At our state-of-the-art manufacturing facility, we engineer high-performance shaker screens with meticulous attention to shaker screen mesh configurations and shaker screen material selection. Our specialized shale shaker screen mesh designs and premium shale shaker screen material formulations deliver exceptional solids control efficiency for demanding drilling applications.

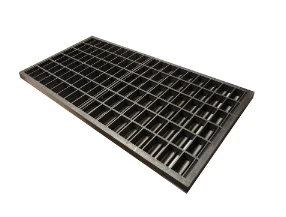

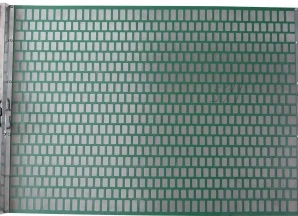

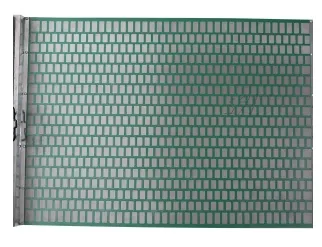

Optimized Shaker Screen Mesh Configurations

Our precision-engineered shaker screen mesh patterns are scientifically designed to maximize fluid throughput while ensuring effective solids removal. The shale shaker screen mesh configurations we offer include various weave types and opening geometries tailored to different formation characteristics. Unlike standard screens, our shaker screen mesh designs incorporate progressive filtration layers that gradually remove particles of decreasing size. This innovative approach to shale shaker screen mesh construction significantly reduces blinding and maintains consistent flow rates throughout operations. Drilling professionals appreciate how our shaker screen mesh technology adapts to changing downhole conditions while preserving drilling fluid properties.

Premium Shaker Screen Material Selection

The foundation of our screen excellence lies in superior shaker screen material choices. We utilize high-grade stainless steel alloys and advanced polymer composites in our shale shaker screen material formulations to withstand harsh drilling environments. Our shaker screen material selection process considers multiple factors including chemical resistance, mechanical strength, and thermal stability. The shale shaker screen material combinations we've developed offer exceptional durability against abrasion while maintaining precise filtration characteristics. Operators report that screens manufactured with our premium shaker screen material formulations demonstrate extended service life even in high-temperature, high-salinity drilling conditions.

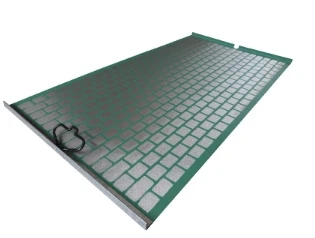

Innovative Shaker Screen Design Features

Our engineering team has revolutionized shaker screen design with several patented innovations that enhance performance. The shaker screen design philosophy balances structural integrity with optimal open area to achieve superior solids control. Unique features of our shaker screen design include reinforced perimeter frames, vibration-dampening layers, and specialized surface treatments. These shaker screen design elements work synergistically to distribute operational stresses evenly across the screening surface. The result is a screen that maintains dimensional stability under continuous vibration while resisting common failure points. Our shaker screen design portfolio includes flat, pyramid, and hybrid configurations to suit various shaker models and drilling applications.

Custom Shale Shaker Screen Mesh Solutions

Understanding that every drilling operation has unique requirements, we offer customized shale shaker screen mesh configurations. Our technical team collaborates with clients to develop tailored shale shaker screen mesh patterns that address specific formation challenges. The custom shale shaker screen mesh solutions we provide consider factors such as particle size distribution, fluid properties, and shaker dynamics. This consultative approach to shale shaker screen mesh development ensures optimal solids control efficiency for each application. Many drilling contractors have significantly improved their fluid management systems through our specialized shale shaker screen mesh designs that target their particular operational challenges.

Advanced Shale Shaker Screen Material Technology

Our research and development efforts continuously advance shale shaker screen material technology. The latest shale shaker screen material innovations include nano-coated surfaces that resist particle adhesion and hybrid composites that combine strength with flexibility. These shale shaker screen material breakthroughs deliver measurable improvements in screen life and filtration consistency. Our material scientists have developed proprietary shale shaker screen material formulations that outperform conventional options in corrosive environments. The shale shaker screen material testing protocols at our facility ensure each new formulation meets rigorous performance standards before being approved for production.

Shaker Screen Specifications FAQs

How does shaker screen mesh design affect performance?

Our shaker screen mesh configurations are engineered to optimize the balance between fluid throughput and solids removal efficiency for different applications.

What are the advantages of your premium shaker screen material?

The advanced shaker screen material formulations we use provide superior resistance to abrasion, corrosion, and thermal degradation in demanding drilling conditions.

How does your shaker screen design improve screen life?

Our innovative shaker screen design incorporates stress-distributing features that prevent common failure points and extend operational lifespan.

Can you customize shale shaker screen mesh for specific formations?

Yes, we specialize in developing tailored shale shaker screen mesh configurations that address unique formation characteristics and drilling fluid properties.

What's new in your shale shaker screen material technology?

Our latest shale shaker screen material innovations include nano-coatings and hybrid composites that deliver significant performance enhancements.

From precision shaker screen mesh configurations to innovative shaker screen design and premium shaker screen material solutions, our comprehensive approach delivers superior solids control performance. Contact our technical team today to discuss your specific screening requirements.