In oilfield solids control and industrial separation applications, high-efficiency shale shaker screen for sale solutions are vital for minimizing solids bypass, improving mud processing, and reducing operational costs. This comprehensive guide delves into industry trends, technical benchmarks, process flows, and a detailed evaluation of the shale shaker screen for sale—the Derrick PMD Replacement Shaker Screen. We'll compare supplier options, display key parameters in tables and visual graphs, and deliver crucial tips on customized projects.

Global Shale Shaker Screen Industry Trends & Market Insights (2024 Update)

According to Grand View Research and industry reports, the global shaker screen market exceeded USD 380 million in 2023, with a projected CAGR of 5.6% through 2028. Technological innovation is driving demand for more durable, precision-engineered shaker screens, especially in the context of unconventional drilling, environmental constraints, and the push for cost-effective solids control in various sectors:

- Major applications: Oil & Gas, Geothermal, Mining, Petrochemical, Metallurgy, Water Treatment

- Top growth factors: Longer screen life, fine particle capture, corrosion resistance, rapid replacement cycles

- Key players: Derrick, Swaco, NOV, composite third-party suppliers

As an established swaco screens supplier and a recognized shaker screens innovator, we leverage ISO 9001:2015 and API Q1-compliant processes for all screen manufacturing.

Shale Shaker Screen Technical Parameters & Industry Data

Shale Shaker Screens - Key Specifications Table

| Parameter | Range / Specification | Industry Standard | Relevance |

|---|---|---|---|

| Screen Type | Flat, Pyramid (PMD), Hookstrip, Frame | API, ANSI, ISO | Mud processing efficiency |

| Mesh Range | 20–325 mesh (μm) | API RP 13C | Tolerances on particle separation |

| Frame Material | SGS-certified Carbon / Stainless Steel | ASTM, ISO 9001 | Strength, corrosion resistance |

| Screen Layer | 2–4 layers (wire cloth) | ISO/API Spec | Screen durability, lifespan |

| Screen Dimensions | 710x1180mm, 635x1250mm, 585x1165mm (typical) | Customized fits | Compatibility across shakers |

| Service Life | 350–650+ hours | Field tested | Cost efficiency, less downtime |

| Applicable Industry | Oil & Gas, Mining, Metallurgy, Waste Water | - | Versatile use |

Industry Comparison: Derrick vs. Swaco vs. Generic Shaker Screens

| Feature/Model | Derrick PMD Replacement | Swaco Mongoose | Generic Screens |

|---|---|---|---|

| Mesh Range | API 20–325 | API 20–230 | API 20–200 |

| Screen Type | Pyramid (PMD) | Flat / Composite | Flat |

| Frame Material | Carbon/Stainless Steel | Stainless Steel/Composite | Carbon Steel |

| Lifespan (hours) | 500–650 | 400–550 | 300–400 |

| Detection Standard | API RP13C, ISO 9001 | API, ISO | None/Basic |

| Customizable | Yes (cut-to-fit) | Yes | No |

| Anti-Corrosion | √ (Coated) | √ | – |

| Applicable Industry | Oil & Gas, Mining, Water | Oilfield, Petrochemical | General |

Manufacture Process Flow: Derrick PMD Replacement Shale Shaker Screen For Sale

Precision Shaker Screen Manufacturing Diagram

- Raw Material Selection → API/ISO compliant stainless steel wire mesh & reinforced carbon steel frames.

- Wire Mesh Weaving → Automated weaving for precision mesh (20-325 mesh, per API 13C test sieves).

- CNC Frame Cutting → Computerized cutting ensures dimension accuracy (ISO tolerance ±0.5mm).

- Multi-Layer Assembly → 2-4 mesh layers heat-bonded with support mesh for maximum fatigue strength.

