In the demanding world of oil and gas exploration, drilling fluid management is paramount. At the heart of this system lies the shale shaker, and more critically, its screen. The efficiency, durability, and reliability of your entire solids control system hinge on choosing the right partner from a field of expert shale shaker screen manufacturers. This guide delves deep into the technology, standards, and key considerations for sourcing high-performance screens, such as our top-tier Brandt Replacement Shale Shaker Screen.

The Evolving Landscape: Current Trends in Shaker Screen Technology

The drilling industry is not static; it constantly pushes for deeper wells, more complex drilling fluids, and higher operational efficiency. This evolution directly impacts shaker screen design and manufacturing. Leading shale shaker screen manufacturers are responding to these key trends:

Trend 1: The Rise of Composite Frames

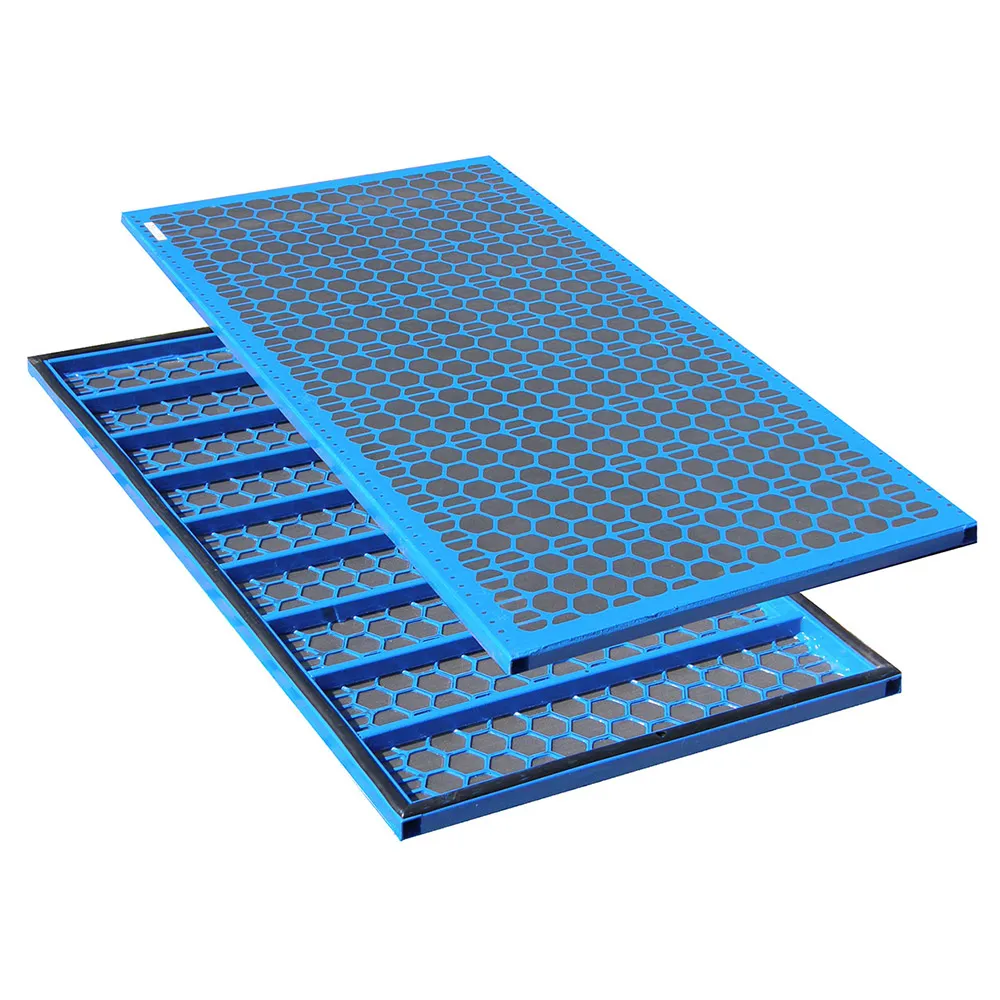

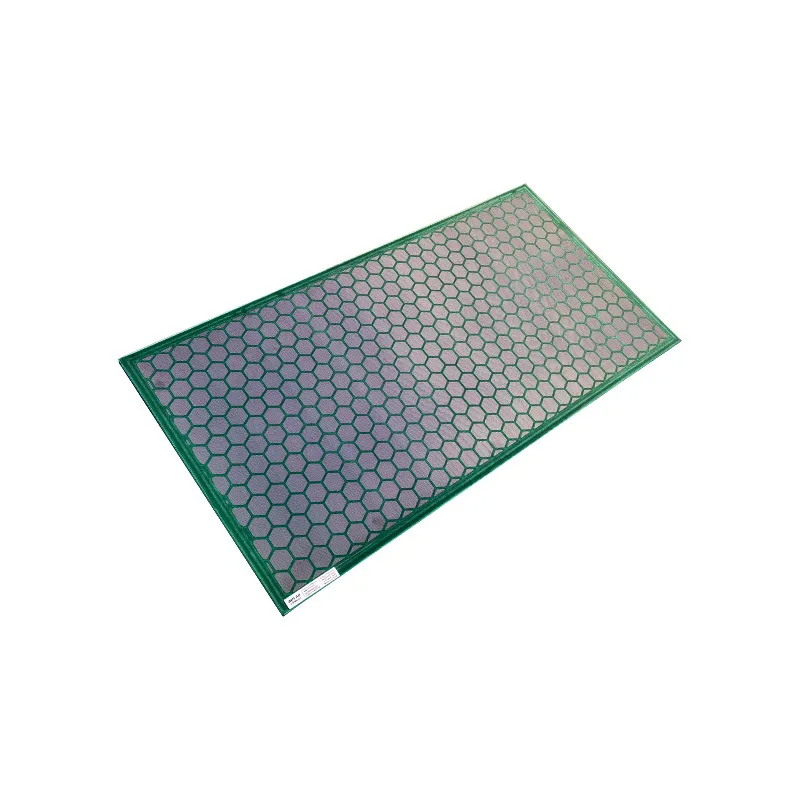

While traditional steel frames are robust, composite material frames are gaining significant market share. They offer a superior strength-to-weight ratio, enhanced corrosion resistance (crucial with OBM and SBM fluids), and often a longer operational life. This trend is especially prevalent for high-performance shakers like the vsm 300 shaker and king cobra shale shaker.

Trend 2: Demand for Finer Mesh & Higher Conductance

