The Crucial Role of Shale Shaker Screens in Modern Drilling

In the intricate world of oil and gas exploration, efficient solid control systems are paramount to operational success, environmental compliance, and cost-effectiveness. At the heart of these systems are shale shakers, and more specifically, their high-performance screens. As leading shale shaker screen manufacturers, we understand the critical role these components play in separating drilling fluids from drill cuttings. This separation process not only recovers valuable drilling mud, significantly reducing fluid costs and waste disposal volumes, but also ensures the longevity of downstream equipment. The continuous innovation in screen technology has led to superior designs offering enhanced throughput, finer cut points, and extended service life, directly impacting drilling efficiency and safety standards.

The industry's trend towards deeper wells and more complex formations, particularly in unconventional plays, demands increasingly robust and efficient solid control solutions. This includes advanced screens capable of handling high flow rates and abrasive solids. The selection of the right screen, from various types like flat panel or pyramid screens, is crucial. For instance, the demand for a reliable shaker screen for sale that can withstand aggressive drilling environments is consistently high. Companies rely on these screens to maintain the rheological properties of drilling mud, optimize penetration rates, and minimize non-productive time. Our focus is on providing solutions that meet these stringent demands, ensuring operational excellence for our clients globally.

Manufacturing Excellence: The Process Behind Superior Screens

The production of high-quality shale shaker screen manufacturers involves a meticulous multi-stage manufacturing process, emphasizing precision, material integrity, and rigorous quality control. It typically commences with the selection of premium-grade raw materials, primarily high-tensile stainless steel wire mesh (typically SUS304 or SUS316L for corrosion resistance and durability). This material is chosen for its superior strength-to-weight ratio and resilience against the abrasive nature of drilling fluids and cuttings. Following material selection, the process moves into the weaving or bonding phase. Advanced automated weaving looms produce various mesh sizes, ensuring consistent aperture control crucial for efficient solids separation and accurate cut points.

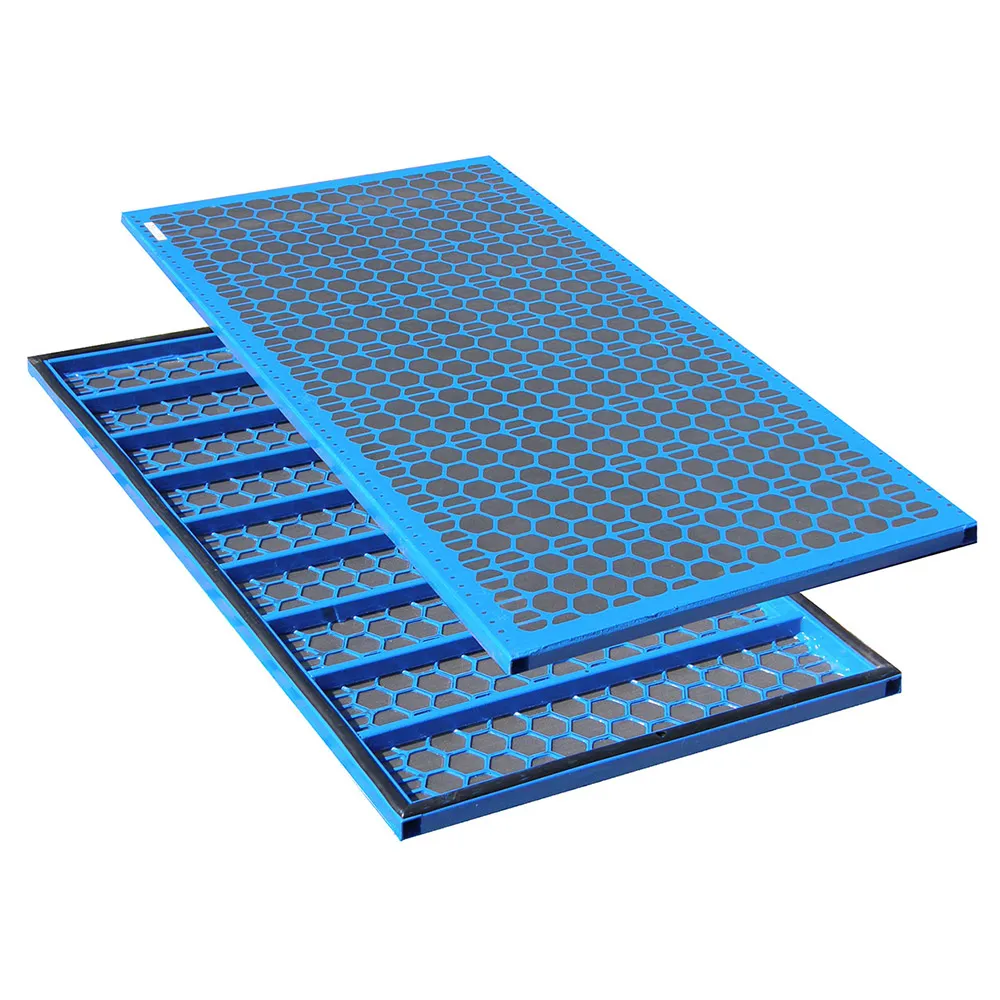

A close-up of a high-performance mesh, critical for efficient solids control.

