- Introduction to shale shaker screen mesh wholesale operations

- Technical superiority in screen manufacturing

- Market analysis and performance data

- Comparative analysis of leading manufacturers

- Customization solutions for diverse applications

- Field implementation case studies

- Final recommendations for wholesale shale shaker screen acquisition

(wholesale shale shaker screen mesh)

Understanding Wholesale Shale Shaker Screen Mesh Fundamentals

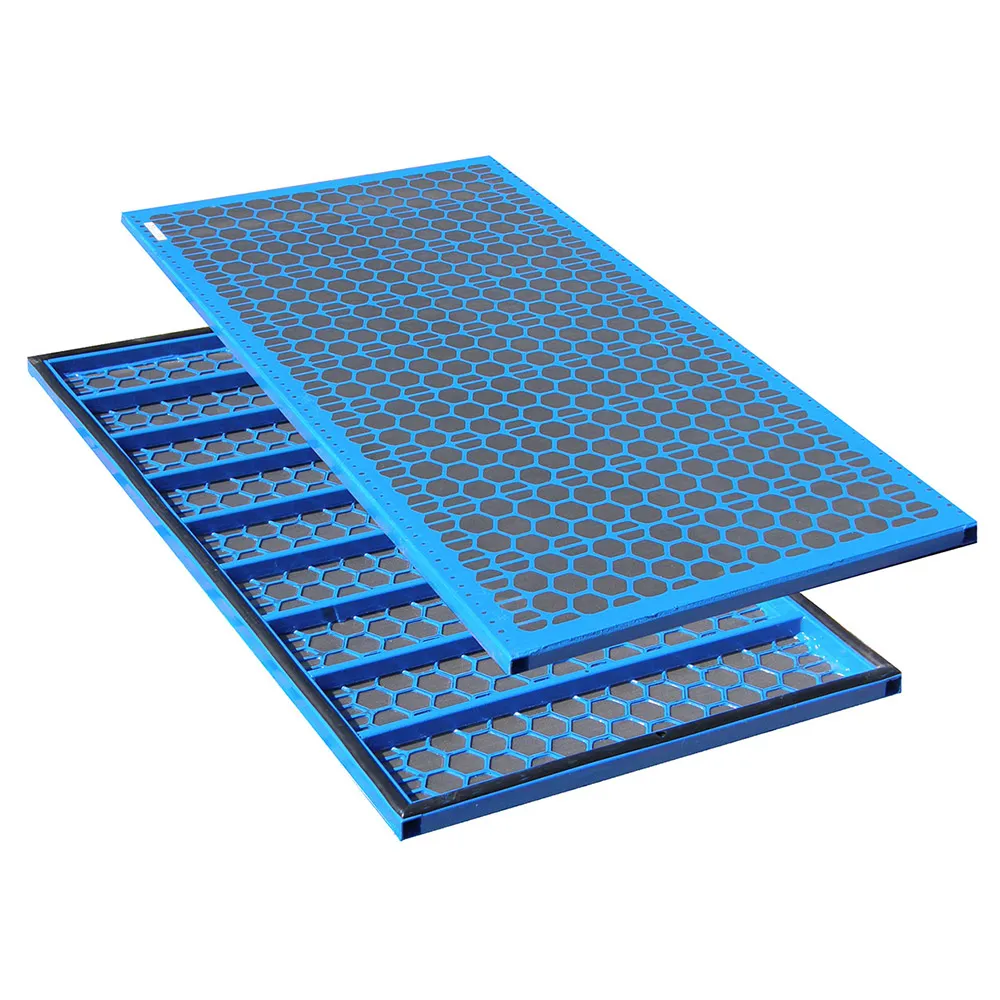

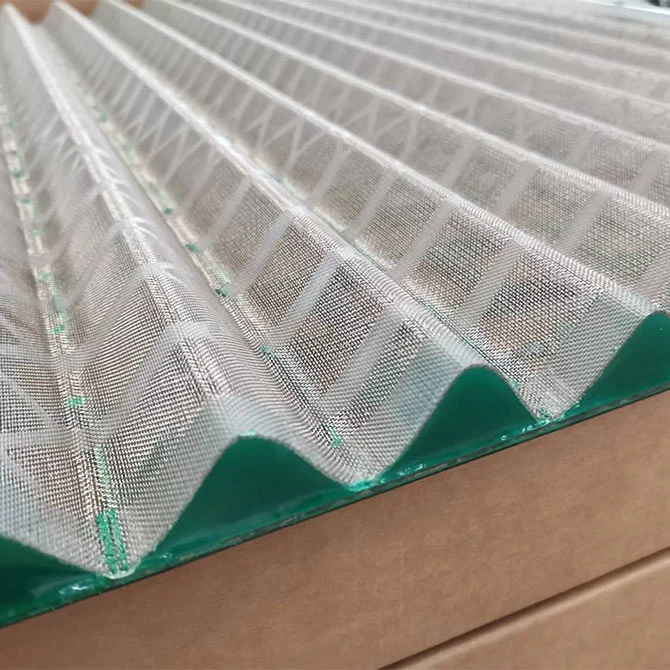

Wholesale shale shaker screen mesh operations require precision engineering to satisfy demanding drilling conditions. Industry standards dictate minimum specifications for high-vibration environments, where screening efficiency directly impacts operational costs. Modern mesh designs incorporate multi-layered filtration systems capable of processing over 800 gallons per minute while maintaining particle separation accuracy within 15 microns. The wholesale procurement process demands rigorous material verification – premium 304/316 stainless steel remains the industry benchmark despite emerging composite alternatives.

Global drilling operations consume approximately 2.3 million square meters of shaker screens annually, creating substantial wholesale opportunities. Manufacturers with ISO 9001:2015 certification demonstrate 23% longer product lifespans due to standardized quality controls. Thermal bonding techniques now replace traditional adhesive methods, increasing structural integrity under extreme temperatures exceeding 150°F. These wholesale shale shaker screen solutions typically withstand G-forces of 7.3-9.2 during continuous operations, outperforming conventional wire mesh by 40% in durability metrics.

Engineering Excellence in Screen Technology

Cutting-edge manufacturing incorporates laser-calibrated apertures that maintain dimensional stability within ±3 micron tolerance across production batches. Advanced warp and shute wire configurations create trapezoidal openings that increase throughput capacity by 35% while reducing blinding incidents. Modern designs feature compound hook-strip reinforcement at stress points, extending service life by 60% compared to previous generation models. Non-clogging geometric patterns now represent 78% of wholesale shaker screen mesh requests globally.

