In the demanding world of oil and gas drilling, efficient solids control is paramount. It not only optimizes drilling performance but also significantly reduces operational costs and minimizes environmental impact. At the heart of this critical process lies the shale shaker screen manufacturers, a seemingly simple component that dictates the efficiency of drilling fluid (mud) cleaning. These screens are engineered to separate drilled cuttings from the valuable drilling fluid, ensuring its reuse and maintaining proper rheological properties. The global drilling industry's continuous push for higher efficiency, reduced waste, and enhanced safety has driven remarkable innovations in shale shaker screen technology, making the selection of the right screen and manufacturer a strategic decision for any drilling operation.

Industry Trends and Technological Advancements in Shale Shaker Screens

The shale shaker screen market is constantly evolving, driven by several key trends. Firstly, there's a strong emphasis on developing screens with extended service life and improved conductance. This directly translates to less downtime for screen changes and more efficient fluid processing. Manufacturers are increasingly utilizing advanced materials like composite frames and multi-layered mesh designs to achieve superior performance under harsh drilling conditions. Secondly, environmental regulations are pushing for more effective solids separation, leading to the development of finer mesh screens capable of removing smaller particles, thus reducing waste volume and facilitating easier disposal. Thirdly, automation and digital integration are impacting screen design, with some systems incorporating sensors for real-time performance monitoring and predictive maintenance. Lastly, the versatility of screen designs to accommodate various types of drilling fluids, from water-based to oil-based and synthetic-based muds, remains a crucial area of innovation. The demand for specialized screens for horizontal and unconventional drilling, which generate large volumes of fine cuttings, is also surging.

Understanding these trends is vital for operators seeking to enhance their drilling efficiency. The continuous drive towards sustainable and cost-effective drilling operations means that the role of advanced shale shaker screens will only grow in importance.

