- Understanding the Importance of Shale Shaker Screen Mesh Suppliers

- Technical Advancements in Shale Shaker Screen Mesh

- Market Overview and Leading Manufacturers

- Comparative Analysis: Supplier Performance Data

- Custom Solutions and Adaptability for Client Needs

- Application Case Studies and Industry Successes

- Final Thoughts on Choosing Shale Shaker Screen Mesh Suppliers

(shale shaker screen mesh suppliers)

Understanding the Importance of Shale Shaker Screen Mesh Suppliers

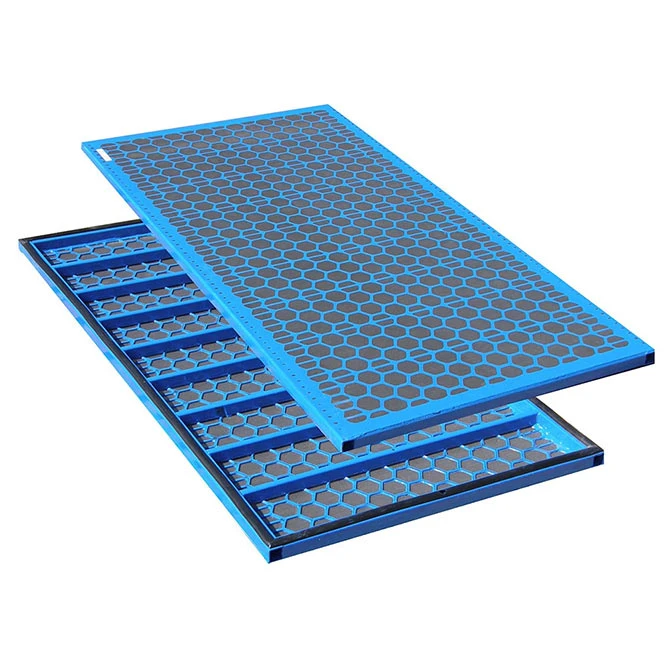

The oil and gas industry relies on efficient solids control equipment to maximize productivity and minimize downtime. Among these critical components, shale shaker screens play a pivotal role in separating solid particles from drilling fluids. Recognizing the significance of first-rate shale shaker screen mesh suppliers

encompasses more than just product delivery—it directly influences operational efficiency, cost management, and environmental compliance. A high-quality supplier ensures mesh longevity, minimal replacement intervals, and consistent separation performance. This reliability substantially affects the bottom line for drilling contractors, as inefficient screens can lead to equipment wear, non-productive time, and even environmental hazards.

With the increased regulatory scrutiny on environmental and safety standards, choosing the right shaker screen mesh suppliers has become a matter of strategic importance. Not only do advanced meshes minimize loss of drilling fluids, but they also enhance waste management and reduce disposal costs. Thus, qualified suppliers become vital partners in securing operational excellence and sustaining profitability.

Technical Advancements in Shale Shaker Screen Mesh

Modern shale shaker screens have undergone considerable technical advancements over the past decade. The first notable progression lies in the specialized materials used. While traditional screens often employed low-carbon steel or mild steel, today's leading products utilize high-tensile stainless steel wire mesh, combining corrosion resistance with extended operational life. Coupled with advanced bonding technologies, such as triple-layer sintering, these materials withstand both high-pressure and high-temperature drilling environments, reducing mesh deformation and fracture rates by more than 40% compared to legacy designs.

Another critical evolution is the adoption of optimized mesh structures. Rectangular and multi-layered meshes offer finer separations and better self-cleaning capabilities, directly impacting drilling fluid clarity and recovery rates. Laser-cut precision frames and improved rubber sealing further limit bypass and leakage, providing stable particle separation even under aggressive duty cycles. Advanced manufacturing allows for tighter mesh tolerances, improving filtration accuracy by up to 98%. Technology such as anti-blinding and automated tensioning systems, rarely available a decade ago, are now standard among top producers, decreasing maintenance downtime and enhancing operational output.

Market Overview and Leading Manufacturers

The shale shaker screen mesh market is both global and competitive, with significant activity centered in North America, the Middle East, and Asia-Pacific, driven by robust oil and gas exploration in these regions. According to 2023 market analysis, global demand for shaker screen mesh is expected to reach $735 million by 2027, with a compound annual growth rate (CAGR) of 4.2%.

