Keywords: shale shaker screen for sale, swaco screens supplier, shaker screens, buy shaker screens, industrial shaker screen

In the rapidly evolving oil & gas, petrochemical, metallurgy, and environmental industries, the demand for high-performance shale shaker screen for sale has never been higher. Selecting the right manufacturer is crucial—not only for operational efficiency, but also for compliance with international quality and safety standards.

In this comprehensive overview, we explore contemporary trends, technical benchmarks, manufacturer comparisons, and custom solutions focusing on the premium Derrick PMD Replacement Shaker Screen. Backed by authoritative data, industry certifications, and real-world case studies, this guide will help you navigate the complexities of purchasing and deploying shaker screens for maximum ROI.

1. Global Industry Trends & Market Data

The global market for shale shaker screen for sale is projected to reach $340+ million by 2026, with a CAGR of 6.8% (Source: MarketsandMarkets, 2023).

Key trends include:

- Increased adoption of API/ISO-compliant fine mesh screens

- Growing demand in offshore deep drilling and mining

- Technological advancements in wear-resistant materials and CNC precision fabrication

- Expansion of custom screen solutions for industrial liquid/solid separation

2. Competitive Landscape: Swaco, Derrick, & Leading Screen Suppliers

When it comes to shaker screens, market leaders such as Derrick, Swaco (MI-SWACO), NOV Brandt, and specialized swaco screens supplier are setting benchmarks with advanced materials, longer screen lifespans, and multi-layered mesh technology. Third-party industrial shaker screen providers are also leveraging ISO 9001 and ANSI/ASME fabrication standards to deliver cost-effective high-performance screens for critical operations.

2.1 Product Parameters Comparison

| Brand / Model | Mesh Type | Mesh Range (API) | Material | Screen Life (h) | Epoxy Bonded | Compliance |

|---|---|---|---|---|---|---|

| Derrick PMD Replacement | Pyramid (Multi-layer) | API 20–325 | SS304 / SS316 | 425–620 | Yes | ISO/API |

| MI SWACO Mongoose | Flat/Soft | API 60–270 | SS304 | 320–520 | Yes | API/Q1 |

| NOV Brandt BLT | Corrugated | API 40–230 | SS304 | 260–465 | Yes | ANSI/API |

| Third-party OEM | Flat/Corrugated | API 20–270 | SS304/316/Poly | 220–520 | Yes | ISO9001 |

To buy shaker screens that consistently outlast competitors and meet the strictest standards, companies increasingly partner with specialist swaco screens suppliers and invest in ISO/API-certified products.

