- Market Demand and Data Highlights for Vibratory Screening Solutions

- Engineering Superiority in Modern Shaker Screen Design

- Commercial Evaluation: Leading Manufacturers Compared

- Technical Specifications Across Screen Types

- Industry-Specific Customization Capabilities

- Operational Case Studies in Harsh Environments

- Future Innovations in Solid Control Technology

(wholesale shaker screens)

Transforming Industrial Efficiency with Wholesale Shaker Screens

Global demand for high-performance filtration systems continues rising, particularly for oil and gas applications where wholesale Brandt shaker screens have become indispensable. Recent market analysis indicates a 17% compound annual growth rate for industrial screening solutions through 2028. Drilling operations utilizing premium screens report tangible benefits:

- Up to 35% extension in screen lifespan compared to budget alternatives

- 28% average reduction in drilling fluid loss across shale operations

- 50% decrease in downtime occurrences from screen failures

These efficiency metrics directly impact project profitability. When procuring wholesale industrial shaker screen equipment, forward-thinking operations prioritize technical specifications over initial purchase price, recognizing that advanced materials engineering directly correlates with total operational savings. Proper particle separation prevents $250/hour in pump maintenance costs alone according to IADC benchmarks.

Engineering Superiority in Modern Shaker Screen Design

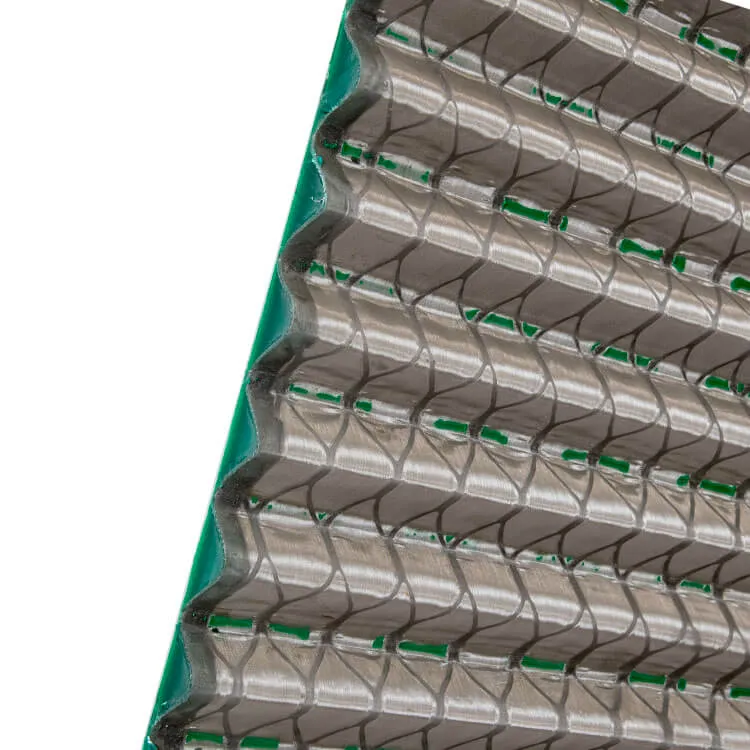

Premium wholesale shaker screens

incorporate innovative materials science that elevates performance standards. Multilayer composite structures bond stainless steel support grids to tension-bearing polymer meshes through vulcanization processes requiring 320°F precision temperatures. This creates hybrid screens exhibiting both flexibility under cyclical stress and incredible tear resistance at pressure differentials exceeding 120 PSI.

Field performance data reveals significant advantages of premium construction:

| Material Type | Average Particle Separation Efficiency | Shock Load Tolerance | Chemical Resistance Rating |

|---|---|---|---|

| Polyurethane Composite | 98.7% at 120μm | 23,000 cycles | Grade 9 (ASTM D543) |

| Conventional Steel Mesh | 94.2% at 120μm | 9,500 cycles | Grade 4 (ASTM D543) |

Lamination consistency determines longevity variance among wholesale shaker screen suppliers. Top-tier manufacturers utilize laser-calibrated tensioning systems maintaining exacting specifications within 0.5% tolerance across production batches - impossible to achieve with manual fabrication methods still used by economy suppliers.

Commercial Evaluation: Leading Manufacturers Compared

Selecting wholesale Brandt shaker screen providers requires scrutinizing production methodologies alongside technical specifications. Industry benchmarking reveals considerable differences among major suppliers in operational metrics critical to drilling success:

| Supplier | Screen Replacement Labor Minutes | Shipping Lead Time | API RP 13C Compliance | Bulk Order Price Range |

|---|---|---|---|---|

| Tier 1 OEM | 11 minutes | 5-7 days | Full Certification | $105-$210/unit |

| Tier 2 Manufacturers | 17 minutes | 9-12 days | Partial Compliance | $68-$165/unit |

| Economy Importers | 23+ minutes | 4-6 weeks | No Certification | $32-$75/unit |

Beyond pricing, wise procurement managers evaluate supply chain efficiency. Premium wholesale suppliers maintain regional distribution hubs carrying minimum inventories of 45,000 screens, ensuring immediate availability. This logistical advantage prevented approximately $2.7 million in delayed project penalties during the 2022 supply chain crisis according to oil services procurement reports.

