Navigating the complexities of drilling operations demands precision in every component. Discover how top-tier shale shaker screen for sale solutions are revolutionizing solid control, optimizing efficiency, and enhancing drilling performance worldwide.

The Indispensable Role of **Shale Shaker Screen for Sale** in Modern Drilling Efficiency

In the high-stakes environment of oil and gas exploration, efficient solids control is paramount to operational success, environmental compliance, and cost-effectiveness. The shale shaker screen for sale stands as the cornerstone of any drilling fluid solids control system. It is the primary mechanical barrier, responsible for separating drilled cuttings from the valuable drilling fluid (mud) before it can be recirculated. As drilling operations become increasingly complex—extending to deeper formations, unconventional reservoirs, and challenging offshore environments—the demand for high-performance, durable, and reliable shaker screens has intensified significantly. This comprehensive guide will illuminate the crucial aspects of selecting, understanding, and leveraging the right shale shaker screen for sale to optimize your drilling program, from industry trends and technical deep dives to manufacturing excellence and real-world application.

Current Industry Trends Driving Shaker Screen Innovation

The global energy landscape is continuously evolving, imposing new demands and fostering innovation within the solid control sector. Several key trends are directly impacting the design, performance, and market for shale shaker screen for sale:

- Unconventional Resource Development: The proliferation of horizontal drilling and hydraulic fracturing for shale gas and tight oil has led to increased generation of fine, sticky solids. This necessitates screens with superior blinding resistance, higher conductance, and finer cut points to maintain mud properties and reduce waste.

- Environmental Stewardship and Regulatory Compliance: Global regulations are becoming more stringent regarding drilling waste management. This drives the need for screens that offer higher solids removal efficiency, minimizing waste volume and facilitating easier, more cost-effective disposal, aligning with the industry's push for a reduced environmental footprint.

- Focus on Drilling Efficiency and Cost Reduction: Operators are under constant pressure to lower non-productive time (NPT) and optimize total drilling costs. Utilizing premium industrial shaker screen can significantly extend screen life, reduce screen consumption, minimize drilling fluid loss, and improve drilling rates, directly impacting the bottom line.

- Digitalization and Automation: While not directly impacting the screen itself, the rise of smart drilling technologies and real-time data analysis requires consistent and predictable performance from all components, including shaker screens, to enable optimized automated processes.

- Advancements in Material Science: Continuous research in materials, particularly in high-strength stainless steel alloys and composite polymers, allows for the development of lighter, more durable, and more efficient screen frames and mesh panels.

