In the competitive world of oil and gas drilling, selecting the right solids control equipment is critical—and none more so than the brandt shaker screens. Designed to work specifically with brandt shaker systems, these screens are engineered to deliver high performance in even the most challenging drilling conditions.

Brandt shaker screens come in a wide variety of mesh sizes and frame constructions. From soft formation drilling to high-volume horizontal wells, these screens provide high separation efficiency and durability. Their compatibility with multiple brandt shaker models ensures seamless integration and optimal operation on most drilling rigs.

Operators using brandt shaker screens benefit from greater drilling fluid recovery, reduced screen replacements, and minimized non-productive time (NPT). Screen integrity and proper fit are essential, which is why genuine or API-compliant replacement screens are recommended for any brandt shaker.

With increased environmental oversight and rising fluid costs, effective solids control systems using brandt shaker screens have become indispensable. Investing in high-quality screens not only safeguards your shaker unit but directly improves your return on investment.

Why the Brandt Shaker Remains a Trusted Industry Workhorse

Over the decades, the brandt shaker has earned its reputation as one of the most reliable and widely used shale shakers in the industry. From land-based rigs in the U.S. to offshore drilling platforms in the North Sea, the brandt shaker is known for consistent solids control, rugged construction, and operational flexibility.

Available in both linear and elliptical motion designs, the brandt shaker efficiently separates cuttings from drilling fluids across a range of flow rates and formations. It supports multiple screen configurations, making it ideal for operators looking to optimize performance with the latest brandt shaker screens.

Whether you’re dealing with high solids volumes or changing formation characteristics, the brandt shaker can be adjusted to suit specific drilling conditions. Its user-friendly screen clamping mechanism and robust vibrator motors help maintain uptime and reduce manual labor costs.

Field-proven across thousands of wells, the brandt shaker is valued not just for its performance but also for its compatibility with aftermarket solutions. With the right brandt shaker screens, even older shaker models can continue operating at peak efficiency, maximizing the lifespan of your equipment.

King Cobra Shaker and Its Compatibility with Brandt Shaker Screens

The king cobra shaker, developed by NOV, is another high-performance shale shaker often found on modern rigs. Known for its aggressive linear motion and modular screen deck, the king cobra shaker offers high capacity and efficient solids conveyance. Fortunately, many brandt shaker screens are designed to be compatible with king cobra shaker models, making screen procurement more flexible and cost-efficient.

The king cobra shaker is built for high-volume drilling operations and demanding formations. Its screen area and vibratory motion are engineered to handle heavy cuttings loads while minimizing fluid loss. When paired with properly matched brandt shaker screens, it can outperform many conventional shaker units in throughput and cuttings dryness.

With its large screen surface area and adjustable deck angles, the king cobra shaker allows for field-tuning and optimization. This is particularly beneficial in directional or extended-reach wells, where cuttings load and fluid behavior can vary greatly.

If you're operating a king cobra shaker, it’s vital to ensure your screen supplier provides compatible brandt shaker screens made to precise specifications. Improper screen fit or inferior mesh quality can lead to screen failure, higher fluid loss, and potential equipment damage.

The Impact of Brandt Shaker Screen Technology on Waste Reduction

Drilling waste management has become a growing concern, especially with rising disposal costs and tighter environmental regulations. Using advanced brandt shaker screens in a brandt shaker or king cobra shaker setup can significantly reduce drilling waste and improve fluid recovery.

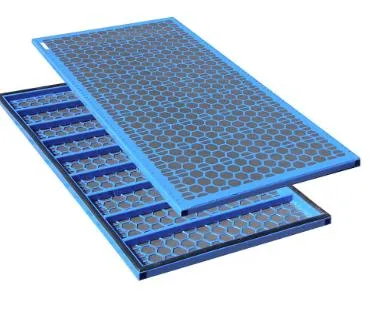

Modern brandt shaker screens use multi-layer mesh technology and composite frame construction to improve strength and separation efficiency. This design helps retain cuttings more effectively while allowing clean fluid to pass through, reducing the need for additional separation equipment downstream.

When installed on a brandt shaker or king cobra shaker, these screens enhance solids conveyance and reduce fluid retention on discharged cuttings. The result is drier cuttings that are easier and less expensive to dispose of—saving operators thousands in waste handling and transportation costs.

Moreover, the longevity of advanced brandt shaker screens reduces screen change-out frequency, minimizing worker exposure to hazardous mud and cutting down on non-productive time. Better screen performance also leads to less dilution and fewer chemical additions to maintain mud properties.

By optimizing your brandt shaker with the right screens, you're not just improving rig efficiency—you're contributing to a more sustainable and environmentally responsible drilling operation.

How to Select the Best Brandt Shaker Screens for Your Operation

Choosing the most suitable brandt shaker screens depends on several key factors, including your brandt shaker or king cobra shaker model, drilling fluid type, formation characteristics, and desired flow rates.

First, consider your mesh requirements. Finer mesh screens (API 140 and above) are excellent for removing smaller particles and are typically used in reactive clay or silt-rich formations. Coarser mesh screens (API 20–60) are better suited for gumbo or large-cuttings applications.

Next, evaluate the screen frame construction. Steel frames offer strong support for high-impact operations, while composite frames are lightweight, corrosion-resistant, and have a longer operational life—ideal for remote or offshore applications.

Also, think about screen motion compatibility. While most brandt shaker screens are designed for linear motion units, screen dynamics can vary slightly between models. Always confirm with the supplier whether the screens are certified to fit your brandt shaker or king cobra shaker.

Finally, price and availability matter. While OEM screens may come at a premium, many reputable third-party manufacturers offer API-compliant brandt shaker screens at competitive rates without compromising performance.

brandt shaker FAQs

What is the difference between Brandt shaker and King Cobra shaker?

The brandt shaker and king cobra shaker are both linear-motion shale shakers designed for high-efficiency solids control. While the brandt shaker is often valued for its reliability and widespread use, the king cobra shaker is recognized for its modular design, large screen area, and aggressive motion—ideal for high-capacity drilling operations. Both units can often use compatible brandt shaker screens, depending on the model.

Are Brandt shaker screens interchangeable with King Cobra shaker units?

Yes, many brandt shaker screens are designed to be compatible with king cobra shaker models, especially those with similar screen dimensions and mounting systems. However, compatibility depends on exact screen design and shaker model. It's important to check with your supplier to ensure proper fit and performance.

What factors affect the lifespan of a Brandt shaker screen?

Several factors influence the lifespan of brandt shaker screens, including drilling fluid properties, cuttings volume, vibration settings, screen tensioning, and proper installation. Using screens made from high-quality mesh and composite frames on your brandt shaker or king cobra shaker can extend operational life and reduce replacement frequency.

How can I reduce drilling waste using shaker screens?

By using high-performance brandt shaker screens on your brandt shaker or king cobra shaker, you improve fluid-solid separation efficiency, resulting in drier cuttings and better fluid recovery. This reduces the volume of waste that needs to be handled or transported, saving costs and supporting environmental compliance.

Where can I find Brandt shaker screens for sale?

You can find brandt shaker screens through OEM channels, authorized distributors, or third-party manufacturers that offer API-certified replacements. Look for suppliers who can confirm screen compatibility with your brandt shaker or king cobra shaker, provide mesh customization, and offer timely delivery to your location.