Industry Trends & Overview: SWACO Screens Supplier Market

The oil & gas drilling sector is continually propelled by the demand for efficiency, operational safety, and cost savings. As such, solids control technologies — particularly swaco screens supplier-produced products — have rapidly evolved.

The growth of shale shaker screen for sale and shale shaker screen for sale offerings on global markets reflects the following industry trends:

- Increased adoption of composite frame shaker screens due to superior screen life and blinding resistance (SPE Journals).

- Greater emphasis among major drilling contractors on solids control efficiency for high-ROP (Rates of Penetration) operations.

- Stringent environmental & safety regulations driving innovation and demand for certified swaco shaker screens.

- Digitization and sensor integration for real-time monitoring and performance analysis of mi swaco shaker screens.

- Customization requests for mesh size, API certification, and screen types to fit region-specific drilling challenges (Drilling Forum).

As a trusted swaco screens supplier, HEBEI MATTS TECH CO. LTD. is aligned with these trends, delivering products rigorously tested for durability, efficiency, and adaptability.

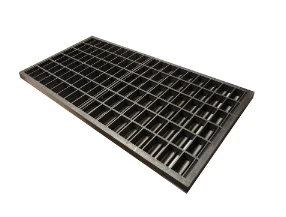

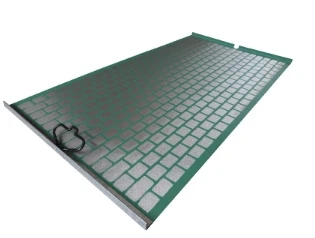

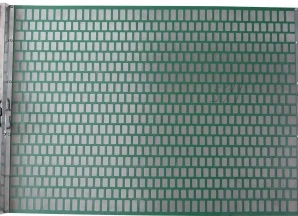