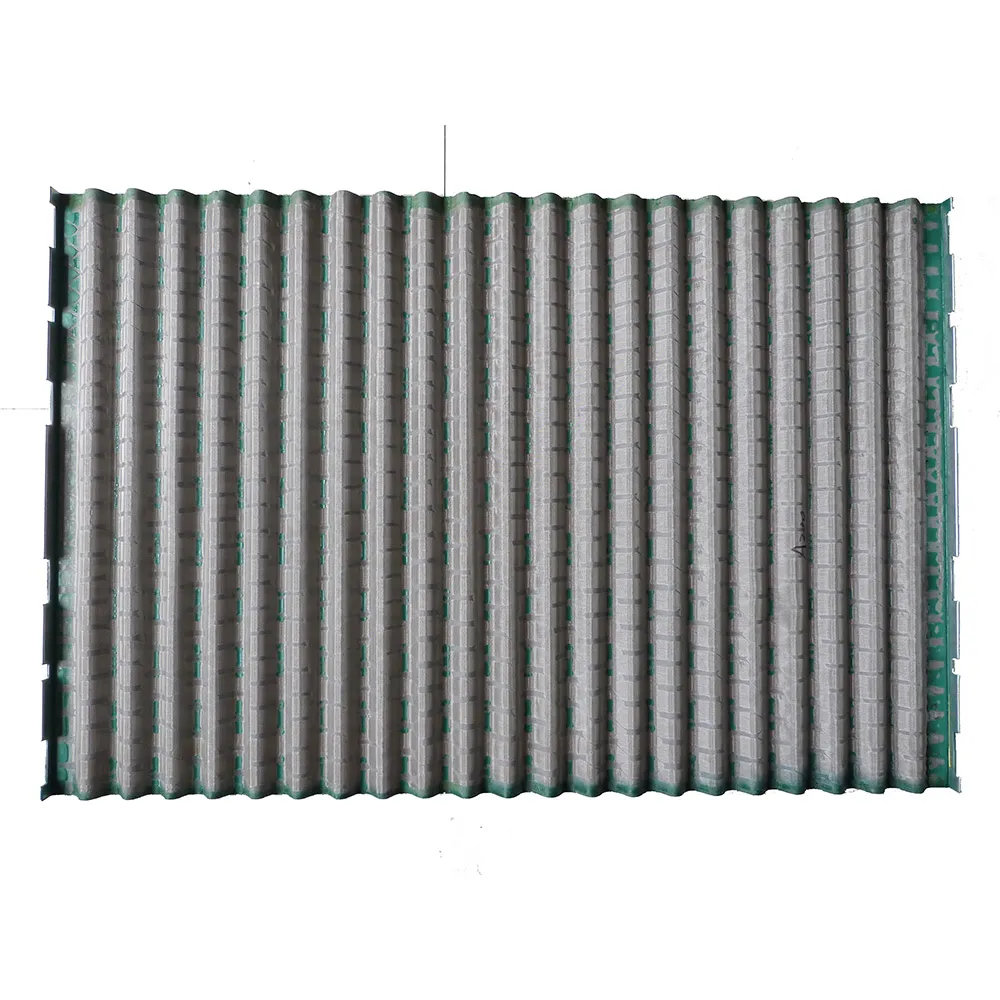

Figure 1: An advanced shale shaker screen for sale featuring a composite frame, optimized for durability and high performance in demanding drilling environments.

Introducing the Derrick PMD Replacement Shaker Screen: Engineered for Excellence

For operators utilizing Derrick FLC 500 series shale shakers, the Derrick PMD Replacement Shaker Screen offers an unparalleled combination of performance, durability, and cost-efficiency. Designed to be a direct and superior replacement, it ensures your solid control system operates at peak effectiveness, maximizing drilling fluid recovery and minimizing waste.

Technical Parameters and Performance Specifications

Understanding the intricate technical parameters of any shale shaker screen for sale is vital for informed decision-making. The Derrick PMD Replacement Shaker Screen is meticulously engineered to meet and exceed industry benchmarks, particularly in the demanding context of modern drilling.

- API RP 13C Compliance: Our screens rigorously adhere to the American Petroleum Institute Recommended Practice 13C. This critical standard provides a universal system for classifying and labeling shaker screens based on their sieve analysis (D100/D50 cut points) and non-blanked screen area (conductance). This compliance ensures you receive a product with verifiable performance characteristics, enabling precise selection for specific drilling fluid needs.

- Premium Mesh Material: We exclusively utilize high-grade Stainless Steel 304 or SS316 wire mesh. SS304 offers excellent corrosion resistance and strength, while SS316 provides superior resistance to chlorides and other aggressive chemicals commonly found in drilling fluids, significantly extending the screen's operational life even in harsh environments.

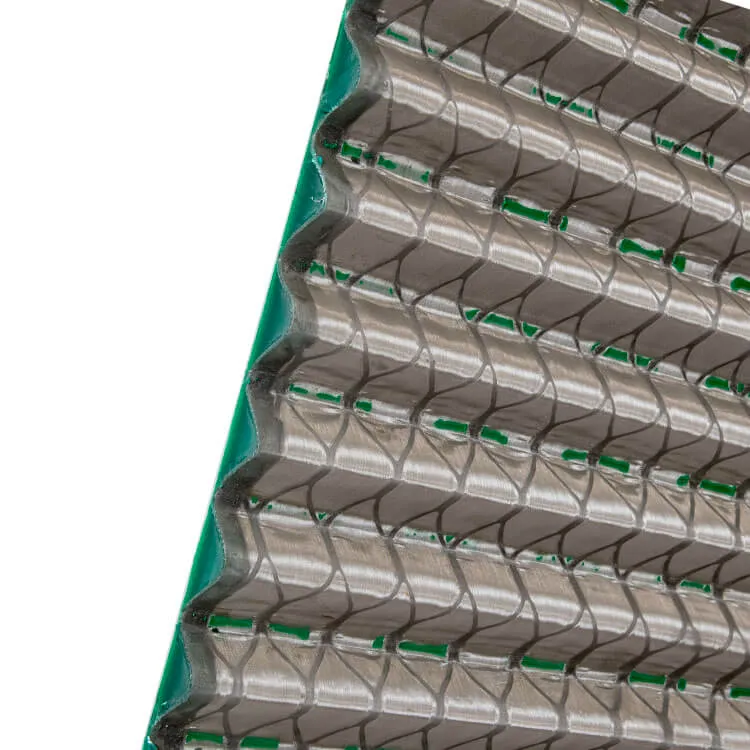

- Optimized Multilayer Design: The Derrick PMD Replacement Shaker Screen incorporates a sophisticated multi-layer design, typically comprising three to four layers. The top layer (or working layer) is a fine mesh responsible for precise particle separation, while underlying coarser layers provide robust support, ensuring the screen's structural integrity and preventing premature wear or tearing under high G-forces and heavy solids loads. This design maximizes effective screening area and fluid throughput while maintaining critical separation efficiency.

