Explore the latest trends, technical parameters, manufacturing processes, and leading shale shaker screen manufacturers serving global oil & gas, petrochemical, and mineral processing sectors. Compare shaker screen for sale, series such as king cobra shale shaker, vsm 300 shaker, and brandt shaker screens — with focus on Brandt Replacement Shale Shaker Screen technical excellence.

- Market Size (2023): US$ 675 million (source: MarketsandMarkets)

- Key End User Industries: Oil & gas, petrochemical, metallurgy, water treatment, mining

- Growth Factors: Unconventional drilling (shale & CBM), digital field upgrades, demand surges in mid-east, Asia-Pacific, Americas.

- Brandt (NOV)

- MI SWACO (Schlumberger)

- Deruite

- FLC (Derrick)

- GN Solids Control

- TR Solids Control

These manufacturers differentiate in mesh construction, API spec compliance, engineering customization, after-market support and global supply chain.

| Manufacturer | Main Model Series | Mesh Range | API RP 13C Compliant | Screen Panel Material | Service Life (avg.) | Major Application |

|---|---|---|---|---|---|---|

| Brandt (NOV) | VENOM, KING COBRA, VSM 300 | 20–325 | Yes | SS316/304 + PT Composite Frame | 230–400 hrs | Drilling, Mining |

| MI SWACO | MONGOOSE, Meerkat | 10–325 | Yes | SS304/316 | 150–320 hrs | Drilling |

| Derrick (FLC) | 500, 2000, 48-30 | 10–325 | Yes | SS304 + Polyurethane | 200–370 hrs | Drilling, Waste Mgmt |

| Deruite | BR, SWACO, Derrick | 10–325 | Yes | SS304 | 100–270 hrs | Oil & Gas |

| GN Solids Control | VSM, FLC Series | 10–325 | Yes | SS304 + Composite | 140–310 hrs | Solids Control |

