- Introduction to shale shaker screen mesh and its industrial relevance

- Global demand and market data for shaker screen mesh suppliers

- Technical advantages and innovation in shaker screen mesh manufacturing

- Comprehensive comparison of main shale shaker screen suppliers

- Tailor-made solutions and customization options

- Real-world application cases and performance evaluation

- Final insights: Choosing a reliable shale shaker screen mesh supplier

(shale shaker screen mesh supplier)

Introduction: The Importance of a Quality Shale Shaker Screen Mesh Supplier

In sectors such as oil & gas drilling, mining, and civil engineering, the role of a high-grade shale shaker screen mesh cannot be overstated. Acting as the critical first line of defense in solid/liquid separation processes, shaker screens ensure operational efficiency, equipment longevity, and process reliability. The right shale shaker screen mesh supplier not only delivers premium products but consistently supports project success with technical guidance and after-sales service. With heightened focus on productivity and environmental standards, the market has seen a sharp evolution in mesh technology and supplier capability.

As end-users demand screens with improved wear resistance, higher throughput, and precise particle size control, competitive suppliers are challenged to surpass industry benchmarks. This article unpacks the innovations, compares key suppliers, and showcases how tailored solutions make a measurable difference in field performance.

Global Demand and Market Insights

The shale shaker screen industry is closely tied to the fluctuating fortunes of oil, gas, and mining sectors. According to MarketsandMarkets, the global shaker screen market size surpassed USD 1.3 billion in 2022, and is projected to grow at a CAGR of 6.2% through 2027, fueled by increased drilling activity and rising environmental regulations that mandate more efficient solid control systems.

North America holds the largest share, with over 40% of installations, but robust expansion is underway in Asia-Pacific, driven by energy infrastructure projects. Increasing adoption of advanced API and composite screens over traditional steel-mesh screens is another notable trend, with suppliers racing to deliver cost-effective upgrades and extended field lifespans.

Environmental and industry standards—such as the API RP13C—have become universal benchmarks, forcing suppliers to innovate and invest in precision manufacturing to ensure compliance and differentiating performance.

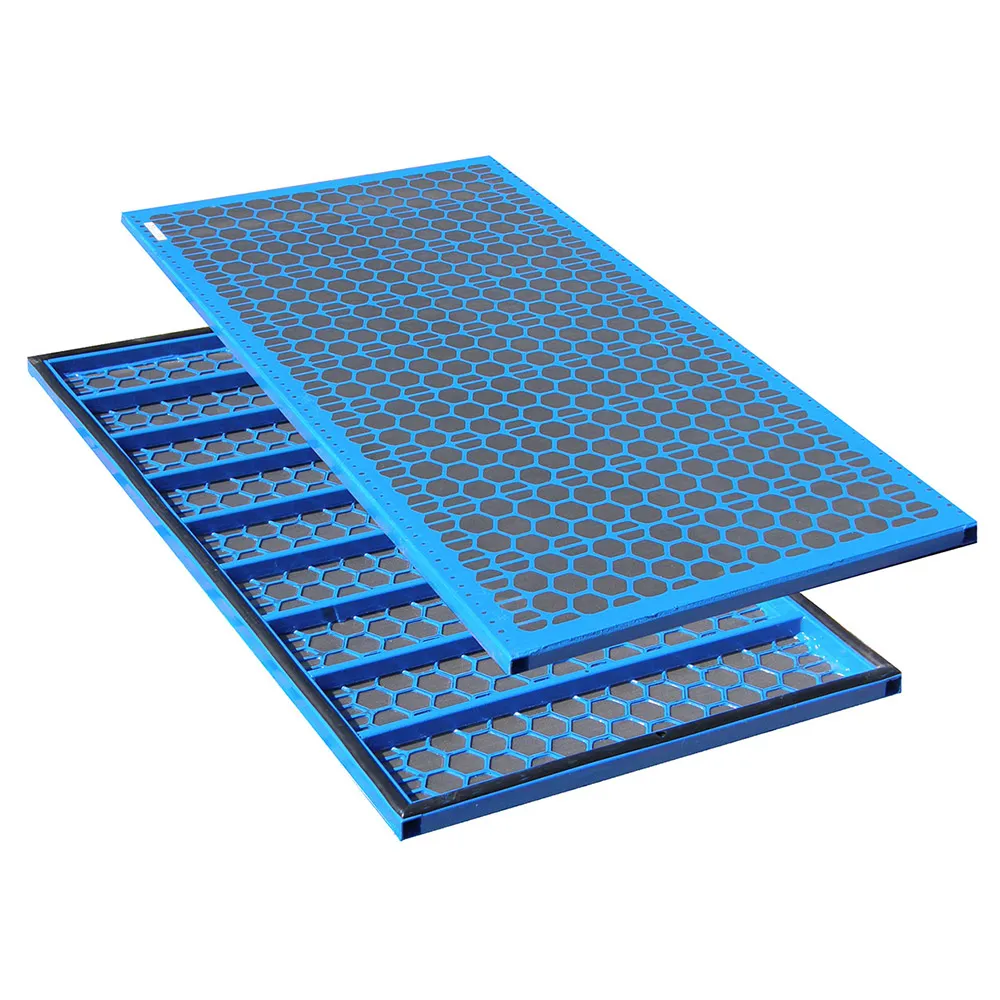

Technological Advantages and Innovation in Screen Manufacturing

Recent advances have redefined expectations from any shaker screen mesh supplier. Mesh composition has evolved from simple woven steels to sophisticated, multi-layer composite plastics and alloys. Modern screens offer up to 50% longer life than their predecessors, reduce blinding, and significantly improve conductivity and flow capacity. For example, triple-layer composite screens can handle flows up to 35m³/hr per panel, outperforming traditional single-layer steel screens by 25%.