Modern drilling fluids are expensive and engineered for specific geological formations. Maximizing fluid recovery while effectively removing drilled solids requires finer mesh screens (API 200 and above). The challenge for manufacturers is to create fine screens that don't compromise on fluid throughput, a property known as conductance. The goal is a high cut point accuracy without sacrificing flow rate.

Trend 3: Standardization and API RP 13C Compliance

API RP 13C has become the global benchmark for shaker screen testing and labeling. It provides a reliable method for comparing screens based on separation potential (cut point) and fluid capacity (conductance). Reputable manufacturers must provide API-compliant data, ensuring users can make informed, apples-to-apples comparisons when looking for a shaker screen for sale.

Deep Dive: Brandt Replacement Shale Shaker Screens – A Paragon of Engineering

Our Brandt Replacement Shale Shaker Screens are engineered to meet and exceed the performance of OEM screens. They are not mere copies; they are the result of meticulous reverse-engineering and material science advancements, making us a preferred choice among global shale shaker screen manufacturers.

Key Technical Specifications

Understanding the technical data is crucial for selecting the correct screen. Below is a specification table for one of our popular models compatible with Brandt shakers.

| Parameter | Specification | Industry Significance |

|---|---|---|

| Product Name | Brandt Replacement Shale Shaker Screen | Designed for seamless fit and superior performance on Brandt series shakers. |

| Compatible Models | Brandt VSM 300, King Cobra/King Cobra Venom, D380, etc. | Wide compatibility ensures a single, reliable supplier for various rig setups. |