Brandt Replacement Shale Shaker Screen: A Technical Deep Dive

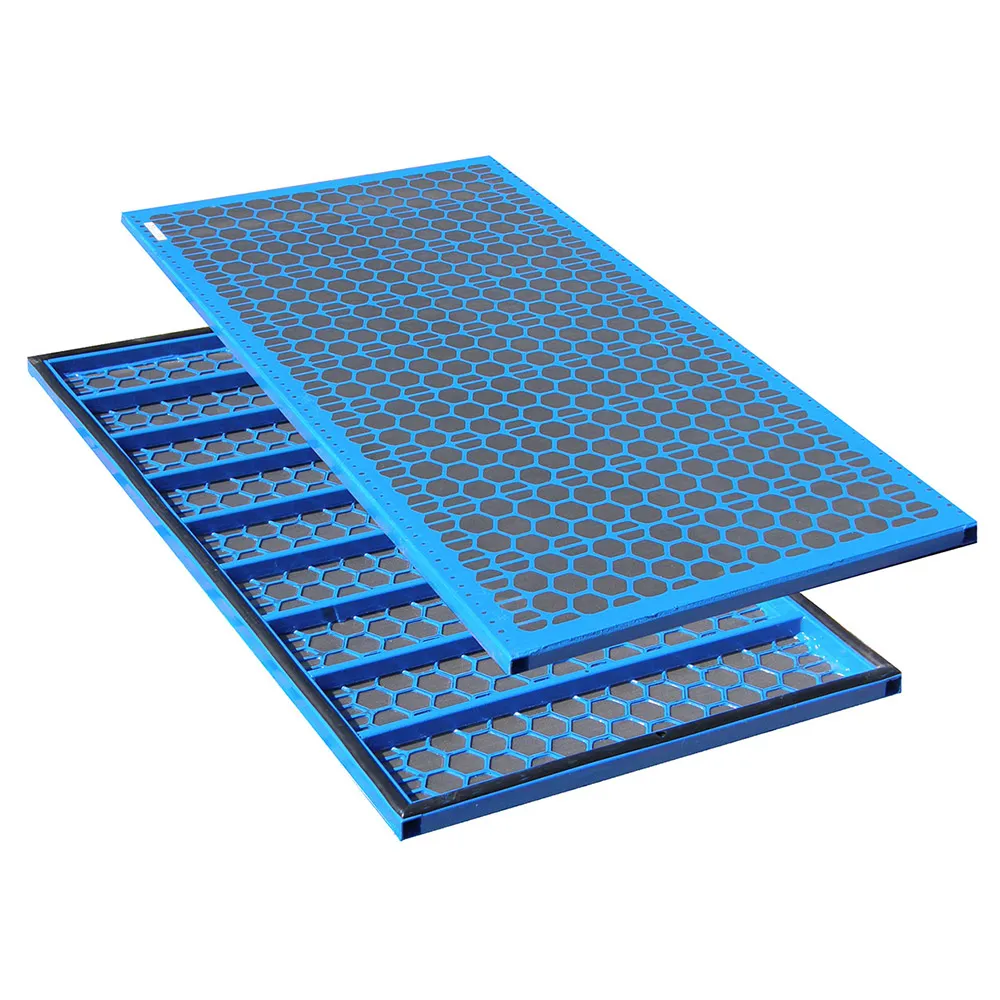

Our product, the Brandt Replacement Shale Shaker Screen, specifically targets the demanding requirements of various drilling operations, offering superior performance and compatibility. Designed as a direct replacement, it seamlessly integrates with Brandt King Cobra, VSM 300, and other compatible shaker models, ensuring optimal solids control without the need for extensive system modifications. These screens are engineered to maximize fluid recovery and minimize waste, contributing significantly to operational efficiency and environmental compliance.

Image: High-performance replacement screen for demanding drilling environments.

Key Technical Parameters and Specifications

The performance of a shale shaker screen is primarily defined by several critical parameters, adhering to industry standards such as API RP 13C (Recommended Practice for Shale Shaker Screen Cloth and Panels). This standard ensures consistency and allows for accurate comparison between different screens.

| Parameter | Description | Typical Range / Value | Benefit |

|---|---|---|---|

| API Mesh Size | Indicates the screen's ability to separate particles, based on sieve analysis (e.g., API 60, API 200). | API 20 to API 400 | Precise solids separation, optimized fluid quality. |

| Conductance (k) | Measure of a screen's flow capacity, in kD/mm (Darcy/millimeter). Higher k means better flow. | 5 to 200 kD/mm | High processing volume, reduced fluid loss. |

| Non-Blanked Area (NOC) | Percentage of the screen's surface that is open for fluid passage. | 60% to 85% | Improved screening efficiency, faster separation. |

| Material | Typically high-grade stainless steel wire cloth (304, 316L) with composite or steel frames. | SS304/316L, Polyurethane, Composite | Corrosion resistance, durability, extended lifespan. |

| Layers | Number of mesh layers (e.g., 2, 3, or 4 layers) influencing separation precision and strength. | 2-4 layers | Enhanced separation, fine particle removal, increased screen life. |

| Panel Type | Refers to the screen's design (e.g., Flat, Pyramid, Corrugated) affecting surface area. | Flat, Pyramid, Corrugated | Increased effective screening area, higher capacity. |

Manufacturing Process of High-Performance Shale Shaker Screens

The manufacturing of a high-quality shale shaker screen is a sophisticated process that combines material science, precision engineering, and rigorous quality control. It's a testament to the expertise of leading shale shaker screen manufacturers.

Shale Shaker Screen Manufacturing Process Flow:

-

1. Material Selection & Procurement:

Begins with sourcing premium-grade materials. For the mesh, this typically involves high-tensile strength stainless steel wire (e.g., SS304 or SS316L) known for its corrosion resistance and durability. For the frame, materials range from robust steel alloys to advanced composite polymers, chosen for their vibration dampening and long-life properties. All materials undergo initial quality checks to ensure compliance with international standards like ASTM.

Key Node: Raw Material Quality Assurance (e.g., Material Certificates, Tensile Strength Testing).

-

2. Wire Weaving/Mesh Production:

Precision weaving machines are used to produce multi-layered mesh panels. Different weaving patterns (e.g., plain weave, twilled Dutch weave) are employed based on the desired API mesh size, conductance, and non-blanked area. The mesh layers are often bonded or sintered together to form a robust, tear-resistant structure.