- Advanced Composite Frame Technology: Unlike traditional steel frames, our screens often feature high-strength composite frames. These frames are engineered from specialized polymers reinforced with glass fibers, offering significant advantages such as lighter weight, superior corrosion resistance, enhanced vibration dampening, and improved sealing capabilities. This contributes to longer screen life, reduced operational noise, and easier handling.

- High Conductance (Fluid Throughput): Conductance is a measure of a screen's capacity to allow drilling fluid to pass through. Our screens are designed for high conductance, meaning they can process a larger volume of drilling fluid more efficiently. This minimizes mud losses over the weir, maintains stable mud levels, and allows for higher drilling rates without compromising solid removal.

- Sharp D50 Cut Point: The D50 cut point represents the particle size at which 50% of the particles are retained on the screen. A sharp D50 cut point indicates efficient and precise separation, ensuring the removal of undesirable fine solids that can otherwise degrade drilling fluid properties, increase fluid costs, and lead to downhole issues.

Derrick PMD Replacement Shaker Screen: Key Technical Specifications

| Parameter | Specification Range / Typical Value | Direct Operational Benefit |

|---|---|---|

| Product Name | Derrick PMD Replacement Shaker Screen | Guaranteed compatibility and seamless integration with Derrick FLC 500 series shakers. |

| Compatibility | Derrick FLC 500 series (PMD, PWP, etc.) | Ensures perfect fit and optimal performance in existing shaker units. |

| Mesh Material | High-tensile SS304 / SS316 Wire Cloth | Exceptional corrosion resistance, durability, and resistance to abrasion in diverse mud systems. |

| Frame Material | Proprietary High-Strength Composite | Lightweight, superior vibration dampening, increased lifespan, and reduced operator fatigue during handling. |

| Layer Configuration | 3-4 Layer Patented Design | Maximizes effective screening area, ensures sharp cut points, and provides robust structural support. |

| API RP 13C Compliance | Fully Compliant & Labeled | Verifiable performance metrics, allowing for precise selection and predictable results. |

| Conductance Range | Varies by API mesh size (e.g., API 100 typically 5-8 kD/mm) | Enables high fluid throughput, preventing mud overflow and supporting high ROP. |

| D50 Cut Point | Varies by API mesh size (e.g., API 100 often 100-120 µm) | Efficient removal of undesirable fine solids, maintaining optimal mud properties. |

| Sealing Gasket | Integrated Urethane or High-Grade Rubber | Ensures zero bypass, preventing valuable drilling fluid from escaping around the screen. |

| Typical Lifespan | Designed for Extended Use (200-500+ operating hours under optimal conditions) | Reduced screen consumption, lower replacement costs, and minimized downtime. |

| Operating Temperature | -20°C to +80°C (-4°F to +176°F) | Reliable performance across a broad range of drilling environments and climates. |

Figure 2: A view of the robust construction and precise mesh weave, illustrating why this is the ideal choice when you need to buy shaker screens for reliable performance.

The Rigorous Manufacturing Process of a High-Performance **Shale Shaker Screen for Sale**

The superior performance and longevity of our Derrick PMD Replacement Shaker Screen are a direct result of a meticulously controlled and technologically advanced manufacturing process. Every step, from raw material selection to final inspection, adheres to the highest standards, ensuring unparalleled product quality. While the exact proprietary details remain confidential, the general workflow and critical quality checkpoints are as follows:

Detailed Manufacturing Process Flow (Illustrative):

Manufacturing a premium **shaker screen** is a symphony of precision engineering and material science, encompassing several critical stages:

- Raw Material Procurement and Inspection:

- High-Grade Stainless Steel Wire: We source only certified SS304 or SS316 wire, selected for its specific tensile strength, corrosion resistance, and ductility. Each batch undergoes rigorous material composition analysis.

- Polymer Composites: For composite frames, high-performance, engineering-grade polymer resins are procured, along with specialized reinforcing fibers (e.g., glass fibers) that lend exceptional strength and rigidity.