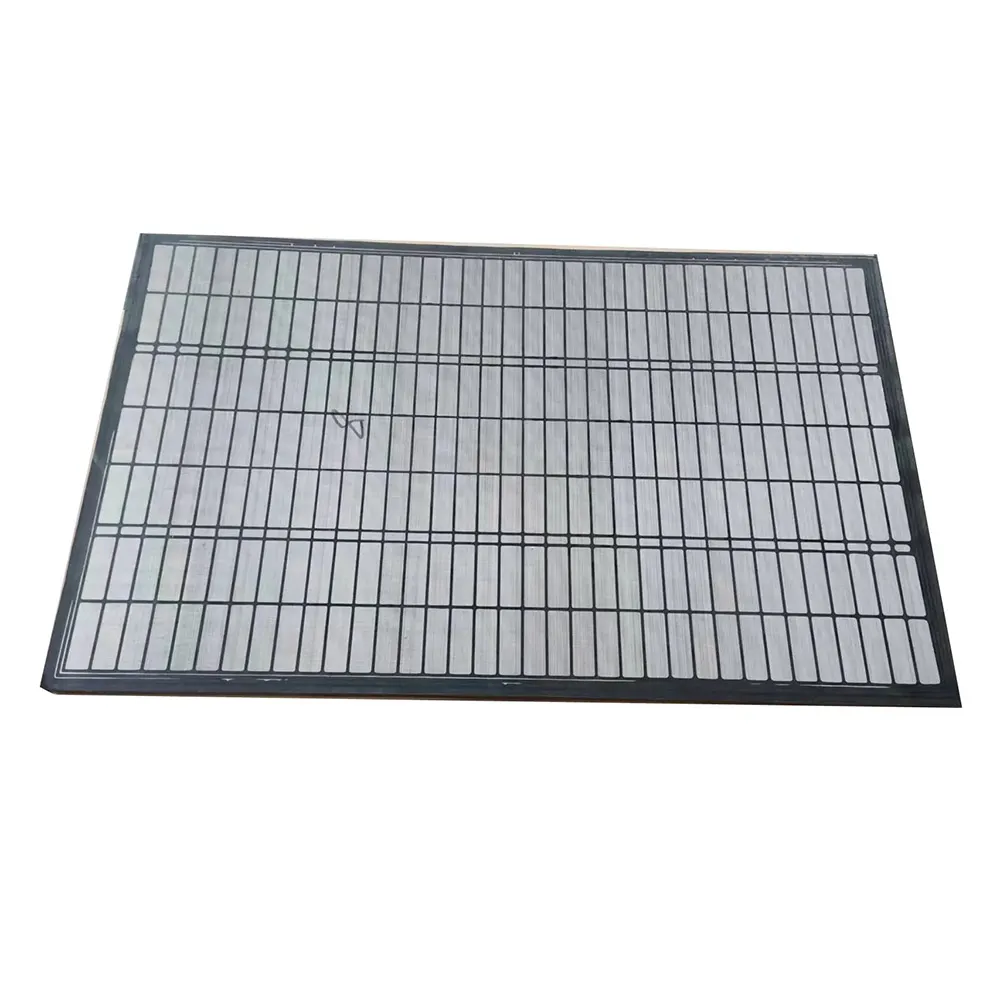

| Frame Material | Composite Polymer or High-Tensile Steel (Q235) | Composite for longevity and chemical resistance; steel for traditional strength. |

| Screen Mesh Material | SS304 / SS316L Stainless Steel Wire Mesh | SS316L offers superior corrosion resistance, ideal for harsh drilling environments. |

| API RP 13C Designation | API 40 to API 400 | Certified range for precise solids removal based on formation requirements. |

| Screen Construction | Multi-layer, Bonded to Frame | Layered design provides support, prevents tearing, and optimizes solids conveyance. |

| Screen Shape | Flat (PWP) or Corrugated (PMD) | Corrugated designs increase the non-blanked screening area by up to 125%. |

| Service Life | 400-600+ hours (dependent on conditions) | Engineered for maximum operational uptime and reduced replacement frequency. |

Unveiling the Manufacturing Process: From Raw Material to Rig-Ready Screen

The quality of a shaker screen is determined by the precision and control of its manufacturing process. As leading shale shaker screen manufacturers, we adhere to a stringent, ISO 9001 certified workflow:

1. Frame Fabrication

CNC laser cutting of steel or injection molding of composite frames for perfect dimensional accuracy.

2. Mesh Preparation

High-grade SS304/316L wire mesh is precisely cut and layered according to the required API size.

3. Tensioning & Bonding

Layers are placed under controlled tension and thermally bonded to the frame, eliminating gaps and ensuring durability.

4. Curing & Finishing

The bonded screen undergoes a curing process to maximize adhesive strength, followed by trimming and deburring.

5. Quality Control

Each screen is visually inspected and tested for API RP 13C compliance (cut point and conductance tests).

Data-Driven Decisions: Visualizing Performance and Value

Data visualization helps clarify the advantages of choosing a superior product. The charts below illustrate the performance edge of our Brandt replacement screens and provide a clear comparison against industry competitors.