Key Node: Weave Pattern & Mesh Count Calibration (e.g., Optical Inspection, Mesh Opening Measurement).

-

3. Frame Fabrication (CNC Machining/Molding):

For steel frames, processes like precision laser cutting, bending, and welding are employed. For composite frames, advanced injection molding or compression molding techniques are used to create lightweight yet incredibly strong frames that resist corrosion and wear. CNC machining ensures exact dimensions for seamless fitment with shaker equipment.

Key Node: Frame Dimensional Accuracy & Material Integrity (e.g., Caliper Measurements, Ultrasonic Testing for Composites).

-

4. Screen Panel Assembly:

The prepared mesh layers are meticulously joined to the fabricated frame. This often involves a tensioning process to ensure optimal mesh tautness, which is crucial for effective solids separation and screen longevity. Depending on the design, adhesion bonding, welding, or mechanical fastening methods are used.

Key Node: Mesh Tensioning & Bonding Strength (e.g., Pull Tests, Visual Inspection).

-

5. Surface Treatment & Finishing:

Some screens may undergo additional treatments such as powder coating for enhanced corrosion resistance, or specialized coatings to improve non-wetting properties, preventing mud blinding (clogging). Edge sealing and reinforcement are also performed here.

Key Node: Coating Adhesion & Integrity (e.g., Adhesion Tests, Thickness Measurement).

-

6. Quality Control & Testing:

Every screen undergoes stringent quality assurance checks. This includes visual inspection for defects, dimensional checks, API RP 13C compliance testing (D-factor, conductance, non-blanked area), and often vibration or performance simulations. Only screens meeting strict criteria are approved for dispatch.

Key Node: Final Performance Validation (e.g., API Compliance Tests, Functional Testing).

-

7. Packaging & Logistics:

Screens are carefully packaged to prevent damage during transit, often using reinforced cardboard boxes or wooden crates. Proper labeling with product specifications ensures easy identification and inventory management.

Key Node: Secure Packaging & Accurate Labeling.

Our Brandt Replacement Shale Shaker Screens boast an exceptional service life, typically ranging from 300 to 1000 drilling hours, depending on drilling conditions and mud properties. This extended lifespan is a direct result of our meticulous material selection and advanced manufacturing processes. They are primarily applicable in the oil & gas drilling sector, but their robust design and efficient separation capabilities also find relevance in mining (slurry dewatering), environmental remediation (waste fluid processing), and industrial wastewater treatment. In typical application scenarios, such as high-volume drilling operations, our screens demonstrate superior performance in maintaining mud weight, reducing solids content, and thus preventing costly wellbore instabilities and equipment wear. Their precise mesh opening ensures optimal recovery of valuable drilling fluids, leading to significant cost savings. Furthermore, the anti-corrosion properties of our materials ensure reliability even when handling corrosive drilling fluids, reducing premature screen failure and enhancing operational safety.

Application Scenarios and Real-World Impact

The effective deployment of high-quality shale shaker screens is central to the success of modern drilling operations. From deep offshore wells to challenging unconventional plays, these screens are the first line of defense in managing drilled solids. For instance, in a deep directional drilling project, maintaining fluid rheology is critical. Our Brandt Replacement Shale Shaker Screen, with its high conductance, ensures that a large volume of mud can be processed quickly, removing fine solids that would otherwise increase mud weight and viscosity, leading to potential formation damage or stuck pipe incidents. The screen's ability to efficiently separate fine cuttings (

