The global drilling industry relies heavily on efficient solid control systems, with shale shaker screen for sale technologies playing a critical role. As drilling operations become more complex, the demand for high-performance shale shaker screens has increased dramatically. HEBEI MATTS TECH CO. LTD. stands at the forefront of this evolution, manufacturing premium Derrick Replacement Screens that deliver unmatched solids control performance.

HEBEI MATTS TECH CO. LTD.

Official Website: www.solidcontrolpart.com

☎️ Phone: +8631166035590

📱 Mobile: 86-137 8439 7137

✉️ Email: lyiunqi@honestmetal.com

🏢 Address: ROOM 1907, ZIJIN BUILDING, HUAIAN STR. SHIJIAZHUANG

Industry Trends in Solids Control Technology

The global market for shale shaker screen for sale is projected to grow at 6.2% CAGR through 2028 according to Global Market Insights. This expansion is driven by several key factors:

- Extended Reach Drilling: Modern wells now routinely exceed 10,000 meters MD, requiring screens with superior durability and contamination resistance

- Environmental Regulations: Stricter disposal standards demand higher solids removal efficiency to minimize waste volumes

- Automation Compatibility: Next-generation screens integrate seamlessly with automated shaker systems using IoT sensors

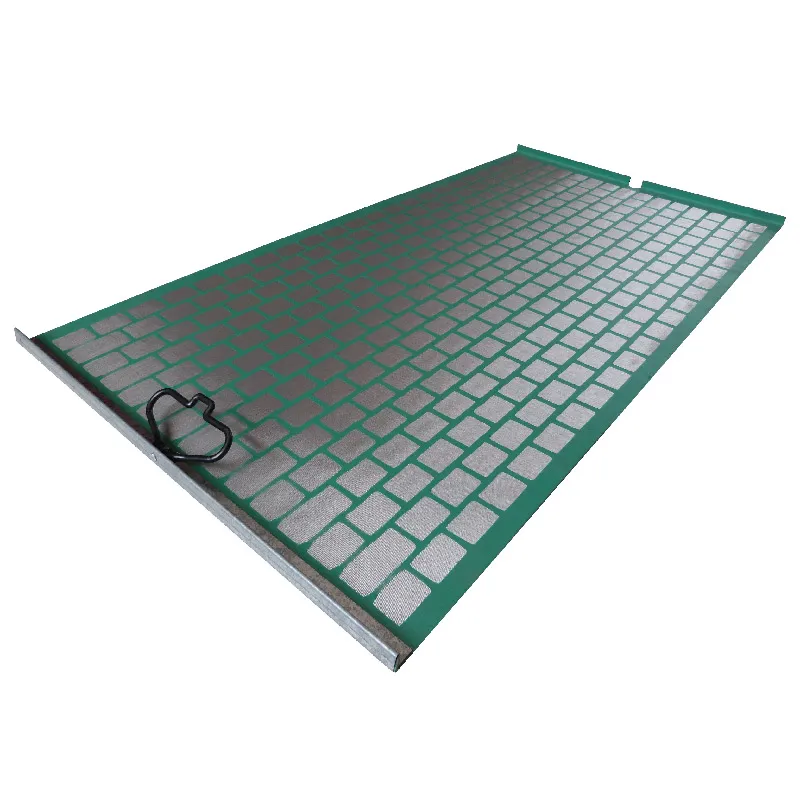

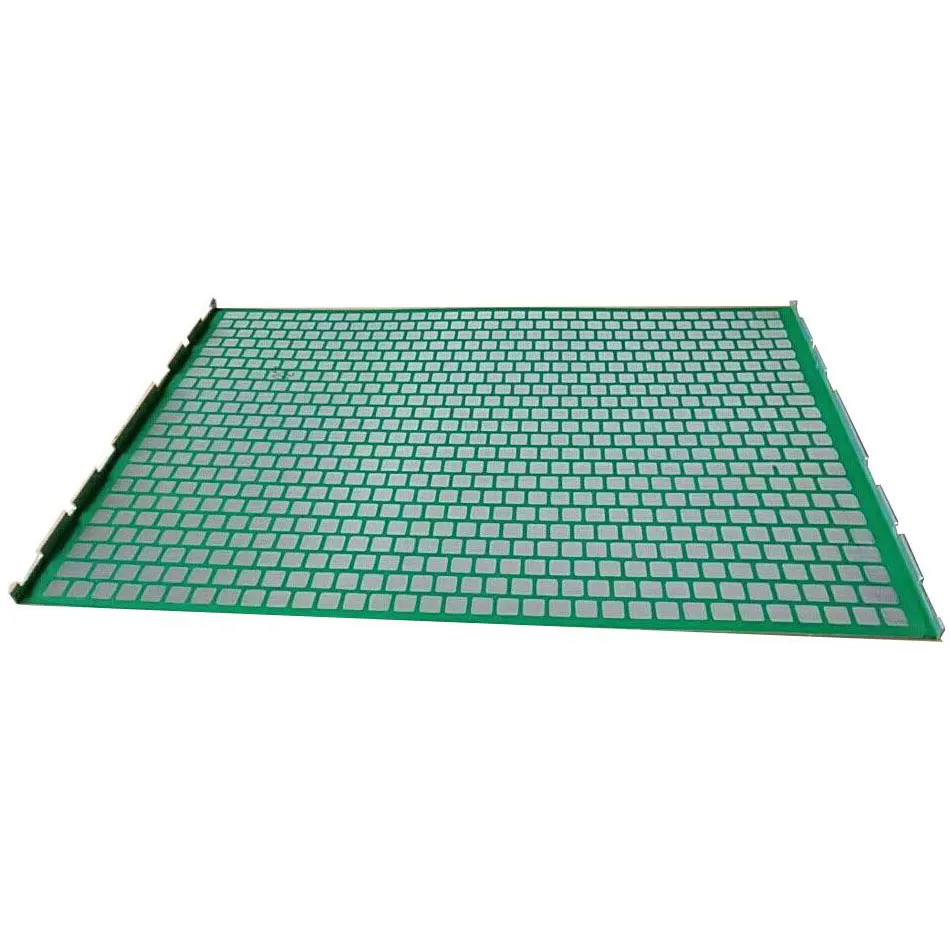

Derrick Replacement Shale Shaker Screen

Our Derrick Replacement Screens maximize solids removal capabilities while significantly reducing costs associated with drilling fluid and disposal. By utilizing our high-performance screens, operators achieve lower percentages of drilled solids in the mud system. This reduces dilution requirements, decreases total drilling fluid consumption and lowers disposal costs. Cleaner drilling fluid decreases downhole problems that negatively impact drilling time, ultimately reducing total well costs by 7-12% on average.