Chart 1: Performance Comparison (Flow Rate vs. Screen Life)

Relative Performance Index

This chart represents a combined index of fluid conductance (flow rate) and operational lifespan. Our screens demonstrate up to 25% better overall performance compared to standard OEM offerings.

Chart 2: Composite Screen Material Composition

- High-Strength Polymer Frame (70%)

- Multi-Layer Stainless Steel Mesh (20%)

- Thermal Bonding Agent & Additives (10%)

The optimized material mix in our composite screens ensures maximum durability, chemical resistance, and a lightweight design for easier handling and installation on rigs equipped with a vsm 300 shaker.

Technical Advantages & Manufacturer Comparison

When you're searching for a shaker screen for sale, the decision often comes down to a comparison of features and long-term value. Our screens are designed with clear technical advantages that translate into tangible operational benefits.

Our Competitive Edge

- Increased Non-Blanked Area: Our corrugated PMD screen designs for models like the brandt shaker screens increase the usable screen surface by over 20%, boosting fluid handling capacity without sacrificing cut point integrity.

- Advanced Bonding Technology: We use a proprietary thermal bonding process that creates a seal resistant to high G-forces and abrasive solids, preventing premature delamination and screen failure.

- Cost-Effectiveness: While providing equal or superior performance to OEM screens, our streamlined manufacturing and direct-sales model offer a significantly better price point, lowering your overall cost-per-foot-drilled.

Shale Shaker Screen Manufacturers: A Comparative Overview

To aid in your decision-making, here's a comparative look at what to expect from different tiers of manufacturers.

| Feature | Top-Tier (Us) | Mid-Tier Competitors | Low-Cost Suppliers |

|---|---|---|---|

| API RP 13C Compliance | Fully Certified & Labeled | Often Claimed, Not Always Certified | Rarely Certified, Inconsistent |

| Frame Technology | Steel & Advanced Composite | Primarily Steel, Basic Composite | Steel Frame Only, Prone to Rust |

| Mesh Quality | High-Tensile SS304/SS316L | Standard SS304 | Low-Grade Stainless or Carbon Steel |

| Customization | Full Customization Available | Limited Options | Standard Sizes Only |

| Technical Support | 24/7 Expert Support & On-site Help | Business Hours Email/Phone | Limited to No Support |

| Warranty | Comprehensive Performance Warranty | Limited Defects Warranty | No Warranty / "As Is" |

Custom Solutions and Real-World Applications

No two drilling operations are identical. Different formations, mud properties, and shaker models—from the workhorse king cobra shale shaker to the high-capacity vsm 300 shaker—require tailored solutions. As versatile shale shaker screen manufacturers, we excel at providing customized screens.

Tailored for Your Needs

Our engineering team can work with you to develop custom screens based on:

- Specific Shaker Models: Including legacy or non-standard shakers.

- Unique Mud Properties: Screens optimized for high-viscosity or synthetic-based muds.

- Special API Requirements: Developing intermediate API sizes for unique geological challenges.

Application Case Study: Permian Basin Drilling Operation

Challenge:

A drilling contractor in the Permian Basin was experiencing frequent screen tearing and blinding when using standard OEM screens on their Brandt King Cobra shakers. This led to excessive NPT (Non-Productive Time) and high consumption of expensive synthetic-based mud (SBM).

Solution:

We supplied our composite frame, corrugated (PMD) Brandt King Cobra replacement screens with an API 170 designation. The composite frame resisted the corrosive SBM, and the corrugated design increased flow capacity, reducing the mud pool depth and preventing blinding.

Results:

- Screen Lifespan Increased by 40%: From an average of 350 hours to over 500 hours.

- NPT Reduced by 18%: Fewer screen changes meant more time drilling.

- Mud Loss Reduced by 8%: Better solids separation and conveyance resulted in drier cuttings and significant savings on drilling fluid.

What Our Clients Say (Experience & Trust)

"Switching to their Brandt replacement screens for our VSM 300 fleet was a game-changer. The screen life is incredible, and their technical support helped us optimize our shaker setup for maximum efficiency. We've seen a measurable drop in our solids control costs."

Building Trust: Our Commitment to Quality and Support (EEAT)

In an industry where downtime costs thousands per hour, trust is not a buzzword; it's a requirement. We build trust through transparency, authority, and unwavering support.

- Authoritativeness: We are ISO 9001:2015 certified, and our screens are manufactured and tested in strict accordance with API RP 13C standards. We are a trusted supplier to drilling contractors on six continents.