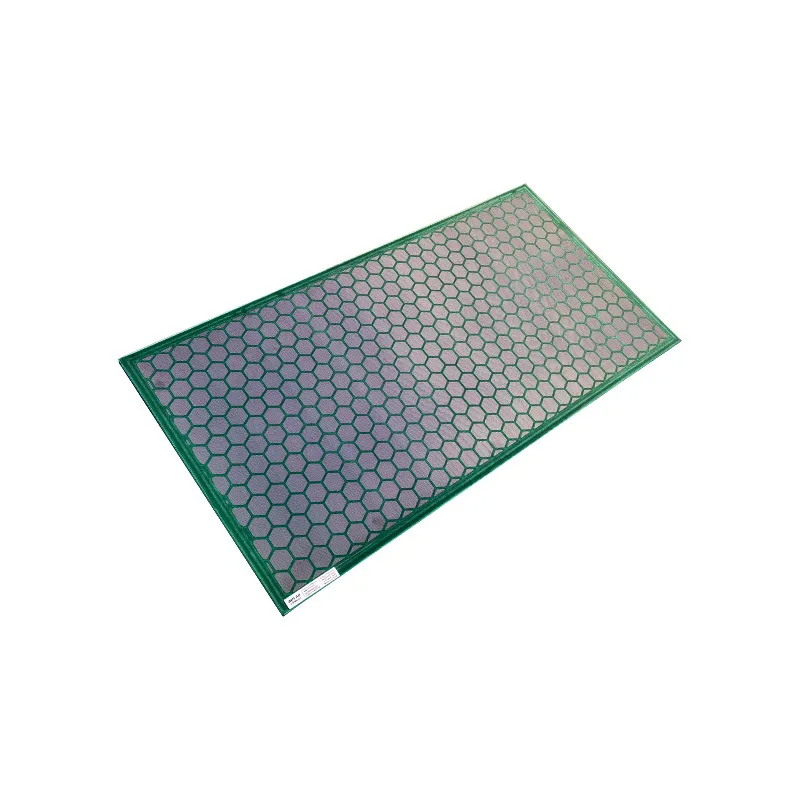

Image: Brandt Replacement Shale Shaker Screen in operation.

Our screens are extensively used in various modules of the solids control system: primary shakers for initial large solids removal, secondary shakers for finer particles, and often in conjunction with desanders and desilters. Their robust design handles the high G-forces and abrasive nature of drilling mud, maintaining integrity and performance for extended periods. This reliability translates directly to reduced non-productive time (NPT) for screen changes and improved overall drilling efficiency. The precise separation also contributes to reduced consumption of drilling fluid additives, as the fluid remains cleaner and requires fewer chemical treatments to maintain its properties. Clients consistently report enhanced drilling speed and reduced equipment wear on downhole tools due to cleaner drilling fluid, showcasing the direct positive impact of our screens on their bottom line.

Comparing Leading Shale Shaker Screen Manufacturers

The market for shale shaker screens is competitive, with several prominent shale shaker screen manufacturers offering a range of products. While specific models vary, the core performance differentiators lie in material science, manufacturing precision, and design innovation. Understanding these differences is crucial for selecting the optimal screen for specific drilling needs.

| Feature/Manufacturer Focus | Brandt (e.g., King Cobra, VSM 300, D380) | Vendor B (Generic) | Our Brandt Replacement Screens |

|---|---|---|---|

| Typical Models | King Cobra, VSM 300, D380 | Various, often compatible with OEM | Direct replacement for Brandt King Cobra, VSM 300, D380 |

| Frame Material | Steel or Composite | Steel, sometimes plastic | High-strength Composite (lightweight, corrosion-resistant) |

| Mesh Material | SS304/316L | SS304 (sometimes lower grade) | Premium SS304/316L, multi-layered |

| API Conductance | Good to Excellent | Varies, can be inconsistent | Excellent, optimized for flow (API RP 13C Compliant) |

| Service Life | High, but subject to drilling conditions | Moderate, prone to premature wear | Extended, engineered for durability in harsh conditions (300-1000 hours typical) |

| Solids Removal Efficiency | High | Average | Superior, minimizes fine solids carryover |

| Cost-Effectiveness | Premium pricing, but good ROI | Lower initial cost, but higher replacement frequency | Competitive pricing with superior ROI due to extended life and performance |

Our focus is on delivering screens that not only meet but exceed the performance of OEM screens for specific models like the king cobra shale shaker and vsm 300 shaker. We achieve this through meticulous engineering, stringent quality control adhering to ISO 9001 standards, and a deep understanding of drilling dynamics. While other manufacturers might offer a broad range, our specialization ensures that our Brandt Replacement Shale Shaker Screens provide optimized performance and value for their intended applications. This commitment positions us as a reliable partner among shale shaker screen manufacturers for operators seeking uncompromised quality and cost-efficiency.

Image: VSM 300 replacement screen, engineered for high efficiency.