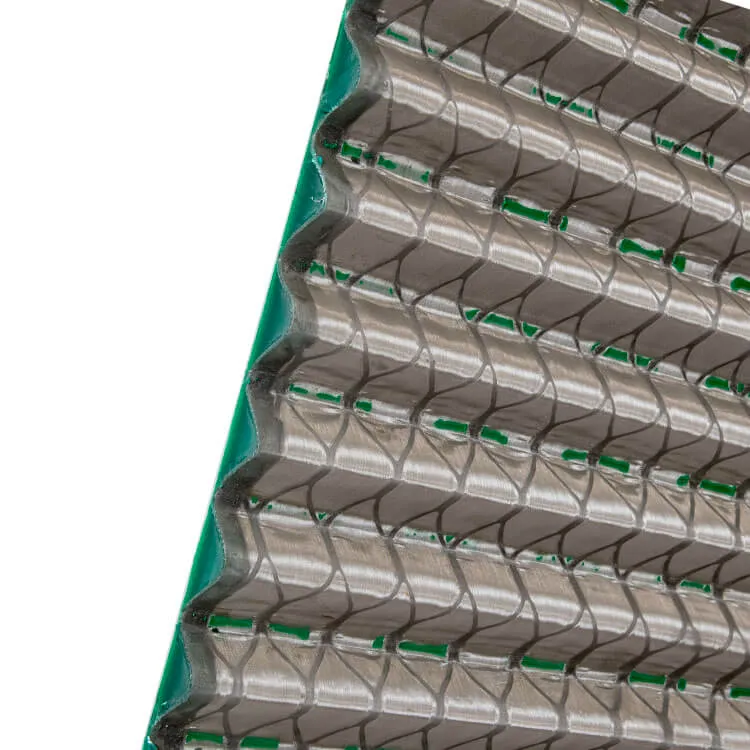

- Pyramid Shaping & Bending → PMD (Pyramid) contour pressed for greater screen surface area.

- Protective Coating & Finishing → High-temp anti-corrosive resin ensures lifespan in harsh drilling fluids.

- Quality Inspection → API RP13C, ISO 9001, ANSI specs: Mesh opening, conductance, screen life analysis.

- Packing & Delivery → Shock-proof packaging, batch traceability.