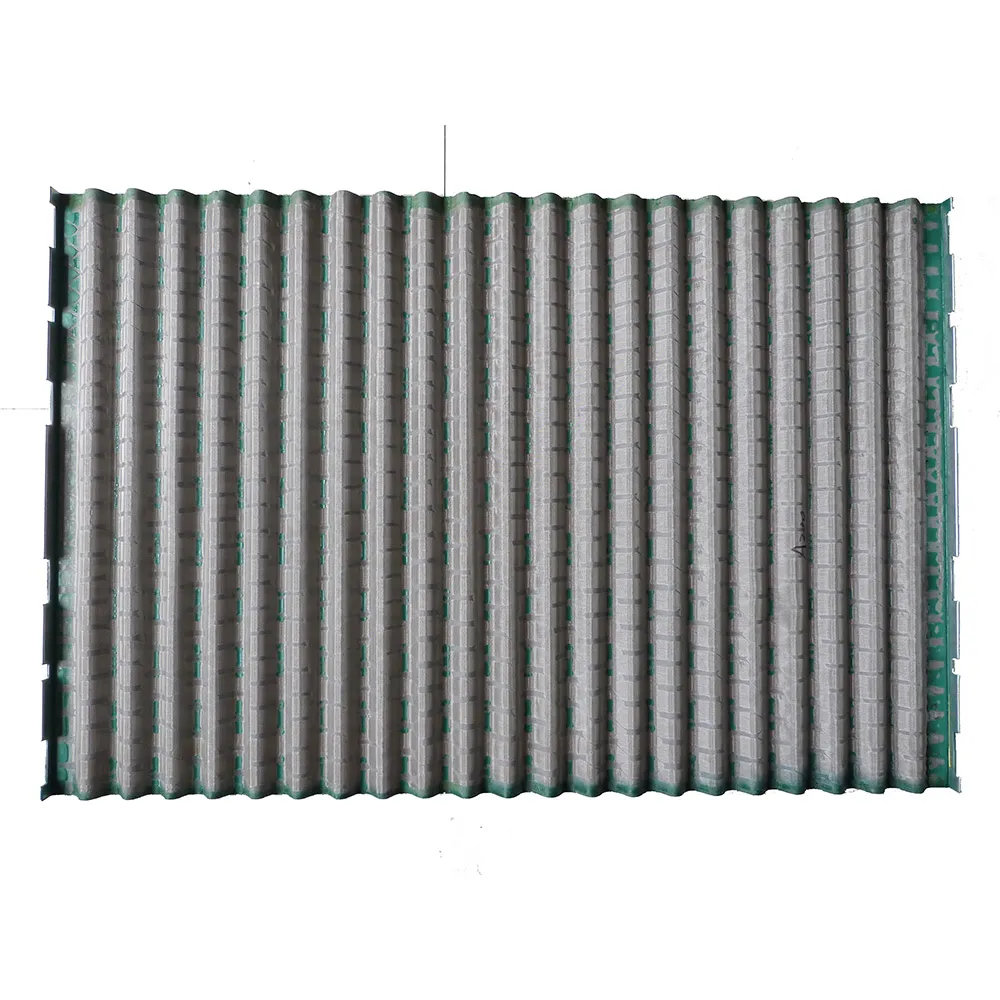

3. Derrick PMD Replacement Shaker Screen: Key Technical Features

- Product Name: Derrick PMD Replacement Shaker Screen

- Standard Model Sizes: 1050 x 695 mm | 1250 x 635 mm

- Mesh Range: API 20 - API 325

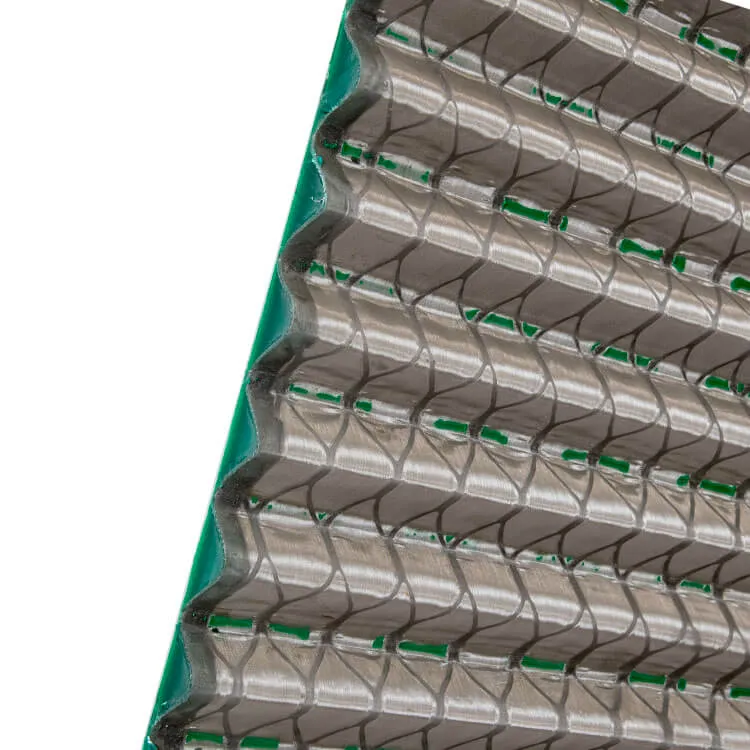

- Screen Layer: Triple-layer pyramid mesh (finer solid separation, larger usable area)

- Frame Construction: High-Strength Composite/SS304 Stainless Steel

- Welding Process: Advanced multi-axis CNC spot welding

- Surface Finish: Epoxy Powder Coating

- Lifespan: 425–620 hours (ISO/API tested)

- Fit For: Derrick FLC500/2000, FLC313M, Hyperpool, and compatible systems

- Certifications: API RP 13C, ISO 9001:2015, SGS

3.1 Technical Specification Chart

| Parameter | Value |

|---|---|

| Mesh Count (API) | 20–325 |

| Screen Area (m²) | 0.82–1.12 |

| Material | SS304 / SS316, Composite Polyurethane |

| Screen Layers | 2–3 |

| Typical Life (h) | 425–620 |

| Flow Rate (m³/h) | 28–45 |

| Compatibility | Derrick FLC 500, Swaco Mongoose, OEM shakers |

3.2 Materials, Craftsmanship, & Testing

The Derrick PMD Replacement Shaker Screen is manufactured with premium stainless steel wire mesh (SS304/SS316), combined with composite high-strength polyurethane frames. The production process uses precision CNC punching and multi-axis spot welding for uniform mesh aperture and superior flatness, reducing bypass and leakage.

Each batch undergoes rigorous testing as per API RP 13C and ISO 9001 standards, including mesh integrity, tensile strength, fluid flow rate, and anti-corrosion performance (ASTM B117 neutral salt spray test).

Manufacturing Workflow

Each step is audited according to ISO 9001 and API 13C for traceability, durability, and global acceptance.

