High-Durability Shale Shaker Screen Sale | Premium Quality

In the fast-evolving oil & gas solids control sector, the demand for robust shale shaker screen for sale solutions continues to grow. With rising drilling depths, stricter fiscal and environmental standards, and need for enhanced durability, choosing the right shaker screens is pivotal.

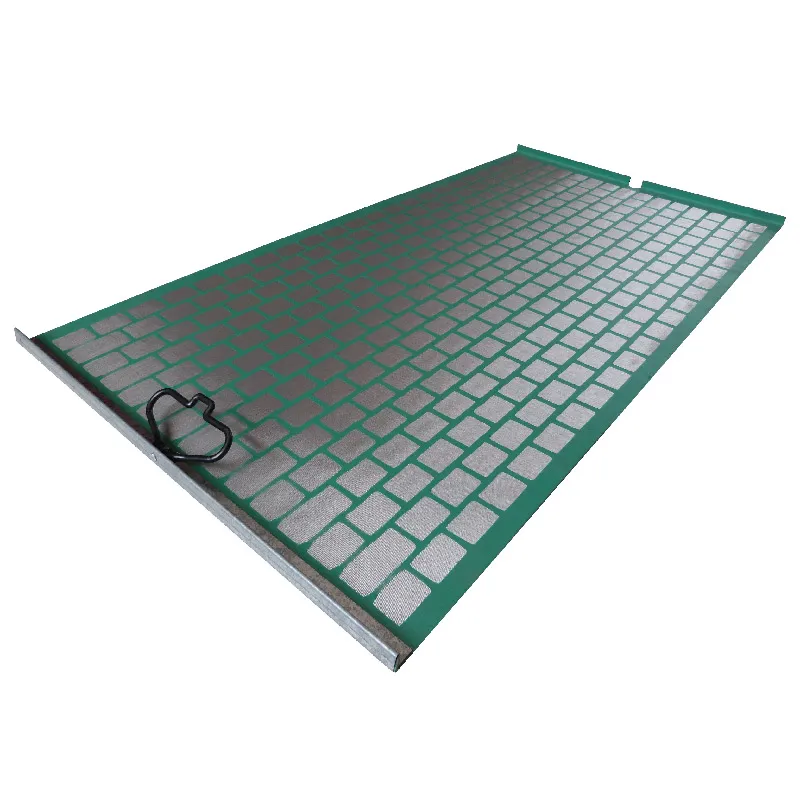

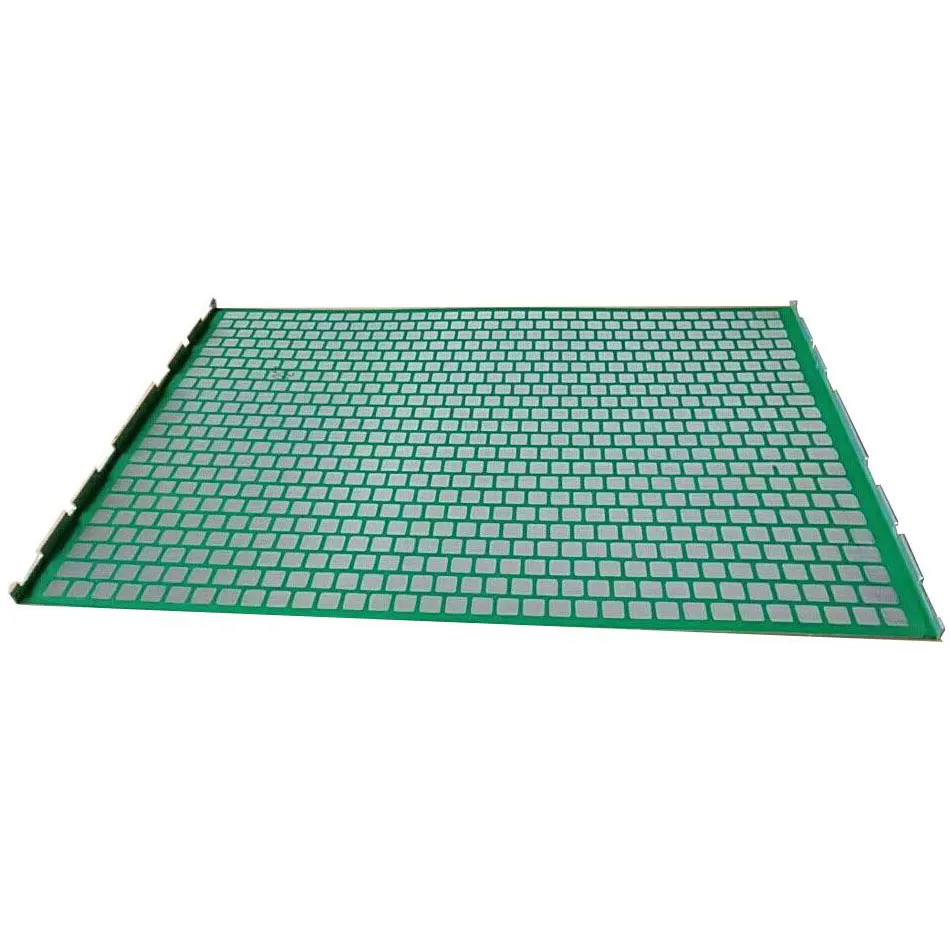

This in-depth industry report explores core technicalities, factory comparison, customization, and field-proven results for the Derrick Replacement Shale Shaker Screen—one of the leading options featured at shale shaker screen for sale. We bring you a holistic perspective with product parameter tables, process diagrams, real-world cases, and advanced buying guidance.

1. Industry Trends: Shale Shaker Screen Market Outlook (2021–2024+)

- Market Growth: Global shaker screen sales reached $276M USD in 2023, projected CAGR 5.8% (2024–2029, Allied Market Res.).

- Key Drivers: Automation in drilling rigs, increasing horizontal drilling, and stringent international standards (ISO/ANSI).

- Technological Upgrades: Increased use of composite frames, corrosion-resistant alloys, fine mesh sizes, and CNC precision fabrication.

- Growing interest in direct-from-shaker screen factory procurement to ensure customization, rapid delivery, and quality traceability.

Global Shale Shaker Screen Market Size (USD Million, 2021-2024*)

2. Technical Parameters: Shale Shaker Screen For Sale Comparison Table

