In today’s demanding drilling environments, swaco screens have become an essential component of effective solids control systems. As the frontline defense in separating cuttings from drilling fluids, these screens play a critical role in optimizing mud performance, preserving equipment lifespan, and reducing environmental impact. Engineered for compatibility with M-I SWACO shakers and third-party equipment alike, swaco screens are designed to deliver maximum separation efficiency without compromising throughput.

Whether you're operating in a land-based rig or an offshore platform, the quality of your screen determines how well your mud is cleaned and recycled. The right swaco screens ensure reduced fluid loss, faster drilling, and lower costs over time. These screens are available in a variety of mesh counts, sizes, and frame types to accommodate every type of drilling condition—from hard rock to soft sediment formations.

Furthermore, technological innovation has led to the development of screens that are not only lighter and stronger but also capable of operating under higher G-forces. The screen’s open surface area, mesh bonding technique, and frame material all influence performance. Therefore, choosing high-performance swaco screens is not just a purchase—it's a strategic investment in the operational success of your rig.

Mongoose Shaker Screens: Advanced Design for Precise Solid Separation

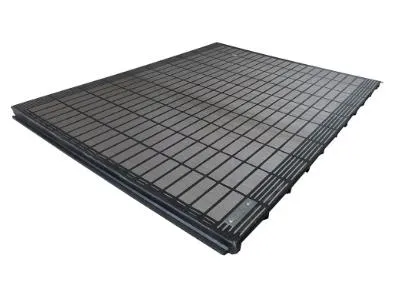

Among the most commonly used in the industry, mongoose shaker screens are designed specifically to enhance the performance of the M-I SWACO Mongoose series shale shakers. These screens feature a proprietary design that increases screen area and improves particle conveyance, which means more fluid is recovered while minimizing screen blinding and wear. Their composite frame structure ensures both flexibility and durability in harsh drilling conditions.

What makes mongoose shaker screens particularly effective is their multi-layered mesh construction, which allows for precise cut-point control. The screen’s pyramid or flat configuration further adapts to specific needs. For example, pyramid designs offer increased screening capacity, while flat screens allow for faster cuttings conveyance in certain fluid systems.

Rig operators favor mongoose shaker screens because they simplify replacement, reduce non-productive time (NPT), and fit seamlessly with existing M-I SWACO shaker models. They can be ordered in various API mesh sizes depending on the formation type and expected solids volume. Moreover, they are widely available from both OEM producers and aftermarket manufacturers, with many third-party swaco screens supplier options offering quality-tested alternatives at competitive prices.

When performance, durability, and compatibility are critical, choosing original or compatible mongoose shaker screens ensures superior results in both conventional and challenging drilling environments.

Swaco Shaker Screens: Built for Durability and High Mud Recovery

Swaco shaker screens are engineered to meet the rigorous demands of continuous drilling. Unlike conventional mesh panels, these screens are constructed using high-grade materials that withstand high vibration, corrosive fluids, and abrasive solids. Their long service life reduces downtime and labor associated with frequent screen changes.

These screens are commonly used in horizontal, directional, and high-angle drilling, where consistent solids removal is paramount. Available in both steel and composite frames, swaco shaker screens offer multiple layers of mesh bonded together using proprietary techniques that prevent delamination and ensure fluid flow consistency. The screens are API RP 13C compliant, meaning their performance can be verified and trusted across global operations.

In challenging wells with sticky clays or high solids loading, swaco shaker screens maintain integrity and performance, enabling more drilling fluid to be recovered for reuse. This reduces the need for additives and fresh mud dilution, leading to more efficient operations. Additionally, the mesh integrity of these screens resists tearing and sagging, which is crucial for minimizing mud loss and keeping equipment operating smoothly.

Rig operators often report significant savings in mud costs and reduced waste handling expenses after switching to advanced swaco shaker screens, whether sourced through OEM channels or from a reliable swaco screens supplier.