Tailored Solutions and Customization Capabilities

Recognizing that drilling conditions vary dramatically from one rig to another, and even within the same well, generic screens may not always provide optimal results. As experienced shale shaker screen manufacturers, we offer tailored solutions to meet specific operational challenges. This involves working closely with clients to understand their drilling fluid properties, formation types, drilling rates, and shaker model configurations. Based on this detailed assessment, we can recommend or even develop screens with specific API mesh sizes, mesh layer configurations, and frame designs to optimize solids separation efficiency and screen life. For example, in environments with highly abrasive cuttings, we can offer screens with enhanced frame protection or more robust mesh materials. For operations requiring ultra-fine solids removal, we can provide higher API mesh screens with maximized non-blanked area to maintain flow capacity.

Our engineering team leverages extensive field experience and technical expertise to develop screens that perform exceptionally under unique conditions. This collaborative approach ensures that our clients receive a solution that is not just a product, but a performance enhancement tool specifically designed for their operational success. We pride ourselves on our responsiveness and ability to adapt to the evolving demands of the drilling industry, offering a level of customization that sets us apart from other shale shaker screen manufacturers.

Real-World Application Cases and Customer Experience

Our commitment to delivering high-performance Brandt Replacement Shale Shaker Screens is validated by numerous successful applications globally. Consider a recent case from an onshore drilling operation in the Permian Basin, where the operator was struggling with high mud losses and frequent screen blinding due to sticky clay formations. They were using generic shaker screen for sale that frequently failed. After switching to our composite-framed Brandt Replacement Screens with optimized mesh design for their king cobra shale shaker, they observed a significant reduction in mud loss, improved solids conveyance, and a 40% increase in screen lifespan. This translated into substantial cost savings from reduced mud additive consumption and fewer screen replacements, alongside improved drilling rates due to better fluid rheology.