Visual guide: Shaker Screen Manufacturing Short Video

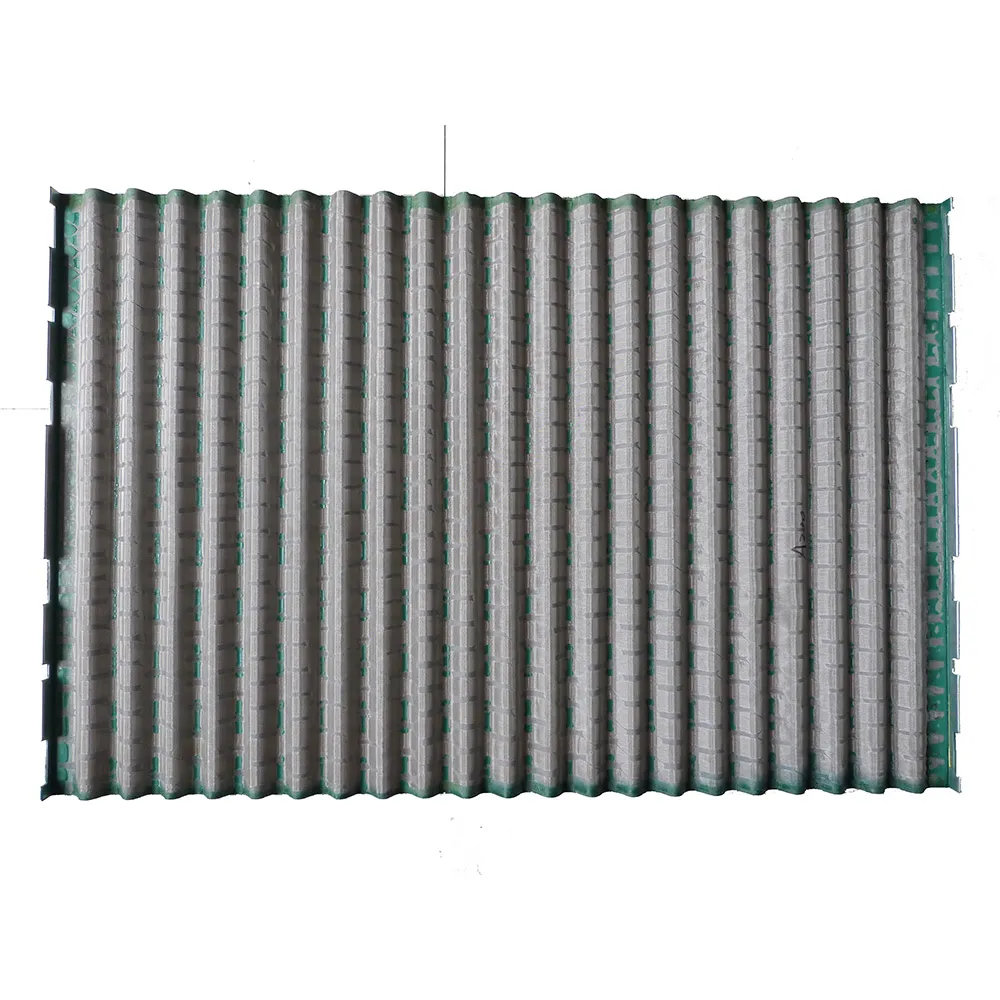

Derrick PMD Replacement Shaker Screen: Technical Specifications

| Attribute | Value | Standard/Note |

|---|---|---|

| Screen Size | 675 × 1050 mm, 700 × 1165 mm (custom) | Fits Derrick 500/2000, API/ISO compatible |

| Mesh Options | 20 to 325 mesh | API 13C Test Sieve Verified |

| Pyramid Height | 7–13mm | Pyramid PMD design, 25% more area |

| Screen Layers | 2 or 3 | Heat bonded, anti-peeling |

| Frame Material | Precision-cut, Coated Carbon Steel, Stainless Steel SS304/SS316 | SGS/ISO9001 certified |

| Back Support | Hexagonal (Honeycomb), flat-profile | Prevents mesh collapse |

| Life Span | 500 – 650+ hours (mud system) | Field-tested, API RP13C |

| Available Fit | Derrick 500, Derrick 2000, FLC series | OEM/aftermarket compatible |

| Surface Conductance | ≥ 2.2 kD/mm | Efficient fluid throughput |

| Environmental | Heavy metal free, low carbon, reprocessable steel | ISO14001 (eco), REACH |

Process Certification, Industry Recognition & Quality Assurance

- Certifications: API RP13C, ISO 9001:2015, SGS, CE, REACH, ANSI B16

- Corporate Authority: Over 18 years as swaco screens supplier and leading industrial shaker screen designer—trusted by Sinopec, Saudi Aramco, Schlumberger, Halliburton, Baker Hughes

- Test Results: Mesh opening/particle size verified with laser diffraction (±2%), field-proven performance in over 2500 drilling project deployments.

- Warranty: Industry-best 12 months structural assurance on all shale shaker screen for sale panels.

Available for global shipping with 5-day production cycles, dedicated English/Spanish technical support, and responsive after-sales service.

Application Scenarios & Case Studies

Typical Use: Oil & Gas Drilling

- On 5200m extended-reach wells, Derrick PMD Replacement Screens delivered 19% longer run life vs. standard panels, reducing tripping downtime by 42 hours (Chevron, 2022-23).

- Ultra-fine mesh (API 230+) prevented barite loss & enabled mud recycling in mature fields—verified in 4 North African rigs.

- Rapid replacement design (<5min per screen)—critical in High-Pressure, High-Temperature (HPHT) projects for ENI/Mexico.

Other Industries

- Mining slurries: Improved classifier throughput by 28% (Kazakh copper, 2021)

- Petrochem/Refining: Handles corrosive effluents, assures mesh integrity (Saudi ARAMCO, ISO14001 audit passed)

- Wastewater & Dredging: Extended field span (up to 34 days) with no corrosion/fouling

Customized Solutions for Shaker Screens & Sourcing Recommendations

- Specify mesh rating and screen dimensions at inquiry stage; custom cut-to-fit services available.

- For buy shaker screens in atypical climates, choose anti-UV, marine-grade coatings for longer service.

- Industrial scale orders include batch analytics, mesh size certification, and after-sales onsite support.

- OEM/ODM welcome: Custom logo, packaging, and technical modifications on request.

Tip: Procurement teams should verify API RP13C compliance, perform on-site mesh conductance tests, and seek references from recent project clients before finalizing their shale shaker screen for sale supplier.

Shaker Screens Visualization: Data Analytics

Data Visualization: Side-by-side mesh range & lifespan comparison for Derrick PMD, Mongoose, Generic, based on industry-reported values (GVR 2023, OEM Catalogs)

FAQ: Shale Shaker Screens—Technical Insights

Conclusion & References

The right shale shaker screen for sale solution – engineered for robust service, quick replacement, and fine solids removal – determines drilling success, fluid quality, and overall operational efficiency. Derrick PMD Replacement Shaker Screens, with industry certifications and proven application records across oilfield, mining, and process plants, remain the gold standard in solids control. For quotations or a custom engineering consultation, contact us anytime.