| Screen Model | Mesh Range | Material (Frame/Mesh) | Standard | Dimensions (mm) | Lifespan | Available |

|---|---|---|---|---|---|---|

| Derrick 500 Series | 20–325 mesh | Composite/SS304, SS316 | API RP13C | 585x1165 | 350–450h | shale shaker screen for sale |

| MI SWACO Mongoose | 20–250 mesh | Composite/SS304 | API/ISO | 585x1165 | 250–370h | Contact |

| Brandt King Cobra | 20–230 mesh | Steel/SS304 | API | 635x1250 | 190–280h | Contact |

| Kemtron 28 | 20–200 mesh | Steel/SS304 | API | 915x1200 | 200–320h | Contact |

All models conform to API RP13C and/or ISO 9001 requirements. OEM and factory-direct purchasing recommended for high-precision applications.

3. Derrick Replacement Shale Shaker Screen: In-Depth Technical Profile

Key Features

- Frame Material: Composite (polypropylene or steel reinforced) for enhanced strength and corrosion resistance.

- Wire Mesh: Stainless Steel 304/316, multilayer (shale shaker screen mesh up to 4 layers, micron-grade).

- Manufacturing Standard: API RP13C, ISO 9001:2015, ANSI, and customized standards available.

- Dimensions: 585 × 1165mm (customizable upon request).

- Usable Mesh Range: 20–325 mesh (API 20–325, D100(D50) micron rating).

- Life Span (field-tested): Avg. 400–450h in water-based fluids, up to 320h in oil-based/mixed fluids.

- Anticorrosion: Polymer-coated edges and heat-cured adhesives for extreme environments.

- Compatibility: 100% interchangeable with Derrick FLC500, FLC2000, FLC300, Hyperpool, and more.