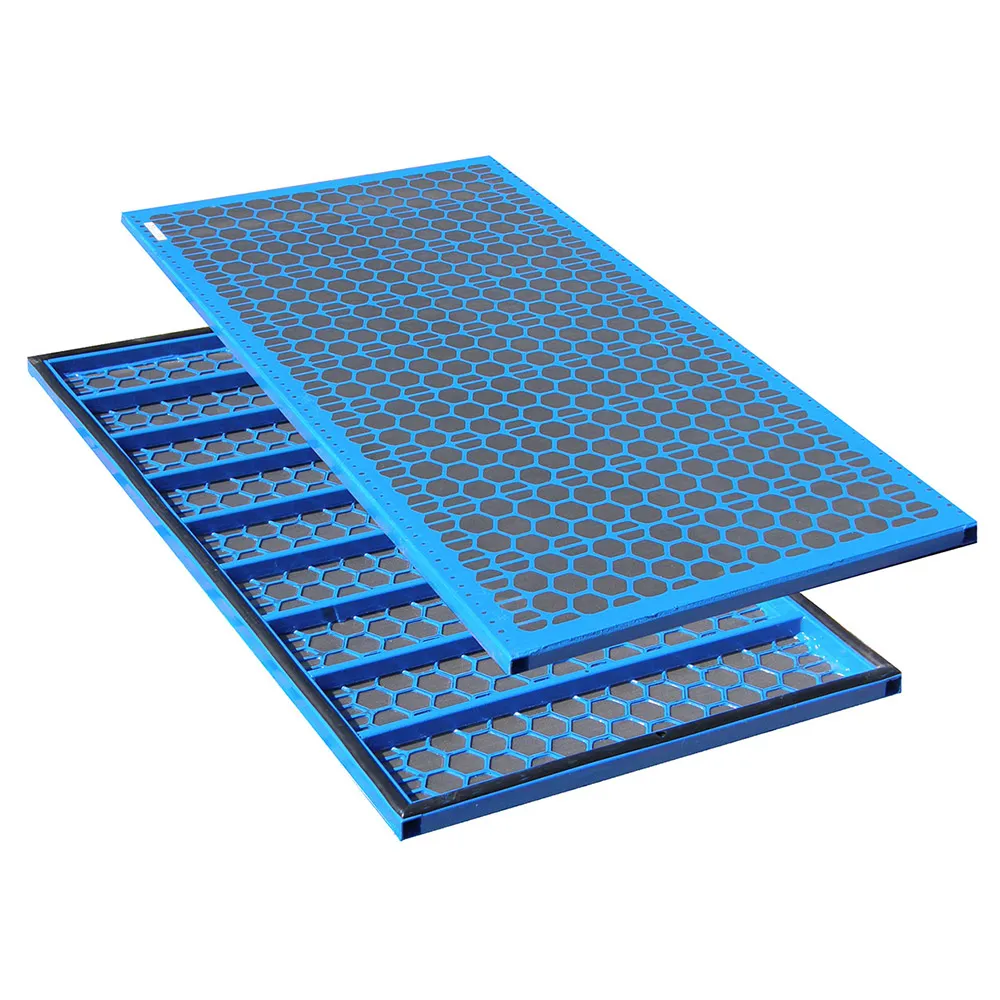

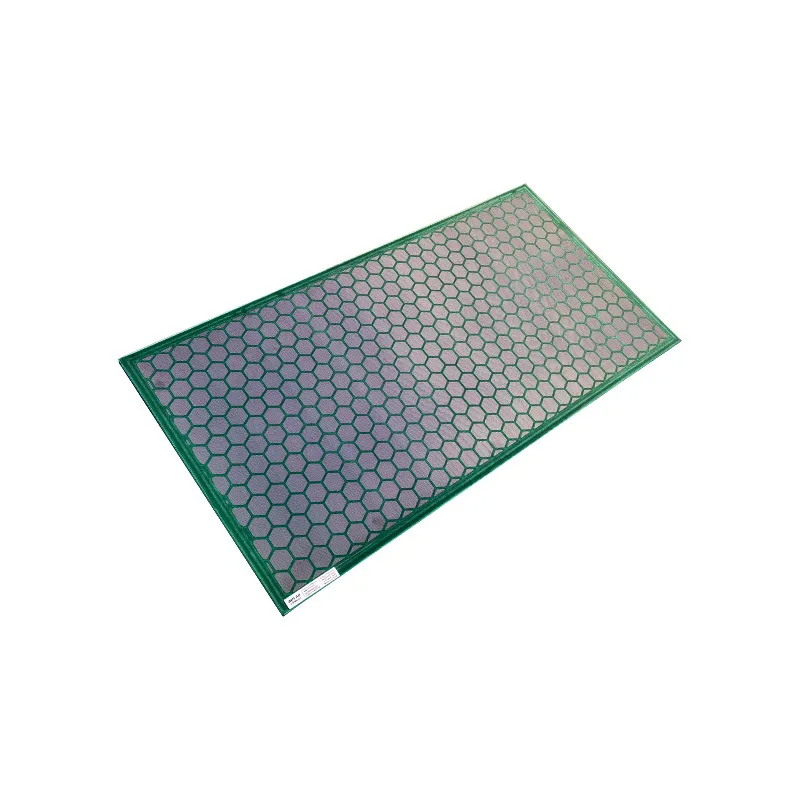

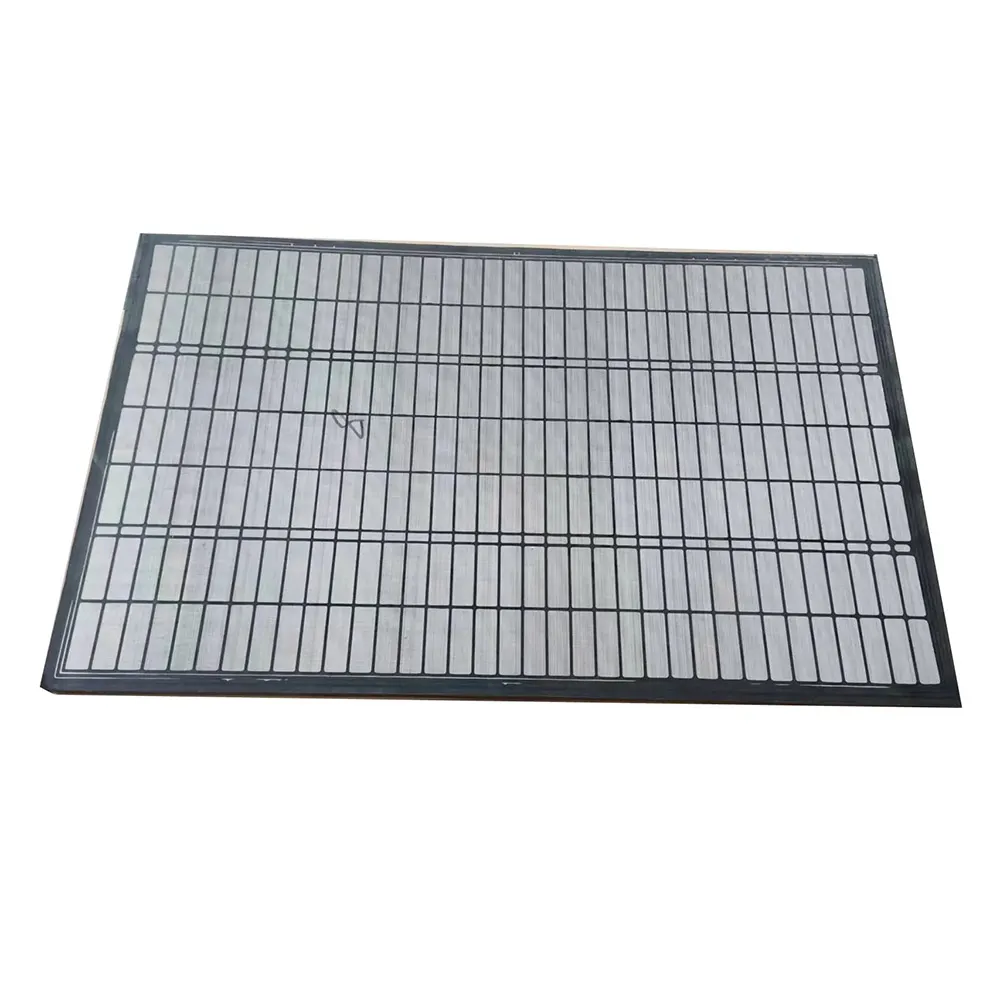

- Product Name: Brandt Replacement Shale Shaker Screen

- Product Link: https://www.solidcontrolpart.com/brandt-replacement-shale-shaker-screen.html

- Compatible Models: King Cobra, King Cobra Venom, VSM 300, D380, LCM-2D, and more.

- Core Standard: API RP 13C/ISO 13501

Brandt Replacement Shale Shaker Screens are the premium solution for solids control systems operating in the harshest fields. Utilized extensively in oil/gas, chemical, and mineral separation processes, these screens ensure optimal cut-point, fluid throughput and lifespan.

| Parameter | Value/Range |

|---|---|

| Screen Material | SS316/SS304 |

| Frame Material | High-strength Polyurethane or PT Composite |

| Mesh Type | Single, Double/Triple Layer |

| Mesh Size | API 20–325 |

| Screen Dimensions | 915×686mm / 1165×610mm (standard Brandt sizes) |

| Screen Area | 0.6–0.8 m² |

| API RP 13C D100 | 130–320 μm (varies by mesh) |

| Conductance | 1.8–9.5 kD/mm (typ.) |

| Working Life | 220–420 hours |

| Corrosion Resistance | Excellent (tested to ASTM B117) |

- Raw Material Inspection: Strict sourcing of SS316/304 mesh, polyurethane or composite thermoplastics, chemical composition verified (ISO 9001:2018, test report attached on batch request).

- Weaving/Annealing: Mesh is woven to API RP 13C, then annealed for strength and flexibility.