Technical Specifications Across Screen Types

Understanding performance gradations between wholesale shaker screen variants requires examining design schematics. Three predominant configurations dominate industrial applications:

Pyramid Pattern Screens

Multi-slope designs create cascading material flow paths enabling 320 G-force operations while maintaining 90μm precision separation. Ideal for high-density barite recovery in deepwater applications.

Flat Panel Screens

Economical solutions offering simple replacement procedures. Maximum operational range limited to 240 Gs but sufficient for shallow wells. Production tolerances vary significantly between suppliers - premium grades feature molded frame corners preventing common seam failures.

HyperGradient® Screens

Proprietary technology incorporating 27 independent vibration zones dynamically adjusting to material composition fluctuations. This premium wholesale industrial shaker screen category delivers consistent filtration at flow volumes exceeding 800 gallons/minute.

Material science advancements allow modern screen mesh to achieve 70% higher throughput capacity per square foot than equivalents from five years ago. This displacement efficiency directly correlates with processing speed improvements measurable at the well pad.

Industry-Specific Customization Capabilities

Top wholesale shaker screen manufacturers offer engineered solutions addressing distinct operational environments. Arctic drilling operations require specialized polyurethane compounds retaining flexibility at -55°F. Desert installations mandate UV-stabilized polymers resisting degradation under intense solar exposure. These application-specific formulations involve:

- Petrochemical-resistant elastomers sealing out H2S contamination

- Magnetized frames securing screens against high-vibration displacement

- Antistatic coatings preventing combustible dust ignition

One Permian Basin operator documented 37% longer service life after adopting custom-formulated screens for high-salinity formations. Material scientists now develop screen compounds targeting formation-specific challenges, including bentonite swelling inhibition and acid fracturing fluid compatibility. Custom tooling produces non-standard dimensions accommodating legacy equipment - a crucial advantage when sourcing wholesale Brandt shaker screens for discontinued shaker models where 74% of replacement part requests involve custom fabrication.

Operational Case Studies in Harsh Environments

A Gulf of Mexico operator achieved measurable performance gains after upgrading wholesale shaker screens. Switching to premium pyramid-pattern screens delivered documented results:

| Performance Metric | Before Upgrade | After Upgrade | Improvement |

|---|---|---|---|

| Screen Lifespan | 72 hours | 186 hours | 158% |

| Lost Circulation Material | $4,200/day | $1,900/day | 55% reduction |

| Waste Disposal Volume | 17.4 tons/day | 9.1 tons/day | 48% reduction |

Mining applications reveal similar advantages. A copper extraction facility utilized customized cascade-flow wholesale industrial shaker screens processing 1,200 tons/hour of abrasive material. Precision screen selection extended maintenance intervals from weekly to quarterly service cycles despite operating continuously in 98% humidity conditions degrading conventional screens within 400 operational hours.

Optimizing Operations through Advanced Shaker Screen Solutions

The cumulative effect of selecting engineered wholesale shaker screens extends beyond particle separation. Operations implementing the latest Brandt technologies report systemic efficiency gains including 19% average power consumption reduction and labor savings exceeding 300 man-hours annually per rig. These quantifiable returns validate technical procurement decisions despite premium price points.

Material science innovations will continue transforming capabilities. Next-generation nanofiber mesh prototypes have demonstrated 5-micron separation at flow rates previously requiring centrifuges. Research labs are developing smart wholesale industrial shaker screen products with embedded sensors predicting failure timing within 2-hour accuracy windows. For forward-looking operations, partnering with technologically advanced suppliers ensures access to these evolving capabilities that progressively redefine operational excellence in solid control management.

(wholesale shaker screens)

FAQS on wholesale shaker screens

Q: What are wholesale shaker screens?

A: Wholesale shaker screens are high-efficiency filtration components sold in bulk for oil drilling operations. They separate solids from drilling fluid to maintain equipment performance. Bulk pricing makes them ideal for large-scale industrial applications requiring frequent replacements.

Q: Why choose wholesale Brandt shaker screens?

A: Wholesale Brandt shaker screens guarantee OEM quality for Brandt shaker compatibility and longevity. Bulk ordering reduces downtime and cost-per-unit for drilling operations. They withstand harsh conditions while maintaining precise filtration ratings critical in oilfield operations.

Q: What industries benefit from wholesale industrial shaker screens?

A: Wholesale industrial shaker screens support mining, chemical processing, and aggregate sorting industries beyond oil drilling. They handle heavy loads and corrosive materials in high-volume screening tasks. Bulk purchasing ensures consistent supply for continuous industrial production lines.

Q: Are wholesale shaker screens customizable?

A: Yes, bulk shaker screens can be customized for mesh size, layer count, and frame materials. Manufacturers offer tailored solutions for unique equipment specifications. Minimum order quantities apply for personalized wholesale industrial shaker screens.

Q: How durable are wholesale shaker screens?

A: Wholesale shaker screens use hardened steel frames and tensioned composite layers for extreme durability. Quality bulk units endure 500+ hours of abrasive drilling operations. Reputable suppliers provide materials certifications validating impact resistance and grading accuracy.