At our state-of-the-art manufacturing facility, we're proud to introduce our latest generation of high-performance shaker screens designed to meet the most demanding industrial applications. Our cutting-edge composite shaker screens, durable stainless steel shaker screens, and specialized rock shaker screens are setting new standards in filtration efficiency and operational longevity. With our innovative shale shaker screens and premium Derrick pyramid screens, we're helping drilling operations worldwide achieve unprecedented solids control performance.

Breakthrough Composite Shaker Screen Technology

Our revolutionary composite shaker screens combine the strength of metal with the corrosion resistance of advanced polymers, creating a product that outperforms traditional screens in challenging environments. The unique hybrid construction features a polyurethane frame bonded to stainless steel mesh.Drilling operations using our composite shaker screens report extended service life and reduced downtime, particularly in applications with high clay content or corrosive drilling fluids.

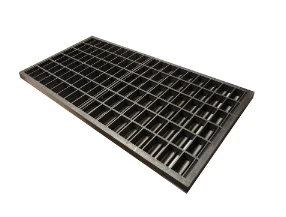

Industrial-Grade Stainless Steel Shaker Screen Durability

The precision-welded framework and tensioned mesh construction maintain consistent filtration performance even under heavy solids loading. Our stainless steel shaker screens feature reinforced hook strips and oversized bonding surfaces that withstand the rigors of continuous operation in demanding oilfield environments. Compared to standard screens, our stainless steel shaker screens demonstrate longer lifespan in saltwater drilling applications and high-temperature formations. The advanced manufacturing process ensures perfect dimensional accuracy for compatibility with all major shaker brands, while the polished surface finish minimizes particle adhesion and simplifies cleaning procedures between shifts.

Specialized Rock Shaker Screen for Extreme Conditions

Designed specifically for hard rock drilling applications, our heavy-duty rock shaker screens feature an innovative multi-layer construction that withstands the impact of abrasive cuttings. The extra-thick wire mesh and reinforced perimeter frame provide exceptional durability in mining, geothermal, and unconventional drilling operations. The unique open-area design of our rock shaker screens maintains optimal fluid throughput while effectively capturing large solids, reducing the frequency of screen changes and associated downtime. Field tests demonstrate that our rock shaker screens can process up to more solids volume before requiring replacement, significantly lowering operational costs for hard rock drilling projects.

High-Efficiency Shale Shaker Screen Performance

The proprietary tensioning system maintains optimal screen flatness throughout the product lifecycle, ensuring consistent filtration performance from first use to replacement. The shale shaker screens utilize a unique frame design that distributes vibrational forces evenly across the screening surface, preventing premature failure at stress points. The color-coded labeling system simplifies mesh identification in the field, helping crews quickly select the appropriate screen for changing formation characteristics.

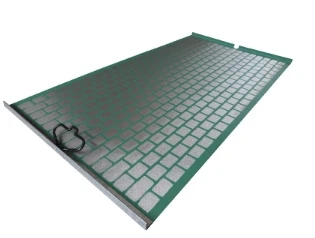

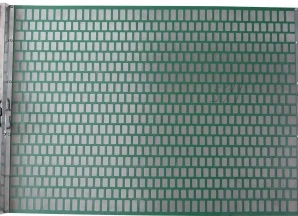

Premium Derrick Pyramid Screens for Maximum Capacity

The pyramid-shaped pattern creates turbulent flow across the screen surface, significantly reducing particle blinding and improving solids conveyance. Our Derrick pyramid screens are manufactured with precision-molded polyurethane pyramids bonded to a stainless steel backing mesh, creating a durable composite structure that withstands high G-force vibration. The screens' unique design also reduces harmonic vibration, extending the service life of shaker components and creating smoother operation. Our manufacturing process ensures perfect compatibility with all Derrick Flo-Line cleaner models, with each screen undergoing rigorous quality testing before shipment.

Shaker Screen FAQs

What makes your composite shaker screens different from traditional designs?

Our composite shaker screens combine polyurethane frames with stainless steel mesh, offering lighter weight, better corrosion resistance, and reduced screen blinding compared to all-metal screens.

How do your stainless steel shaker screens perform in saltwater environments?

The stainless steel construction of our stainless steel shaker screens provides exceptional corrosion resistance in saltwater applications, typically lasting longer than standard screens.

When should I use rock shaker screens instead of standard models?

Our rock shaker screens are specifically designed for hard rock drilling with abrasive solids, featuring reinforced construction that withstands impact better than conventional screens.

What's the advantage of Derrick pyramid screens over flat screens?

The three-dimensional design of our Derrick pyramid screens improves solids conveyance.

How do your shale shaker screens reduce fluid loss?

Our shale shaker screens feature precision mesh and optimal tensioning that captures fine solids while allowing maximum fluid return.

From innovative composite shaker screens to high-capacity Derrick pyramid screens, our comprehensive product line offers solutions for every solids control challenge. Contact our technical team today to discover how our advanced shaker screen technologies can optimize your drilling operations.