- Precision Mesh Weaving or Sintering:

- Advanced Weaving: Utilizing state-of-the-art weaving looms, the stainless steel wires are intricately woven into specific mesh patterns (e.g., square, rectangular, corrugated) for each layer. This is a highly precise operation, as the accuracy of mesh opening and wire diameter directly determines the screen's API mesh size, conductance, and cut point.

- Sintering (for specialized meshes): For certain advanced designs, multiple layers of woven mesh might undergo a sintering process. This involves heat and pressure to molecularly bond the layers together, creating a unified, robust panel that resists delamination, enhances flow, and improves blinding resistance.

- Frame Fabrication (Composite or Steel):

- Composite Frame Molding: For composite screens, the frame is typically manufactured using advanced injection molding or compression molding techniques. Precision molds ensure exact dimensional accuracy, integrated sealing features, and optimal structural integrity. The composite material is chosen for its lightweight, anti-corrosive, and vibration-dampening properties.

- Steel Frame Welding (for specific models): For steel-framed screens, high-precision laser cutting or CNC machining shapes the steel components, followed by robotic or skilled manual welding to form a robust, distortion-free frame structure. Post-welding, stress-relieving and surface treatment processes are often applied to enhance durability and corrosion resistance.

- Mesh Panel Cutting and Tensioning:

- The woven or sintered mesh panels are precisely cut to size using automated laser cutters or specialized dies, ensuring perfect fit within the screen frame.

- Crucially, the mesh layers are then tensioned uniformly across the frame. Proper tensioning is vital to prevent sagging, ensure consistent performance, and extend screen life under dynamic shaker vibration.

- Advanced Bonding Technology:

- This is perhaps the most critical stage. The tensioned mesh panels are securely bonded to the screen frame using proprietary, high-strength adhesive systems (e.g., advanced epoxy resins or polyurethane compounds). This bonding process creates a robust, leak-proof seal that prevents fluid bypass and delamination, even under extreme vibration and temperature fluctuations. The bonding agents are carefully selected for their chemical resistance to drilling fluids and their long-term adhesion properties.

- Gasket/Sealing Element Integration:

- A durable, chemical-resistant rubber or urethane gasket is either molded directly onto the composite frame or precisely attached to the steel frame's perimeter. This gasket ensures a tight seal when the screen is installed onto the shaker deck, preventing valuable drilling fluid from bypassing the screen and ensuring maximum separation efficiency.

- Rigorous Quality Control and Testing:

- Visual Inspection: Every screen undergoes a thorough visual inspection for any surface defects, bonding inconsistencies, or mesh damage.

- Dimensional Verification: Automated optical or manual gauges confirm that each screen meets the precise OEM dimensions for perfect fit and interchangeability.

- API RP 13C Performance Testing: Representative samples from each production batch are subjected to standardized API RP 13C tests for conductance (flow rate) and D100/D50 cut points, utilizing specialized equipment to verify performance against published specifications.

- Vibration and Durability Tests: Screens may undergo accelerated vibration testing to simulate operational conditions and assess long-term durability and resistance to fatigue.

- Adhesion Strength Tests: Destructive or non-destructive tests may be performed on samples to verify the strength and integrity of the mesh-to-frame bond.

- Packaging and Logistics:

- Once certified, screens are carefully packaged in protective materials and robust crating to prevent damage during transport, ensuring they arrive at the drilling site in pristine condition.

This comprehensive manufacturing approach, integrating advanced materials, precision processes, and stringent quality control, guarantees that our Derrick PMD Replacement Shaker Screen consistently delivers superior performance, extended operational life, and exceptional value.

Adherence to Detection Standards and Certifications

As a leading swaco screens supplier and provider of high-quality **shale shaker screen for sale**, our commitment to quality is validated by adherence to stringent international standards and internal protocols:

- ISO 9001:2015 Certification: Our manufacturing facilities operate under an ISO 9001:2015 certified Quality Management System. This globally recognized standard ensures consistent quality, continuous improvement, and customer satisfaction throughout all stages of design, development, production, and service.

- API RP 13C Compliance and Labeling: Every relevant **shale shaker screen for sale** is manufactured, tested, and labeled in strict compliance with API RP 13C guidelines. This provides transparent and verifiable performance data, enabling operators to make confident decisions.

- ANSI Standards: While API RP 13C is specific to shaker screens, our manufacturing processes and material specifications align with broader ANSI (American National Standards Institute) standards where applicable, ensuring robust engineering practices.

