return on investment through optimized mud management and reduced operational costs.

Application Scenarios and Technical Advantages of High-Performance Shale Shaker Screen for Sale

High-performance shale shaker screen for sale are indispensable across a multitude of industries, though their primary and most critical application remains in oil and gas drilling. Here, they are deployed on shale shakers – the first line of defense in solids control – to separate coarse drilled cuttings from the valuable drilling fluid (mud). This process is vital for mud conditioning, which involves maintaining optimal rheological properties, reducing fluid disposal costs, and preventing premature wear of drilling equipment. Beyond oil and gas, these screens find utility in applications requiring precise solid-liquid separation, such as mining (mineral processing), industrial wastewater treatment, and even specialized food processing, where their robust construction and filtration capabilities are highly valued for their efficiency and reliability.

The technical advantages of investing in premium industrial shaker screen solutions are multifaceted. Firstly, improved solids removal efficiency leads to cleaner drilling mud, which in turn enhances drilling performance by reducing torque and drag, minimizing bit wear, and preventing differential sticking. Secondly, a higher fluid conductance means the shakers can handle larger volumes of mud, increasing drilling rates and reducing non-productive time. Thirdly, extended screen life, particularly for specialized designs like the Derrick PMD Replacement Shaker Screen, significantly lowers operational costs by reducing the frequency of screen changes and associated labor. Furthermore, the precise cut-point capabilities of these screens contribute to reduced mud loss, as less valuable fluid is discarded with the cuttings. This not only offers substantial cost savings in mud chemicals but also aligns with environmental sustainability goals by minimizing waste generation and facilitating easier waste disposal. For example, a 15% reduction in mud volume due to better separation can translate to millions in savings over a complex drilling campaign.

In critical offshore drilling environments, the anti-corrosion properties of SS316 mesh become paramount, ensuring screens withstand harsh saltwater conditions and corrosive drilling fluids. Similarly, for applications involving highly abrasive formations, screens with enhanced wear resistance, often featuring thicker wire diameters or specialized bonding agents, offer extended durability and reduce the need for frequent replacements. The ability of a screen to maintain its integrity and filtration performance under high vibration and flow rates directly translates to operational stability and reduced risks of screen blinding or tearing. The comprehensive benefits, from energy conservation through efficient fluid recycling to superior corrosion resistance, underscore why investing in top-tier shaker screens is a strategic imperative for any discerning operator seeking to optimize their drilling program and minimize downtime.

Manufacturer Comparison: Choosing Your Trusted Shaker Screens Supplier

When seeking to buy shaker screens, prospective buyers are faced with a diverse market of manufacturers and suppliers. Renowned names like Derrick Corporation and M-I SWACO (now part of Schlumberger) have long dominated the industry, setting benchmarks for quality and innovation with their proprietary shaker designs and corresponding screens. However, a growing number of specialized manufacturers, including reputable swaco screens supplier and independent producers of replacement screens, offer compelling alternatives. The choice often boils down to a balance of brand reputation, product performance, cost-effectiveness, and the availability of responsive customer support and technical expertise. Understanding the distinct offerings and philosophies of these manufacturers is key to making an informed decision for your specific operational needs, ensuring compatibility and optimal performance with your existing equipment fleet.

| Feature/Supplier Type | OEMs (e.g., Derrick, M-I SWACO) | Specialized Replacement Shale Shaker Screen for Sale Suppliers (e.g., Solid Control Part) |

|---|---|---|

| Product Range | Full range of shakers & screens; proprietary designs. | Focus on high-quality replacement screens compatible with major OEM shakers (e.g., Derrick PMD, SWACO Mongoose). |

| Innovation & R&D | Pioneers in screen technology, often set industry standards. | Focus on reverse engineering improvements, cost-effectiveness, and specialized solutions while adhering to API RP 13C. |

| Cost-Effectiveness | Premium pricing, often justified by brand and proprietary tech. | More competitive pricing, offering significant savings without compromising performance. Studies show up to 30% cost reduction. |

| Customization | Limited, generally standard product lines. | Often more flexible for specific material or mesh configurations for unique drilling challenges. |

| Lead Times | Can vary based on demand and global supply chains. | Often shorter, more agile supply chains due to dedicated manufacturing. |

| Certifications | Full range of industry and quality certifications. | Often hold ISO certifications (e.g., ISO 9001) and adhere to API RP 13C standards, ensuring quality parity. |

While OEMs like Derrick provide screens specifically engineered for their own shakers (e.g., the Derrick 500 series requiring the Derrick PMD Replacement Shaker Screen), specialized suppliers often excel in providing high-quality, fully compatible alternatives. These alternatives are designed to meet or even exceed OEM specifications in terms of API RP 13C compliance, D100 cut-point accuracy, and service life, all while offering a more attractive cost proposition. Many specialized suppliers, including those acting as a reliable swaco screens supplier for Mongoose or ALS models, emphasize their commitment to rigorous quality control, adherence to ISO 9001 standards, and extensive testing to ensure their products perform optimally in real-world drilling conditions. This ensures that operators can maintain the efficiency of their existing shaker fleet without being locked into a single supplier for consumables, providing crucial operational flexibility.