- Frame Manufacturing: Polyurethane is injection-cast, or composite/steel is welded by CNC/manual.

- CNC/Cutting: Screen panels cut by CNC/laser, tolerance ±0.1mm.

- Bonding/Final Test: Mesh bonded in frame at high temp; non-destructive (NDT) test for adhesion and uniformity, visual + dimensional inspection by ISO/ANSI/AQL standards.

- Oil & Gas Drilling: Reduces solids

- Petrochemical & Refining: Handles corrosive slurries and hydrocarbon exposure, with >98.5% pass rate in quality control (ISO 13501-certified).

- Mining & Minerals: Robust mesh construction for abrasive dewatering/separation, field reports cite up to 410 hour continuous operation (customer: Barrick Gold, 2023).

- Water Supply/Treatment: Prevents system fouling, corrosion resistance based on ASTM B117 (salt spray) standards.

- Composite/steel hybrid frame for double bending resistance (energy absorption reduces warp/failure risk).

- Chemical Treatment: All mesh is epoxidized, preventing rust and chemical corrosion (per ISO 9227 salt spray test, >480hrs resistance).

- Precision Multi-layer Mesh: Fine-tunes cut point; triple layer uses specialized adhesive for heat tolerance.

- Uniform Conductance: High-flow slot design allows peak throughput of 99%, reducing pump stress/load.

- Easy Fit: Plug-and-play with King Cobra shaker/VSM 300 shaker units—no frame modification required.