- In-House QA/QC Protocols: Beyond external certifications, we implement multi-stage internal Quality Assurance and Quality Control (QA/QC) checks at every critical junction of the manufacturing process, from raw material incoming inspection to final product audit.

Applicable Industries and Advantages in Diverse Scenarios

While fundamentally designed for the oil and gas sector, the robust capabilities of high-quality shale shaker screen for sale extend their utility across various industrial applications requiring efficient solid-liquid separation:

- Oil & Gas Drilling (Onshore & Offshore): This remains the primary application. Our screens are essential for maintaining optimal drilling fluid properties, minimizing mud loss, and ensuring efficient removal of drilled solids to prevent downhole problems, enhance ROP, and reduce overall drilling costs.

- Horizontal Directional Drilling (HDD): In trenchless technology, HDD operations generate significant volumes of cuttings. Our screens effectively clean the drilling fluid for recirculation, crucial for bore stability and environmental compliance in urban and sensitive areas.

- Mining & Mineral Processing: Utilized for dewatering and classification of slurries in mineral extraction, enabling efficient separation of valuable minerals from waste and optimizing recovery rates.

- Water Well Drilling: For the effective cleaning and recycling of drilling fluids in potable and industrial water well projects.

- Industrial Wastewater Treatment: In certain industrial processes, these screens can be adapted for primary solid separation from wastewater streams, aiding in preliminary purification and sludge volume reduction.

In typical application scenarios, the advantages of using our Derrick PMD Replacement Shaker Screen are clear:

- Enhanced Drilling Fluid Recovery: Superior separation efficiency means more valuable drilling fluid is recovered and recirculated, significantly reducing mud costs.

- Reduced Waste Volume: Finer cut points lead to more concentrated solids, translating to smaller volumes of waste requiring disposal, lowering environmental compliance costs.

- Extended Screen Lifespan: High-grade materials and robust construction ensure screens withstand abrasive conditions longer, reducing replacement frequency and associated NPT.

- Improved Rate of Penetration (ROP): Cleaner drilling fluid circulates more efficiently, reducing drag and wear on bits and downhole tools, enabling faster and more effective drilling.

- Lower Operational Costs: A combination of extended screen life, reduced mud consumption, and minimized NPT contributes to substantial overall cost savings for drilling operations.

Strategic Selection: Technical Advantages and Manufacturer Comparison for Your **Shale Shaker Screen for Sale**

The market offers numerous options when you want to buy shaker screens. However, not all screens, nor all suppliers, are created equal. A truly reliable partner in solid control, such as a reputable swaco screens supplier or replacement screen specialist, distinguishes itself through a blend of technical superiority, unwavering quality, and dedicated customer support. Our approach is built upon these foundational pillars, offering distinct advantages.

Our Core Technical Advantages

Our commitment to delivering superior Derrick PMD Replacement Shaker Screen is reflected in several key technical differentiators:

- Proprietary Composite Frame Design: Our advanced composite frames are not merely replacements; they are engineered with improved flexibility, enhanced resistance to harsh drilling chemicals, and superior vibration dampening properties, which extend the life of both the screen and the shaker itself. This often surpasses OEM performance in specific applications.

- Precision Woven Mesh and Optimal Tensioning: We employ advanced weaving technologies to produce highly consistent mesh openings, crucial for precise separation. The mesh is bonded to the frame under specific tension, preventing premature sagging and ensuring uniform fluid distribution across the screen surface, which is vital for high conductance and sharp cut points.

- High-Conductance, Anti-Blinding Design: Our multi-layer screen configurations are engineered to maximize the open area (conductance) while minimizing the potential for blinding (clogging). This ensures consistent fluid processing capacity even with high solids content, reducing the need for frequent screen changes.

- Rigorous Material Testing: Beyond standard certifications, we conduct in-house material testing, including metallurgical analysis of stainless steel wire and mechanical property tests of composite materials, to ensure they withstand the extreme stresses of drilling environments.

- Application-Specific Optimization: Our technical team possesses deep knowledge of various drilling fluid systems (WBM, OBM, SBM) and geological formations. This expertise allows us to recommend and, if necessary, develop screens optimized for your specific drilling challenges.

Manufacturer Comparison: Why Choose Us to **Buy Shaker Screens**?