Tailored Solutions: Customization and Why to Buy Shaker Screens from Specialists

Recognizing that no two drilling operations are identical, the ability to offer customized solutions for shale shaker screen for sale is a significant advantage. While standard screen sizes and mesh configurations cater to most needs, specific drilling conditions – such as highly reactive shales, ultra-deep formations, or unconventional plays – may require screens with tailored characteristics. This could involve variations in mesh layers, wire diameter, frame materials, or even unique bonding agents to enhance resistance against specific chemicals or abrasive solids. Specialist manufacturers often possess the agility and technical expertise to develop and produce these bespoke screens, optimizing performance for highly specific operational challenges where standard off-the-shelf products might fall short, providing a true competitive edge in complex drilling environments.

Engaging with a specialized supplier when you buy shaker screens offers several benefits beyond mere cost savings. Firstly, direct access to engineering teams allows for collaborative problem-solving and the development of screens precisely calibrated for challenging formations or drilling fluids. For example, if an operator is experiencing excessive blinding or premature wear with standard screens, a specialist can recommend or design a screen with an optimized API mesh size or a different weave pattern to mitigate these issues. Secondly, these suppliers often maintain comprehensive inventories for popular models like the Derrick PMD Replacement Shaker Screen, ensuring rapid dispatch and minimizing lead times, which is crucial for maintaining continuous drilling operations. This level of responsiveness and deep product knowledge is often a hallmark of dedicated industrial shaker screen providers who prioritize client-specific solutions and support.

Furthermore, specialist suppliers frequently provide dedicated technical support, assisting operators with screen selection, installation guidance, troubleshooting, and any operational queries, ensuring you extract maximum value from our shaker screens. Their focus on a core product line, like shaker screens, enables them to accumulate significant practical experience and offer highly relevant advice. This comprehensive service approach, combined with a commitment to quality and adherence to industry standards like ISO 9001, ensures that operators receive not just a product, but a complete solution designed to enhance their drilling efficiency and reduce overall operational expenditure. This consultative approach fosters long-term partnerships built on trust and mutual success, critical in the high-stakes drilling industry.

Real-World Application: Case Studies with Shale Shaker Screen Performance

The true measure of a shale shaker screen for sale's performance lies in its real-world application and demonstrable impact on drilling operations. Consider a drilling project in the Permian Basin, where an operator faced significant challenges with high fluid loss and rapid screen wear due to abrasive cuttings from deep shale formations. After consulting with a specialized supplier, they transitioned from conventional flat screens to Derrick PMD Replacement Shaker Screens with an optimized mesh configuration. The result was a remarkable 25% reduction in drilling fluid consumption, an increase in average screen life by 35%, and a measurable improvement in ROP (Rate of Penetration) due to better mud conditioning. This case highlights how selecting the right screen can directly translate into tangible cost savings and operational efficiencies, validating the investment in high-quality industrial shaker screen products and demonstrating the expertise of the supplier.

Another compelling example comes from an offshore exploration well in the North Sea. Here, the challenge was handling high volumes of challenging drilling fluid containing a mix of fine and coarse solids, exacerbated by the need for strict environmental discharge regulations. A major swaco screens supplier recommended a specific multi-layer composite screen for their M-I SWACO shakers, designed for both high flow capacity and superior fine solids removal. Post-implementation, the operator reported a 15% improvement in solids removal efficiency, allowing them to meet discharge limits more consistently and reducing the volume of waste requiring disposal by 10%. Furthermore, the robust construction of these screens minimized downtime associated with screen changes, contributing to a smoother, more continuous drilling operation with fewer interruptions. These cases underscore the significant value proposition offered by meticulously engineered and appropriately applied shaker screens, proving their reliability and effectiveness in diverse, demanding environments.

These successes are not isolated incidents but rather reflective of a broader trend where operators are recognizing the strategic importance of high-performance solids control equipment. By investing in premium screens and collaborating with knowledgeable suppliers, drilling companies are able to tackle increasingly complex geological challenges while simultaneously improving their environmental footprint and economic viability. The detailed analysis of such application cases provides valuable insights into optimizing screen selection and utilization, ensuring that every decision to buy shaker screens is backed by performance and reliability, ultimately contributing to a more sustainable and profitable drilling industry. This commitment to proven results builds invaluable trust with clients worldwide.