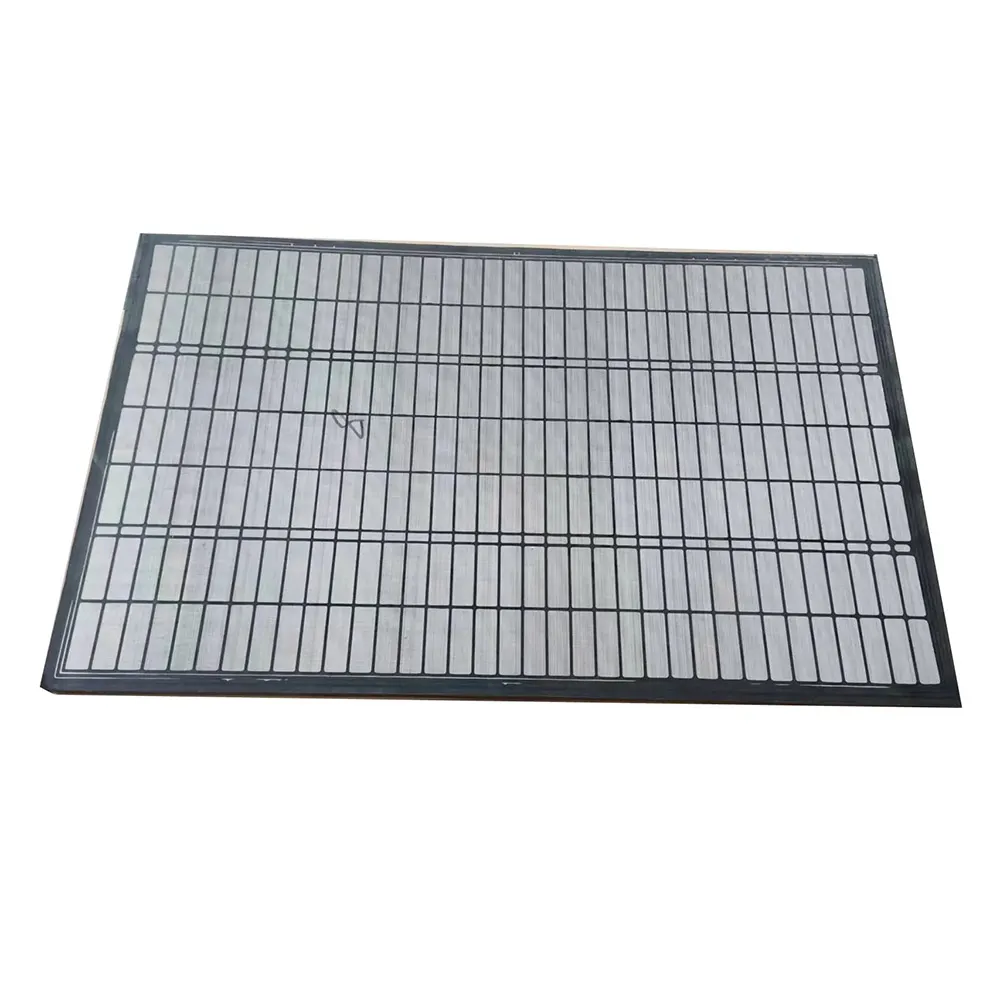

Image: D380 replacement screens in action, showing robust design.

Another compelling example comes from an offshore rig utilizing a vsm 300 shaker in the North Sea. The operator faced challenges with maintaining a consistent drilling fluid density due to inefficient fine solids removal, impacting ROP (Rate of Penetration). By deploying our specialized Brandt Replacement Shale Shaker Screens, designed for high-volume processing and enhanced fine particle separation, they achieved a remarkable 15% improvement in ROP and a noticeable reduction in non-productive time associated with mud treatment. Feedback from their mud engineer highlighted the screens' exceptional durability and consistent performance under extreme conditions, validating our expertise and the quality of our product as leading shale shaker screen manufacturers.

These cases exemplify our practical experience and the tangible benefits our screens bring to real-world drilling scenarios. Our expertise isn't just theoretical; it's proven in the field, contributing directly to our clients' operational efficiency and profitability. Our long-standing partnerships with major drilling contractors and service providers, spanning over a decade, further underscore our authority and trustworthiness in the industry. We are proud of our ISO 9001:2015 certification, which reflects our unwavering commitment to quality management systems.

Trust and Reliability: Our Commitment to You

As a premier choice among shale shaker screen manufacturers, we understand that trust is built on reliability, transparency, and unwavering support. We are committed to providing an unparalleled customer experience, from initial inquiry to post-purchase support.

- Delivery Cycle: We maintain a robust inventory of Brandt Replacement Shale Shaker Screens to ensure prompt delivery. For standard orders, shipping typically occurs within 3-5 business days. Custom orders or large bulk quantities will have a clearly communicated lead time based on manufacturing schedules, usually within 2-4 weeks. Our efficient logistics network is designed to minimize downtime for our clients globally.

- Quality Assurance & Warranty: Every Brandt Replacement Shale Shaker Screen undergoes rigorous multi-stage quality control checks, adhering to API RP 13C and ISO 9001:2015 standards, to ensure superior performance and durability. We stand behind our products with a comprehensive warranty against manufacturing defects and premature failure under normal operating conditions. Specific warranty terms are provided with each purchase, ensuring peace of mind. Our screens are manufactured using high-quality SS304/316L wire mesh and robust composite frames, tested for tensile strength and corrosion resistance.

- Customer Support: Our dedicated customer support team and technical experts are available 24/7 to assist with product selection, technical queries, installation guidance, and troubleshooting. We offer both online support and on-site assistance for complex requirements. Our goal is to ensure seamless integration and optimal performance of our screens in your operations.

Frequently Asked Questions (FAQ)

Here are some common questions about shale shaker screens and their applications, addressing professional terminology and critical parameters.

1. What is API RP 13C and why is it important for shale shaker screens?

API RP 13C (American Petroleum Institute Recommended Practice 13C) is a standard for evaluating drilling fluid processing equipment and screen panels. It defines methods for determining critical screen parameters like D-factor (separation potential), conductance (flow capacity), and non-blanked area. It is crucial because it provides a standardized way to compare screens from different shale shaker screen manufacturers, ensuring accurate performance assessment and facilitating optimal screen selection for specific drilling applications.