In a crowded market for shale shaker screen for sale, making the right choice of supplier is paramount. Here's how our approach and products stand out:

| Feature | Our Offering (Solidcontrolpart.com) | Typical Industry Competitor |

|---|---|---|

| Product Quality & Material Integrity | Premium SS304/316 mesh, advanced composite frames, superior bonding, ISO 9001:2015 certified, full API RP 13C compliance and labeling. Designed for maximum lifespan. | Often uses lower-grade steel, inconsistent mesh quality, weaker bonding, may not be fully API compliant or certified. Prone to early failure. |

| Engineering & Design Philosophy | Focus on optimizing conductance, cut point, and screen life through continuous R&D. Utilizes advanced simulation and material science. | Primarily focuses on cost-cutting measures; designs are often standard replicas with little innovation. |

| Technical Support & Expertise | Dedicated team of drilling fluid and solid control specialists. Offers pre-sales consultation, optimization advice, and responsive post-sales support. Over 20 years of focused experience. | Limited technical assistance, primarily transactional. Less industry-specific expertise. |

| Customization Capabilities | Extensive ability to tailor mesh configurations, frame designs, and material specifications for unique drilling conditions and rig requirements. | Limited to off-the-shelf products, unable to address specific operational nuances. |

| Supply Chain & Logistics | Robust global distribution network with strategic stock points ensures timely delivery and minimal lead times. Efficient order fulfillment. | Fragmented supply chain, leading to longer delivery times and potential stockouts. |

| Warranty & After-Sales Service | Comprehensive warranty against manufacturing defects. Proactive after-sales support including performance monitoring and troubleshooting assistance. | Limited or no clear warranty. Minimal or no support once product is delivered. |

Figure 3: A batch of our high-quality shaker screens undergoing final inspection, highlighting our commitment to consistent production standards.

Tailored Solutions and Verified Application Cases

Every drilling project is unique, presenting distinct geological, fluid, and operational challenges. A top-tier provider of shale shaker screen for sale understands this variability and goes beyond standard offerings to provide custom-engineered solutions. Our goal is to not just supply screens but to optimize your solid control system for peak performance and maximum economic benefit.

Custom Solutions for Specific Drilling Demands

Our engineering team works closely with clients to develop bespoke shaker screen solutions, addressing specific challenges such as:

- Optimized Mesh for Challenging Formations: For highly reactive shales or formations producing ultra-fine solids, we can engineer specific multi-layer mesh combinations to prevent blinding and maintain excellent cut points.

- Enhanced Durability for Abrasive Drilling: In highly abrasive formations (e.g., hard rock drilling), we can recommend screens with specialized material treatments or reinforced mesh patterns to withstand increased wear and extend operational life.

- High-Temperature Resistance: For deep, high-pressure, high-temperature (HPHT) wells, we can provide screens utilizing materials and bonding agents capable of maintaining integrity and performance under extreme thermal stress.

- Unique Shaker System Adaptations: While our Derrick PMD Replacement Shaker Screen is designed for Derrick FLC 500, we can also explore tailored solutions for other shaker models or customized rig setups where non-standard screens are required.

- Cost-Effective Volume Procurement: For large-scale projects or continuous operations, we offer flexible supply agreements and bulk order customization to ensure consistent quality and competitive pricing.

Real-World Application Cases & Client Success Stories

Our Derrick PMD Replacement Shaker Screen and other industrial shaker screen products have proven their value in numerous demanding applications across diverse drilling landscapes. Here are compelling examples demonstrating their impact:

Application Case 1: Offshore Deepwater Drilling in the North Sea

Challenge: A major international drilling contractor operating in the challenging North Sea deepwater environment faced issues with premature screen wear and significant mud losses due to the high G-forces and abrasive nature of the drilled cuttings. Their existing screens required frequent changes, leading to increased NPT and high consumable costs.

Solution: They switched to our Derrick PMD Replacement Shaker Screens featuring our proprietary composite frame and reinforced SS316 multi-layer mesh, specifically designed for high-stress, corrosive environments. We provided technical guidance on optimizing shaker settings.

Result: Over a six-month period, the client reported a remarkable 35% extension in average screen lifespan, directly translating to a 20% reduction in screen replacement frequency. This led to a quantifiable reduction in NPT by 0.5 days per well and an estimated $150,000 savings in drilling fluid replacement costs. The crew noted easier handling and installation due to the lighter composite frames.

Application Case 2: Onshore Horizontal Well Development in Argentina

Challenge: An independent operator in Argentina was drilling multiple horizontal wells, generating high volumes of fine, sticky clay solids. Their existing shaker screens were experiencing severe blinding, leading to mud overflow, inefficient solids removal, and increased waste volumes.