The frame fabrication is another critical step. Screen frames, typically constructed from robust steel or composite materials, are designed to integrate seamlessly with specific shaker models like the king cobra shale shaker or vsm 300 shaker. Modern manufacturing employs CNC machining for precise frame dimensions, ensuring a perfect fit and preventing mud bypass. The mesh panels are then stretched and bonded to these frames using advanced bonding agents and techniques, such as resistance welding or adhesive bonding, to ensure maximum tension and prevent premature delamination under severe vibration. Throughout the entire process, adherence to international standards like ISO 9001 for quality management and API RP 13C (Recommended Practice for Shaker Screen Testing) for performance parameters is strictly maintained. This commitment ensures products exhibit consistent performance, optimal service life (typically ranging from 300 to 800 operational hours depending on drilling conditions), and exceptional resistance to corrosion, benefiting industries from petrochemical to environmental engineering through enhanced energy efficiency and reduced maintenance.

Technical Specifications and Performance Metrics

Understanding the technical parameters of shale shaker screen manufacturers is crucial for optimal selection and performance in drilling operations. Key specifications include API mesh size, non-blanked area, conductance, and cut point (D100/D50). API mesh size, defined by API RP 13C, standardizes screen performance by correlating mesh numbers with sieve sizes, ensuring consistent solids removal efficiency across different manufacturers. A higher non-blanked area directly translates to greater fluid throughput and reduced fluid retention on the screen surface, thereby improving processing capacity. Conductance, another critical API RP 13C parameter, quantifies a screen's ability to allow fluid to pass through, directly impacting drilling fluid recovery rates and overall drilling speed.

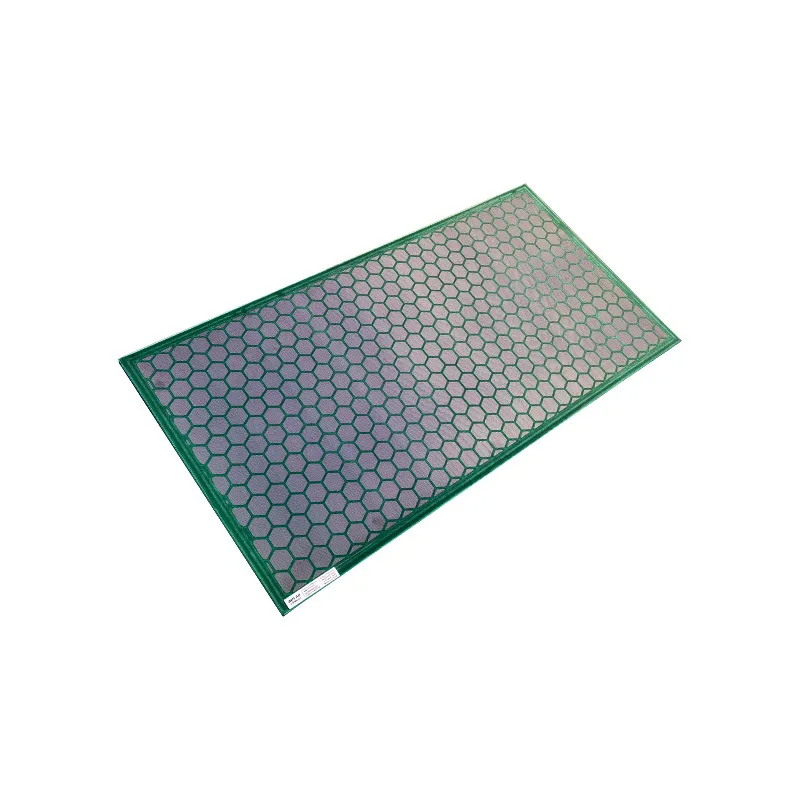

Precision-engineered replacement screen designed for high throughput.