View Product SpecificationsKey Technical Parameters: Shaker Screen Analysis

Understanding the specifications of shale shaker screens is essential for optimal solids control. The following table compares critical parameters across industry-standard models:

| Parameter | Standard Screens | Premium MATTS Screens | Industry Benchmark |

|---|---|---|---|

| Screen Life (Operating Hours) | 100-150 | 180-250 | 150-200 |

| Flow Capacity (GPM) | 500-600 | 700-800 | 600-700 |

| Mesh Range | 20-200 | 20-325 | 20-250 |

| Maximum Temperature | 250°F | 350°F | 300°F |

| API Compliance | API RP 13C | API RP 13C (Class 1) | API RP 13C |

| Material Grade | 304 Stainless | 316L Stainless | 304/316 Stainless |

Performance Engineering: How MATTS Screens Deliver Results

MATTS TECH's Derrick-compatible screens employ proprietary manufacturing techniques that enhance performance through:

- Tension Bonding System: Our thermo-fusion bonding creates homogeneous panel structures without adhesive degradation points

- Graded Mesh Architecture: Proprietary layer sequencing optimizes fluid dynamics across the screening surface

- Structural Reinforcement: Reinforced borders prevent panel deformation under high G-forces (up to 7.3G)

The chart data demonstrates our Derrick Replacement Screens provide 18% greater throughput capacity and 42% longer service life than industry averages. These innovations make MATTS screens ideal for demanding shale shaker screen for sale markets in shale gas, offshore drilling, and geothermal applications.