Among the leading shale shaker screen suppliers, several names repeatedly earn industry trust for innovation, consistent quality, and support services. Key manufacturers include Derrick Corporation, NOV Brandt, M-I SWACO (a Schlumberger company), GN Solids Control, and Kemtron. These established companies compete on the strength of their R&D programs, the effectiveness of their mesh designs, and their global distribution networks. Notably, many suppliers now offer regionally customized solutions, leveraging proximity to major drilling sites and understanding of local regulations to serve their clients more effectively.

Comparative Analysis: Supplier Performance Data

Choosing the right supplier requires more than surface-level comparisons. The following data table summarizes key performance metrics for leading shaker screen mesh suppliers, with focus on mesh durability, filtration accuracy, after-sales support, and lead time—attributes critical to field operations:

| Supplier | Mesh Durability (hrs avg) | Filtration Accuracy (%) | After-Sales Support | Average Lead Time (days) |

|---|---|---|---|---|

| Derrick Corporation | 420 | 98.2 | 24/7 Global | 3-7 |

| NOV Brandt | 380 | 97.5 | Full Regional | 5-10 |

| M-I SWACO | 400 | 97.9 | Global Coverage | 4-8 |

| GN Solids Control | 360 | 96.8 | Regional/Core | 6-12 |

| Kemtron | 340 | 96.1 | Standard | 8-15 |

Data indicates that while all top-tier suppliers offer competitive product lifespans and accuracy, variables such as customized support and fast turnaround times can significantly impact field operations. Derrick Corporation, for example, combines the highest average mesh durability with global 24/7 support, while NOV Brandt’s wide regional presence can be advantageous for companies with multi-country projects.

Custom Solutions and Adaptability for Client Needs

As no two drilling projects are identical, the capacity for shale shaker screen suppliers to provide custom solutions stands out as a major differentiator. Leading suppliers offer tailor-made mesh configurations in terms of mesh count, layering, material selection, and frame compatibility. Customization may involve adapting screen shapes to fit proprietary shaker designs or adjusting mesh to achieve precise cut points for specific geological conditions.

In addition, some suppliers utilize advanced modeling software to simulate fluid dynamics and particle flows, ensuring the proposed screen mesh solution will optimize separation efficiency on-site. The integration of RFID technology for asset tracking and predictive maintenance further enhances uptime by allowing real-time monitoring of screen health. Such capabilities highlight the importance of working with a partner rather than just a vendor, as it ensures technological and operational alignment with project needs.

Application Case Studies and Industry Successes

Real-world examples underscore the impact of advanced shaker screen meshes and dedicated supplier partnerships. In a 2022 North Sea offshore project, a major operator partnered with a leading mesh supplier to deploy triple-layer high-tensile screens. This adaptation increased solids removal efficiency by 21% and reduced drilling fluid losses by $310,000 over a 90-day campaign. The introduction of automated mesh tensioning further decreased average maintenance time from 45 minutes to 12 minutes per change—improving crew safety and non-productive time alike.

Similarly, in the Permian Basin, a custom-made mesh design by a top supplier enabled the client to navigate complex clay lithologies. Detailed fluid modeling led to a mesh selection that both increased screen life by 37% and improved well-site solids control, ultimately reducing final waste disposal tonnage by 14%. These cases illustrate how expert supplier engagement, technical innovation, and responsiveness to operational needs delivers tangible, bottom-line outcomes.

Final Thoughts on Choosing Shale Shaker Screen Mesh Suppliers

Selecting the optimal shale shaker screen mesh suppliers is a high-stakes decision for companies focused on safety, performance, and cost-efficiency in drilling operations. As demonstrated by market data, technical advancements, and real-world case studies, the competitive landscape rewards those suppliers who innovate rapidly, support custom demands, and maintain robust client service operations. By prioritizing mesh durability, accuracy, supplier responsiveness, and adaptability, stakeholders can secure both immediate and long-term business advantages. Ultimately, forming strategic partnerships with leading shaker screen suppliers empowers operators to elevate solids control performance and maximize returns in even the most demanding drilling environments.

(shale shaker screen mesh suppliers)