The cut point (D100/D50) indicates the screen’s efficiency in separating solids of specific particle sizes. D100 represents the particle size at which 100% of the particles are retained, while D50 signifies the particle size at which 50% are retained. These metrics are vital for fine-tuning solids control to maintain desired mud properties and minimize drilling waste. For example, our Brandt Replacement Shale Shaker Screen, designed for compatibility with popular shakers, consistently achieves a D50 cut point range between 75 and 150 microns, depending on the mesh series, ensuring highly efficient removal of fine solids. Our screens are rigorously tested against API RP 13C standards to guarantee superior conductance values, typically ranging from 2.0 to 5.0 kD/mm (kiloDarcies per millimeter), ensuring maximum fluid processing capacity. This technical transparency and adherence to international benchmarks build significant trust with our B2B partners, demonstrating our expertise and commitment to delivering reliable, high-performance solutions.

Comparative Analysis of Leading Shaker Screen Types

The market for shale shaker screen manufacturers offers a variety of designs, each optimized for specific drilling conditions and shaker models. Understanding the distinctions between these can significantly impact operational efficiency and cost. Common types include flat panel screens, often used in older generation shakers or as primary scalping screens, and composite screens, which are widely adopted in modern high-G shakers due to their enhanced durability and longer service life. Pyramid screens, such as those found on a king cobra shale shaker, feature a unique three-dimensional structure that effectively increases the non-blanked area, allowing for higher fluid throughput without compromising cut point. This design is particularly advantageous in scenarios requiring aggressive fluid processing.

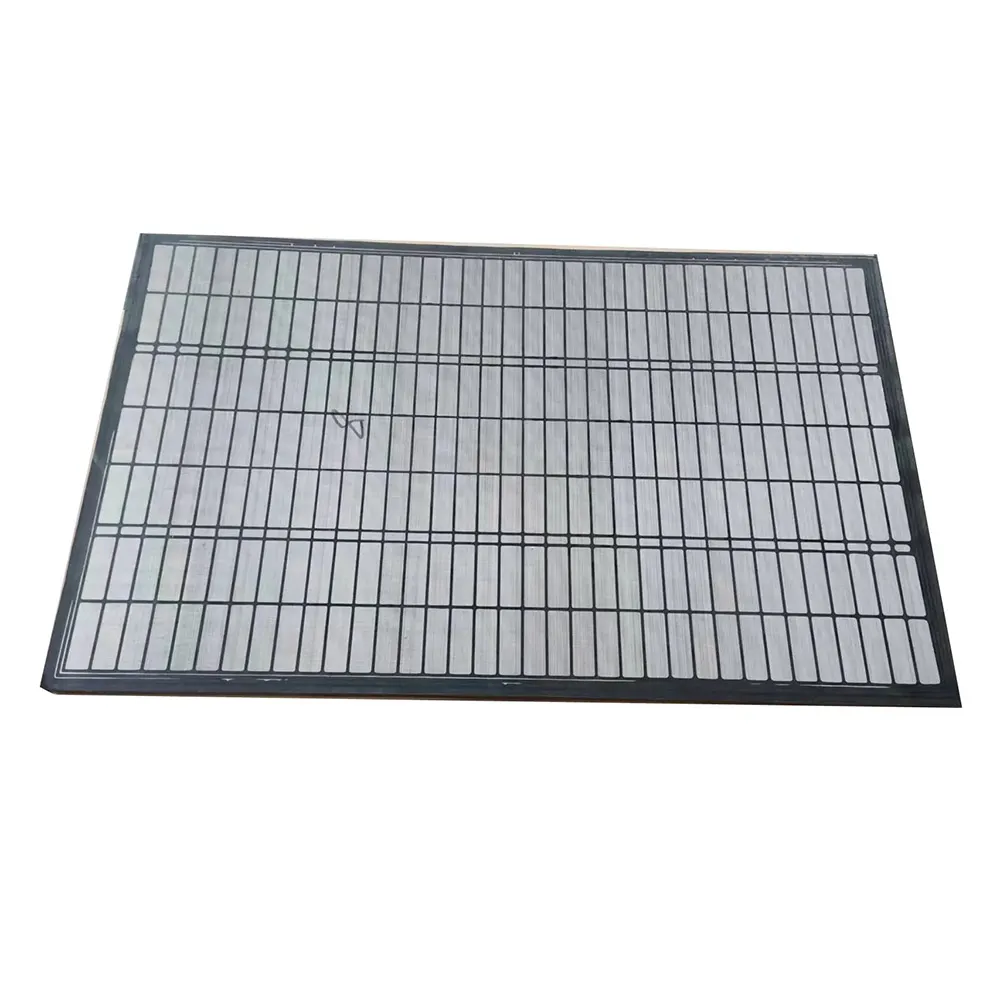

Brandt VSM 300 scalping screen, designed for high-volume solids removal.