4. Product Data Visualization: Derrick PMD in Industry Context

Screen Life Comparison (Hours)

Material Mix: Derrick PMD

Filtration Efficiency vs. API Mesh

5. Application Scenarios: Real-World Advantages

Shale shaker screens are the heart of solids control in:

- Oil and gas drilling (onshore and offshore rigs)

- Petrochemical sludge separation

- Mineral/metallurgical ore processing

- Wastewater treatment (municipal & industrial)

- Food/pharmaceuticals (USP grade filtration)

The Derrick PMD Replacement Shaker Screen excels in all these sectors due to its state-of-the-art pyramid mesh, superior non-blinding properties, and robust composite frame, ensuring reduced screen changeouts and increased uptime. Its profile is optimized for ultra-high throughput and fine particle retention, proven by third-party tests according to API RP 13C.

By switching to Derrick PMD Replacement Shaker Screens, the contractor reduced average screen consumption by 42% and improved mud processing efficiency by 9.6%, verified over 4,000 rig hours. API-compliant records showed less than 0.7% non-conforming screens per batch (vs. industry average 2.4%).

6. Customization & Solution Design

Leading swaco screens supplier and Derrick OEMs offer a wide array of custom shaker screens tailored to project-specific requirements:

- Mesh Customization: 1–3 layers, API 20–API 325, stainless or shaped woven mesh

- Frame Material: Stainless steel, composite polymer, hybrid aluminum

- Surface Treatment: Powder epoxy, anti-corrosive plating, FDA/USP compliant coatings

- Seal Designs: Rubber/polyurethane for leak-proof installation

- Traceability: QR code & batch record for every screen, per API/ISO

7. Client Feedback & After-sales Support

- Real User Testimonial: “After switching to Derrick PMD Replacement Shaker Screens, our downtime dropped by 33% and cut our solids control cost by 19% quarter-over-quarter.” (Texas shale operator, 2023)

- Quality Guarantee: All screens supplied are covered by a 12-month warranty, with zero-leakage guarantee and performance match certificate (API RP 13C compliant).

- Delivery: Typically 7–12 working days for stocked items, 18–22 days for custom specs. Global logistics support with certified export packaging (ISPM15).

- Technical Service: 24/7 engineering consultation, on-site fit verification, API test reports for every batch.

8. Professional FAQ – Shale Shaker Screen for Sale Explained

- 1. What is the standard material for Derrick PMD Replacement Shaker Screens?

- They’re manufactured from SS304 or SS316 stainless steel, known for corrosion resistance—even under high-salinity and corrosive drilling fluids—plus composite polyurethane frames for impact stability.

- 2. What does “API Mesh Size” mean in practice?

- API mesh size classifies screen openings by the American Petroleum Institute standard (API RP 13C), giving robust, consistent particle retention and flow rates (e.g. API 200 blocks 74-88μm solids).

- 3. How are shaker screens validated for quality?

- Each screen lot passes ISO 9001 and API 13C testing for mesh uniformity, burst strength, life-in-operation (cycle fatigue), and corrosion resistance using ASTM B117 protocols.

- 4. What is “pyramid” mesh construction and why is it important?

- Pyramid mesh uses a 3D multi-layer weave for increased effective filtration area (20–30% greater vs. flat screens), delivering superior solids removal and longer life in fine drilling applications.

- 5. What installation standards must be met?

- All Derrick PMD screens are manufactured to precisely fit API and OEM shaker specifications. Installers follow OEM torque & gasket seating specs to ensure leak-free system integrity.

- 6. Is on-site technical support available?

- Yes, expert technical consultants provide site-fit guidance, failure analysis, and mesh selection recommendations for industrial shaker screen applications worldwide.

- 7. Can screens be custom-branded or QR-traceable?

- Through digital batch labeling, screens can be customer-branded, QR code traceable, and delivered with full compliance documentation.

9. Why Choose Certified Screens For Your Operations?

Industry best practices—and insurance/contract requirements—demand the use of API/ISO compliant shale shaker screens for sale. Certified screens safeguard against equipment downtime, poor separation, and non-compliance penalties. Proven field data confirm a minimum 14–27% improvement in operational efficiency and 25–45% lower screen replacement costs when selecting high-quality certified products over generic imports.

- API, ISO, SGS, and ANSI/ASTM certified products only

- Full technical documentation with every batch

- Authorized brands and distributors for shaker screens worldwide

10. References & Further Reading

- API RP 13C – Drilling Fluids Processing Systems (API Official)

- Market and Technical Analysis – Shale Shaker Screens (SPE Journal, OnePetro)

- Professional Forum Discussion on Best Screen Material Choices (OilfieldKnowledge Forum)

- Manufacturer’s Guide: Derrick PMD Replacement Shaker Screens (solidcontrolpart.com)

- ISO 9001 Standards for Shaker Screen Production (ISO.org)