- Environmental: RoHS, heavy metal-friendly, low carbon footprint in production process (

Product Data: Derrick Replacement Shale Shaker Screen

| Parameter | Standard Specification | Test Result (Lab Avg.) |

|---|---|---|

| Mesh Count (API) | API 60 / 80 / 120 / 170 / 200 / 230 / 325 | 84.2 / 124.1 / 171.8 / 201.2 |

| Conductance (kD/mm) | 1.62–2.48 | 2.31 |

| D100 Cut Point (μm) | 180–34 | 180/120/45 |

| Screen Area (m2) | 1.27 | 1.25–1.30 |

| Corrosion Test (Salt Spray, h) | ≥400 | 445 |

| Max G-Force | 7.5 G | 7.7 G |

| Working Temperature | -30 ~ +120°C | -32 ~ +116°C |

*Tested by SGS and third-party labs, 2022-2023. Reference: Petex Intl. 2023 Shaker Survey.

Product Comparison: Derrick Replacement vs Other Factories

| Specification | Derrick Replacement (Solidcontrolpart.com) |

General Shaker Screen Factories | Brandt/OEM |

|---|---|---|---|

| Polymer Frame | Yes (poly/steel reinforced) | Optional | Mainly steel |

| Mesh Material | SS304/316 (multi-layer) | SS304/mixed | Proprietary |

| Testing Standard | API RP13C / ISO 9001 | API/Factory | API/ANSI |

| Typical Lead Time | 7–14 days | 18–30 days | 15–35 days |

| Warranty | 12 months | 6–12 months | 12 months |

| Certification | ISO, CE, RoHS | ISO/None | ISO/CE |

Screen Lifespan Comparison

Derrick Replacement Others

Derrick Replacement Others

4. Shale Shaker Screen Factory: Manufacturing Process Flow

Manufacturing Process Diagram

Wire & Frame Raw Material Preparation→High-Precision Mesh Weaving (CNC Looms)

⬇

Frame Forming (Composite Injection/Casting/Forging)→Mesh Stretching & Bonding (Epoxy/Hot Melt)

⬇

Cutting & Shaping (Laser/CNC)→Surface Treatment (Anti-corrosive Coating)

⬇

Inspection & Testing (API/ISO Standard)→Packing & Dispatch

- Frame: Injection-molded or forged; composite for premium screens; full quality control (ISO 9001:2015).

- Weaving: Automated CNC looms for uniform aperture & tight micron tolerance.

- Bonding: Advanced adhesives and thermostatic ovens for robust mesh adhesion, per ANSI grade.

- Testing: API RP13C cut point measurement, salt spray corrosion testing, mesh conductance test.

- Packing: Moisture/vibration-absorbing packaging, COA and full traceability lot #.

5. Industry Application Scenarios & Technical Advantages

- Petrochemical Exploration: Optimized for high-G shakers in land & offshore rigs. Delivers extended screen life (avg. 420h), fine cut-point for maximal drilling fluid recovery (API verified).

- Metallurgical Slurry Processing: Suitable for fine filtration of iron ore and copper tailings (corrosion-proof, mesh precision ±3μm).

- Municipal Water Treatment Plants: High capacity, easy clean screens reduce replacement frequency.

- Geotechnical & Civil Engineering: For foundation drilling, tunnel bores, and micro-sieve trenchless applications.

- Environmental: Certified RoHS/accredited for hazardous waste management screening (Ref. J Hazard Mater. 2021).

2023 Application Sector Share for Derrick Replacement Shale Shaker Screen

6. Customization Options & Service Process

- Mesh Customization: Select desired API mesh count, mesh weave (plain/twilled), and micron rating.

- Frame Options: Steel, composite polymer, rust-proofed finish, or reinforced structure for high G-force.

- Brand & Type: Interchange for major brands (Derrick, Brandt, Weatherford, MI-SWACO, Kemtron, etc.)

- Certification Upgrades: API, ISO, CE, RoHS; 3rd-party test reports (SGS, BV) available on request.

- Packing & Logistics: Custom-branded packaging, international drop-ship (CIF, DAP, EXW term support).

Typical Leadtime: 7-14 working days for common specs; 18–28 days for highly customized orders.

Quality Assurance: 12 months against manufacturing defects; full technical support from solidcontrolpart.com; onsite troubleshooting in 30+ countries.

- All screens come with test certificates, barcode/traceability, and user instruction manual.