Finding the Right Swaco Screens Supplier for Quality and Availability

Choosing a trusted swaco screens supplier can be just as important as selecting the right screen itself. A dependable supplier not only ensures consistent product quality and API compliance but also provides fast delivery, technical support, and options for customization. As the demand for cost-effective solids control solutions grows, many international and regional suppliers have stepped up to provide aftermarket or OEM-compatible swaco screens that meet industry standards.

Suppliers offering mongoose shaker screens and swaco shaker screens often carry a wide inventory to meet urgent drilling needs. Whether you require pyramid-style screens, hook-strip, or composite frame screens, a capable swaco screens supplier will provide a variety of options tailored to your shaker model and drilling conditions.

Look for suppliers with quality control certifications, robust testing protocols, and the ability to trace mesh compliance with API RP 13C standards. Many top suppliers also provide assistance with screen selection, optimizing mesh combinations, and ensuring proper installation techniques to maximize performance.

International buyers frequently turn to manufacturers located in China and Southeast Asia for bulk orders, citing cost advantages and consistent production quality. However, regional suppliers in the U.S., Canada, and the Middle East may offer logistical advantages, faster service, and localized support. Ultimately, partnering with the right swaco screens supplier can lead to better screen performance, less rig downtime, and smoother operations.

How Swaco Screens Enhance Drilling Efficiency and Reduce Costs

Using high-performance swaco screens directly influences the economics and efficiency of your drilling operation. Every barrel of drilling fluid that is recovered means less fluid lost to waste and lower operating costs. By preventing the unnecessary disposal of usable fluid, swaco shaker screens protect both budgets and the environment.

Efficiency is further improved through reduced screen replacement frequency. Durable mesh and frame construction mean screens last longer, even under high-G vibrations. This leads to lower screen consumption rates, fewer interruptions, and less labor required for maintenance. Whether using mongoose shaker screens in a land rig or offshore platform, the benefits of fewer changeouts and less NPT are clear.

Additionally, properly selected swaco screens improve mud rheology by removing harmful solids before they recirculate through the system. This maintains pump performance, prevents bit balling, and helps maintain proper hydrostatic pressure in the wellbore. As a result, drilling proceeds faster, with fewer issues and lower mud treatment costs.

For these reasons, investing in quality swaco screens from a trusted swaco screens supplier is one of the most impactful upgrades any rig can make. It delivers measurable performance improvements, safety benefits, and long-term savings that far outweigh the initial investment.

swaco screens FAQs

What are Swaco screens used for in drilling operations?

Swaco screens are used in shale shakers to remove solid cuttings from drilling fluids. They are essential for maintaining the cleanliness and reusability of drilling mud, which is critical for wellbore stability, pressure control, and cost management. These screens help reduce fluid loss, improve mud quality, and prevent equipment wear caused by abrasive solids.

What is the difference between Swaco shaker screens and mongoose shaker screens?

Swaco shaker screens refer to all screen types manufactured or compatible with M-I SWACO shakers, while mongoose shaker screens are specifically designed for the M-I SWACO Mongoose shaker series. Mongoose screens are known for their high G-force resistance, pyramid design, and large screening area. Both types are highly efficient, but mongoose screens are tailored for performance in Mongoose shaker systems.

How can I verify the quality of a Swaco screens supplier?

To verify a swaco screens supplier, check for API RP 13C compliance, quality certifications (like ISO), and customer references. Reputable suppliers will provide test results for mesh integrity, conduct regular inspections, and offer technical support. It’s also important to evaluate their inventory capabilities, delivery timelines, and warranty policies before making a purchase.

What is the typical lifespan of a Swaco screen?

The lifespan of a swaco screen depends on drilling conditions, fluid properties, mesh size, and frame material. On average, high-quality screens last from 30 to 100 hours of active drilling. Composite frame screens typically outlast steel ones due to better flexibility and corrosion resistance. Proper handling, storage, and shaker maintenance also extend screen life.

Where can I buy high-quality Swaco screens at a competitive price?

High-quality swaco screens are available through authorized distributors, aftermarket manufacturers, and international suppliers—especially in China and the Middle East. To find the best balance of price and quality, look for a swaco screens supplier with proven experience, mesh certification, and screen customization capabilities. Always request sample screens or mesh test reports before bulk purchases.