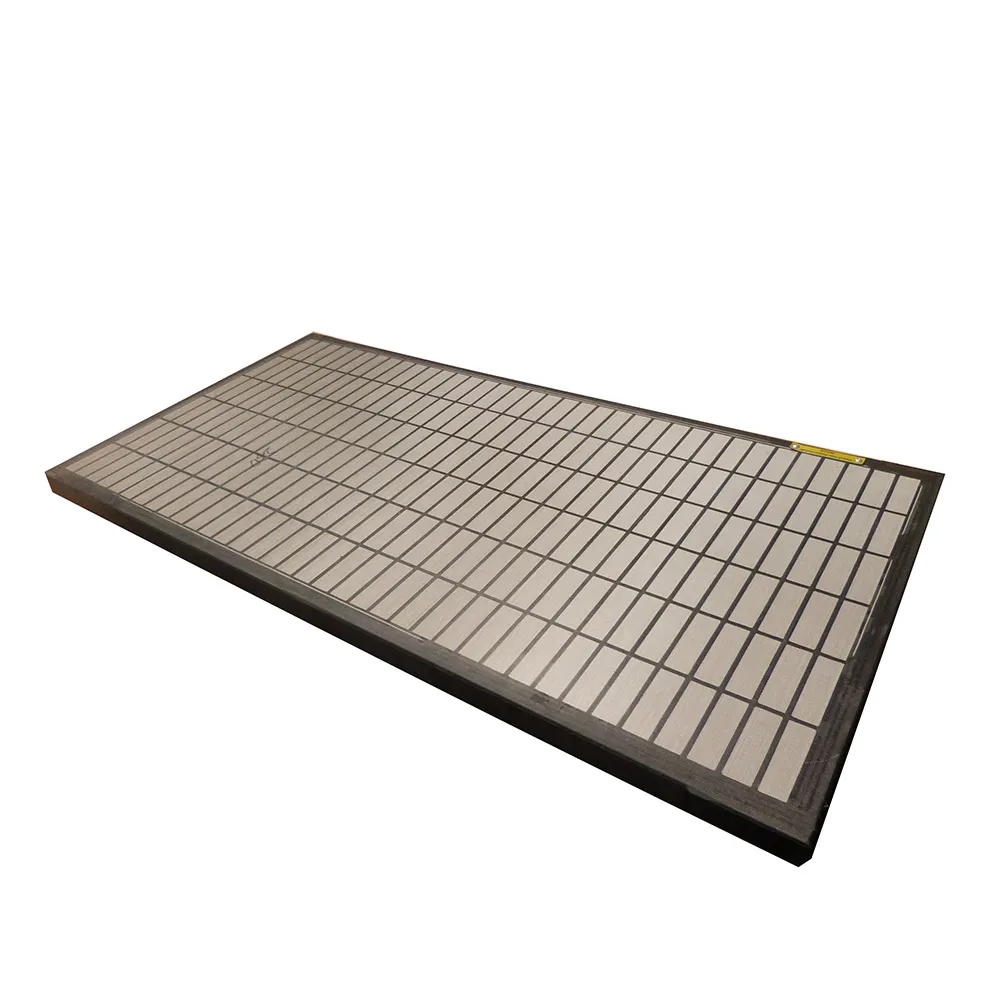

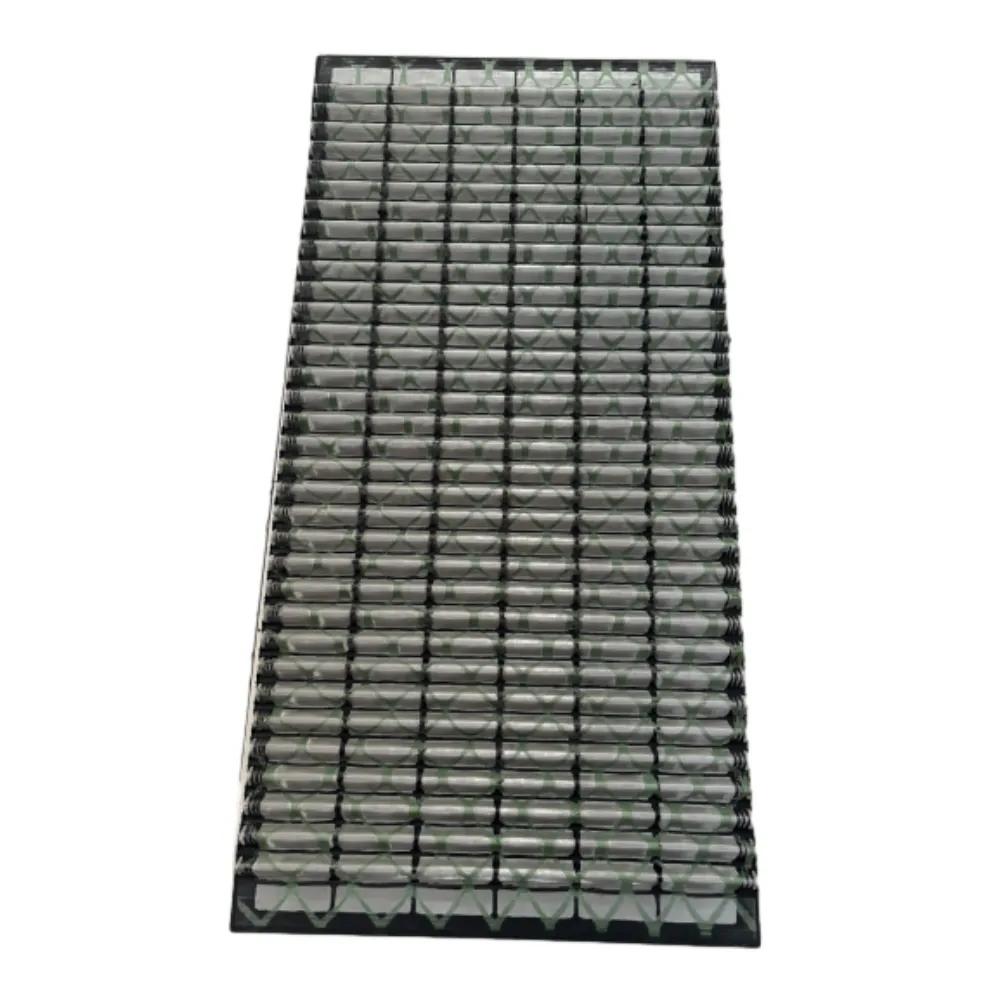

Product Spotlight: MI SWACO Composite Replacement Shaker Screen

The MI SWACO Composite Replacement Shaker Screen is meticulously designed to enhance drilling performance, reduce downtime, and maximize return-on-investment for operators. Widely trusted across global oilfields, these screens are engineered to outperform OEM and conventional steel frame alternatives.

- Composite material for outstanding screen life and mechanical strength.

- Excellent blinding resistance—minimal maintenance and reduced rig downtime.

- Consistent solids control enabling optimal mud properties throughout extended drilling campaigns.

- Available in multiple mesh configurations to suit varied field conditions and mud specifications.

- API RP 13C (ISO 13501) compliant and widely benchmarked for quality.

Test Results Summary:

The Mi SWACO composite screens showed exceptionally good screen life, keeping mud properties on a predetermined level. No screen change or condition affected solids-control efficiency or rig-downtime for the entire test period. Tested screens showed perfect solids-control efficiency, blinding resistance and durability. Drilled solids content in the fluids was maintained at the level required by the client. Screen life of some of the models exceeded expectations.