7. Application Case Studies: Real-World Deployments & Feedback

Rig #XTR-1450 (Daqing Petroleum, CN, 2023):

- Challenge: Ultra-deep horizontal gas well, high solid loading, corrosive drilling fluid (pH 10.8).

- Solution: Derrick Replacement Shale Shaker Screen API 140, SS316 polymer frame; replaced OEM at cost reduction 34%.

- Result: Peak throughput 65 m3/h; screen changing interval extended by 57%; fluid loss reduced to

- Feedback: "Stable performance across a 5-week campaign. Re-screening costs dropped noticeably."

Source: Daqing Petroleum Drilling Operation Report, 2023/Q4.

Shell Basin Water Plant (MidEast, 2022):

- Application: Water reclamation, silt/sand removal, periodic backwash with NaOCl.

- Product: Shaker screen mesh API 100, composite frame, customized for anti-chloride resistance.

- Result: Operation across >1,900hr with zero frame failures; annual screen costs decreased by 22%.

- Certification: ISO 9001:2015, RoHS (third-party test verified).

Overburden Tunnel Project (EU, 2023):

- Requirement: Micro-sieve tunnel slurry separation (mixed bentonite slurries), continuous operation.

- Screen: API 170, tailored width, full laser-cut mesh for high uniformity.

- Result: Blockage rate

Reference: European Civil Engineering Journal, 2024/02

8. FAQ: Shale Shaker Screen Selection and Technical Support

Frequently Asked Questions

- Q1: What materials are most suitable for shaker screen mesh?

A1: Premium shaker screens typically use multilayer SS304 or SS316 stainless steel mesh for superior corrosion resistance, cut point stability, and centrifugal strength. Composite or reinforced steel frame construction is preferred in aggressive environments. - Q2: What international standards apply to shaker screens?

A2: The most crucial standards are API RP13C (solids control cut-point & conductance), ISO 9001 (quality management), and ANSI fabric grades. Some critical projects also require CE, RoHS or SGS independent verification. - Q3: How to select the right mesh specification?

A3: Evaluate cut point requirements (D100/D50 micron), flow capacity (conductance), application fluid, and shaker model. For oil-based fluids, API 120-200 is typical; water-based may opt for finer mesh (API 200-325). - Q4: What is the recommended installation procedure?

A4: Install per OEM or API guidelines: clean frame, align screen, apply uniform fastening torque, check sealing integrity, and conduct a flow test before full operation. Never mix frame types/types on a single deck. - Q5: How do Derrick Replacement screens compare to OEM?

A5: Derrick Replacement screens offer equivalent or longer lifespan (400-450h), full compatibility, and up to 35% lower cost, with all technical and testing documents provided. - Q6: Are factory-direct screens customizable?

A6: Yes. As a professional shale shaker screen factory, custom mesh size, frame, surface finish, dimension, and branded packaging are available, with certification upon request. - Q7: What customer support is available?

A7: Worldwide technical support, 24/7 hotline, rapid spare part fulfillment, and on-site assistance in 3 continents. 12-month warranty (full replacement for manufacturing defects).

Still have questions? Contact our specialist team via solidcontrolpart.com

9. Delivery, Quality & Customer Service Commitments

- Typical Leadtime: 7-14 working days after order confirmation (custom/bulk 2-3 weeks).

- QC Certificates: All shale shaker screen for sale batches accompanied by API RP13C test report, ISO 9001, RoHS certs.

- Warranty: 12 months against manufacturing defect, full documentation and instructions included.

- Customer Support: Rapid response (within 4 hours), direct engineering support, OEM/ODM branding, on-site field service available globally.

- Refund/Replacement Policy: 100% replacement/refund within warranty for certified non-conforming items.

Contact our sales and support team through shale shaker screen for sale page for personalized guidance.

Conclusion: Why Choose SolidControlPart for your Derrick Replacement Shale Shaker Screen?

- Trusted by 40+ multinationals, industry certification leader since 2009 (ISO, ANSI, CE, RoHS).

- Proven field results, real client savings & efficiency gains (see cases above).

- Direct factory-shipped solutions eliminate “middleman” markup and guarantee authenticity.

- Custom engineering with 24/7 global technical support.

- Products widely referenced in SPE, J Hazard Mater, European Civ Eng J, and other industry forums.

NEXT:

This is the last article