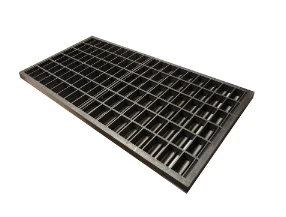

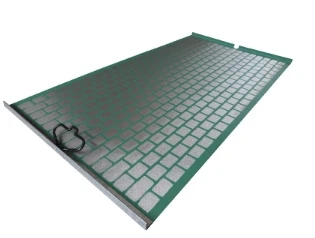

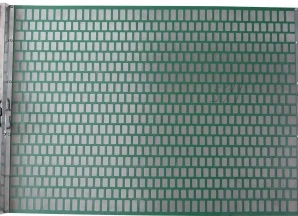

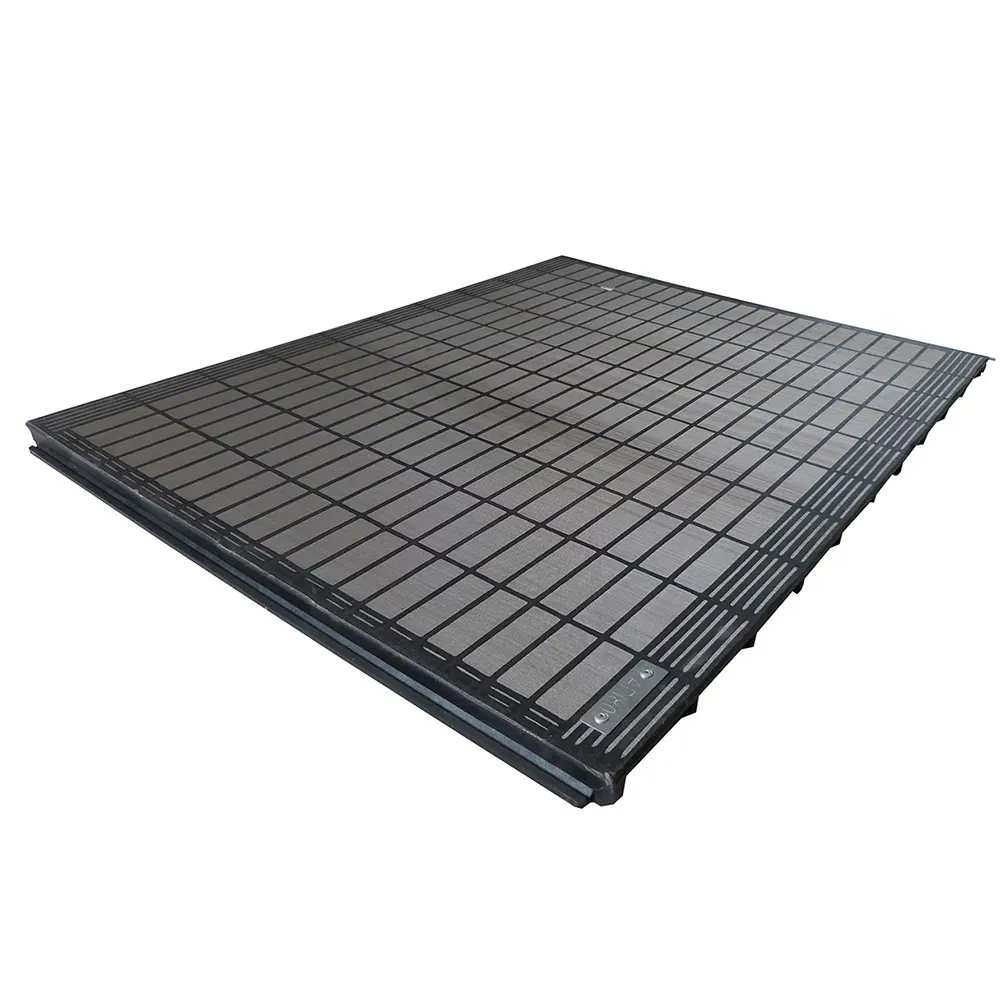

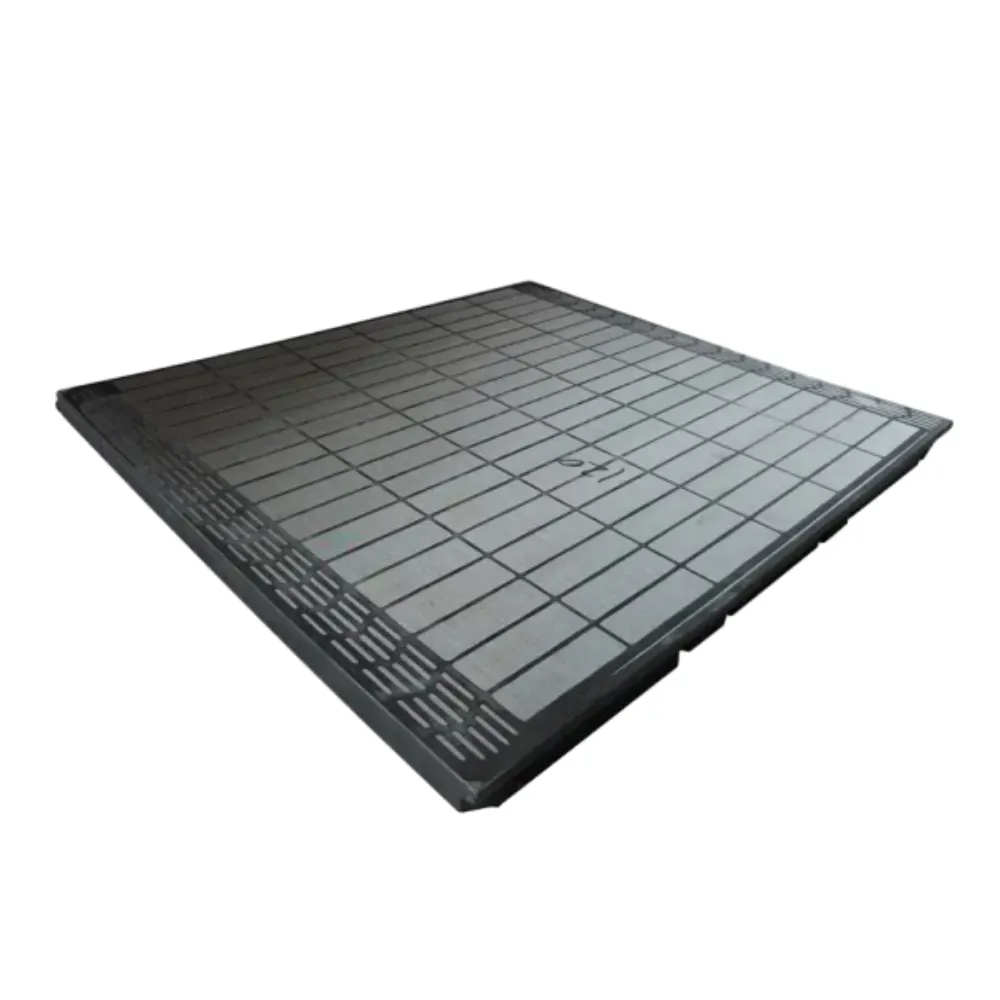

Swaco Replacement Shale Shaker Screens

The Swaco Replacement shaker screens which made by us are high-capacity composite shaker screens are the most rugged, long-lasting and efficient screens available. The new composite screens, unique in the industry, provide resistance to corrosive drilling fluids.

The screens also offer significant fluid capacity, excellent resistance to blinding, drier solids discharge and a large net usable screen area. Composite construction creates an ultra-tight seal between the screen and screen bed and eliminates solids buildup and costly solids bypass.

The unique screen-locking mechanism wedges the screen firmly in place and allows the screen to be removed for repair or replacement.

View Product Details

Global Shale Shaker Screen Market Analysis

The drilling fluids purification industry has experienced significant technological advancement, with composite screens now representing over 35% of market share. As leading shale shakerscreen manufacturers, we monitor these developments closely.

Recent industry reports indicate that shale shakers for sale in North American markets have grown by 12.7% CAGR since 2020, primarily driven by new shale plays. The demand for mongoose shaker screens with API RP13C compliance has increased by 18% year-over-year, indicating a shift toward premium quality products.

