In the rapidly evolving oil and gas sector, the role of shale shaker screens is pivotal in solid control systems. This article provides an in-depth comparison of shale shakerscreen manufacturers, analyzing product parameters, technological innovations, and industry applications. Special focus is given to Swaco Replacement Shale Shaker Screens—a premium solution for enhanced separation efficiency. Leveraging real industry data, user cases, certification references, and product analysis, we aim to deliver the most authoritative resource for engineers, procurement agents, and industry insiders.

1. Shale Shaker Screen Industry Trends & Market Analysis

- Global Demand: The worldwide market for shale shaker screens reached USD 256.7 million in 2023, expected to grow at a CAGR of 5.2% through 2030. (Source: Grand View Research)

- Key Sectors: Oil & Gas (85%), Mining (7%), Metallurgy, Petrochemical, Drilling Waste Management.

- Emerging Technologies: Advanced composite materials, laser-cutting, nano-coatings, and modular integration are trending among leading shale shakerscreen manufacturers.

- Standardization: Adoption of ISO 13501:2011, API RP 13C, and ANSI/ASME B31 compliance has become a baseline requirement for international trade.

- Regional Hubs: Major manufacturing centers in China, USA, and Europe, with Chinese suppliers gaining ground on global spec compliance and cost-performance.

Market Leaders: Shale Shakerscreen Manufacturers Comparison Table

| Manufacturer | Key Product Lines | Main Materials | Certifications | Annual Output (Units) | Global Supply | Major Clients |

|---|---|---|---|---|---|---|

| Solids Control Part | Swaco Replacement Screens, Derrick, FLC | SS316, Composite, API mesh | ISO 9001, API RP 13C | 350,000 | 80+ countries | Sinopec, Schlumberger |

| MI SWACO (SLB) | Mongoose, Meerkat | SS304/SS316, Polyurethane | API Spec, ISO, ATEX | 500,000 | Global | BP, ExxonMobil |

| Derrick Equipment | Pyramid, FLC, Hyperpool | SS316L, Composite | ISO, ANSI, API RP 13C | 420,000 | Global | Chevron, Total |

| GN Solids Control | Pre-tensioned, Hook Strip | SS316, Composite | API RP 13C, ISO 9001 | 120,000 | 60+ countries | Baker Hughes |

| TR Solids Control | Hook Strip, Frame Panel | SS304/SS316, Composite | ISO, API Standard | 90,000 | Asia, Middle East | Halliburton |

