About HEBEI MATTS TECH CO. LTD.

Company Name: HEBEI MATTS TECH CO. LTD.

Official Website: https://www.solidcontrolpart.com

Telephone: +8631166035590

Email: lyiunqi@honestmetal.com

Mobile: 86-137 8439 7137

Address: ROOM 1907, ZIJIN BUILDING,HUAIAN STR. SHIJIAZHUANG

As a leading member of the shale shaker screen manufacturers sector, HEBEI MATTS TECH CO. LTD. is dedicated to providing superior solutions for oil & gas, mining, and drilling solids control. Our commitment to quality, technological innovation, and global service has positioned us as an authoritative supplier in the industry.

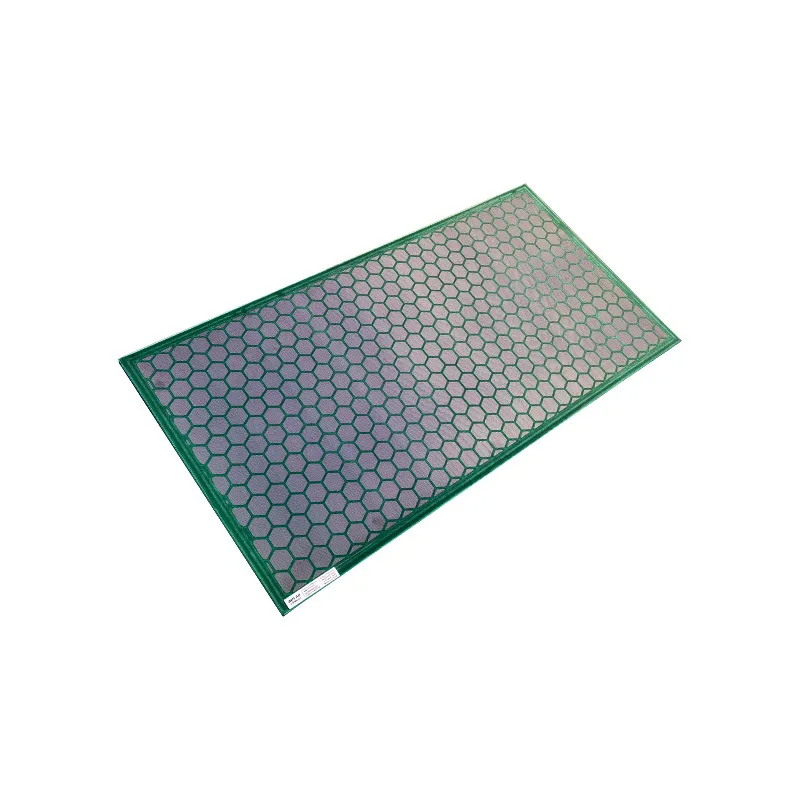

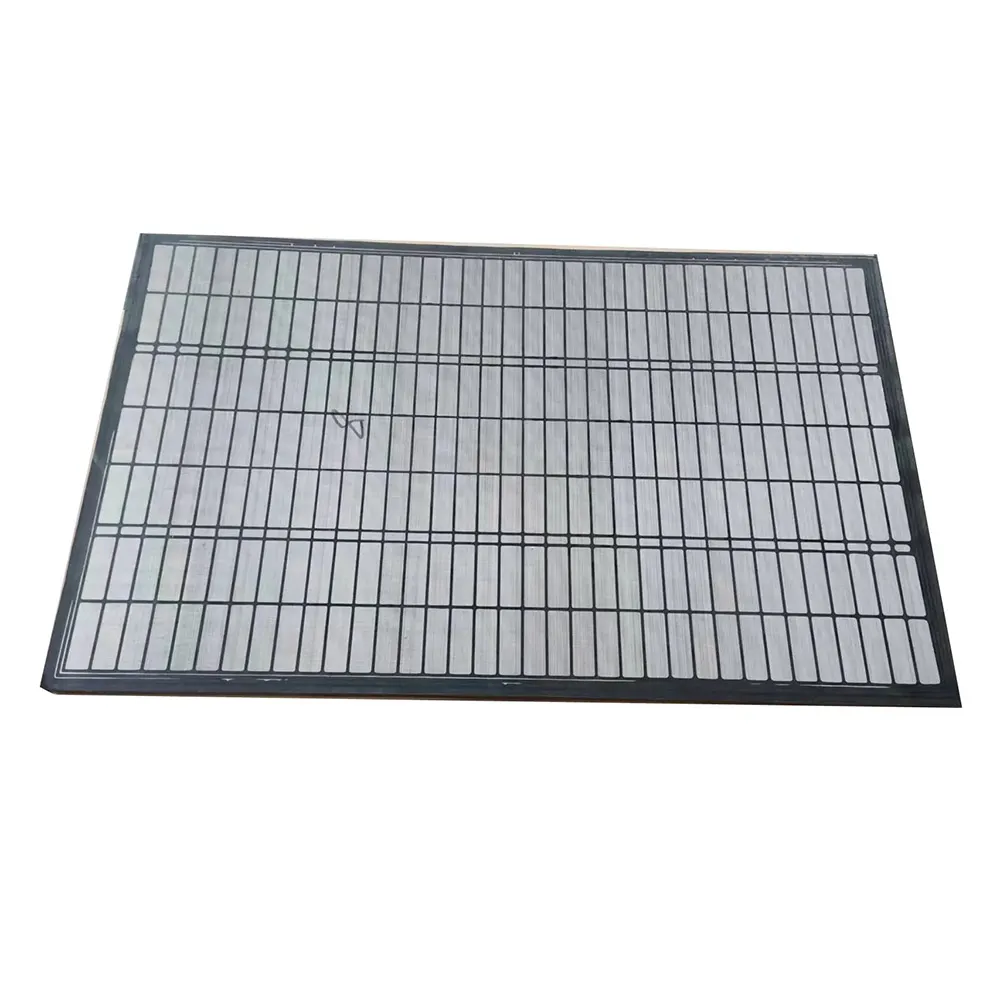

Product Highlight: Brandt Replacement Shale Shaker Screen

Brandt Replacement Shale Shaker Screen

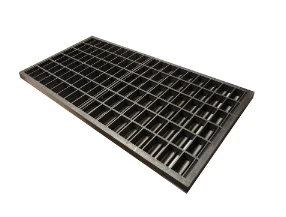

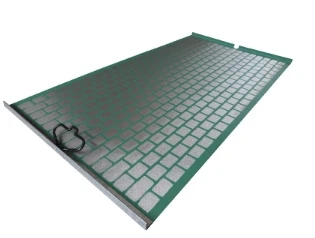

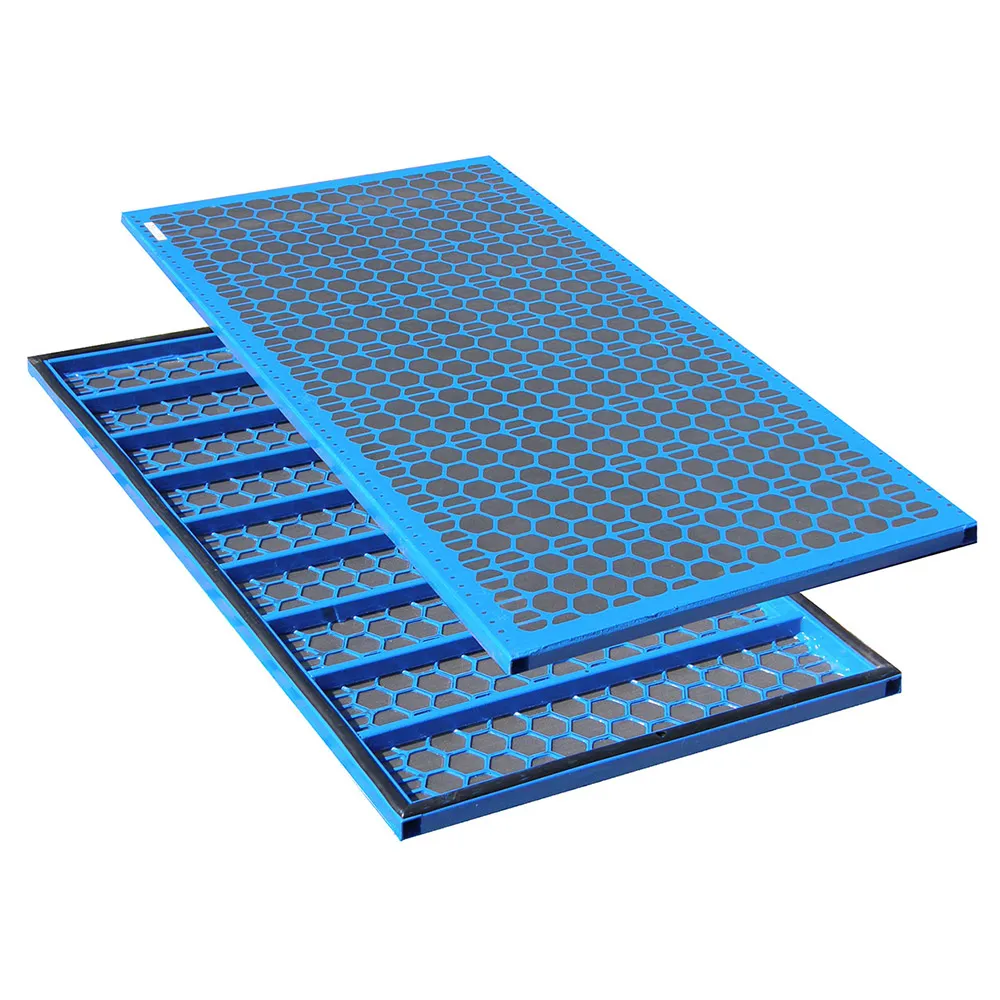

