Introduction to Swaco Screens Supplier & Market Landscape

In the evolving realm of solids control, the importance of reliable, high-performance shaker screens cannot be understated. As the oil and gas sector pushes for greater drilling efficiency and cost savings, operators are turning to proven, reputable swaco screens supplier partners who offer the latest in shale shaker screen technology. Trends like composite frame evolution, advanced wire mesh, and environmental durability are shaping the industry, while stringent standards are raising expectations for both product and supplier alike.

Swaco screens and their compatible solutions—including mi swaco shaker screens, composite replacement models, and durable fine-mesh screen types—play a pivotal role in optimizing the solids control process. Modern swaco screens supplier teams must now meet the rising bar for environmental resistance, screen life, and solids separation efficiency demanded in today’s challenging drilling environments (JPT, 2023).

This article provides a deep dive into the state-of-the-art for shaker screen for sale and shale shaker screen for sale options, with a focus on technical benchmarking, application scenarios, and how HEBEI MATTS TECH CO. LTD. stands out as your trusted swaco screens supplier.

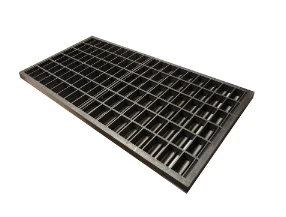

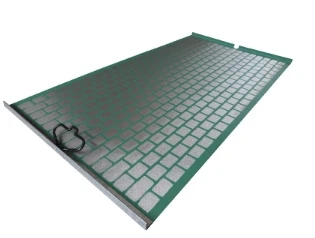

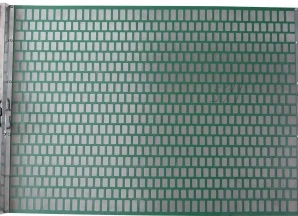

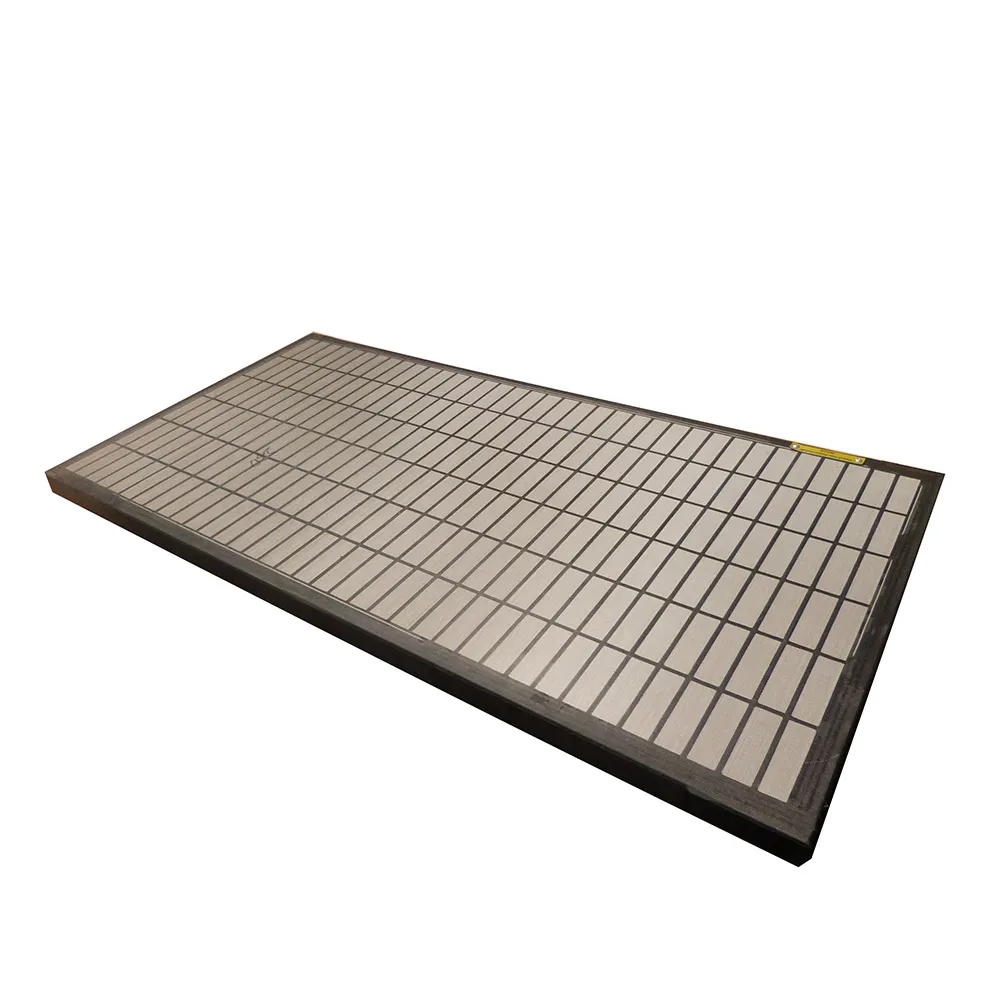

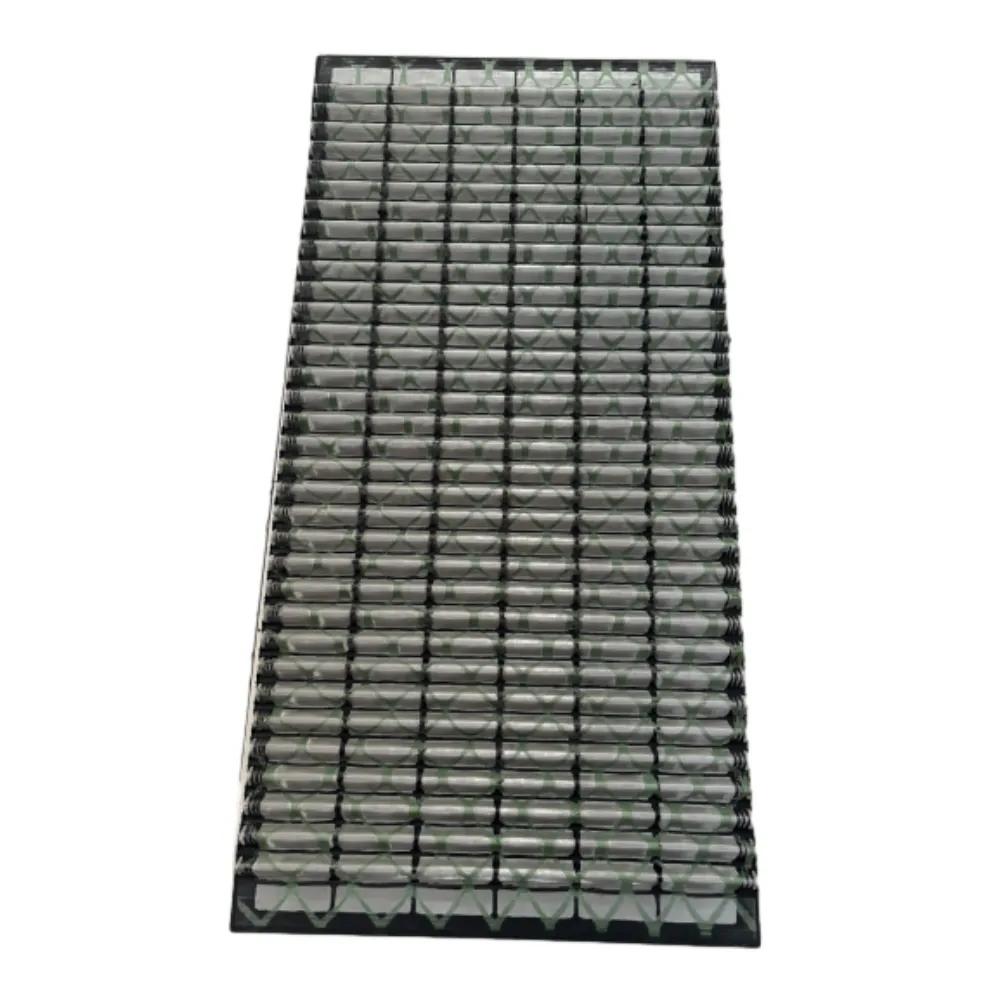

Product Highlight: MI SWACO Composite Replacement Shaker Screen

The MI SWACO Composite Replacement Shaker Screen, offered by HEBEI MATTS TECH CO. LTD., represents the latest in screen technology (product page). These screens have demonstrated outstanding screen life, maintaining essential mud properties at predetermined levels. No screen change or deterioration affected solids-control efficiency or caused rig downtime throughout extensive field tests. Key observations from independent industry reviews further reinforce the quality benchmark achieved:

- Perfect solids-control efficiency

- Exceptional blinding resistance and durability

- Superior drilled solids content management

- Screen life exceeded expectations in field comparisons (PetroWiki, 2022)

Industry Trends for Swaco Screens Supplier

The global market for swaco screens supplier solutions is growing, with rising demand for advanced shaker screens capable of withstanding harsh abrasive conditions found in unconventional shale plays, deepwater rigs, and high-temperature wells. Notable industry trends include:

- Rapid adoption of composite frame technology for lighter weight and increased screen longevity

- Higher adoption of fine wire mesh (up to API 325) for improved cut-point and capacity

- Increased focus on environmentally friendly, longer-life screens (World Oil, 2022)

- Stringent API RP 13C compliance as a basic expectation for international tenders

- Rising deployment of digital inventory management for screen supply

As a premier swaco screens supplier, HEBEI MATTS TECH CO. LTD. leads the way by integrating advanced R&D and production control, ensuring every screen meets or exceeds latest industry standards and operational requirements.

Technical Parameters for Leading Swaco Screens Supplier

| Supplier | Screen Model | Frame Material | Mesh Range (API) | Blinding Resistance | Screen Life (Hours) | Certification |

|---|---|---|---|---|---|---|

| HEBEI MATTS TECH CO. LTD. | MI SWACO Composite Replacement | Composite/SS 304 | API 20-325 | High | 650–900 | API RP 13C |

| M-I SWACO (OEM) |

OEM-Composite | Composite/SS304 | API 40-325 | Excellent | 600–900 | API RP 13C |

| BrandT | King Cobra Hybrid | Composite/Steel | API 20-230 | Moderate | 500–600 | API RP 13C |

| GN Solids Control | Replacement GN API | Composite, Steel | API 60-300 | High | 600–800 | API RP 13C |

Application Scenarios for Swaco Shaker Screens

- Onshore and Offshore Oil & Gas Drilling: Primary solids removal in both land rigs and offshore platforms with varying drilling fluids.

- Mining & Mineral Processing: Used in beneficiation circuits for fine solids separation and tailings management.

- Geothermal Projects: Handling abrasive geothermal fluids with high silica content.

- Environmental Remediation: Separation of hydrocarbon-contaminated solids in cleanup operations.

- Drilling Waste Management: Maximizing fluid recovery in cuttings drying systems.

As a specialized swaco screens supplier, HEBEI MATTS TECH CO. LTD. has experience delivering tailored screens to match unique asset and operational needs world-wide.

Key Technical Data of MI SWACO Composite Replacement Shaker Screen

- Model: MI SWACO Composite Replacement Shaker Screen

- Frame Material: Composite / Stainless Steel 304

- Wire Mesh Grades: API 20–325, wide range for diverse drilling requirements

- Average Screen Life: 650–900 hours (field-proven)

- Blinding Resistance: High (minimized downtime)

- Adherence: API RP 13C and ISO 9001

- Compatible With: Direct fit for MI SWACO MONGOOSE, MEERKAT, BEM series, DERRICK FLC, BRANDT COBRA/VENOM, and more

Find more information on product specifications and model compatibility by visiting our composite replacement swaco screens supplier page.

Professional Q&A: Swaco Screens and Solids Control Terminology

Conclusion & References: The Authority in Swaco Screens Supply

As global drilling operations become more demanding, the stakes for selecting the right swaco screens supplier have never been higher. Through technical expertise, adherence to standards, and a proven record on the field, HEBEI MATTS TECH CO. LTD. stands at the forefront—supplying durable, high-performing mi swaco shaker screens that meet the modern requirements for solids control, mud property management, and cost optimization.

For more information on how our swaco screens supplier solutions can elevate your project, connect with us at lyiunqi@honestmetal.com or call +8631166035590. Explore the full product line, specs, and applications at the MI SWACO Composite Replacement Shaker Screen page.

References:

- “Shale shakers and screens: key components for solid control”—PetroWiki

- “Advanced shaker screens respond to market demand”—World Oil

- “Screen technology keeps improving”—Journal of Petroleum Technology, SPE