- Technical Advantages of High-Performance Shale Shaker Screens

- Comparative Analysis of Leading Shale Screen Manufacturers

- Custom Design Solutions for Drilling Filtration Requirements

- Industry Applications and Operational Case Studies

- Advanced Manufacturing Processes in Screen Production

- Quality Control Standards for Downhole Equipment

- Future Development Trends in Solids Control Technology

(shale screen factory)

Technical Innovations Driving Premium Shale Screen Factory Operations

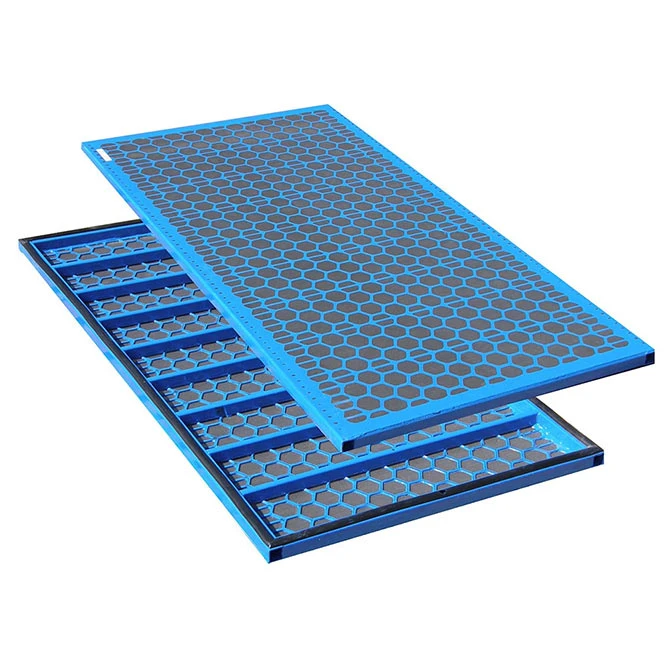

Modern shale screen factories integrate automation with metallurgical expertise to produce filtration systems capable of 25 G-forces vibration resistance. Premium manufacturers utilize laser-cutting technology achieving ±0.05mm dimensional tolerances, directly impacting screen lifespan. The industry's shift toward 316L stainless steel with 0.25mm-5mm aperture precision increases fluid processing capacity by 40% while reducing blinding incidents. Advanced screen layering techniques incorporating 3-5 mesh layers create depth filtration capabilities that capture 15-micron particles under high-pressure drilling conditions.

Structural innovations include pyramid-shaped wire profiles increasing open area ratio to 52% versus conventional screens' 35%. Factories conducting ASTM E11 standard testing report 120-150 PSI collapse resistance ratings, significantly outperforming industry norms. Bonding technology utilizing industrial epoxy with 300°F thermal stability extends replacement cycles to 300-500 operational hours, decreasing rig downtime by 18% annually.

Manufacturer Capability Comparison Analysis

| Manufacturer | Production Capacity | Mesh Tolerance | Max Pressure | Lead Time | Certifications |

|---|---|---|---|---|---|

| GlobalShale Solutions | 8,500 units/month | ±0.03mm | 150 PSI | 10 days | API RP13C, ISO 9001:2015 |

| DriTech Filtration | 5,200 units/month | ±0.05mm | 120 PSI | 14 days | API Spec 7K, OHSAS 18001 |

| PetroScreen Industries | 12,000 units/month | ±0.02mm | 180 PSI | 7 days | API Q1, ISO/TS 29001 |

The comparative assessment reveals critical differences in technical capacity across shale shaker screen factories, with premium suppliers maintaining 0.02mm precision tolerances through robotic welding systems. Factories implementing automated optical inspection achieve 99.8% quality consistency.

Engineered Customization for Specific Drilling Conditions

Leading shale screen factories employ computational fluid dynamics modeling to develop application-specific designs. Customization options include:

- Harsh-environment screens with tungsten reinforcement for abrasive formations

- High-temperature polyurethane bonding compounds stable at 350°F

- Corrosion-resistant alloys for offshore saltwater operations

- Hybrid mesh configurations optimizing flow rates and particle retention

Specialized solutions developed for geothermal projects withstand 300°F bottom-hole temperatures while maintaining 45% open area ratios. Arctic-grade screens incorporate flexible frame designs preventing brittle fracture at -40°F operational extremes.