We manufacture pretension replacement screens for the Brandt shale shaker, combining proven mesh combinations with a unibody design for improved separation efficiency. These pretension screens are engineered to meet the exact design specifications of the Brandt shale shaker and can be installed directly onto the unit using standard stock wedges. All screens are API Rp 13C compliant, providing reliability and performance for demanding screening applications.

- Direct installation on Brandt units.

- API Rp 13C tested & certified.

- High efficiency mesh compositions.

- Exceptional mechanical integrity for extended service life.

Let HEBEI MATTS TECH CO. LTD. work with you to develop a successful screening program tailored to your operation.

Product Page: https://www.solidcontrolpart.com/brandt-replacement-shale-shaker-screen.html

Industry Landscape: Shale Shaker Screen Manufacturers Sector Overview

Shale shaker screen manufacturers play a vital role in modern drilling operations across oil & gas, mining, and environmental remediation markets. The demand for high-performance shaker screens is driven by the need for cost‑effective cuttings removal, reduced fluid loss, and increased equipment longevity. With manufacturers investing in precision mesh technology, robust frame engineering, and compliance with international standards, the sector is advancing rapidly with notable contributions from HEBEI MATTS TECH CO. LTD. and global peers.

Key Parameter Comparison Table: Global Shale Shaker Screen Manufacturers

| Manufacturer | Technology | Compliance | Mesh Range (API) | Main Application | Region |

|---|---|---|---|---|---|

| HEBEI MATTS TECH CO. LTD. | Pretension Unibody | API Rp 13C | API 20 - API 325 | Oil & Gas, Mining | China |

| M-I SWACO | Hook Strip/Frame | API, ISO | API 10 - API 325 | Drilling | USA |

| National Oilwell Varco | Composite | API Rp 13C | API 20 - API 230 | Oil & Gas | USA |

| Steel Frame Nigeria Ltd. | Steel Frame/Plate | API | API 40 - API 250 | Mining | Nigeria |

| Deruite Shaker Screens | Pyramid/Flat | API, ISO | API 20 - API 200 | Mud Recycling | China |

| GN Solids Control | Composite/Wave | API, IADC | API 20 - API 325 | Solids Control | China |

