HEBEI MATTS TECH CO. LTD.

Official Website: https://www.solidcontrolpart.com

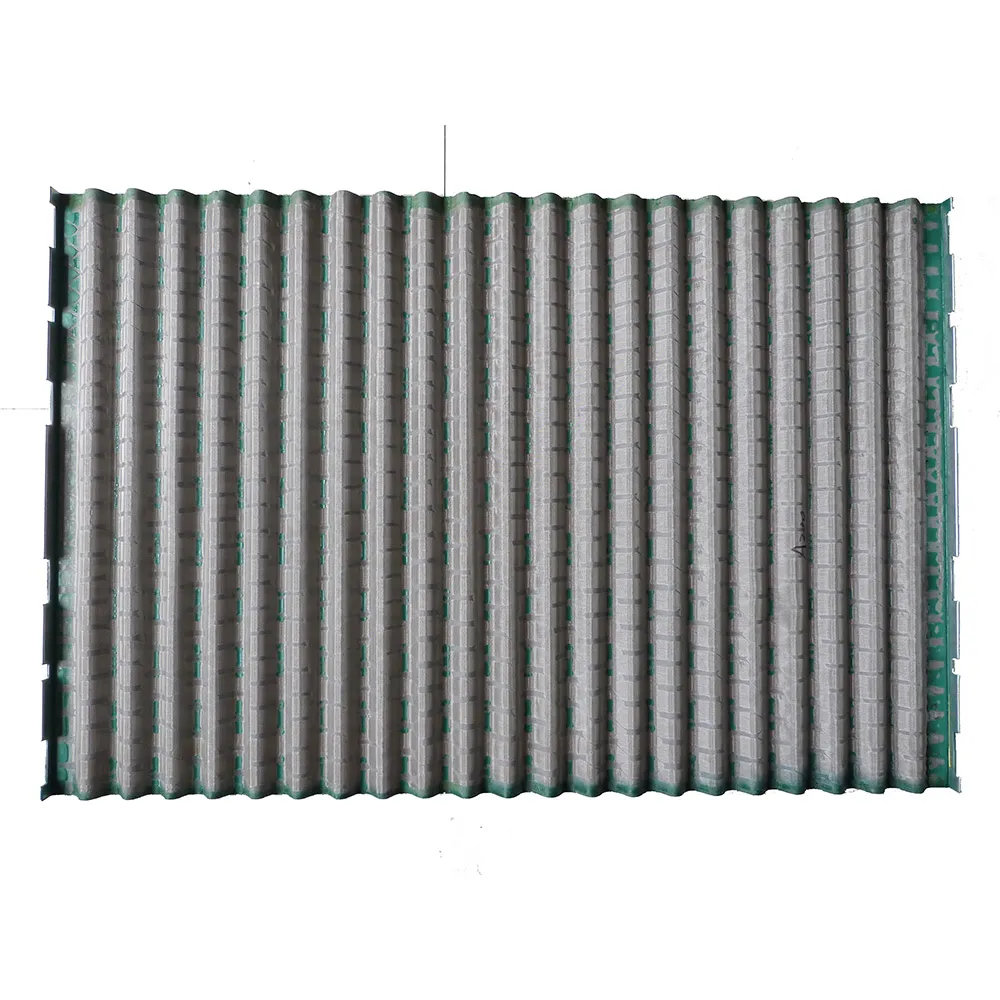

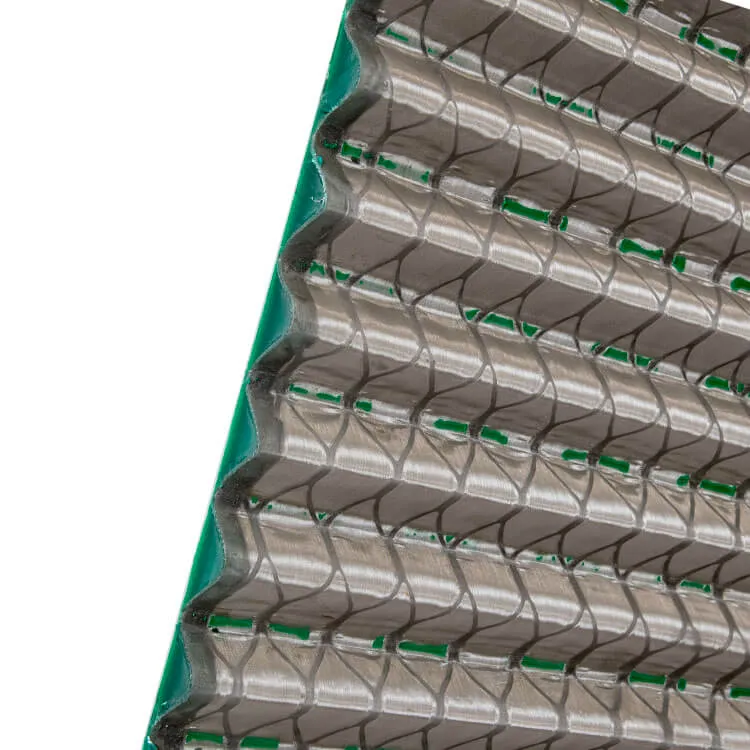

Innovative Solids Control Solution: Derrick PMD Replacement Shaker Screen

The Derrick PMD Replacement Shaker Screen represents a breakthrough in drilling fluid processing technology. These high-performance screens serve as replacement products for conventional flat screens, delivering between 125% to 150% increase in effective screening area without requiring modifications to existing shaker equipment. By adopting these wave-type screens, drilling operations can significantly enhance drilling fluid quality and substantially boost productivity. HEBEI MATTS TECH manufactures these advanced screens across the complete mesh size spectrum from 20 to 325, providing optimal solutions for various drilling conditions.

Drilling Technology Evolution & Market Shifts

The global drilling fluids processing equipment market is projected to reach $7.8 billion by 2028 (CAGR 5.1%). This growth is primarily driven by increased shale exploration activities and deepwater drilling operations requiring advanced solids control solutions. The Derrick PMD Replacement Shaker Screen technology addresses two critical industry challenges: the need for higher filtration efficiency and equipment compatibility with existing infrastructure.

Modern drilling operations generate significantly more drilled solids than conventional wells due to faster penetration rates. According to the Society of Petroleum Engineers (SPE), inadequate solids removal accounts for over 40% of drilling fluid-related non-productive time. This makes high-performance screen technology like the Derrick PMD Replacement Shaker Screen not just an operational upgrade but a financial imperative for modern drilling operations seeking to maximize efficiency.

Engineering Specifications & Performance Metrics

| Parameter | PMD Screen | Conventional Screen | Improvement |

|---|---|---|---|

| Effective Screening Area | 32.5 sq. ft. | 26.0 sq. ft. | +25% |