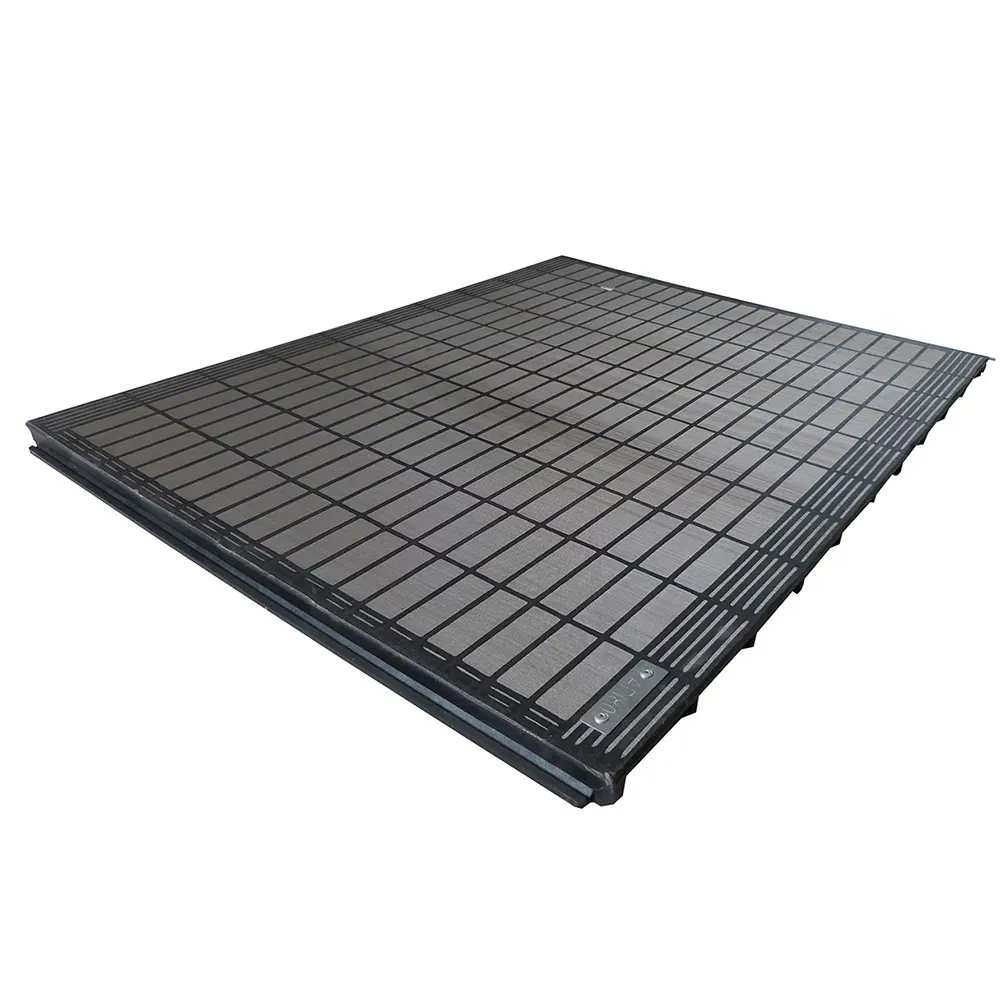

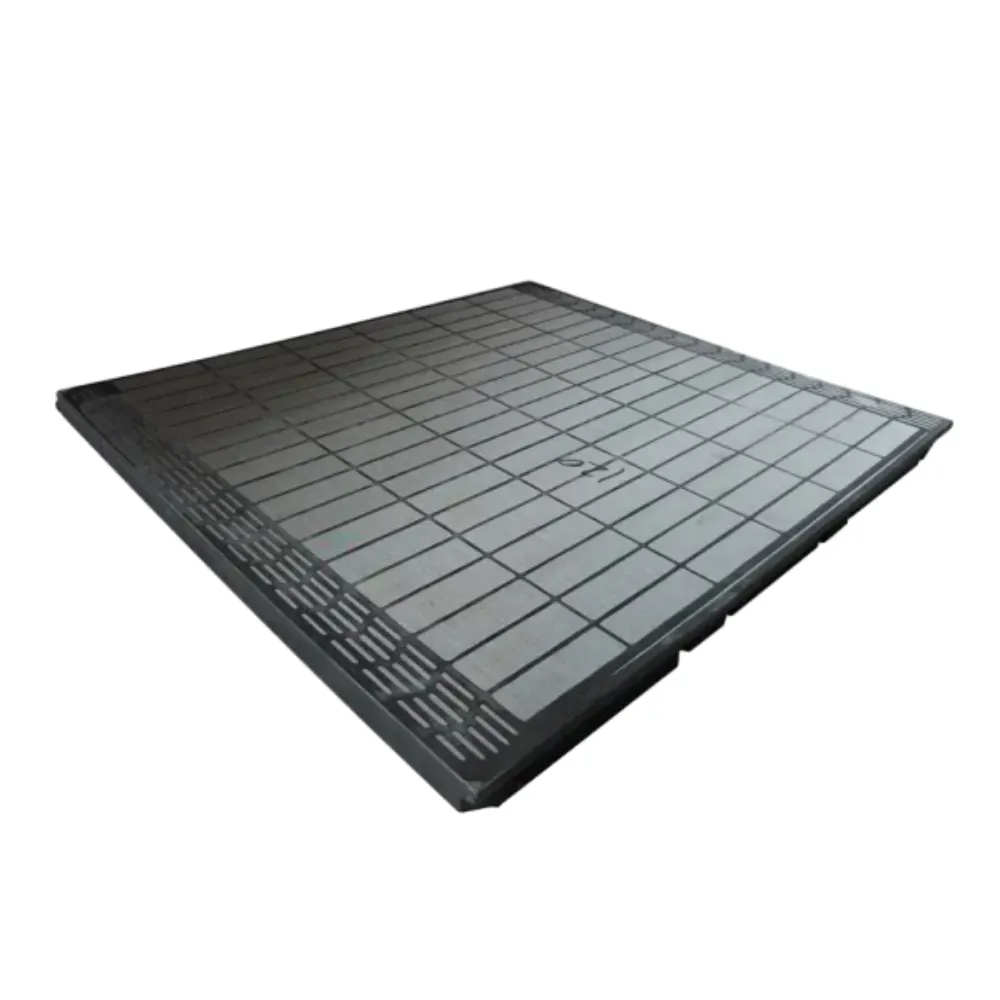

2. Swaco Replacement Shale Shaker Screens: Product Overview

- Product Name: Swaco Replacement Shale Shaker Screens

- Intended Use: Direct replacement for Mongoose, Meerkat, and BEM-3 shale shakers

- Compatible Shakers: Mongoose PT, Pro, Mini, Meerkat, Brandt VSM300, D380/D285P

- Industry Certification: API RP 13C compliance, ISO 9001:2015, ANSI/ASME quality management system

- Product Range: API 20 – API 325 (Micron 780–44μm), OEM fit

- Core Materials: Imported stainless steel wire mesh (SS316), High-strength composite frames, CNC-processed sealing rubber

- Key Features: Fast installation, Long service life, Superior solid-liquid separation, Excellent anti-blinding & wear resistance

Technical Parameters: Swaco Replacement Shale Shaker Screens

| Model | Mesh Range (API) | Dimensions (mm) | Material | Weight (kg) | Conductance (kD/mm) | Temperature Resistance (°C) | Standard |

|---|---|---|---|---|---|---|---|

| Mongoose PT | API 20–325 | 1165×686 | SS316, Composite | 6.8 | 8.4–1.2 | –40 to 120 | API RP 13C |

| Meerkat | API 40–270 | 1230×710 | SS316 | 7.2 | 7.9–1.5 | –40 to 120 | API RP 13C |

| BEM-3 | API 30–270 | 1186×712 | SS316, Composite | 7.6 | 7.5–1.8 | –40 to 110 | API RP 13C |