Technical Parameter Trends Among Shale Shaker Screen Manufacturers

Brandt Replacement Shale Shaker Screen: Major Technical Data

| Specification | Brandt Replacement Screen | VSM 300 Shaker | King Cobra Shale Shaker |

|---|---|---|---|

| Mesh Range (API) | API 20 – API 325 | API 20 – API 230 | API 40 – API 250 |

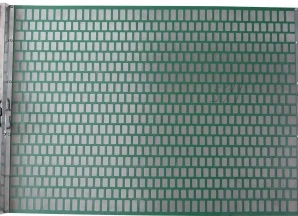

| Screen Type | Pretension, Unibody | Pyramid, Flat Panel | Flat, Welded Frame |

| Compliance | API Rp 13C | API | API |

| Material | SS304/SS316/Composite | SS304/PVC/Composite | SS304/Carbon Steel |

| Service Life (hrs) | >=380 | 320–350 | 300–320 |

| Efficiency (%) | 92–98 | 90–95 | 89–93 |

Essential Solutions: Shale Shaker Screen Manufacturers and Their Applications

Shale shaker screens are critical for the efficiency and success of solid control systems in diverse drilling operations. Shale shaker screen manufacturers design advanced mesh technologies for:

- Oil & Gas Drilling: Cutting separation, mud recycling, performance optimization for deep and horizontal wells.

- Mining & Quarrying: Removal of oversize solids to maintain fluid clarity and reduce wear of downstream equipment.

- Environmental Remediation: Cleanup of contaminated slurries and water for safe disposal or reuse.

- Directional & Horizontal Drilling: Enhanced mechanical stability and resistance to blinding and plugging.

- Chemical Processing: Handling abrasive or corrosion-sensitive slurries to protect process integrity.

The brandt shaker screens, vsm 300 shaker, and king cobra shale shaker models exemplify the sector’s focus on ruggedness, accurate cut point control, and regulatory compliance.

Industry FAQs: Technical Questions & Answers

A1: Leading shale shaker screen manufacturers utilize SS304, SS316 stainless steel, composite frames, and special polymer coatings for superior strength, corrosion resistance, and longevity. (Source: SPE Journal)

A2: Mesh size is designated by API number under the API RP 13C standard, indicating particles retained on each mesh. This ensures cross-manufacturer compatibility. (Source: Drilling Formulas)

A3: Pyramid screens offer 15–35% greater screening area via corrugation, enhancing throughput. Flat screens are cost-effective and simpler to install, ideal for certain shaker models.

A4: Brandt replacement screens are pretensioned and can be mounted directly using standard wedge or hook mechanisms without additional hardware, ensuring quick, secure fitting.

A5: API RP 13C compliance guarantees accurately declared cut point and conductance, ensuring high performance and compatibility for end-users globally. (See:API.org)

A6: Under normal mud conditions, Brandt Replacement Shale Shaker Screens provide >=380 hours’ service, depending on solid loading and fluid chemistry (Refer to chart above).

A7: Certified shale shaker screen manufacturers like HEBEI MATTS TECH CO. LTD. engineer replacement screens to match or exceed OEM standards in performance, service life, and compliance – supported by field data and API testing reports.

Technology, Compliance, and Innovation in Shale Shaker Screen Manufacturing

- Compliance: All production lines adhere to API RP 13C guidelines for cut point accuracy and screen integrity.

- Innovation: Ongoing R&D in composite frames and anti-blinding coatings deliver higher operational efficiencies.

- Expertise: Decades of field experience, documented in technical journals (OnePetro) and industry forums.

- Trustworthiness: HEBEI MATTS TECH CO. LTD. maintains global certifications and is a vetted supplier for major oilfield equipment projects worldwide.

For genuine shale shaker screen manufacturers solutions or to acquire shaker screen for sale, king cobra shale shaker compatible screens, brandt shaker screens, and vsm 300 shaker options, contact HEBEI MATTS TECH CO. LTD. on +8631166035590 or email lyiunqi@honestmetal.com for a technical consultation.