| Maximum Flow Rate | 800 GPM | 600 GPM | +33% |

| Fine Particle Separation | Down to 74μm | 100μm | +35% Finer |

| Mesh Durability | 300-400 hrs | 180-250 hrs | +67% Longevity |

| Pressure Distribution | Uniform across surface | Center-focused | Better Wear Resistance |

| Installation Time | 25-35 minutes | 45% Faster |

Implementation Success Story: Offshore Drilling Project

An offshore drilling project in the Gulf of Mexico replaced their conventional screens with Derrick PMD Replacement Shaker Screens. The results were transformative:

- Fluid processing capacity increased by 38% without equipment upgrades

- Screen replacement frequency reduced from weekly to monthly cycles

- Dilution requirements decreased by 28%, reducing chemical costs

- Solids control efficiency improved to 98.7% according to API standards

The project manager reported: "Implementing Derrick PMD Replacement Shaker Screens delivered an unexpected 18% reduction in total fluid management costs while simultaneously improving drilling rates by enabling higher flow rates through the system."

Engineering Technical FAQ

Industry Research & Technical References

- "Solids Control Technology Advancements" - Journal of Petroleum Technology: https://jpt.spe.org/solids-control-technology-advancements-drilling-efficiency

- "Wave Screen Technology Impact on Drilling Fluid Economics" - SPE Paper 205362: https://onepetro.org/SPEOTC/proceedings-abstract/21OTC/3-21OTC/205362

- API Recommended Practice 13C - Shaker Screen Standardization: https://www.api.org/products-and-services/standards/important-standards-announcements/api-13c

- Global Solids Control Equipment Market Analysis 2023-2030: https://www.researchandmarkets.com/reports/solids-control-equipment-market

Optimize Your Solids Control System

Upgrade to high-efficiency Derrick PMD Replacement Shaker Screens to increase fluid processing capacity, extend screen life, and reduce drilling fluid costs. Contact our engineering team today for customized solutions.

Request Technical SpecificationsHEBEI MATTS TECH CO. LTD. | Phone: +8631166035590 | Email: lyiunqi@honestmetal.com