Operators now prioritize screens that reduce drilling fluid loss by at least 15% compared to conventional options. This aligns with the performance characteristics of our Swaco Replacement screens, which demonstrate consistent results under challenging conditions according to IADC field tests.

Performance Metrics Comparison

Technical Specifications Comparison

| Parameter | MATTS Standard Screens | Industry Average | Premium Competitor | API RP13C Standard |

|---|---|---|---|---|

| Screen Life (hours) | 450-600 | 250-350 | 400-500 | ≥300 |

| Max Flow Rate (GPM) | 750 | 550 | 650 | ≥500 |

| Blinding Resistance | Excellent | Average | Good | - |

| Corrosion Resistance | Grade A | Grade C | Grade B | Grade B |

| Mesh Range | API 20-325 | API 20-250 | API 20-300 | API 20-200 |

| Solids Discharge Moisture | 15-20% | 25-35% | 20-25% | ≤30% |

Industrial Applications

Our screens deliver exceptional performance across multiple environments:

Onshore Drilling Operations

Ideal for shale gas extraction sites where consistent performance under high solids load is crucial. Our mongoose shaker screens maintain flow rates up to 35% higher than standard designs.

Offshore Platforms

Corrosion-resistant design withstands saltwater environments. When evaluating shale shakers for sale in marine applications, our screens demonstrate 3x longevity compared to standard options.

Geothermal Wells

Specialized high-temperature formulations maintain structural integrity at temperatures exceeding 150°C. Critical for geothermal operations where screen failure causes significant downtime.

Technical Expertise: Shale Shaker Screens FAQ

Q: What materials provide optimal corrosion resistance in shale shaker screens?

A: Our screens use dual-layer composite materials with stainless steel reinforcement and polymer infusion. This combination exceeds standard 316 stainless steel by 60% in salt spray tests while maintaining tensile strength.

Q: How do mongoose shaker screens differ from conventional designs?

A: Mongoose configurations feature a tensioned hook-strip system that maintains uniform screen tension across 40% more surface area than bolt-down designs. This minimizes "dead zones" where solids accumulation typically occurs.

Q: What installation standards apply to shale shakerscreen manufacturers?

A: We adhere to API RP13C (ISO 13501) dimensional standards and ISO 9001:2015 manufacturing processes. Installation must follow ASME BPE-2019 guidelines for sealing surface preparation and torque specifications.

Q: How do composite screens reduce blinding compared to metal screens?

A: Our triple-layer polyurethane infusion creates non-stick surfaces with hydrophobic properties that reduce clay adhesion by up to 75%. The open-area percentage is 15% greater than comparable stainless steel mesh.

Q: What vibration parameters optimize screen life expectancy?

A: Maximum screen life is achieved at vibration frequencies between 1,750-2,000 RPM with G-forces maintained at 5.3-7.1G. Excessive vibration above 7.5G accelerates fatigue failure by 300%.

Q: What pressure rating is required for HPHT wells?

A: For high-pressure/high-temperature applications, shale shakers for sale should specify screens rated for 750 psi operating pressure and thermal stability at 175°C, exceeding API 13C minimum standards.

Q: How is structural integrity verified during manufacturing?

A: We employ computed tomography (CT) scanning to detect micro-fractures and digital image correlation for strain analysis. Each batch undergoes resonant frequency testing to ±2% tolerance per ASTM E1875 standards.

Industry Recognition & Research

-

Society of Petroleum Engineers: Solids Control Optimization in Extended-Reach Wells

2023 technical report highlighting 23% efficiency gains using advanced composite screens

-

IADC Drilling Fluids Manual: Screen Life Expectancy Benchmarks

Revised 2022 edition includes performance comparisons of leading shale shakerscreen manufacturers

-

Journal of Petroleum Technology: Corrosion Management in Drilling Fluids

2024 research quantifying materials savings through advanced screening technology

Innovative Shale Shaker Solutions

As globally recognized shale shakerscreen manufacturers, HEBEI MATTS TECH CO. LTD. delivers premium quality mongoose shaker screens engineered for maximum efficiency and durability in challenging drilling environments.

Request Technical Specifications