Laser-cutting, micro-welding, and precision calibration now ensure not only tight mesh tolerance but also seamless branding and traceability—critical for large operations with strict inventory control. Anti-corrosion coatings, self-cleaning structures, and quick-release mechanisms further minimize maintenance downtime, making technical superiority a tangible asset in competitive projects.

Suppliers capable of delivering API-compliant, custom-engineered screens have become the go-to partners for rig operators and EPC contractors seeking optimized operating costs and hassle-free regulatory audits.

Supplier Comparison: Data-Driven Selection Criteria

Selecting a shale shaker screen supplier or a shaker screen mesh supplier requires meticulous evaluation of quality, compliance, lifespan, logistics, and technical support. The following table gives a comparative overview of leading global brands to support informed decision-making:

| Supplier | Compliance (API RP13C/ISO) |

Screen Type | Average Service Life | Global Footprint | Customization | Annual Output (Units) |

|---|---|---|---|---|---|---|

| Brand A | Yes | Composite/Steel | 6-8 Weeks | 80+ Countries | Flexible | 1.8 Million |

| Brand B | Yes | Polyurethane/Steel | 5-6 Weeks | 60+ Countries | Standard | 1.2 Million |

| Brand C | No (Under review) |

Woven Wire | 2-3 Weeks | 30+ Countries | Limited | 500,000 |

| Brand D | Yes | Composite/Plastic | 8-10 Weeks | Global | Custom Designs | 2.4 Million |

As revealed above, suppliers differ greatly not only in technical strength but also in geographic reach, product versatility, and scalability. Brands with strong commitment to compliance and tailored engineering demonstrate clear leadership in market share and long-term client satisfaction.

Customization Options: Tailored Solutions for Unique Challenges

No field operation is identical—reservoir characteristics, drilling fluids, climate, and budget constraints all inform the ideal screen specification. Recognizing this, leading shaker screen mesh suppliers collaborate with clients to develop fully bespoke solutions. Customization may range from mesh sizing (10 to 325 API), frame material, shape, and reinforcement type, to anti-static, anti-clogging, or ultra-heavy-duty anti-abrasion features.

Advanced providers also offer on-site consultation and rapid prototyping, shrinking development cycles and minimizing trial-and-error replacements. According to a recent industry survey, over 65% of top-tier drilling contractors prioritize suppliers with proven customization capabilities, while 80% report reduced downtime after adopting tailored screening systems.

- Material Science: Stainless, plastic, or hybrid frames matched to corrosive or high-impact environments

- Dimensional Flexibility: Screens cut and sealed to fit proprietary rig models or mobile operations

- Enhanced Durability: Heat-treated, composite-laminated options for extreme duty cycles

- Branding & Tracking: Embedded RFID, QR coding, or laser etching for asset management

The ability to adapt to any operational parameter is a hallmark of the most responsive and dependable suppliers.

Application Cases: Real-World Performance and ROI

Operators across five continents have reported transformative outcomes from upgraded mesh products and switching suppliers. For example, a major Middle Eastern oilfield transitioned from basic steel screens to API-compliant composite screens custom-designed for their abrasive drilling fluids. The result was an extension of screen lifespan by 46% and a 20% reduction in fluid loss, saving approximately $410,000 annually in direct costs.

In Latin America, a gold mining operation adopted high-flow polyurethane screens manufactured by a global supplier, which enabled continuous 24/7 separation with 98% solids capture efficiency—an improvement of 13% over previous deployments. This directly contributed to enabling environmental compliance and securing a multi-year government contract.

Each successful case underlines the impact of choosing the right shaker screen mesh supplier and having access to advanced, fit-for-purpose technologies.

Final Insights: How to Select the Best Shale Shaker Screen Mesh Supplier

Selecting the right shale shaker screen mesh supplier encompasses far more than sourcing a compliant product. It means forging a partnership with an organization that offers technical excellence, rapid response, and a true understanding of your operational context. Industry leaders stand out by delivering not just quality goods but scalable support, after-sales service, and the ability to respond to emergent engineering challenges.

- Assess compliance and technical certifications to ensure regulatory alignment.

- Prioritize suppliers with strong local and international support networks.

- Request case studies and monitor real-world performance improvements.

- Choose partners with transparent customization workflows and robust quality assurance processes.

As the demands of oil, gas, and resource extraction intensify, sourcing from reliable, innovative, and customer-focused suppliers is not only wise—it is essential. Continuous improvement and thoughtful selection of your shaker screen supplier will drive both operational safety and competitive advantage on a global scale.

(shale shaker screen mesh supplier)