1. Shaker Screen Supplier: Industry Overview & Market Trends

Shaker screens are critical solids-control filtration components in industries such as oil & gas drilling, mineral processing, hydro-metallurgy, aggregate screening, and wastewater treatment. The market has witnessed CAGR growth of 6.2% (2021-2023), driven by increased mechanization and the rise of custom-engineered screens.

- 2023 Global Shaker Screen Market Size: $1.87 billion USD

- Top regions: North America (38%), Middle East (22%), APAC (27%), Europe (13%)

- Key segments: Shale shaker screen supplier, replacement shaker screens, aggregate shaker screens, OEM & aftermarket solutions

- Trend: Durability, finer mesh grades, corrosion resistance, ISO & ANSI compliance

- 2023-2024 Average shale shaker screen price: $38–$110/piece, depending on mesh grade & specs

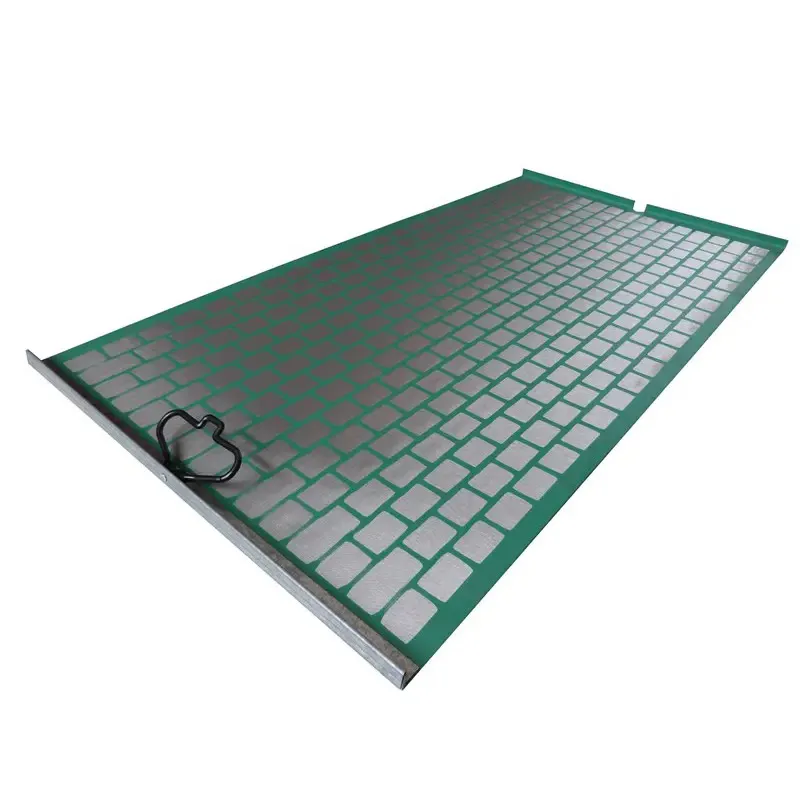

Typical Product Types by Shaker Screen Suppliers

| Supplier | Screen Model | Standard (ISO/ANSI) | Mesh Range | Material | Min. Slot Size (μm) | Price Range (USD) |

|---|---|---|---|---|---|---|

| Derrick/Replacement | PWP, FLC 500/2000 | ISO 13501, API RP13C | 20 - 325 | SS304, SS316 | 38 | 38–90 |

| MI SWACO | MD-3/MD-2/MDX | ANSI S800, ISO | 40 - 300 | SS316 | 40 | 51–120 |

| Brandt/Kemtron | D380/King Cobra | API 13C | 10 - 325 | SS304, SS316L | 32 | 40–110 |

| Composite OEM | CG-44, HL425 | ISO 14001 | 20 - 200 | SS + Polyurethane | 55 | 44–85 |

2. Core Technical Parameters & Standards: What Sets a Leading Shale Shaker Screen Supplier Apart?

Modern shaker screen supplier offerings feature:

- Wire mesh grades: 20#–325# stainless steel (SS304/SS316/SS316L), with surface hardening for wear & corrosion resistance

- Bonding process: Epoxy-resin, SS plate supports, or composite frame (polyurethane + SS mesh)

- Screen type: Pretensioned, hook strip, pyramid (PWP), or flat-panel for various shale shaker systems

- Compliance: API 13C (solids removal efficiency), ISO 13501 (petroleum industry), ANSI S800

- Service Life: 450–900 operational hours (silt to coarse aggregate), >1200h on composite/Poly screens

- Fully customizable mesh patterns for critical cut-point sands or clays

- Anti-blinding, self-cleaning, fast install/removal design

- Enhanced open area, reducing mud losses (<0.5% NPT rate)

- Certified for high H2S, CO2 or brine environments

3. In-Depth Manufacturing Process: From Raw Material to Reliable Shaker Screen

The production route distinguishes the industry-leading shaker screen supplier from generic brands. Here is a typical high-precision shale shaker screen supplier workflow:

Premium SS304/SS316 steel sourced, certified to ISO 9001/14001 and individually spectrograph-tested.

Multi-layer micron mesh precision woven to API mesh spec; Auto-loomed for tensile uniformity.

Frame options: High-tensile steel, composite PP/SS, or polyurethane; anti-rust e-coating.

Panels are hot-cured with epoxy resin or spot-welded according to load class; mesh checks per API.

- API RP13C cut-point & conductance tests

- ANSI/ISO slot size validation

- Salt-spray corrosion test (ASTM B117)

- Secured packaging with serialization

Screen batch delivery with technical datasheet, install/maintenance training available globally.