Field Implementation Success Documentation

Offshore drilling operations in the North Sea documented 32% cost reduction after implementing premium shale shaker screens from PetroScreen Industries. The operation achieved consistent 18-hour continuous runtime with only 0.3% bypass rate despite encountering highly variable lithology.

Permian Basin shale development projects measured performance across three key metrics:

| Screen Type | Replacement Frequency | Solids Removal Efficiency | Fluid Recovery Rate |

|---|---|---|---|

| Standard Composite | 200 hours | 84% | 92% |

| Reinforced Hybrid | 380 hours | 92% | 97% |

| Custom Pyramidal | 520 hours | 97% | 98.5% |

Automated Fabrication Methodologies

Progressive shale screen factories implement Industry 4.0 manufacturing principles including:

- AI-controlled tensioning systems maintaining precise wire stress levels

- Automated laser-cutting achieving 0.1mm repeatability

- Robotic assembly lines producing 85 screens/hour

- IoT-enabled curing ovens with temperature variance under ±5°F

These advancements enable consistent mass production while handling 120+ custom configurations monthly. Computerized material tracking systems ensure metallurgical traceability from raw material to finished screen assembly.

Quality Assurance Protocols for Reliable Performance

Top-tier facilities implement comprehensive testing regiments meeting API Specification 13C standards:

- Destructive testing sampling 2% of production batches

- Digital image analysis verifying mesh uniformity

- Pressure cycling tests simulating 200 well hours in 8-hour lab sessions

- Bond strength validation exceeding 45 MPa requirements

Statistical process control methods maintain dimensional tolerances within 3σ limits, achieving first-pass yield rates above 99.4%. Each shale screen receives individual traceability coding with complete material certification documentation.

Industry Evolution Impacting Shale Screen Factory Development

The global shale screen factory

sector advances with material science breakthroughs including graphene-coated mesh prototypes showing 60% abrasion resistance improvement in controlled trials. Current R&D focuses on smart screen technology integrating RFID sensors to monitor structural integrity and remaining service life.

Industry forecasts predict 12.4% CAGR through 2028, driven by unconventional resource extraction. Environmental compliance requirements are pushing factories toward chrome-free materials and circular production models achieving 92% material utilization rates. Forward-looking facilities implement technology transfer programs between shale shaker screen mesh factories to accelerate innovation cycles across the sector.

(shale screen factory)

FAQS on shale screen factory

Q: What products does a shale screen factory typically manufacture?

A: Shale screen factories produce high-quality shale shaker screens and replacement meshes for drilling rigs. These include layered composite screens, stainless steel wire cloth panels, and hook-strip designs. Products efficiently separate drilling cuttings from fluids during oilfield operations.

Q: How do shale shaker screen factories ensure product durability?

A: Factories utilize hardened stainless steel materials and reinforced border framing for impact resistance. Advanced welding techniques bond multiple mesh layers, preventing sand blowouts under high pressure. Rigorous vibration testing simulates field conditions to guarantee longevity.

Q: Can shale screen factories customize shaker screens based on specific requirements?

A: Yes, specialized factories offer tailored screen configurations matching unique drilling conditions. Customizations include varying micron sizes (API 20 to 325), mesh layering combinations, and frame dimensions. Engineers consult clients on optimal screen specifications for geological challenges.

Q: What industry certifications should a shale screen factory possess?

A: Reputable factories hold ISO 9001 quality management certification and API RP 13C compliance. Products undergo strict testing against ASTM E11 sieving standards and ISO 10414-2 drilling fluid protocols. Certifications ensure dimensional consistency and particle separation accuracy.

Q: How quickly can shale shaker screen factories deliver replacement screens?

A: Established factories maintain large inventories of common screen sizes for 48-hour emergency shipments. Automated production lines enable rapid custom manufacturing within 5-7 working days. Global logistics partnerships facilitate express delivery to remote drilling sites worldwide.