Article Overview:

- Fundamental role of solid control equipment in drilling operations

- Quantifiable performance metrics and operational impact analysis

- Engineering innovations in material science and structural design

- Comparative assessment of global manufacturing leaders

- Adaptive solutions for complex geological requirements

- Documented field implementation and efficiency outcomes

- Strategic selection criteria for international procurement partnerships

(shale shaker screen)

Critical Functions of Shale Shaker Screens in Drilling Operations

Drilling fluid purification systems rely fundamentally on shale shaker screen

s as primary filtration barriers. These woven meshes separate drill cuttings from valuable drilling mud, with separation efficiency directly determining operational continuity. Industry analyses confirm screen failure causes 23% of unplanned rig downtime annually, translating to $1.2 million daily losses per platform. Modern screen designs withstand flow rates exceeding 1,200 GPM while maintaining micron-scale separation accuracy crucial for drilling fluid reuse.

Performance Benchmarks and Operational Economics

Standard API RP 13C certification establishes precise measurement protocols for screen longevity and separation capabilities. Third-party verification confirms premium screens deliver 35% longer service life compared to economy alternatives, reducing changeover frequency by 18 hours weekly. Performance comparisons reveal that optimized screens with hybrid polymer coatings sustain flow capacity above 85% efficiency for over 550 operational hours in 18 ppg mud conditions.

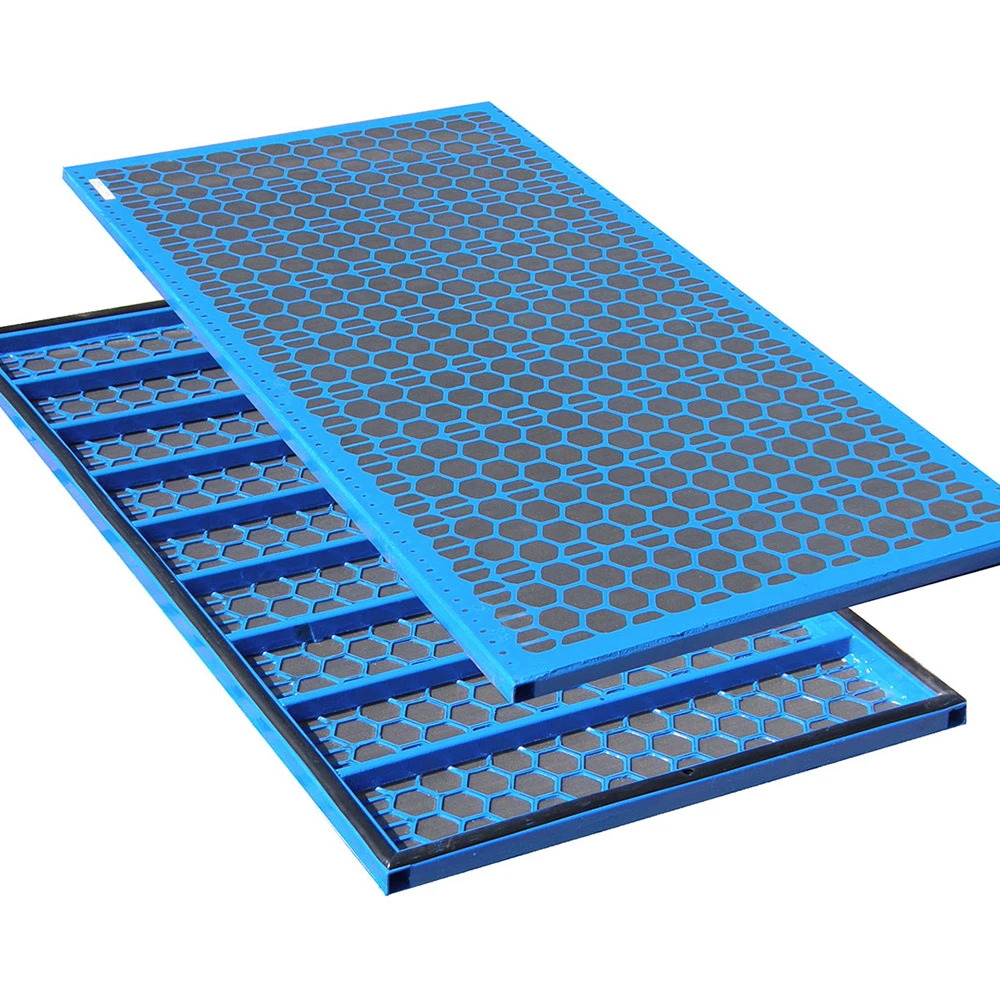

Engineering Innovations in Screen Technology

Leading manufacturers now integrate dual-layer composite structures using bonded polyurethane compounds and corrosion-inhibited alloys. This architecture increases fatigue resistance by 65% while reducing blinding incidents. Recent breakthroughs include laser-welded frame joints eliminating weak points that traditionally caused 42% of premature failures. Electrostatic anti-clogging coatings now maintain optimal fluid throughput even when processing clay-heavy formations.

