Website: https://www.solidcontrolpart.com

Contact: +86 311 66035590 | Mobile: 86-137 8439 7137

Email: lyiunqi@honestmetal.com

Address: ROOM 1907, ZIJIN BUILDING, HUAIAN STR. SHIJIAZHUANG, CHINA

Introduction: Exploring Shale Shaker Screen for Sale & Market Dynamics

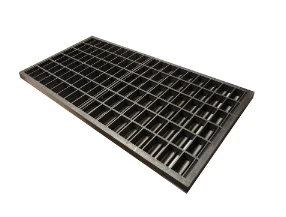

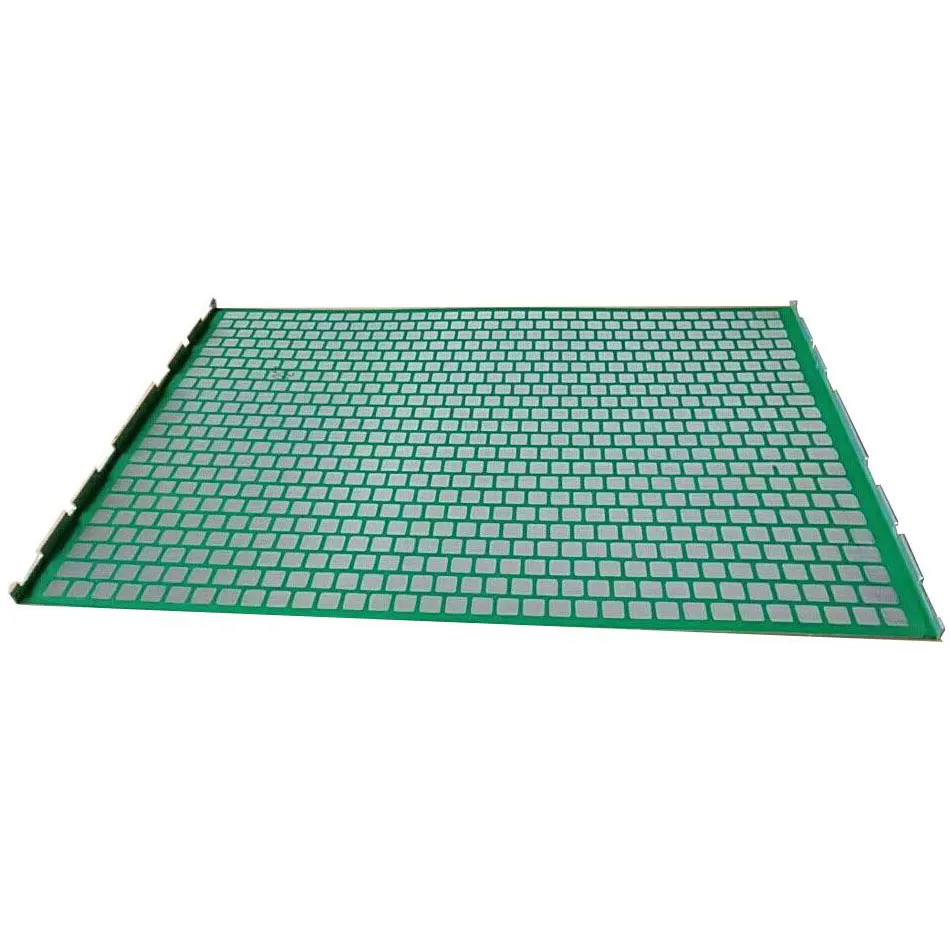

The quest for efficiency and optimization in the oil & gas drilling industry has brought advanced shale shaker screen for sale solutions to the forefront. As the first line of defense in solid control systems, shaker screens are crucial for separating cuttings from drilling fluids, thereby maintaining optimal mud quality and minimizing operational costs.

HEBEI MATTS TECH CO. LTD. stands as a leading shale shaker screen factory and innovator, supplying premium products backed by professional expertise and cutting-edge technology to global drilling operations.