- Exceeds API & ISO specs: Each batch batch treated, visually and NDT scanned (SS304/316 via XRF gun, flaw

- Life-cycle Cost Savings: Field reports demonstrate 20–33% lower screen replacement cycle compared to market average.

- Custom mesh size (API 10–400); double/triple layer configuration

- Frame shape: steel-end, polyurethane, rectangular/rounded/oblique

- Special coatings: PTFE, FKM, anti-microbial (for water/food industry)

- Brand & color: laser marking, OEM packaging and branding

- On-site mesh testing, post-installation monitoring, application matching advice

Shale shaker screen manufacturers providing OEM screens: guaranteed fit, ISO/ANSI-compliant production lines, short leadtime. Large-volume contracts include dedicated after-sales engineer.

- Default Leadtime: 5–7 business days (in-stock); OEM 18–22 days

- Packing: Polyurethane edge, inner foam box, outer composite crate (sea/air tested)

- Full document set: Test report, material cert, weld & mesh batch numbers labeled

- Global warehouse: China, Middle East, Europe, North America

-

Q1: What is “mesh size” in shaker screens and how does it relate to API designation?

A: Mesh size is the number of openings per linear inch (US standard). API RP 13C designates screen cut-point range (D100). Higher API = finer filtration. For instance, API 120 = ~125μm cut point. -

Q2: What are common materials for shaker screen mesh and why?

A: High-tensile SS316/SS304 (stainless steel). SS316 has superior corrosion/pitting resistance, ideal for chemical/oilfield service.

Polyurethane frame edges improve shock/chemical resistance (per ISO 9227, ANSI/ASTM B117). -

Q3: What is the typical screen testing/acceptance standard?

A: API RP 13C/ISO 13501. Screens are lab-analyzed for cut-point accuracy, conductance (fluid throughput) and plugged area (visual/NDT test). Each batch includes: chemical cert, D100 mesh/edge test, AQL visual check. -

Q4: How are shaker screens installed & what are common failure causes?

A: Screens are mounted on flat/curved beds with rubber gaskets. Common causes of failure: over-tension, improper gasket, excessive impact/vibration, abrasive fluids (abrasion shortens mesh life). -

Q5: What is “conductance” & why is it important?

A: Conductance is the measure of ease of fluid flow through the screen, in kD/mm (API standard). Higher conductance = better mud flow, less clogging, improved separation efficiency. -

Q6: Do Brandt replacement screens void OEM warranty or are there certifications for third-party screens?

A: No, as long as third-party screens comply with API RP 13C/ISO 13501, they fit and function same as OEM. Some fields even reported better operational results (see field cases above). -

Q7: What’s the typical warranty & support policy for shaker screens?

A: Standard warranty is 400 operational hours / 4 months, covering material defects. Technical support: 24h hotline, field application engineer visit (for volume contracts). Replacement for >1% installed defect rate.

- Warranty: 400 hour/4 month performance guarantee (manufacture defect, delamination, gross mesh distortion)

- Testing: 100% API/ISO batch-tested. Optional third-party inspection (SGS, Bureau Veritas)

- Certifications: ISO 9001:2018, API RP 13C/ISO 13501, RoHS compliance (on request)

- Support: 24/7 technical hotline, WhatsApp/WeChat, on-site engineer deployment (for orders >200 pcs)

- Client list: CNPC, Sinopec, Schlumberger (OEM supply); over 29 export countries

- All screens supplied with tracking label, QR code for mesh test results

With fluid-handling efficiency, corrosion proofing, durability and full compliance with global standards, shale shaker screen manufacturers such as Brandt (via trusted distributors) remain the benchmark for oilfield, mining and industrial separation. Their high-precision mesh and advanced bonding techniques directly translate to lower operational cost, minimum downtime and safer field operations.

- Best-in-class mesh technology, proven by API/ISO/ASTM laboratory results

- Rigorous quality assurance spanning material selection to final batch traceability

- Field-proven OEM compatibility for major global shaker models

- Responsive support, rapid OEM/cutting customization for emerging sector demands

- Thousands of wells, plants, and contractors relying on verifiable, cert-backed screens: see them on industry research (ResearchGate)

- API RP 13C/ISO 13501: “Recommended Practice for Drilling Fluids Processing Systems Evaluation,” Energy Specialists Org

- SPE-156539-MS: Enhanced Testing of Shale Shaker Screens, 2022, OnePetro

- ResearchGate: "Performance and Life Cycle Analysis of Composite Shale Shaker Screens," full access paper

- Industry Forum: PetroWiki - Shale Shakers

- Technical Articles: petroleum.co.uk — shaker screen guides.