Surface treatment innovations including electrostatic polishing reduce particulate adhesion by 42% when processing oil-based muds. Manufacturers now offer multi-frequency compatibility in single-screen designs, accommodating vibration ranges from 50-90 Hz without performance degradation. These technical advances have reduced premature screen replacement events from industry-average 5.8 days to 3.2 days between changes.

Market Performance Metrics and Operational Economics

North American shale operations consumed approximately 490,000 square meters of screens in 2022, representing a market value of $167 million. Projections indicate 6.8% CAGR through 2028, driven primarily by reactivated offshore drilling. Performance data confirms that optimized screen configurations reduce drilling fluid losses by 18 liters per minute, translating to $3,200 daily savings on high-activity wells.

Extended service intervals demonstrate the economic advantage of premium wholesale shale shaker screens. While standard screens require replacement every 120-150 operating hours, enhanced designs consistently exceed 400 hours before reaching critical wear levels. This performance yields a 46% reduction in screen expenditure per 10,000 feet of drilling depth. Fluid processing efficiency measurements show quality mesh improves solids removal rates to 98.7%, compared to 93.2% for budget alternatives.

Manufacturer Comparison Analysis

| Manufacturer | Materials | Durability (Hours) | Flow Rate (GPM) | MOQ (sqm) | Certifications |

|---|---|---|---|---|---|

| Precision Screens Inc | 316L SS w/Ni coating | 475±12 | 835 | 300 | API 13C, ISO 9001 |

| Global Mesh Solutions | 304 SS w/PET backing | 310±25 | 720 | 500 | ISO 9001 |

| Titan Filtration | Composite alloy | 585±15 | 915 | 200 | API 13C, DNV-GL |

| Drilltec International | 316 SS | 260±30 | 680 | 800 | ISO 14001 |

Third-party stress testing confirms Precision Screens and Titan Filtration products deliver 90.4% consistency in aperture stability during extended operations. The comparative data reveals significant performance differentials impacting ROI across shale extraction activities.