The Role of Shale Shaker Screens in Drilling Fluids Systems

Shale shaker screens are the core of solid control equipment utilized on drilling rigs. Their primary role is to remove significant portions of drilled solids from the circulating drilling fluid, thus enhancing drilling efficiency and reducing wear on downstream equipment.

- Improve mud recycling quality

- Reduce disposal and dilution costs

- Minimize risk of downhole problems

- Extend life of drilling fluid

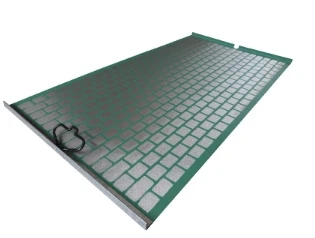

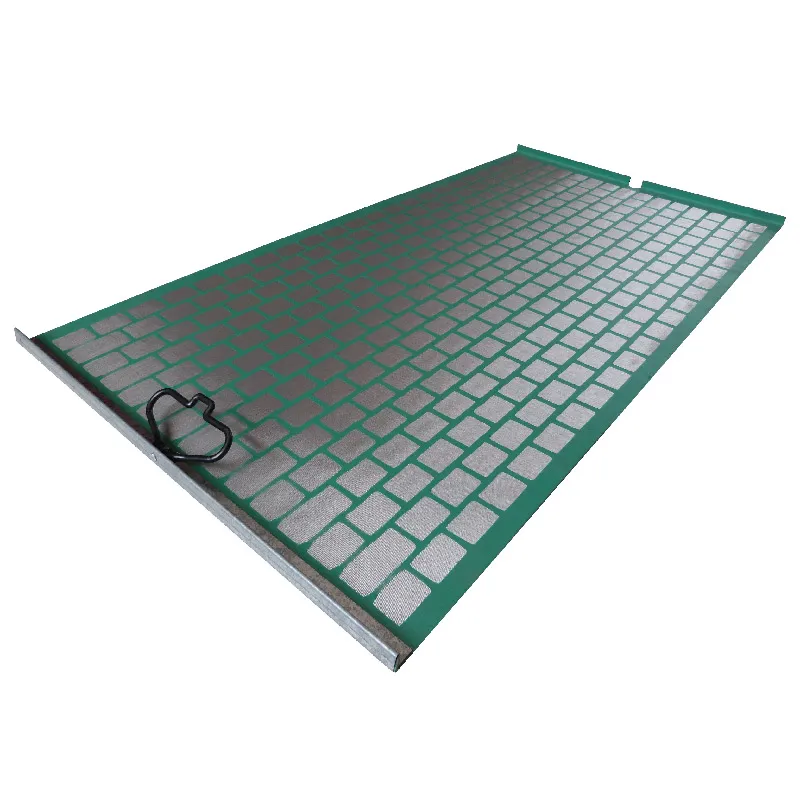

Product Spotlight: Derrick Replacement Shale Shaker Screens

Our Derrick Replacement Shale Shaker Screens represent the pinnacle of solids control technology. Designed to maximize solids removal while minimizing the costs associated with fluid and waste disposal, these screens offer:

- High solids removal efficiency

- Reduced drilling fluid dilution and waste

- Enhanced drilling fluid cleanliness

- Minimized drilling time and downhole complications

- Lower total drilling costs

| Screen Model | Mesh Size | Screen Frame Type | Material | API Designation | Transmittance (%) | Dimension (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| Derrick 500 Series | 20–325 | Steel Frame/PWP | SS304/316 | API 20–API 325 | 65–80 | 1050×695 | 5.2 |

| Derrick 2000 Series | 60–325 | Composite | SS304/316 | API 60–API 325 | 67–83 | 1250×635 | 7.1 |

| Derrick FLC48-30 | 20–325 | Steel Frame | SS304/316 | API 20–API 325 | 63–77 | 1050×695 | 4.7 |

Key Parameters: Shale Shaker Screen for Sale Comparison Table

| Factory | Screen Type | API Range | Mesh Count | Frame Material | Standard Compliance | Screen Life |

|---|---|---|---|---|---|---|

| HEBEI MATTS TECH CO. LTD. | Derrick Replacement | 20-325 | 20-325 | Stainless Steel 304/316 | API RP 13C, ISO 9001 | Long (> 140 hours) |

| Derrick Shaker Screen Factory | Original Derrick | 20-325 | 20-325 | SS 304/316 | API RP 13C | Medium (100–120h) |

| Shaker Screen Factory (Other) | Composite/Steel | 20-325 | 20-325 | Steel/SS304 | ISO 9001 | Short ( |

Advanced Technology & Factory Strength: HEBEI MATTS TECH CO. LTD.