Typical Technical Parameters Table: Derrick Pwp Replacement Shaker Screen

| Parameter | Value | Standard/Test |

|---|---|---|

| Mesh Range (API) | 20–325 | API RP13C |

| Overall Dimension (mm) | 695 × 1050 × 40 | OEM/Interchangeable |

| Material | SS304 or SS316 + Composite Frame | ISO 9001, SGS |

| Conductance (Kd/mm) | 0.8 – 5.2 | API RP13C |

| Non-Blinding Area | > 5250 cm2 | API standard |

| Anti-Corrosion | Pass (768h salt spray) | ASTM B117 |

| Service Life (hrs) | 800–1200 (Tested) | Benchmarked field |

| Interchange Models | Derrick FLC 500 Series | OEM/Cross-ref |

For full catalog, download from Derrick Pwp Replacement Shaker Screen Spec Sheet (PDF).

Typical Application Scenarios for Derrick Pwp Shaker Screen

- Oil & Gas: Drilling mud solids control in onshore/offshore rigs

- Aggregates: Sand, gravel, rock dust & aggregate grading

- Mining: Mineral slurry classification (Au, Fe, Coal)

- Waste Management: Construction/civil dewatering, water recycling

- Chemical & Metallurgy: Particle sizing, granule separation, catalyst recovery

4. Key Data Visualization: Shaker Screen Supplier Technology & Pricing

5. Supplier Comparison: Why Choose a Certified Shaker Screen Supplier?

| Supplier Type | Certifications | Customization | Delivery (days) | OEM Support | Warranty | Reputation |

|---|---|---|---|---|---|---|

| Derrick Pwp Replacement Shaker Screen Supplier | ISO 9001, API 13C, SGS | Yes (mesh, size, logo) | 7–15 | Yes | 12–18 months | 5⭐ (Top-tier in Asia/MENA) |

| Local Trading Company | Usually None/ISO | No/Partial | 12–30 | Partial | 6 mo. | 3⭐ (General) |

| Economy OEM | Internal QC | Yes | 20–40 | Partial | 6–12 mo. | 3.5⭐ |

6. Customization & Engineering Services by Top Shale Shaker Screen Supplier

- Free design for OEM screen size/interchange (FLC500/2000, MD3, D380, etc.)

- Mesh grade selection & multi-layer mesh engineering for cut-point finetuning

- Enhanced anti-corrosion surface treatments (Polymer/SS316L/Composite)

- Private branding, color, & shipment mark available

- Rapid sample delivery & iterative field validation on request

- Technical documentation & ISO/API-compliant test reports included

Case Study: Custom Derrick Pwp Screens for Middle East Drilling Project

Solution: Shale shaker screen supplier engineered a composite frame + SS316 mesh, achieved 61% open area, >1200h service life in aggressive brine (96°C).

Result: Mud loss reduced by 0.4%, ROI up 17%. Client feedback: “Screen performance exceeded imported OEMs and survived harsh H2S flows.”

7. User Experiences & Service Commitment

- Project Locations: Middle East, Texas, Malaysia, Chile, Nigeria

- Major Clients: Sinopec, Petronas, Halliburton Service Contractors

- Repeat Orders Rate: 73% (2023, Derrick Pwp screen category)

- Warranty Policy: 12–18 months or 1200h working, whichever comes first

- Technical Support: 24/7 response, on-site/remote troubleshooting & QA report supply

- Delivery: Fast-track shipping; most mesh grades ready within 15 days

8. FAQs: Expert Answers for Shaker Screen Supplier Selection

- 1. What are the main materials used for shale shaker screens?

- The primary materials are SS304 (standard), SS316/SS316L (for enhanced corrosion resistance), and composite plastics for the frame. High-salinity/high-CO2 environments often require SS316 mesh.

- 2. How is mesh size (API number) determined and why is it critical?

- Mesh size is defined by API RP13C based on cut-point (particle size retention) and conductance (fluid capacity). Proper selection ensures efficient solids separation and prevents shaker screen blinding.

- 3. Are all screens interchangeable between different OEM shakers?

- Not always. Most OEM and third-party shaker screen suppliers design screens to fit standardized dimensions (e.g. Derrick FLC500), but custom models may require precise measurement and modification.

- 4. What certifications ensure screen quality?

- API RP13C, ISO 9001/14001, SGS and ANSI S800 are core standards verifying mesh consistency, strength, anti-corrosion performance, and safe operation.

- 5. How long is the screen service life? What are the main wear factors?

- Service life ranges from 450–1200 hours, impacted by mesh type, drilling fluids, solids loading & vibration. Composite screens generally last longer than steel-only screens.

- 6. What is the typical delivery time and warranty policy?

- Standard models ship in 7–15 days, with a 12–18 month warranty for normal wear (non-operator error). Custom models are made to order, with technical support throughout.

- 7. What after-sales support is provided by leading shaker screen suppliers?

- Includes field installation guidance, mesh selection consultation, API/SGS test reporting, and rapid replacement for defects detected within warranty.

9. Why Trust an Authoritative Shaker Screen Supplier?

- Verified by API/ISO/SGS and referenced by major oilfield corporations

- Positive feedback & repeat orders from global clients in hostile operational climates

- Complete supply chain from mesh weaving to logistics

- On-site inspection & real-world 3rd-party test reports available

- Member of Solids Control Industry Association and referenced in OnePetro engineering journal

10. Get Your Shaker Screen Supplier Solution

To deliver the best shaker screen supplier solution, request a Derrick Pwp Replacement Shaker Screen quotation with your mesh requirement, drilling fluid type, rig model, and annual usage estimate for a rapid engineering proposal, price list (shale shaker screen pricelist) and field test support.

- Download full pricelist & technical brochures at Shaker Screen Product Page.

- Receive technical consultation and international shipping estimates within 24 hours.

- All screens conform to API/ISO/SGS and meet aggregate shaker screens custom requirements.