For more, visit the official product page: MI SWACO Composite Replacement Shaker Screen

Comparative Parameter Table: SWACO Screens Supplier (Market Overview)

| Supplier | Main Material | Mesh Range (API) | Frame Type | Typical Screen Life (hours) | Compliance |

|---|---|---|---|---|---|

| HEBEI MATTS TECH CO. LTD. | Advanced Composite● | API 20 - 325 | Composite & Steel | 350 - 800 | API RP 13C |

| Brand X | Steel/Composite | API 20 - 200 | Steel | 200 - 550 | API RP 13C |

| Brand Y | Composite | API 35 - 270 | Composite | 300 - 650 | ISO 13501 |

| Brand Z | Steel | API 30 - 120 | Steel | 160 - 330 | Internal |

Key Technical Specifications: MI SWACO Composite Replacement Shaker Screen

| Parameter | Value | Advantage |

|---|---|---|

| Frame Material | Composite Polymer + Steel | Lightweight, High Rigidity, Rust-Resistant |

| Mesh Range | API 20 – API 325 | High Precision Solids Filtering |

| Standard Compliance | API RP 13C (ISO 13501) | Industry Acceptance & Reliability |

| Service Life | 350 – 800 hours (Field Tested) | Cost Saving, Less Downtime |

| Blinding Resistance | Excellent | Less Maintenance, Consistent Performance |

| Application | M-I SWACO Shale Shakers, Hi-G Dryers | Versatile, Easy Compatibility |

Application Scenarios: Where SWACO Screens Make a Difference

- Oil & Gas Drilling Rigs: Primary solids control via primary and secondary shakers (Land, Offshore, Deepwater).

- Horizontal Directional Drilling (HDD): Mud recycling and contamination prevention for infrastructure and pipeline boring.

- Mining, Water Well & Geothermal Projects: Screening for drilling fluids in diverse geological formations.

- Environmental Remediation & Waste Management: Solid-liquid separation in various cleaning and recovery applications.

- High-Volume Dewatering Operations: Advanced shakers equipped with swaco screens supplier products for large-volume mud handling.

Professional FAQ: SWACO Screens Technologies & Standards

1. What frame materials are best for shale shaker screens?

Answer: Modern swaco screens supplier products often use composite polymers reinforced with steel. This combination provides high structural integrity, corrosion resistance, and reduced overall weight, prolonging screen lifespan and simplifying handling.2. What is the mesh range typically offered for MI SWACO shaker screens?

Answer: The typical mesh range is API 20 to API 325, allowing for selection based on solids removal requirements and mud specification. Higher API numbers indicate finer screen openings.3. What standard governs shaker screen specifications?

Answer: API RP 13C (ISO 13501) is the industry standard, dictating mesh size nomenclature, conductance, cut point (D100), and labeling, ensuring screens from a swaco screens supplier are easily interchangeable and predictable in performance.4. How does blinding resistance impact drilling operations?

Answer: Excellent blinding resistance minimizes screen blockage, reduces maintenance frequency, and guarantees continuous solids removal, which preserves downstream equipment longevity.5. Are MI SWACO Composite Replacement Shaker Screens compatible with all shaker models?

Answer: They are engineered to fit major M-I SWACO shakers (including Mongoose, Meerkat, BEM-600/650, and others) as well as some third-party brands. Always check compatibility charts from your swaco screens supplier.6. How is “screen life” measured, and what factors affect it?

Answer: Screen life is measured in operational hours under continuous field or lab conditions. Key factors: drilling fluid properties, solids loading, mechanical vibration intensity, and mesh type/material.7. Is there a recommended procedure for installation and maintenance of MI SWACO screens?

Answer: Yes, always follow OEM and supplier guidelines: verify frame/mount fit, tighten screens evenly, check and clean regularly, and record usage for optimal performance tracking and timely replacement.Why Choose HEBEI MATTS TECH CO. LTD. as Your Swaco Screens Supplier?

- Rich Experience: 10+ years in solids control technology and global partnerships with major drilling contractors.

- Cutting-Edge R&D: Collaborative design, continuous field validation, and rapid response to client demands.

- Strict Quality Assurance: All products certified per API and ISO 13501 standards.

- Global Support: Responsive technical consultation, on-time shipping, and full aftersales commitment.

- Competitive Pricing: Direct-from-factory supply, providing top-tier shaker screen for sale at attractive terms.

For consultation or to become a distributor, contact us at lyiunqi@honestmetal.com or +86 137 8439 7137, or visit swaco screens supplier product page.

References & Industry Resources

- R. J. Stirling, "Performance Enhancement of Composite Frame Shaker Screens," SPE OnePetro, 2016

- API Specification RP 13C/ISO 13501: Standard Guidelines for Shale Shaker Screens, API

- Drilling Forum: "How to Select the Best Shale Shaker Screen?", Forum Source

- Modern Shale Drilling Magazine: "Composite Screens Extend Drilling Efficiency" (Read)

- B. G. Little, “Solids Control: Screen Technology Developments,” ScienceDirect