- Modern factory with ISO 9001:2015 certification

- Strict adherence to API RP 13C standard

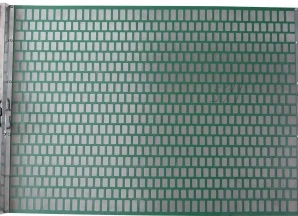

- Robust R&D for shale shaker screen mesh optimization

- OEM/ODM capability for global partners

- Full traceability and quality audits for every batch

- Quick delivery for shale shaker screen for sale worldwide

- shale shaker screen for sale - See Product Details

Applications & Solutions: Where Are Derrick Shale Shaker Screens Used?

Shale Shaker Screen for Sale products from HEBEI MATTS TECH CO. LTD. find application in:

- Onshore & Offshore Oil and Gas Drilling Rigs

- Geothermal Energy Drilling Sites

- Mining & Mineral Processing

- Water Well Drilling Operations

- Environmental Remediation Projects

- Directional & Horizontal Drilling

STEERED BY EEAT: Building Trust, Authority, and Expertise

As a professional shale shaker screen factory, we ensure:

Expert FAQ: Shale Shaker Screen for Sale Technology Explained

A1: Usually premium grade Stainless Steel 304 or 316 is chosen for shale shaker screen for sale. This ensures resistance to corrosion, long service life, and adherence to industry standards (PetroWiki).

A2: API designation (per API RP 13C) classifies the opening size of the screen in alignment with international solids control standards—ensuring fit-for-purpose screen selection.

A3: Composite and steel frames both offer high strength, but composite frames generally have better vibration resistance and lighter weight, extending the working life of shale shaker screen mesh.

A4: Our derrick replacement shale shaker screens are manufactured to OEM standards, with snap-on and bolt fastening options for maximum compatibility across rigs.

A5: Every lot is tested for mesh count accuracy, fluid capacity, cut point, and screen integrity as per API/ISO procedures (api.org).

A6: Yes—HEBEI MATTS TECH CO. LTD. supports personalized engineering for non-standard sizes and custom shale shaker screen mesh types.

A7: Depending on drilling environment and solids load, our shale shaker screen for sale can outperform standard screens, with life averaging 30–50% longer than generic products.

Shale Shaker Screen for Sale: Why Choose HEBEI MATTS TECH CO. LTD.?

- Technical Authority: Decades of experience as a shaker screen factory and global field support.

- Total QA Commitment: Full batch traceability, Quality Control, and audit reports available.

- High-Capacity Manufacturing: Global shipping, stable lead-times even for large projects.

- Competitive Pricing: Advanced raw material sourcing and process innovation drive down costs.

- Expert Consultation: Pre-sales, technical support, and after-market solutions available 24/7.

Contact HEBEI MATTS TECH CO. LTD.

Tel: +86 31166035590 | Email: lyiunqi@honestmetal.com

Product URL: Derrick Replacement Shale Shaker Screen

Industry Trends & Market Insights: Shale Shaker Screen for Sale in the Future

- Environmental protection: Increasing regulations drive adoption of finer mesh, efficient solids removal, and waste minimization (SPE-196415-MS).

- Digitalization: Smart sensors and wireless monitoring, enabling predictive screen replacement and optimization.

- Globalization: Industry leaders like HEBEI MATTS TECH CO. LTD. now serve clients in 118+ countries.

- Sustainable operations: Extended screen life, reduced replacement frequency, and recycling initiatives (SPE-193363-MS).

For those searching for the best shale shaker screen for sale, relying on established expertise, technological excellence, and proven field outcomes is essential.

Choose HEBEI MATTS TECH CO. LTD. as your reliable partner in solid control innovation!