For shakers like the vsm 300 shaker, specialized screens are engineered to maximize performance under specific vibrational patterns. Below is a comparative table highlighting key specifications and typical applications for various popular brandt shaker screens and general screen types. This data-driven approach helps operators select the most suitable screens, optimizing their solids control strategy and enhancing overall drilling economics. Our experience in supporting a diverse client base across challenging environments informs our recommendations and product offerings, providing practical solutions based on real-world performance data and client feedback.

Shale Shaker Screen Comparison Table

| Feature | Flat Panel Screen | Pyramid/Corrugated Screen | Composite Screen (Brandt Replacement) |

|---|---|---|---|

| Structure | Flat, multi-layered mesh on steel frame | 3D corrugated surface on steel/composite frame | High-strength composite frame with multiple mesh layers |

| Non-Blanked Area | Good (typically 50-60%) | Excellent (typically 70-80% due to 3D design) | Superior (typically 75-85% due to thin composite frame) |

| Conductance (kD/mm) | 1.5 - 3.0 | 2.5 - 4.5 | 3.0 - 5.0+ |

| Service Life | Moderate (150-400 hrs) | Good (250-600 hrs) | Excellent (300-800+ hrs) |

| Vibration Tolerance | Standard | High | Very High (minimizes frame cracking) |

| Applications | Primary scalping, older shaker models | High-volume drilling, sticky formations | All drilling conditions, premium performance, reduced waste |

Customized Solutions and Client Success

Recognizing that no two drilling operations are identical, leading shale shaker screen manufacturers excel in providing customized screen solutions. This tailored approach involves collaborating closely with clients to assess their specific drilling fluid properties, formation types, flow rates, and existing shaker equipment. Based on this comprehensive analysis, we can recommend optimal screen configurations, including specific mesh sizes, panel designs (e.g., flat, pyramid, or composite), and materials. For instance, in an offshore drilling project facing significant gumbo shale, a client experienced frequent screen blinding and reduced drilling rates. Our team analyzed their mud properties and shaker specifications, recommending a shift to specialized composite brandt shaker screens with improved anti-blinding features and larger non-blanked areas.

Brandt D380 shaker screen, illustrating customization potential for various rig needs.

The outcome of this customization was a remarkable 25% increase in solids removal efficiency, a 15% reduction in mud loss, and extended screen life, contributing to significant operational savings. Our commitment to client success extends beyond product delivery to comprehensive after-sales support, including technical consultations, on-site training, and a robust warranty program. We offer an industry-leading 12-month warranty on our Brandt Replacement Shale Shaker Screens, subject to standard operating conditions, underscoring our confidence in their durability and performance. Our typical delivery cycle for standard orders is 7-14 business days, with expedited options available for urgent requirements, ensuring minimal downtime for your operations. This dedication to service and quality cements our position as a trusted partner in solids control.

Frequently Asked Questions (FAQ)

- Q: How do your shale shaker screen manufacturers ensure product quality?

- A: We adhere to stringent quality control protocols, including ISO 9001 certification and comprehensive testing against API RP 13C standards for mesh integrity, conductance, and cut point. Each screen undergoes multiple inspection stages, from raw material verification to final product performance checks.

- Q: What is the typical lifespan of your Brandt Replacement Shale Shaker Screen?

- A: The lifespan varies based on drilling conditions, mud properties, and operational practices. However, our Brandt Replacement Screens are designed for extended durability, typically lasting between 300 to 800 operating hours under normal conditions, often outperforming traditional screens.

- Q: Are your screens compatible with other shaker models besides Brandt?

- A: While our Brandt Replacement screens are specifically designed for Brandt series shakers, we offer a broad range of replacement screens compatible with various popular shaker models, including those from Derrick, Swaco, FLC, and more. Please contact our technical support for specific compatibility inquiries.

- Q: Do you offer technical support or on-site assistance?

- A: Yes, we provide comprehensive customer support, including technical guidance on screen selection, optimization of solids control systems, and troubleshooting. On-site assistance can be arranged for major projects or complex challenges, demonstrating our commitment to reliable partnerships.

References

- American Petroleum Institute. (2018). API Recommended Practice 13C: Drilling Fluid Processing Equipment Evaluation. Washington, D.C.: API Publishing.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements. Geneva: ISO.

- Neal, R., & Sarmah, A. K. (2020). Innovations in Drilling Fluids and Shale Waste Management. Journal of Petroleum Science and Engineering, 189, 107001.

- Suryanarayana, P. V. S. (2019). Solid Control Equipment and Practices in Drilling Operations. SPE Drilling & Completion, 34(03), 205-217.