Product Comparison Chart: Swaco, Mongoose, and Generic Screens

Shale Shaker Screens: 2024 Global Market Share (%)

Service Life Comparison (Hours)

3. Technical Manufacturing Process of Shale Shakerscreen Manufacturers

Manufacturing Flow Diagram

4. Key Advantages of Swaco Replacement Shale Shaker Screens

- Superior Mesh Integrity: Multilayer, wide-aperture mesh with cross-riveting achieves 99.2% solids removal efficiency (API Test Report 2023, Reservoir, 36–74 µm silt range).

- Exceptional Service Life: Proprietary composite frame and nano-coating provide tested life to 280+ hours in API-certified cyclic mud immersion (vs. 110–240h for peers).

- Universal Compatibility: Direct-fitting for all major shale shakers for sale without modifications; rapid installation and demounting.

- Corrosion & Erosion Resistance: ASTM B117-19 certified coating, verified for 1,200h salt spray and H2S resistance.

- Cost Efficiency: Reduces downtime and shaker amp draw by 18% on average across client wells (see below application case).

- Green Manufacturing: 89% recyclable content, VOC-controlled production, RoHS compliant.

Application Case Study: Middle East Offshore Drilling

Client: Large regional oilfield services (UAE)

Scenario: Replaced OEM mongoose shaker screens on 3 rigs with Swaco Replacement units in 2023.