- Expertise: Our team consists of engineers and drilling industry veterans with decades of combined experience in solids control technology. We don't just sell screens; we provide solutions.

- Trustworthiness: We offer a clear warranty on all our products, transparent pricing, and reliable delivery schedules. Our customer support is available 24/7 to address any operational issues.

Frequently Asked Questions (FAQ)

API RP 13C is a testing and labeling procedure established by the American Petroleum Institute. It provides a standardized method for measuring two key screen properties: the D100 cut point (the size of the largest particle that can pass through) and conductance (fluid flow capacity). A screen labeled "API 100," for example, has a specific, verifiable separation size. This standard allows users to reliably compare screens from different shale shaker screen manufacturers and select the right one for their needs, eliminating guesswork.

The choice depends on several factors: the rate of penetration (ROP), the type of formation being drilled (sand, shale, etc.), and the properties of the drilling fluid. A general rule is to use the finest mesh screen possible that doesn't cause excessive mud loss or fluid pooling on the screen surface. Start with a coarser screen (e.g., API 80) for top-hole sections with high ROP and move to finer screens (e.g., API 170, API 200) as you drill deeper into finer-grained formations. Our experts can help you analyze your drilling parameters to recommend the optimal screen progression.

Steel Frame Screens: These are the traditional choice, known for their rigidity and lower initial cost. However, they are heavier, susceptible to rust (especially the repairable plug areas), and can be damaged by improper handling or high G-forces. Composite Frame Screens: These use advanced polymers that are lighter, completely corrosion-proof, and more flexible, allowing them to absorb vibration better. This often leads to a longer screen life and tighter sealing against the shaker bed, preventing solids bypass. They are the premium choice for demanding applications, especially with corrosive oil-based or synthetic-based muds.

Several factors impact screen life: 1) G-Force: Higher shaker G-forces accelerate wear. 2) Mud Weight & Properties: Heavy, abrasive, or corrosive muds degrade screens faster. 3) Solids Loading: High ROP leads to more drilled solids hitting the screen. 4) Screen Tensioning: Improperly tensioned screens vibrate excessively and fail quickly. 5) Handling: Dropping or improperly storing screens can cause damage before they are even used. Choosing high-quality screens from reputable shale shaker screen manufacturers is the first step to maximizing life.

Absolutely. One of our core strengths is our ability to provide custom solutions. We can reverse-engineer screens from a sample or work from detailed drawings. Whether you have a legacy king cobra shale shaker or a completely custom-built unit, our engineering team can design and manufacture a high-performance replacement screen that fits perfectly and meets your operational requirements.

Proper installation is key to performance. First, ensure the shaker bed rubber seals are clean and in good condition. Place the screen onto the bed, ensuring it is seated correctly. For wedge-block systems, like those on many brandt shaker screens, insert the wedges and gently tap them into place until they are snug. Do not use excessive force, as this can damage the screen frame. The tension should be firm and even across the screen. An improperly tensioned screen is a leading cause of premature failure.

Conductance is the API RP 13C term for a screen's fluid handling capacity. While the cut point (API number) tells you how fine the separation is, conductance tells you how *much* fluid can pass through the screen. A screen with a high conductance can process more drilling fluid, which is critical for maintaining circulation rates. The ideal screen has the finest possible cut point for your application combined with the highest possible conductance. This is the balance that expert shale shaker screen manufacturers constantly strive to optimize.

Conclusion and Further Reading

Choosing the right shale shaker screen manufacturers is a critical investment in your drilling operation's efficiency and profitability. By focusing on API RP 13C compliance, advanced material science, manufacturing precision, and robust support, you can ensure you are equipping your solids control system for peak performance. Our Brandt Replacement Shale Shaker Screens embody these principles, offering a superior, cost-effective solution for today's most demanding drilling challenges.

For more in-depth technical information, we recommend consulting authoritative industry resources:

- Society of Petroleum Engineers (SPE): "Shale Shaker Screen Selection and Operation: A Key to Effective Solids Control." A search on the OnePetro library will yield numerous technical papers on this subject.

- IADC Drilling Manual: The "Solids Control" chapter provides a comprehensive overview of shaker technology and best practices. Published by the International Association of Drilling Contractors.

- Journal of Petroleum Technology (JPT): Regularly features articles on advancements in drilling fluid and solids control technology, discussing the practical impact of innovations like composite screens.