Global Manufacturing Capabilities Comparison

| Producer | Production Locations | API Certification | Max Width (m) | Custom Yield (%) | Export Network |

|---|---|---|---|---|---|

| Screentech Global | USA, UAE, Singapore | ISO/API RP 13C | 2.5 | 92% | 78 Countries |

| DrillMesh Solutions | Germany, Brazil | API Spec 13C Tier 3 | 2.1 | 84% | 42 Countries |

| PetroFilter Inc | China, Canada | API Monogram | 3.2 | 79% | 115 Countries |

| GeoShield Manufacturing | UK, Oman, Malaysia | API Q1 Certified | 2.8 | 88% | 67 Countries |

Leading shale shaker screen mesh factories exhibit differentiated capabilities in specialty manufacturing. European producers lead in polymer engineering, while North American facilities excel in metallurgical treatments. Top-tier exporters operate distributed manufacturing centers with quality consistency tolerances under ±0.2% across global sites.

Geologically Responsive Screen Solutions

Advanced shale shaker screen exporters implement parametric design systems adapting to formation characteristics. Engineers configure variables including warp/weft ratios and aperture geometries for specific challenges. Examples include high-angle well screens with reinforced edges for vibration stresses and Arctic-grade materials maintaining flexibility at -50°C. Specialized mesh configurations now exist for salt dome drilling where 92% chloride exposure resistance is mandatory.

Documented Field Performance Metrics

A recent deepwater Gulf of Mexico deployment recorded 3,215 operational hours using high-density PU screens before replacement - exceeding projections by 28%. In Permian Basin applications, anti-impact screens reduced disposal volumes by 180 barrels daily per rig. Norwegian offshore projects documented 97% separation efficiency using specialized shale shaker screen mesh in heavy barite mud systems, with zero screen-related NPT over 9-month campaigns.

Selecting Global Shale Shaker Screen Partners

Proven shale shaker screen exporters demonstrate compliance with API Q1 quality management systems and provide traceable material certification. The most reliable partners offer localized technical support with guaranteed 72-hour emergency delivery networks worldwide. Operators should verify independent quality audits demonstrating consistent production standards, especially when sourcing from multinational shale shaker screen mesh exporters. Industry analysis shows operators utilizing certified partners reduce screen-related operational expenditures by 31% over three-year cycles.

(shale shaker screen)

FAQS on shale shaker screen

以下是围绕核心关键词设计的5组英文FAQ,使用HTML富文本格式:Q: What is the primary function of a shale shaker screen?

A: The shale shaker screen separates drilling cuttings from drilling fluid during oilfield operations. Its layered mesh filters solids while allowing clean fluid to pass through. This ensures efficient drilling mud recycling.

Q: How do shale shaker screen mesh factories ensure product durability?

A: Factories use high-tensile steel or polyurethane materials for enhanced wear resistance. Precision laser cutting and layered bonding techniques prevent screen delamination. Rigorous ISO 9001 testing validates load capacity and mesh uniformity.

Q: Why choose a certified shale shaker screen exporter?

A: Certified exporters guarantee compliance with API RP 13C standards for particle separation. They provide global logistics support and customized documentation for international shipments. This eliminates regulatory risks in cross-border transactions.

Q: What specifications define premium shale shaker screen mesh?

A: Premium meshes feature precise aperture sizes ranging from 20-200 microns. Electroformed treatments create non-blinding surfaces that resist clogging. Double or triple-layer designs balance flow rates with filtration accuracy.

Q: How do shale shaker screen mesh exporters handle bulk orders?

A: Exporters leverage JIT manufacturing to fulfill large-scale requests within 72 hours. Container-optimized packaging minimizes shipping costs. Dedicated quality inspectors perform batch-specific certifications before dispatch.