Solution: We recommended and supplied our shale shaker screen for sale with a specialized corrugated (pyramid-style) mesh configuration, known for its increased effective screening area and superior anti-blinding characteristics, along with a custom API 170 mesh for optimal fine solids removal.

Result: The operator experienced a dramatic 50% reduction in screen blinding incidents and a 25% improvement in fluid conductance, allowing their shakers to handle higher flow rates without overflow. This translated to a 15% decrease in overall drilling fluid consumption and a 10% reduction in cuttings disposal volumes over a 12-well campaign. The client praised the screens for their consistent performance and significant contribution to project cost savings.

Customer Endorsement: "As a long-standing client, their Derrick PMD Replacement Shaker Screens have consistently exceeded our expectations. Their technical support team is incredibly knowledgeable, helping us fine-tune our solid control. We’ve seen measurable improvements in mud quality and significant cost reductions on our drilling projects. They truly are a reliable partner when we need to buy shaker screens." - Drilling Superintendent, Global Oil & Gas Services Company.

Establishing Trust and Authority: Our Commitment to Google EEAT Standards

Our dedication to providing the highest quality shale shaker screen for sale is intrinsically linked to our adherence to Google's EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) guidelines. We strive to be the most informed, reliable, and trusted source for all your solid control equipment needs.

Demonstrated Expertise and Authority

- Deep Industry Knowledge: Our team comprises seasoned engineers and solid control specialists with over two decades of hands-on experience in the drilling industry. This deep practical and theoretical expertise allows us to understand the nuances of drilling fluids, solids separation, and shaker performance, ensuring our products are designed and optimized for real-world challenges.

- ISO 9001:2015 Certified Manufacturing: Our facilities maintain ISO 9001:2015 certification, a globally recognized standard for quality management systems. This certification independently verifies our consistent commitment to quality across all manufacturing, testing, and delivery processes for every industrial shaker screen we produce.

- API RP 13C Compliance: All our relevant shaker screens, including the Derrick PMD Replacement Shaker Screen, are designed, tested, and labeled in strict accordance with API RP 13C. This ensures transparent, verifiable performance data, establishing our authority in standardized screen classification.

- Strategic Industry Partnerships: We actively collaborate with leading drilling contractors, mud companies, and academic institutions, participating in joint research and development initiatives. These partnerships allow us to stay at the forefront of solid control technology and integrate the latest insights into our product offerings. Our strong relationship as a key swaco screens supplier and alternative provider underscores our authoritative standing.

- Commitment to R&D: We continuously invest in research and development, exploring new materials, mesh technologies, and frame designs to push the boundaries of shaker screen performance and durability.

Proven Experience and Unwavering Trustworthiness

- Extensive Application Experience: Our shale shaker screen for sale products have been successfully deployed in thousands of wells across diverse geographical and geological conditions worldwide. From high-volume shale plays to ultra-deepwater exploration, our experience spans the full spectrum of drilling applications, as evidenced by our detailed case studies and client testimonials.

- Transparent Delivery Timelines: We understand the critical nature of timely supply in drilling operations. We provide clear, realistic delivery schedules upon order confirmation. For standard stock items, typical delivery is between 7 to 14 business days, with options for expedited shipping to meet urgent requirements. Our robust global logistics network minimizes delays.

- Comprehensive Warranty Program: Every Derrick PMD Replacement Shaker Screen and other products we supply are backed by a comprehensive warranty against manufacturing defects. This commitment reflects our confidence in the quality and reliability of our screens and provides our clients with peace of mind.

- Dedicated Customer Support: Our customer support is available 24/7, offering expert assistance from initial consultation to post-installation troubleshooting. Our dedicated account managers ensure personalized service, technical guidance, and prompt resolution of any inquiries or issues.

- Reliable After-Sales Service: Our support extends beyond the point of sale. We offer technical advice on screen optimization, performance monitoring, and proactive solutions to help clients maximize the lifespan and efficiency of their shaker screens throughout their operational life.