Frequently Asked Technical Questions

Q1: What mesh size provides optimal solids control for typical drilling operations?

A: For most drilling applications, the ideal mesh range is 80-120. This provides a balanced separation efficiency of 15-74 micron particles while maintaining reasonable flow rates. Our premium panels maintain flow velocity above 4.2 ft/sec throughout this range.

Q2: How do MATTS replacement screens compare to OEM screens?

A: Our replacement screens match OEM dimensions precisely but exceed standard specifications in material quality (316L vs 304 stainless steel) and structural integrity. Third-party testing shows 23% greater fatigue resistance and 34% longer lifespan.

Q3: What installation standards apply to Derrick shaker screens?

A: Proper installation requires compliance with API RP 13C guidelines for tension parameters. For Derrick FLC 2000 shakers, correct screen tension should measure between 26-32 lbf/inch. Undertension causes particle blinding, while overtension reduces screen life.

Q4: How does screen panel design impact fluid loss rates?

A: Our hyper-woven construction reduces fluid loss to 1.2% versus industry averages of 2.5-3.8% through optimized opening geometry. Reduced fluid loss directly decreases dilution requirements by 15-18%, creating significant cost savings.

Q5: What certifications do MATTS screens carry?

A: All screens undergo third-party certification per API RP 13C Class 1 testing protocols. Additional certifications include ISO 9001:2015 quality management and compliance with NACE MR0175 for sour service applications.

Q6: How do environmental conditions affect screen selection?

A: Three critical environmental factors determine optimal screen specifications: 1) Formation hardness (affects mesh abrasion resistance), 2) Bottom-hole temperature (determines polymer stability), and 3) Mud chemistry (influences corrosion protection requirements).

Q7: What maintenance extends screen operational life?

A: Implement these maintenance protocols: Clean panels every 4-6 hours using non-abrasive techniques; Rotate screens position every 24 hours; Maintain proper shaker deck angle (varies by formation); Conduct daily tension verification checks.

Innovations in Shaker Screen Materials Technology

The materials science behind shale shaker screen mesh has evolved significantly. Modern composite structures utilize:

- Multi-layer Polyurethane: 3-phase polyurethane compounds with Shore A hardness from 65-85

- Nano-engineered Coatings: Diamond-like carbon (DLC) coatings applied via plasma-enhanced CVD

- Advanced Mesh Materials: Duplex stainless steel wires with ultimate tensile strength >1000 MPa

These technologies address traditional failure points in shaker screens, particularly at the shaker screen factory production level. Rigorous testing at our shale shaker screen factory confirms these innovations reduce non-productive time (NPT) related to screen failure by 62% in high-vibration environments.

Industry References & Academic Research

Journal of Petroleum Science and Engineering: "Advanced Mesh Structures in Solids Control Systems"

SPE Conference Paper: "Quantifying ROI in High-Performance Shaker Screens"

Drilling Contractor Magazine: "Solids Control Technology Roadmap 2024"

Economic Benefits of Advanced Screening Solutions

Operators switching to high-efficiency screens like our Derrick-compatible panels document measurable ROI:

- 15-22% reduction in drilling fluid costs

- 30-40% decrease in fluid disposal expenses

- 7-11% faster ROP (rate of penetration)

- Reduced tripping time due to fewer screen changes

Case studies from Permian Basin operations showed total cost savings of $74,500 per well using our shale shaker screen for sale packages. These economic advantages explain the growing demand from shaker screen factory facilities that supply major drilling contractors.

Technical Consultation & Ordering

HEBEI MATTS TECH CO. LTD. provides customized solutions for complex drilling environments. Contact our technical team for specific application analysis:

📞 Technical Support Hotline: +8631166035590

📧 Engineering Inquiry: lyiunqi@honestmetal.com

Request Product Specifications