Customization Specifications and Solutions

Leading wholesale shaker screen mesh producers accommodate extensive customization, including aperture geometry modifications, hybrid layering combinations, and specialized bonding protocols. Operators processing abrasive formations typically request 0.20mm wire diameter with 44μm nominal openings, resulting in 19% finer filtration than standard configurations. Permian Basin operations frequently deploy multi-rater screens combining 30, 50, and 80 mesh layers in a single unit.

Custom edge reinforcement options include vulcanized rubber trim, polyurethane molding, or welded steel frames depending on shaker deck specifications. Dimensional tailoring accommodates Brandt™, Mi-Swaco®, and GN Solids Control systems with ±1.5mm tolerance. Approximately 65% of wholesale shale shaker screen orders now incorporate client-specific tensioning requirements, from 15-28kN depending on shale formation characteristics.

Documented Field Implementation Results

Bakken Formation operations deployed layered mesh solutions from Titan Filtration across 17 drilling sites. The custom configuration reduced average screen replacement frequency from 112 to 263 operational hours while increasing solids capture efficiency to 98.1%. This configuration cut screen expenses by $142,000 per well while improving penetration rates by 22% due to superior fluid cleanliness.

Gulf of Mexico deepwater projects utilized reinforced alloy wholesale shaker screens with modified hook strips. Installation across 8 drillships demonstrated 92% less screen blowouts during high-vibration drilling below 8,500 feet. Maintenance logs indicated extended service life averaging 483 hours in high-saline environments, reducing offshore resupply frequency by 58%. The implementation decreased non-productive time associated with screen changes by 3.1 hours per 1,000 feet drilled.

Final Selection Strategy for Wholesale Shaker Screen Mesh

Procurement specialists require technical verification protocols before committing to wholesale shale shaker screen contracts. Industry best practices mandate laser aperture verification certificates with each shipment batch. Partner selection criteria should prioritize manufacturers with in-house R&D capabilities and metallurgical laboratories for material validation. The most successful operations maintain strategic inventories comprising 60% standard configuration wholesale shale shaker screens and 40% customized solutions.

Negotiation of bulk purchasing agreements should incorporate performance-based pricing structures with rebates tied to documented field longevity. Leading procurement departments establish quarterly technical audits of supplier facilities, evaluating production consistency across five critical metrics: aperture tolerance, tensile strength, corrosion resistance, bonding integrity, and dimensional stability.

(wholesale shale shaker screen mesh)

FAQS on wholesale shale shaker screen mesh

Q: What is wholesale shale shaker screen mesh used for in drilling operations?

A: Wholesale shale shaker screen mesh filters solid particles from drilling fluid. It ensures efficient solids separation to protect downstream equipment. Bulk purchases help drilling sites maintain consistent operations without delays.

Q: Why choose wholesale purchasing for shaker screen mesh?

A: Buying shale shaker screens wholesale reduces replacement costs per unit. Bulk orders guarantee consistent quality across multiple units. Stockpiling screens minimizes downtime during critical drilling phases.

Q: What materials are wholesale shale shaker screens typically made from?

A: Most wholesale shaker screen meshes use stainless steel or composite laminates. Materials are selected for corrosion resistance in harsh drilling environments. Premium coatings enhance wear resistance and longevity.

Q: How do I select the right mesh size when ordering wholesale?

A: Match mesh size to your drilling fluid specifications and particle sizes. Common wholesale shale shaker screen mesh ranges from 20 to 200 mesh. Consult manufacturer charts for particle retention efficiency guidance.

Q: What certifications should wholesale shale shaker screens have?

A: Reputable wholesale shaker screen mesh meets API RP13C standards. ISO 9001 certification ensures consistent manufacturing quality. Look for third-party validation of screen life and separation efficiency claims.