Frequently Asked Questions (FAQ) about Shale Shaker Screen for Sale

Q1: What is the API RP 13C standard and why is it important for shaker screens?

A1: API RP 13C (Recommended Practice for Shaker Screen Designation) is a global standard for evaluating and designating the performance of shale shaker screen for sale. It provides a consistent method for measuring key parameters like mesh designation, D100 separation point (cut point), and conductance. Adherence to this standard ensures transparency and comparability between different screens and manufacturers, allowing operators to accurately predict screen performance and make informed purchasing decisions. It's crucial for ensuring you buy shaker screens that meet verified performance criteria, significantly reducing guesswork and improving operational efficiency.

Q2: How do I choose the correct mesh size for my drilling operation?

A2: Choosing the correct mesh size for your shale shaker screen for sale depends on several factors, including the type of drilling fluid (e.g., water-based, oil-based), the geological formation being drilled (e.g., soft clay, hard shale), desired solids removal efficiency, and drilling rate. Generally, coarser screens (lower API mesh number) are used first in the shaker cascade to remove larger cuttings, followed by finer screens (higher API mesh number) for smaller solids and to prepare the mud for downstream equipment like centrifuges. Your mud engineer and solids control specialist can provide specific recommendations based on real-time drilling conditions and the performance goals for your industrial shaker screen system, ensuring optimal mud recovery and solids disposal.

Q3: What are the benefits of composite frame shaker screens compared to steel frame screens?

A3: Composite frame shaker screens, like many Derrick PMD Replacement Shaker Screens, offer several advantages over traditional steel frame screens. They are typically lighter, which simplifies handling, reduces installation time, and lowers shipping costs. Their composite material often provides superior vibration dampening, leading to reduced noise levels on the rig floor and extended screen life by mitigating metal fatigue. Additionally, composite frames are generally more resistant to corrosion and chemical attack from aggressive drilling fluids, further enhancing their durability and operational lifespan in comparison to some conventional steel-framed shaker screens. This translates to fewer replacements and more consistent performance, a key consideration for long-term drilling projects.

Our Commitment: Delivery, Quality Assurance, and Customer Support

At Solid Control Part, our commitment extends beyond merely offering shale shaker screen for sale; we provide a complete partnership focused on operational excellence. Our streamlined manufacturing and logistics ensure competitive delivery cycles, often within 7-14 business days for standard orders and expedited options for urgent requirements. We understand that timely delivery of essential components like the Derrick PMD Replacement Shaker Screen is critical to maintaining uninterrupted drilling operations. Our global distribution network is designed to get the right screens to your rig, precisely when and where you need them, minimizing costly downtime and ensuring seamless progress on your projects.

Quality assurance is the cornerstone of our operations. Every industrial shaker screen undergoes a stringent multi-point inspection process, adhering to ISO 9001 certified quality management systems and strictly complying with API RP 13C standards. This meticulous approach guarantees consistency and superior performance across our product range. Our products are backed by a comprehensive 12-month warranty against manufacturing defects, underscoring our confidence in their durability and performance. This commitment to quality ensures that when you buy shaker screens from us, you are investing in reliability and peace of mind. Our experienced technical support team is available around the clock to assist with screen selection, installation guidance, troubleshooting, and any operational queries, ensuring you extract maximum value from our shaker screens. Whether you need a specific Derrick PMD Replacement Shaker Screen or are looking for a reliable swaco screens supplier, our experts are ready to provide tailored solutions and unparalleled service, solidifying our position as a trusted partner in solids control.

Conclusion

The performance of a shale shaker screen for sale is a critical determinant of drilling efficiency, mud integrity, and overall project profitability in the oil and gas industry. By understanding the intricacies of their manufacturing, technical parameters, diverse application scenarios, and the strategic advantages offered by specialized suppliers, operators can make informed decisions that translate into significant operational benefits. Investing in high-quality screens like the Derrick PMD Replacement Shaker Screen ensures not only superior solids control and extended service life but also contributes to reduced environmental impact and enhanced economic viability of drilling operations. As the industry continues to push boundaries in complex drilling environments, the role of advanced industrial shaker screen technology will only grow in importance, making strategic procurement a cornerstone of successful and sustainable drilling campaigns. Trust in expertise, verifiable data, and dedicated support for your essential solids control needs.

References

- American Petroleum Institute. API Recommended Practice 13C: Recommended Practice for Shaker Screen Designation.

- International Organization for Standardization. ISO 9001: Quality management systems – Requirements.

- Derrick Corporation. Official website and product specifications.

- Schlumberger (M-I SWACO). Official website and solids control publications.

- Journal of Petroleum Technology (JPT). Various technical articles on solids control and drilling fluids.