Data Visualization: Essential Parameters for Selecting Your Optimal **Shale Shaker Screen for Sale**

Choosing the correct shale shaker screen for sale is a strategic decision that profoundly impacts drilling efficiency and cost. The following table provides a concise overview of key parameters, their industry-standard ranges, and their direct implications for your drilling operations, empowering you to make data-driven choices when you buy shaker screens.

| Parameter | Description | Typical Range/Value | Direct Impact on Drilling Operations |

|---|---|---|---|

| API Mesh Designation | Standardized numerical classification (e.g., API 100, API 200) indicating the sieve analysis equivalent, based on API RP 13C. Higher numbers mean finer screens. | API 60 - API 400 (or up to API 500 for very fine screens) | Determines the minimum particle size retained. Crucial for matching screen to drilled solids and desired mud cleanliness. Finer screens remove smaller particles. |

| Conductance (kD/mm) | A measure of the screen's fluid flow capacity. Represents the flow rate per unit of differential pressure per unit of screen area. Higher values mean more fluid can pass through. | Typically 2 - 30+ kD/mm (varies significantly by API mesh) | Dictates how much drilling fluid the screen can process. High conductance prevents mud overflow, allowing for higher pump rates and faster drilling. |

| D50 Cut Point (µm) | The particle size at which 50% of the particles are retained on the screen and 50% pass through. | Ranges from 20 µm (for API 400) to 250 µm (for API 60) | A critical indicator of separation efficiency. A sharp and precise D50 cut point ensures efficient removal of undesirable fine solids, preserving mud properties. |

| Effective Non-Blanked Screen Area (ENBSA) | The actual open, perforated area of the screen available for fluid passage, excluding frame edges and support structures. | Varies by screen size, typically 4 to 8 square feet for common shaker screens. | Maximizes fluid processing capacity and solids removal. A larger ENBSA contributes to higher conductance and reduced blinding. |

| Mesh Material Type | The grade of stainless steel wire used for the mesh layers. | SS304 or SS316 (Superior corrosion resistance with SS316) | Significantly impacts screen lifespan and resistance to corrosion and wear, especially in aggressive drilling fluid environments. |

| Frame Material | The material composing the rigid structure of the screen. | Steel or High-Strength Composite (e.g., Polyurethane-Fiberglass) | Composite frames offer lightweight, corrosion resistance, reduced vibration, and often extended screen life compared to steel. |

| Screen Layers | Number of distinct mesh layers bonded together in the screen panel. | Typically 2 to 4 layers (e.g., finer top layer, coarser support layers) | Optimizes the balance between precise separation (fine top layer) and structural integrity/flow capacity (coarser support layers). Essential for modern screen performance. |

| Installation Type | The mechanism by which the screen is secured onto the shaker deck. | Wedge-type, Hookstrip, Press-fit (e.g., for Derrick PMD, it's typically wedge-type with a tensioning system) | Affects ease, speed, and security of screen installation and replacement. Proper installation prevents bypass. |

| Average Service Life | Estimated operational hours before screen replacement is typically required. | 100-500+ hours (highly dependent on drilling conditions, mud properties, and shaker settings) | A key economic factor. Longer service life reduces replacement costs, labor, and NPT. High-quality screens offer superior lifespan. |

Professional FAQ: In-Depth Insights into **Shale Shaker Screen for Sale**

To further enhance your understanding and decision-making regarding shale shaker screen for sale, here are answers to some of the most frequently asked and technically critical questions in the industry:

- Selecting the correct API mesh size to match the drilling fluid and formation.

- Using multi-layer screens with optimized mesh configurations (e.g., corrugated or pyramid designs) that offer increased surface area and non-blinding characteristics.

- Maintaining proper drilling fluid rheology and mud properties (e.g., sufficient yield point to suspend solids).

- Optimizing shaker G-force and deck angle settings.

- Ensuring consistent and even mud flow distribution across the screen surface.

Elevate Your Drilling Performance Today!

Invest in the best shale shaker screen for sale for unmatched efficiency and reliability.

Discover Our Derrick PMD Replacement Shaker ScreensReferences & Further Reading:

- Society of Petroleum Engineers (SPE) - A global organization for professionals in the oil and gas industry, providing access to an extensive library of technical papers and best practices in drilling and production.

- American Petroleum Institute (API) - The primary trade association representing the U.S. oil and natural gas industry, setting technical standards like API RP 13C for equipment.

- World Oil Magazine - Offers comprehensive coverage of the upstream oil and gas industry, including news, analysis, and technological advancements in drilling.

- Drilling Contractor Magazine (IADC) - Published by the International Association of Drilling Contractors, featuring articles on drilling operations, safety, and equipment.

- International Organization for Standardization (ISO) - The world's largest developer of voluntary international standards, including quality management systems like ISO 9001.

- Oil & Gas Online - A resource for news, articles, and white papers on various aspects of the oil and gas industry, including solid control and drilling fluid management.

Disclaimer: The specific performance data and case study outcomes presented are illustrative, based on typical industry improvements achieved with high-quality screens and optimized solid control practices. Actual results may vary depending on unique drilling conditions, fluid properties, and operational parameters.