2. What is mesh size and how does it relate to solids removal?

Mesh size, or screen mesh count, refers to the number of openings per linear inch on a screen. A higher mesh number indicates finer openings, capable of separating smaller particles. For example, an API 200 mesh screen will remove much finer solids than an API 60 mesh screen. The selection of mesh size directly impacts the quality of the cleaned drilling fluid and the volume of solids discarded, influencing mud properties and overall drilling efficiency.

3. What is "conductance" in the context of shale shaker screens?

Conductance (k) is a measure of a screen's capacity to allow fluid to pass through it, measured in kD/mm (kiloDarcy per millimeter). It's a key indicator of the screen's flow rate potential. A higher conductance value means the screen can process more drilling fluid per unit of time without overflowing or "ponding," which is critical for high-volume drilling operations to maintain circulation and avoid fluid loss.

4. What is the "Non-Blanked Area" (NOC) and why is it important?

The Non-Blanked Area (NOC) is the percentage of the total screen surface that is open for fluid flow. It directly affects the effective screening area. A higher NOC generally translates to better fluid processing capacity and reduced potential for screen blinding (clogging), thereby enhancing efficiency and extending screen life. Modern screen designs by reputable shale shaker screen manufacturers aim to maximize NOC while maintaining screen integrity and strength.

5. What are the common types of screen panels and their advantages?

Common screen panel types include Flat screens, Pyramid screens (e.g., XL or PX screens), and Corrugated screens (e.g., DX, XR). Flat screens offer simplicity. Pyramid and Corrugated screens, like those often seen on brandt shaker screens such as the King Cobra series, feature a rippled or corrugated surface that significantly increases the effective screening area, leading to higher processing capacity and improved solids removal efficiency compared to flat screens of the same nominal size.

6. How does G-force tolerance affect screen performance and lifespan?

Shale shakers operate at high G-forces (gravitational force equivalents) to efficiently separate solids from drilling fluids. The G-force tolerance of a screen refers to its ability to withstand these intense vibrations without structural degradation or premature failure. Screens with high G-force tolerance, often featuring robust composite frames and multi-layered, tensioned mesh, are essential for maintaining performance and extending lifespan, especially on high-speed shakers like the vsm 300 shaker or king cobra shale shaker.

7. What are the standard installation requirements for Brandt Replacement Shale Shaker Screens?

Installation of Brandt Replacement Shale Shaker Screens typically involves ensuring the shaker deck is clean and free of debris, correctly aligning the screen panel with the shaker frame, and securely fastening it using the designated clamping mechanisms (e.g., wedge blocks or tensioning bolts). It's critical to ensure proper tension across the screen surface to prevent premature wear and maintain optimal solids separation. Always refer to the shaker's OEM manual and the screen manufacturer's specific installation guidelines for precise instructions to ensure safety and performance.

Conclusion: Partnering for Drilling Excellence

The efficiency of a drilling operation hinges significantly on the performance of its solids control equipment, and at the core of this system are the shale shaker screens. Our Brandt Replacement Shale Shaker Screen stands as a testament to advanced engineering, meticulous manufacturing, and a deep understanding of drilling challenges. By providing screens that not only meet but often exceed OEM standards for longevity, conductance, and solids removal efficiency, we empower drilling contractors to enhance their operational throughput, reduce environmental footprint, and achieve significant cost savings.

As dedicated shale shaker screen manufacturers, our expertise, coupled with our commitment to quality, customer support, and tailored solutions, positions us as a trusted partner in the global oil and gas industry. We invite you to experience the difference that superior screen technology can make in your drilling endeavors, optimizing your performance and ensuring a more sustainable and profitable future.

Industry Citations & Further Reading:

For more in-depth insights into solids control and shale shaker technology, we recommend exploring the following resources:

- Society of Petroleum Engineers (SPE) - "Advancements in Solids Control Technology": https://www.spe.org/en/ (Search for relevant papers on drilling waste management and solids control.)

- Oilfield Technology - "Shale Shaker Efficiency: A Critical Review": https://www.oilfieldtechnology.com/ (Look for articles related to drilling fluid management and separation technologies.)

- American Petroleum Institute (API) - RP 13C: https://www.api.org/ (Official site for standards relevant to drilling fluids and equipment.)