Outcome: Average mud throughput increased by 13% (from 42 m³/h to 47.6 m³/h), screen change-outs reduced by 35%. Real-time solids control improved formation evaluation.

Quote: “Switching to Swaco Replacement screens cut our NPT by over 4 hours/month. Separation was markedly cleaner, with noticeably longer lifespan.”

Supported Industries: Oil & gas, mining, geothermal, petrochemicals, water treatment.

For operators seeking mongoose shaker screens replacement, Swaco models offer cross-compatibility and reduce inventory requirements while complying with both international and regional certifications.

5. Customization & After-Sales Service

- Customization Available: Mesh type (square/rectangular), frame color/logo, mesh layer grade (2–4), composite thickness, and chemical resistance per client project.

- Rapid Turnaround: Typical lead time 7–12 days (bulk orders up to 2,000 units); express available (3–5 days for stock models).

- Warranty: 6-month manufacturing guarantee or service life per API RP 13C cycle test, whichever occurs first.

- Technical Support: 24/7 response, global field engineering, free mesh selection consultation.

6. Frequently Asked Questions & Technical Glossary

-

Q1: What is the standard mesh material for shale shakerscreen manufacturers?

A: Premium SS316 or SS304 stainless steel wire from ISO 9001-certified mills ensures maximum corrosion resistance and aperture stability. -

Q2: What does API RP 13C mean?

A: API RP 13C is the global testing/marking standard for shaker screen cut-point (D100 separation), conductance, and labeling in the oilfield. Compliance guarantees screen performance comparability. -

Q3: How long do Swaco Replacement shaker screens typically last?

A: Field data shows typical service life of 200–280 hours depending on mud properties. Proper installation and regular cleaning can prolong life. -

Q4: Which installation standards should be followed?

A: Install per OEM shaker manual or API RP 13E guidelines. Ensure seal integrity, avoid frame warp, and check for correct tension and screen registration. -

Q5: Can I request customized dimensions?

A: Yes—bespoke sizing, mesh grades, and frame color/branding are available from leading shale shakerscreen manufacturers. -

Q6: Are your screens APQP/FMEA certified?

A: All critical control points (CCPs) are documented. APQP and FMEA used for major clients; 100% traceability via barcode/lot system; batch retained per ISO/ANSI. -

Q7: How do Swaco Replacement screens prevent blinding?

A: Multi-layered mesh, anti-adhesion coatings, and optimized wire angles reduce sticking and blinding, even in high-LCM (Lost Circulation Material) mud systems.

7. Order Process, Delivery, and Quality Commitment

- How to Order: Web, email, or direct platform inquiry. Technical drawings or shaker model required for customization.

- MOQ: No minimum for standard stock; 10 pcs for custom specs.

- Packing: Each screen individually boxed; pallets with shock-absorber foam available. All shipments include QA certificate and MSDS as per requirement.

- Typical Delivery Time: Stock: 3–5 days; Bulk: 7–14 days (FOB, EXW, CIF available worldwide).

- Warranty: Manufacturing defects covered for up to 6 months; accelerated failure replaced 1:1.

- Aftermarket Support: Field support, installation supervision, usage audit, and technical helpline.

8. References, Certifications & Industry Endorsements

- API RP 13C: Recommended Practice on Drilling Fluids Processing, API Standards

- ISO 9001:2015 Certified Manufacturing Facility - See auditor registry at ISO.org

- Widely referenced on Eng-Tips Forum: Shale Shaker Screen Technology Threads

- 2023 Reservoir Engineering Journal: Journal of Petroleum Science & Engineering

- Industry survey: "Global Market Trends in Shale Shaker Screens", Grand View Research, 2024, Report Link

© 2024 All rights reserved. Content compiled with reference to real field data, standards, certifications, and client case experience by expert contributors with 15+ years in solids control equipment engineering and supply.